Page 5

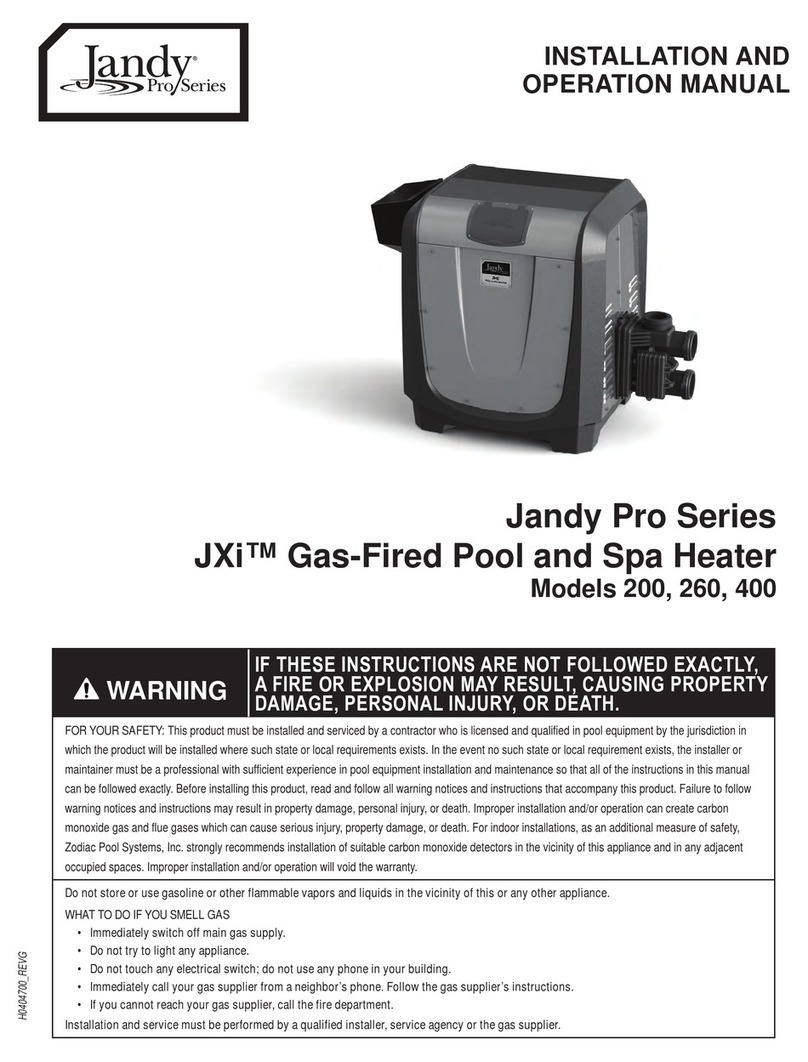

Jandy®JXi™Gas-Fired Pool and Spa Heater | Installation & Operation Manual

1.3 Warranty

The Jandy JXi heater is sold with a limited factory

warranty.

Make all warranty claims to your Jandy dealer or

directly to Jandy. Claims must include the heater

serial number and model (this information can be

found on the rating plate), installation date, and

name of the installer. Shipping costs are not included

in the warranty coverage.

The warranty does not cover damage caused

by improper assembly, installation, operation,

winterizing, field modification, or failure to earth bond

and properly ground the unit. Also, damage to the

heat exchanger by corrosive water is NOT covered

by the warranty.

1.4 Technical Assistance

Consult the Jandy technical support department or

your local Jandy dealer with any questions or problems

involving your Jandy equipment. An experienced

technical support staff is ready to assist you in

assuring the proper performance and application of

Jandy products. For technical support call the Jandy

technical support department at (800) 822-7933.

1.5 Specifications

Supply Gas

INSTALLATION LOCATION* NATURAL GAS (NG) CERTIFIED INDOOR (US ONLY), OUTDOOR / COVERED SHELTER

LIQUID PROPANE (LP) OUTDOOR / COVERED SHELTER

OUTDOOR OPERATION AMBIENT

AIR ANY OUTDOOR OPERATION IN AMBIENT AIR UP TO 40°F (4°C)

GAS PIPE HEATER GAS VALVE

CONNECTION†

NATURAL GAS (NG) 3/4 in NPT

LIQUID PROPANE (LP)

Inlet Gas supply Pressure ‡

Min

NATURAL GAS (NG) 4.0 in WC

LIQUID PROPANE (LP)

Water Pipe/Heater Connection NATURAL GAS (NG) • PVC/CPVC 2 in unthreaded

• Jandy threaded union

LIQUID PROPANE (LP)

Water Flow Rate

Min

NATURAL GAS (NG) 30 gpm

(76 lpm)

LIQUID PROPANE (LP)

Working Water Pressure NATURAL GAS (NG) 2 psi**

LIQUID PROPANE (LP)

Exhaust Vent Connection Size (Cate-

gory I)§ See Section 3.3.4

NATURAL GAS (NG) • Model 200: 6 in

• Model 260: 7 in

• Model 400: 8 in

LIQUID PROPANE (LP)

Exhaust Vent Connection Size (Cate-

gory III)§ See Section 3.3.4

NATURAL GAS (NG) • All Models: 4 in

LIQUID PROPANE (LP)

Electrical Supply NATURAL GAS (NG) • 120 VAC@<5amps

• 240 VAC@<2.5amps

LIQUID PROPANE (LP)

High Altitude

NATURAL GAS (NG)

Appliances are normally derated when installed at high elevation. This is

not necessary with the JXi heater because it has a special venturi-type

combustion system which self-compensates for changes in barometric

pressure. Air flow through the blower inlet pulls the correct flow of gas into

the burner regardless of air density.

JXi heaters are CSA certified for elevations of up to 4,500 feet above sea

level. At elevations above 4,500 ft., the heater BTU output can be expected

to be reduced by 4% for every 1,000 feet over 4,500 feet above sea level.

LIQUID PROPANE (LP)

* Indoor installation is not recommended for liquid propane heaters.

**Adjustable water pressure switch factory set to 7 psi.

See section 5.3 for adjustment instructions.

Review Special Precautions for liquid propane heaters (Section 4.3)

Any changes to the heater, gas controls, gas valve, air orifice, gas orifices, wiring, or

improper installation may void the warranty. If change is required to any of the above;

contact your local Jandy distributor, visit www.jandy.com or call technical support at

800.822.7933.

†For gas pipe size requirements see Section 4

‡Value displayed is for operating (fired) pressure not static.

§ Use type B double-wall gas vent, per table 13.1(a) NFPA 54