Section 2. System Description

Levolor II by Jandy Model K-2000 is a computer-

controlled device that detects low and high water

conditions.

This model can be used in any situation where a

consistent liquid level is desired and a high and low

level situation can be detected and acted upon, such as

a Vanishing Edge pool. It automatically lls the pool

when the water level is too low and stops lling the pool

when the water level is normal

The K-2000 Kit contains a sensor, remote sensor

housing, control box, and solenoid valve. For details

about the materials in the kit and a list of additional

materials needed to install the K-2000 kit, refer to

Section 3.1, Materials and Tools.

Sensor

The sensor has three (3) probes: one (1) short probe

to measure the high water level, one (1) long probe to

measure the minimum operating level of the water, and

one (1) long common probe. The long probes come in

4", 18"and 30"lengths.

The sensor is a slip-type sensor that glues to a 1"

coupling.

Depending on the kit, the sensor comes with 50 to

500 feet of wire at the top and three (3) stainless steel

contacts at the bottom. The excess wire should be cut

off after you have completed the installation.

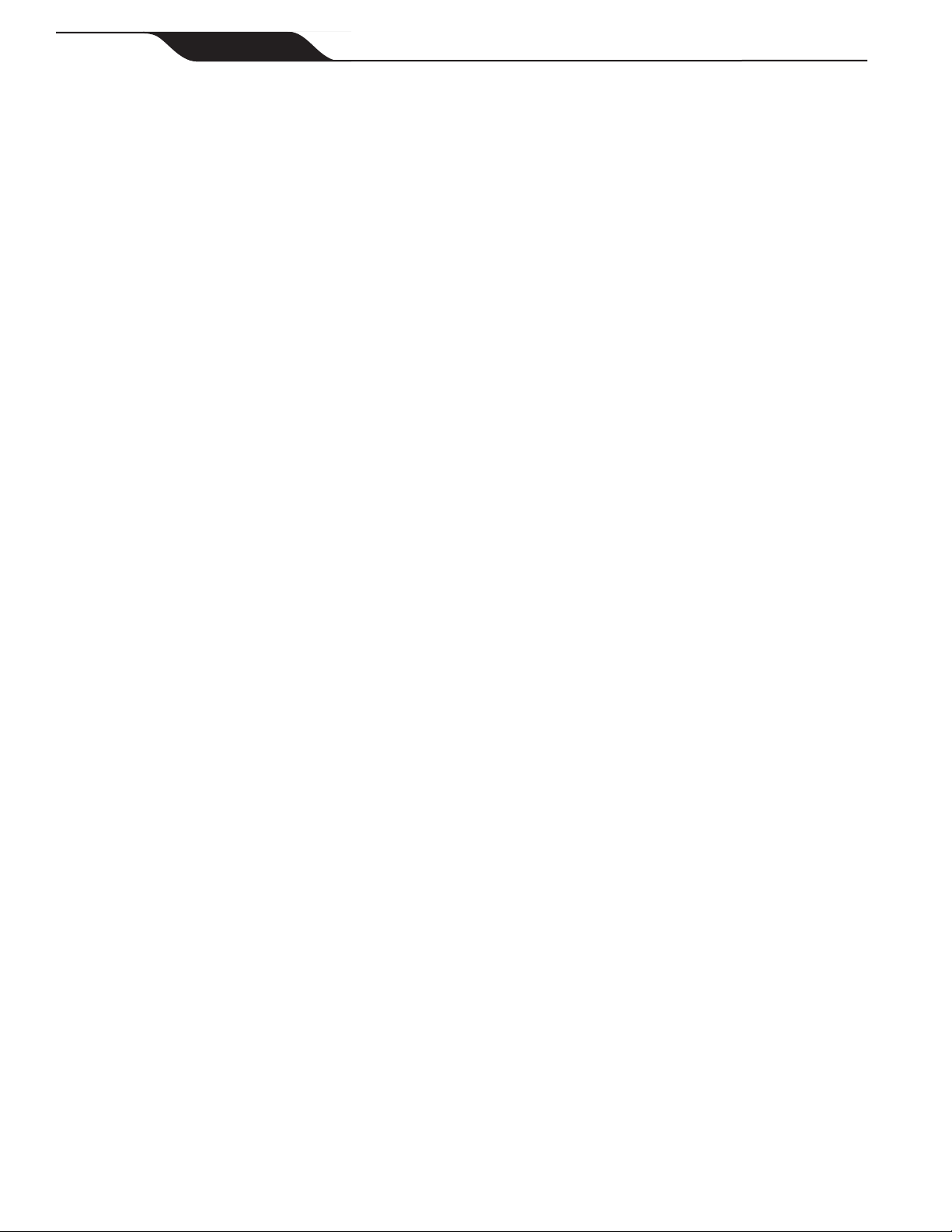

Control Box

The control box has ve (5) LED lights. They are:

- Power

- Sensor

- Fill

- High Water Sensor

- High Water Pump

For details about the functions of the lights, refer to

Section 4.1, Controller Lights.

The control box is factory wired for 220 volt operation,

but can optionally be rewired for 110 volt operation. See

Section 3.3, Changing Wiring for 110 Volt Operation.

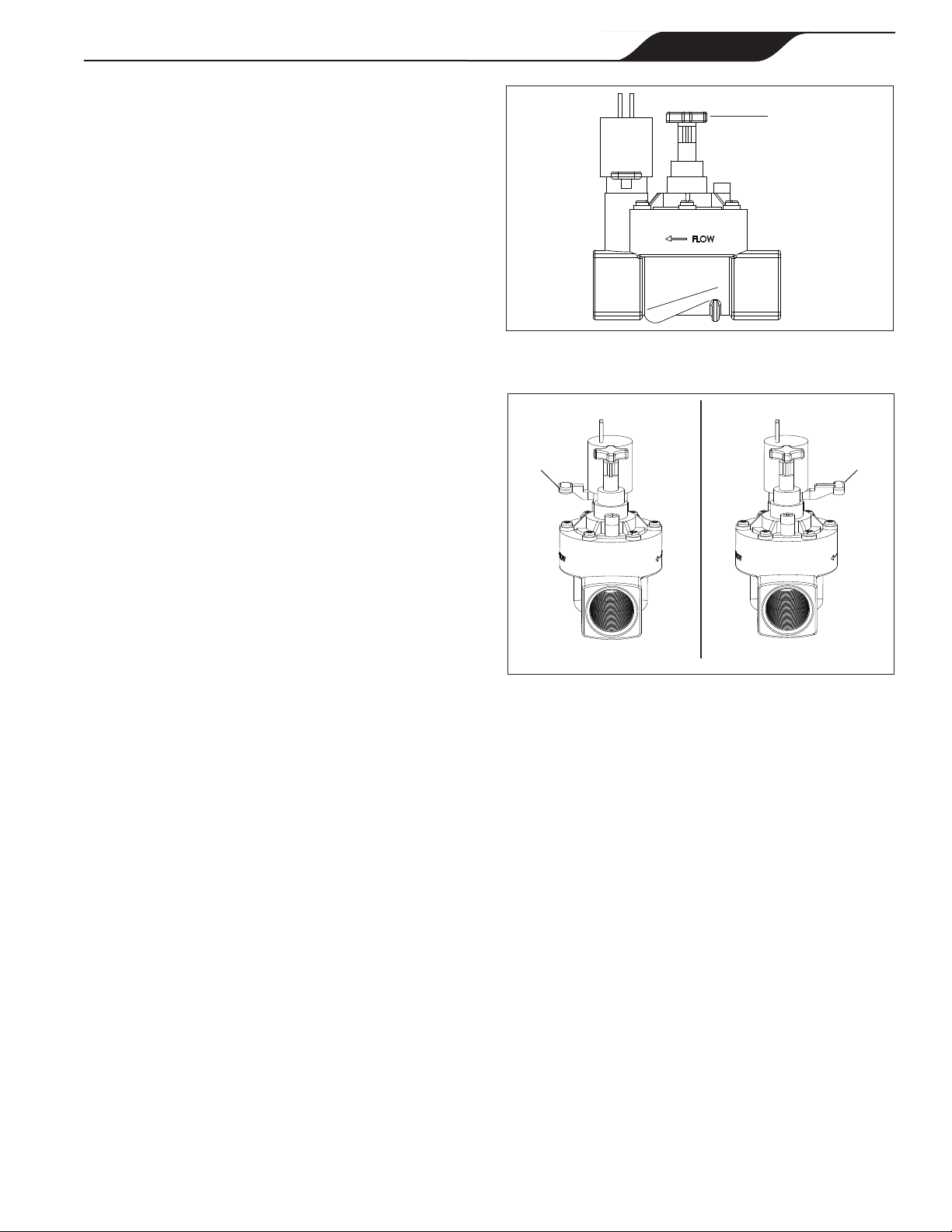

Valve

The K-2000 requires one (1) 24VAC solenoid valve.

The Jandy-supplied valve (PN SOL100) has a pressure

rating that cannot exceed 125 PSI.

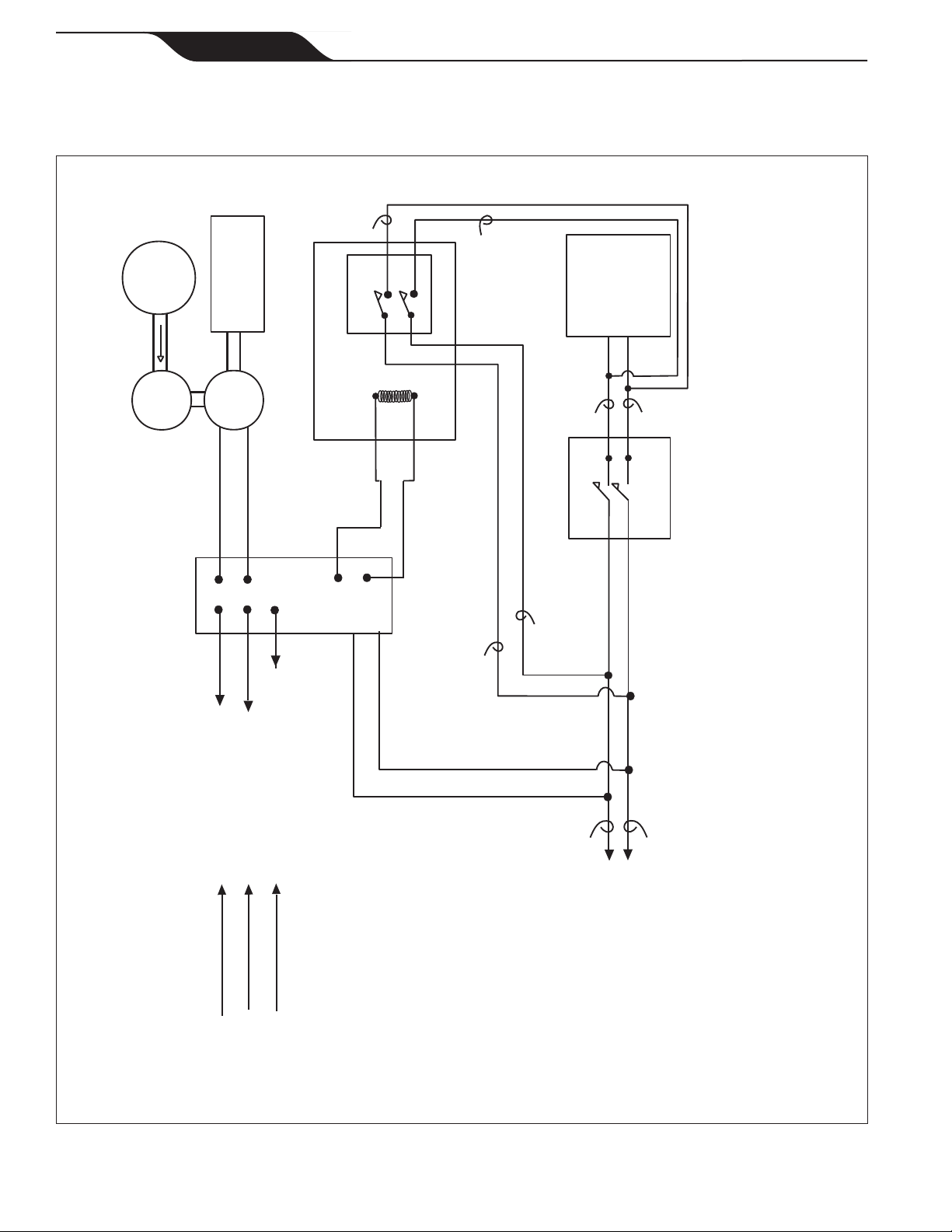

2.1 ElectricalSpecications

Input: 110VAC, 50/60 HZ, 0.5 AMPS

220VAC, 50/60 HZ, 0.5 AMPS

Valve Output: 24VAC@ 1 AMP

Relay Output: 24VDC@ 1 AMP

CAUTION

Model K-2000 is factory wired for 220VAC

service. Ifavailableelectricalserviceis

110VAC,thepowersupplywiringmustbe

changedtooperateon110VACasshownin

Figures3and4.

Page 5

ENGLISH

Jandy Pro Series Levolor®II Electronic Water Leveler

Models K-2000 |Installation and Operation Manual