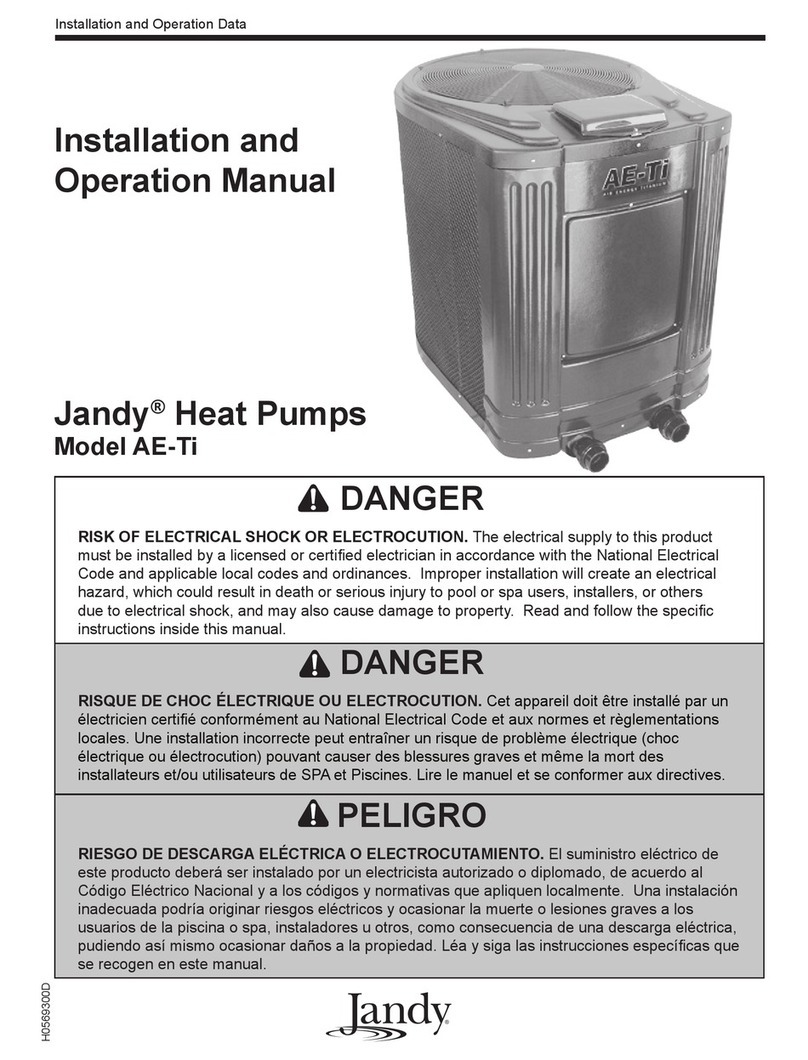

Page 1

Table of Contents

Section 1. General Information ..................5

1.1 Introduction......................................................... 5

1.2 Consumer Information and Safety...................... 5

1.2.1 Spa/Hot Tub Safety Rules............................5

1.2.2 Swimming Pool Energy Saving Tips ............ 6

1.3 Warranty ............................................................. 6

1.4 Codes and Standards......................................... 6

1.5 Technical Assistance........................................... 7

1.6 Materials Needed For Installation....................... 7

1.6.1 Materials for All Installations ........................ 7

1.6.2 Recommended Materials for Installations.... 7

1.7 Specifications...................................................... 7

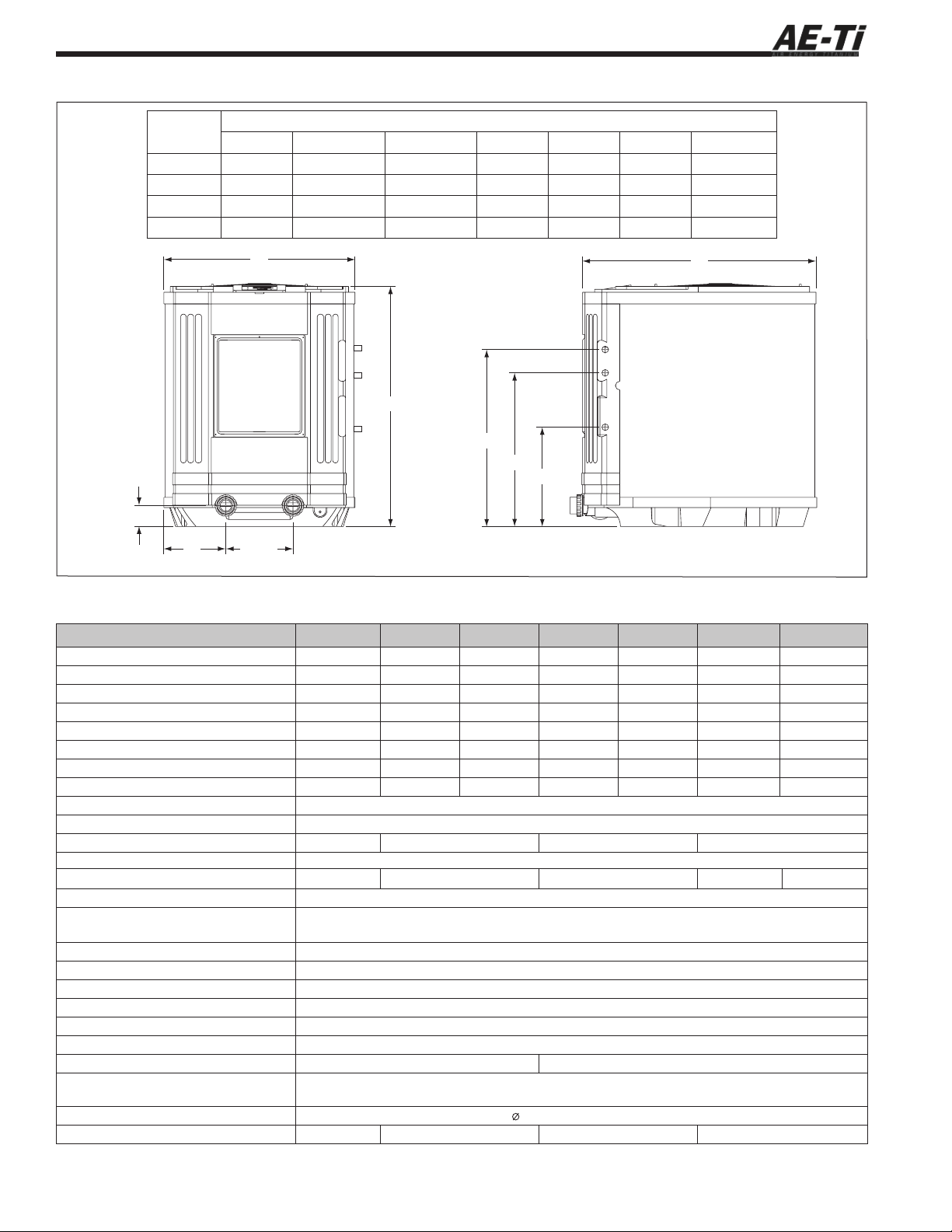

1.7.1 General Specifications................................. 7

1.7.2 Dimensions .................................................. 7

1.7.3 Technical Specifications............................... 8

Section 2. Installation Instructions ...........9

2.1 General Information ............................................ 9

2.2 Location Requirements....................................... 9

2.2.1 Introduction .................................................. 9

2.2.2 Clearances................................................... 9

2.2.3 Equipment Pad ............................................ 9

2.2.4 Indoor Installations..................................... 10

2.2.4.1 Condensation and Drainage ................ 10

2.2.5 Outdoor Installations.................................. 10

2.2.5.1 Lawn Sprinklers ................................... 10

2.2.5.2 Roof Run-off......................................... 11

Section 3. Water Connections .................11

3.1 Plumbing Layout .............................................. 11

3.2 Water Connections at Heat Pump .................... 11

3.3 Check Valve Installation.................................... 11

3.4 Automatic Flow Control Valve........................... 11

3.5 Filtration System Layouts ................................. 11

3.5.1 Shared Filtration System............................ 11

3.5.2 Independent Filtration System ................... 11

3.6 Multiple Unit Installation.................................... 13

3.6.1 Heat Pump and Heater Combination......... 13

3.6.2 Multiple Heat Pump Connections............... 13

Section 4. Electrical Connections............13

4.1 General Information .......................................... 16

4.2 Main Power....................................................... 16

4.3 Bonding (Earthing)............................................ 16

4.4 Pump Connection (Maintain Temp Feature) ..... 16

4.5 Optional Remote Controls ................................ 16

4.5.1 Connection to a Remote Pool-Off-Spa

Selector (3-Wire Connection)..................... 16

4.5.1.1 Install the Remote Pool-Off-Spa

Selector................................................ 16

4.5.1.2 Configure the Control Panel ................ 21

4.5.2 Two-Wire Connection to an AquaLink®RS

or TSTAT.................................................... 21

4.5.2.1 Configure the AquaLink®RS Control

System................................................. 21

4.5.2.2 Install the Remote TSTAT or

AquaLink®RS ...................................... 21

4.5.2.3 Configure the Control Panel ................ 21

4.5.3 Four-Wire Connections to AquaLink®

RS 485 Communication............................. 22

4.5.4 Connection to a Secondary

User Interface ............................................ 23

Section 5. Operation..................................23

5.1 Initial Start-up Precautions................................ 23

5.2 Operating the Controller ................................... 24

5.2.1 Off Mode .................................................... 24

5.2.2 Pool Mode - (Normal Heat)........................ 24

5.2.3 Pool Mode - (Optional Maintain Heat)........ 24

5.2.4 Spa Mode - (Normal Heat)......................... 24

5.2.5 Spa Mode - (Optional Maintain Heat) ........ 24

5.3 Operating Features of Units with

Optional Chiller ................................................. 25

5.3.1 Pool Mode - (Normal Chill)......................... 25

5.3.2 Pool Mode - (Optional Maintain Chill) ........ 25

5.3.3 Spa Mode - (Optional Maintain Chill)......... 25

5.4 User Setup Options .......................................... 25

5.4.1 Language Setup......................................... 25

5.4.2 Temperature Scale Setup ..........................26

5.4.3 Spa Timer Setup ........................................ 26

5.4.4 Display Light Setup.................................... 26

5.5 Set Point Lockout.............................................. 26

5.6 Water Pressure Switch Adjustment................... 26

Section 6. General Maintenance .............27

6.1 Water Chemistry ............................................... 27

6.2 Winterizing........................................................ 27

6.3 Spring Start-Up ................................................. 28

6.4 Inspection and Service ..................................... 28

6.4.1 Owner Inspection....................................... 28

6.4.2 Professional Inspection.............................. 29

Section 7. Professional Maintenance

and Service ..............................29

7.1 Heat Pump Design............................................ 29

7.2 Heat Pump Components and

Their Operation................................................. 30

7.3 Service Setup Options...................................... 30

7.3.1 Maintain Temperature ................................ 30

7.3.2 Maintain Temperature Delay ...................... 30

7.3.3 Remote ...................................................... 30

7.3.4 Defrost Selection........................................ 30

7.3.5 Test Mode .................................................. 30