6

Decals

DO NOT ENTER GRAIN TANKWHEN

AUGER IS RUNNING.

KEEPOFF THE LADDER WHILE

THEMACHINE IS OPERATING,

INTRANSPORT OR THE

UNLOADINGAUGER IS IN MOTION

3 4 5 6 7

89

11 12

10

DO NOT ENTER GRAIN TANK WHEN

AUGER IS RUNNING.

KEEP OFF THE LADDER WHILE

THE MACHINE IS OPERATING,

IN TRANSPORT OR THE

UNLOADING AUGER IS IN MOTION

14

15

13

8

16

FLOWINGGRAINTRAPS

ANDSUFFOCATES

VICTIMSINSECONDS!

NEVERPLAYINOR ON GRAIN CART

YOUCANDIEIN SECONDS

INFLOWINGGRAIN!

HELP!

FOR FARM USE ONLY

FLOWING GRAIN TRAPS

AND SUFFOCATES

VICTIMS IN SECONDS!

NEVER PLAY IN OR ON GRAIN CART

YOU CAN DIE IN SECONDS

IN FLOWING GRAIN!

HELP!

CHECK ALL WHEEL NUTS

DEALER OR MANUFACTURER IS NOT

RESPONSIBLE FOR DAMAGE CAUSED BY

LOOSE WHEEL NUTS.

CHECK TIRE INFLATION

DO NOT INFLATE TIRES MORE THAN 6 PSI

OVER THE RECOMMENDED PRESSURE

PRINTED ON THE SIDE OF THE TIRE.

WARNING

HIGH PRESSURE FLUID HAZARD

To prevent serious injury or death:

Relieve pressure on system before repairing

or adjusting or disconnecting

Wear proper hand and eye protection when

searching for leaks. Use wood or cardboard

instead of hands.

Keep all components in good repair.

WARNING

DO NOT ADJUST, SERVICE, CLEAN OR LUBRICATE

THE MACHINE UNTIL ALL POWER IS SHUT OFF.

KEEP ALL SAFETY SHIELDS IN PLACE.

KEEP PEOPLE AND OBJECTS CLEAR OF EQUIPMENT

BEFORE APPLYING POWER OR MOVING THE MACHINE.

PREVENT PEOPLE FROM RIDING ON THE MACHINE.

FALLING CAN CAUSE SERIOUS INJURY OR DEATH.

BEFORE HIGHWAY TRAVEL, SECURE A SLOW-MOVING

VEHICLE EMBLEM TO THE REAR OF THE MACHINE.

MAKE SURE ALL FLASHER, TURN INDICATOR AND

BRAKE LIGHTS ARE WORKING PROPERLY BEFORE

HIGHWAY TRAVEL.

DEALEROR MANUFACTURER IS NOT

RESPONSIBLEFOR DAMAGE CAUSED BY

CHECKTIRE INFLATION

DONOT INFLATE TIRES MORE THAN 6 PSI

OVERTHE RECOMMENDED PRESSURE

PRINTEDON THE SIDE OF THE TIRE.

HIGHPRESSUREFLUID HAZARD

Topreventseriousinjury or death:

Relievepressureonsystem before repairing

oradjustingordisconnecting

Wearproperhandand eye protection when

searchingforleaks. Use wood or cardboard

insteadofhands.

Keepallcomponentsin good repair.

DONOTADJUST, SERVICE, CLEAN OR LUBRICATE

THEMACHINEUNTIL ALL POWER IS SHUT OFF.

KEEPALLSAFETY SHIELDS IN PLACE.

KEEPPEOPLEAND OBJECTS CLEAR OF EQUIPMENT

BEFOREAPPLYINGPOWER OR MOVING THE MACHINE.

PREVENTPEOPLEFROM RIDING ON THE MACHINE.

FALLINGCANCAUSE SERIOUS INJURY OR DEATH.

BEFOREHIGHWAYTRAVEL, SECURE A SLOW-MOVING

VEHICLEEMBLEMTO THE REAR OF THE MACHINE.

MAKESUREALL FLASHER, TURN INDICATOR AND

BRAKELIGHTSARE WORKING PROPERLY BEFORE

HIGHWAYTRAVEL.

1

2

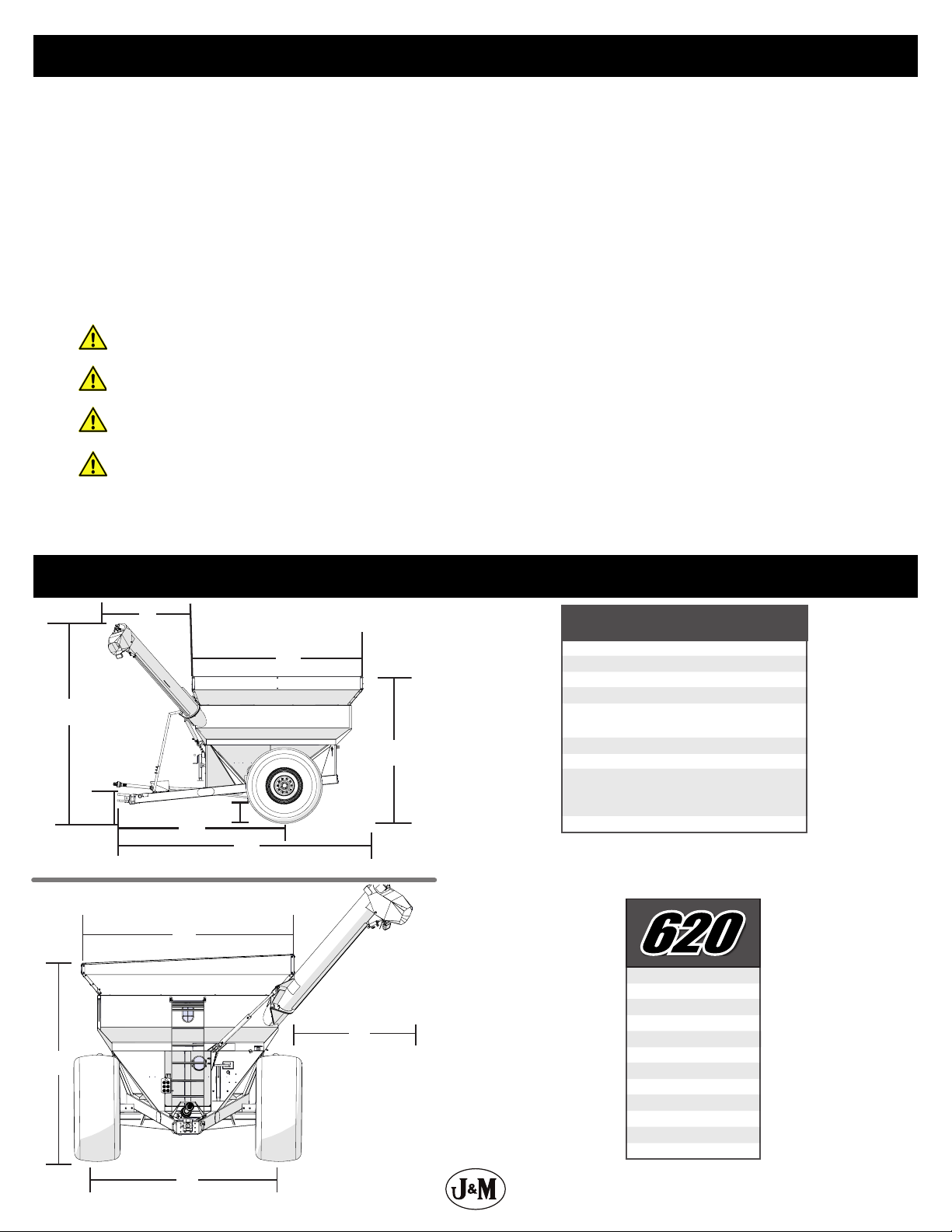

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged or Missing

Description Part No.

1 J&M Oval Decal (Medium) 5-1/2” x 8-1/2” JM0010179

2 www.jm-inc.com Decal JM0019239

3 Danger, Do Not Enter Grain Tank Decal JM0018033

4 Danger, Keep O Ladder Decal JM0018034

5 Warning, Keep Hands Away Decal JM0018039

6 Closed Decal JM0025434

7 Open Decal JM0025433

8 Danger, Electric Lines Decal JM0015099

9 J&M Oval Decal (Large) 9-1/2” x 15” JM0015151

10 Warning, Do Not Adjust Or Service Decal JM0014979

11 Warning, High Pressure Fluid Hazard Decal 4” x 4” JM0010163

12 Check Tire Ination Decal JM0018041

13 Check All Wheel Nuts Decal JM0018043

14 Important Operating Instructions Yellow Grain Cart Decal JM0021245

15 For Farm Use Only Decal JM0018038

16 Danger, Flowing Grain Traps Grain Cart Decal JM0018037