Important Safety Notice

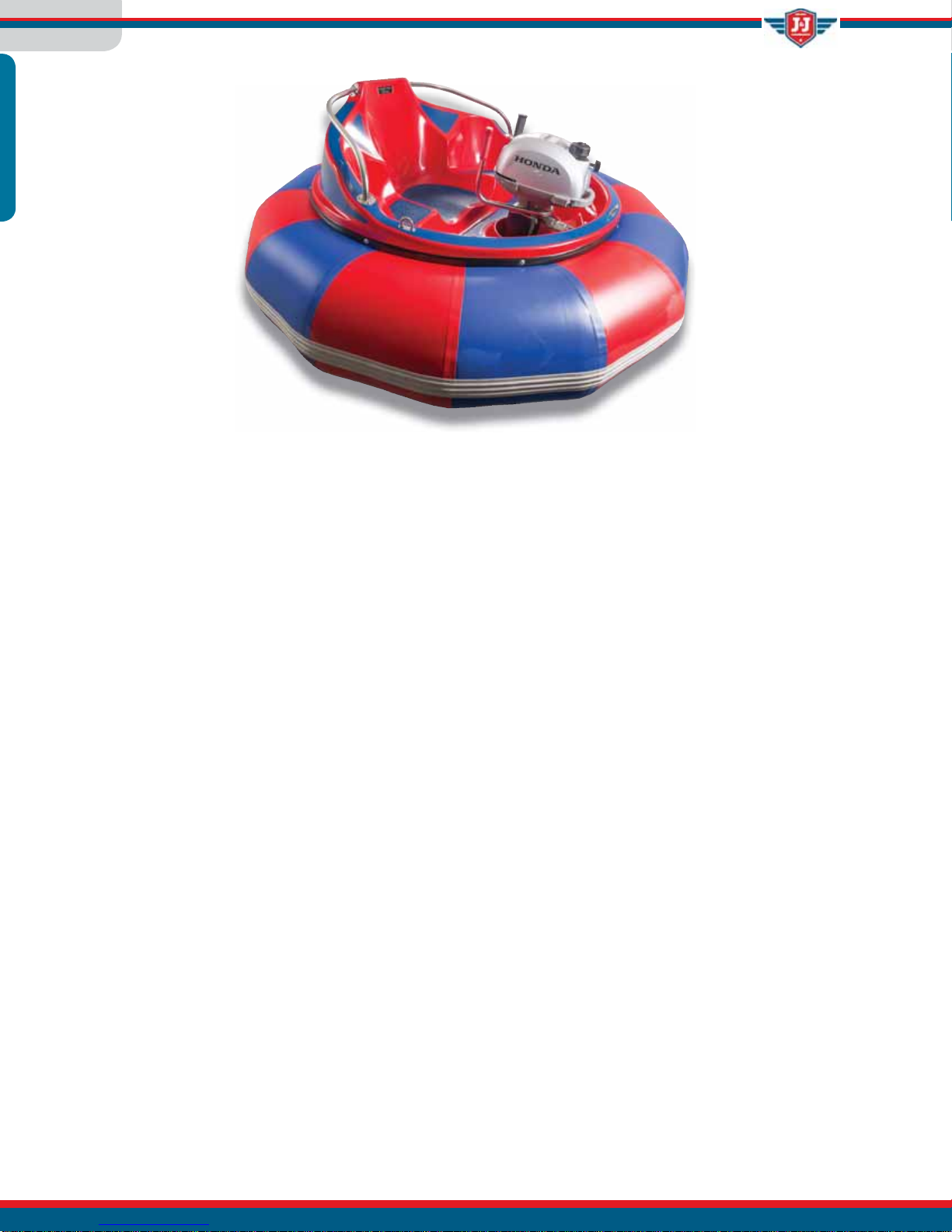

Proper service and repair procedures are vital to safe, reliable operation of J&J bumper boats, as well as

to the personal safety of those performing the repairs. This manual outlines procedures for servicing

and repairing J&J bumper boats, using safe, effective methods. The procedures contain many NOTES,

CAUTIONS and WARNINGS which should be followed (along with standard safety procedures) to reduce

the possibility of personal injury or improper service, which could damage the go kart or compromise its

safety.

It is important to note that repair procedures, techniques, tools and parts for servicing J&J bumper boats,

as well as the skill and experience of the individual performing the work, vary widely. It is not possible to

anticipate all conceivable ways, or conditions under which J&J bumper boats may be serviced, or to provide

cautions to all possible hazards that may result. Standard precautions should be used when handling

toxic or flammable fluids, and safety goggles or other protection should be used during cutting, grinding,

chiseling, prying or any other process that can cause material removal or projectiles. J&J recommends the

use of safety goggles or approved glasses during all servicing of J&J bumper boats.

All information contained in this manual is based on the latest product information available at the time

of printing. We reserve the right to make changes at any time without notice. All rights reserved. Except as

expressly provided herein, no part of the manual may be reproduced, copied, transmitted, disseminated,

downloaded or stored in any storage medium, for any purpose, without prior written consent of J&J

Amusements, Inc. An Oregon Corporation. J&J Amusements, Inc. grants permission to download a single

copy of this manual onto a hard drive or other electronic storage medium to be viewed for personal use,

provided that such electronic or printed copy of this manual contains the complete text of this copyright

notice. Any unauthorized commercial distribution of this manual is strictly prohibited.

4897 Indian School Rd NE

Suite 150

Salem Oregon 97305-1126

www.jjamusements.com

Phone: 503-304-8899

Toll Free Phone: 800 -854-3140

Fax: 503-304-1899

Toll Free Fa x: 800 -366 -7505

JJ

&Amusements, Inc. Technical Contact Information

We value your feedback; technical comments and

suggestions are helpful to us. Please e-mail your

comments to service@jjamusements.com.

From time to time, updates may be made to this manual.

For the latest updates, please visit our technical website at

http://jjamusements.com/technical/index.htm.

As you read this manual, you will nd information that is preceded by a NOTE symbol. e purpose of this message is to prevent

damage to the go kart, other property, or the environment.

SAFETY MESSAGES

Your safety and the safety of others are very important. To help you make informed decisions, we have provided safety messages

and other information throughout this manual. Of course, it is not practical or possible to warn you about all of the hazards

associated with servicing a go kart. You must use your own good judgement.

You will nd important safety information in a variety of forms, including:

SAFETY MESSAGES - preceded by a safety alert symbol and one of four signal words:

DANGER, WARNING, CAUTION, or SAFETY ITEM.

THESE SIGNAL WORDS MEAN:

DANGER..............................You WILL be KILLED or SERIOUSLY INJURED if you do not follow the subsequent instructions.

WARNING............................You CAN be KILLED or SERIOUSLY INJURED if you do not follow the subsequent instructions.

CAUTION................................................................... You WILL be INJURED if you do not follow the subsequent instructions.

SAFETY ITEM ... This safety device was installed at the factory and may be required by state, local, or ASTM standards.

INSTRUCTIONS - how to service these bumper boats correctly and safely.