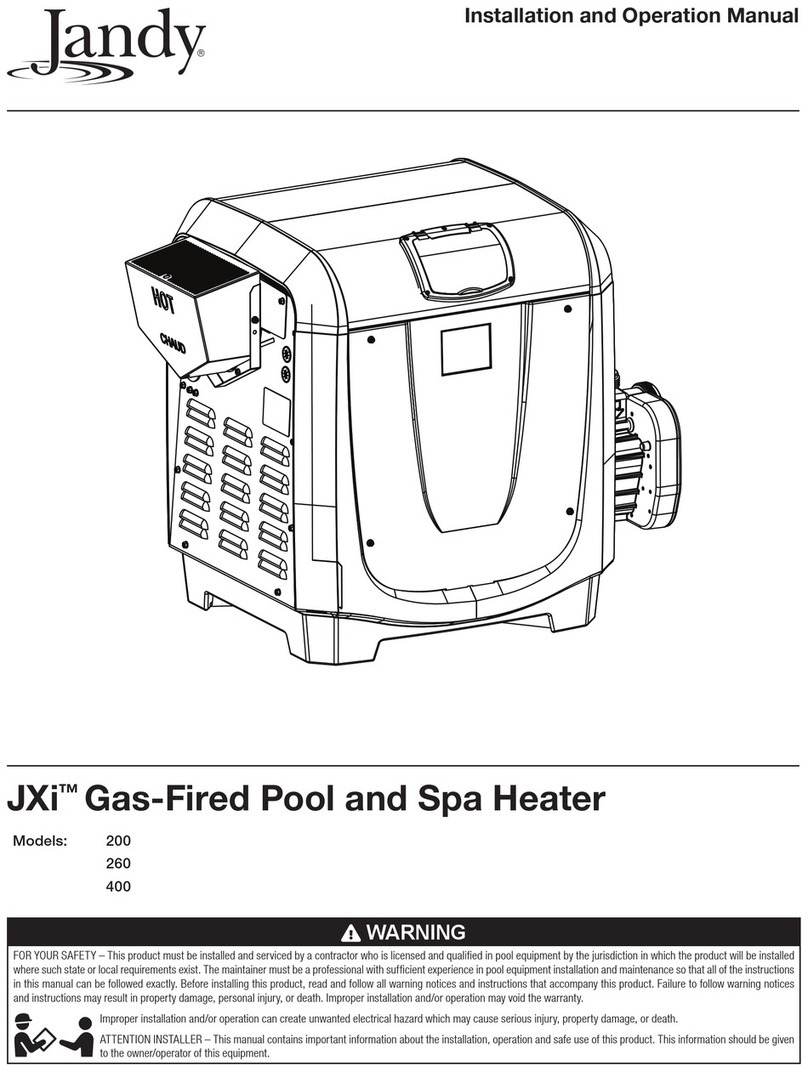

Page 2 ENGLISH Jandy®Pro Series, JXi™Gas-Fired Pool & Spa Heater |Installation & Operation Manual

Table of Contents

Section 1. General Information ....................... 3

1.1 Technical Assistance.......................................... 3

1.2 Warranty............................................................. 3

1.3 Consumer Information and Safety...................... 3

1.4 General Operation Description........................... 3

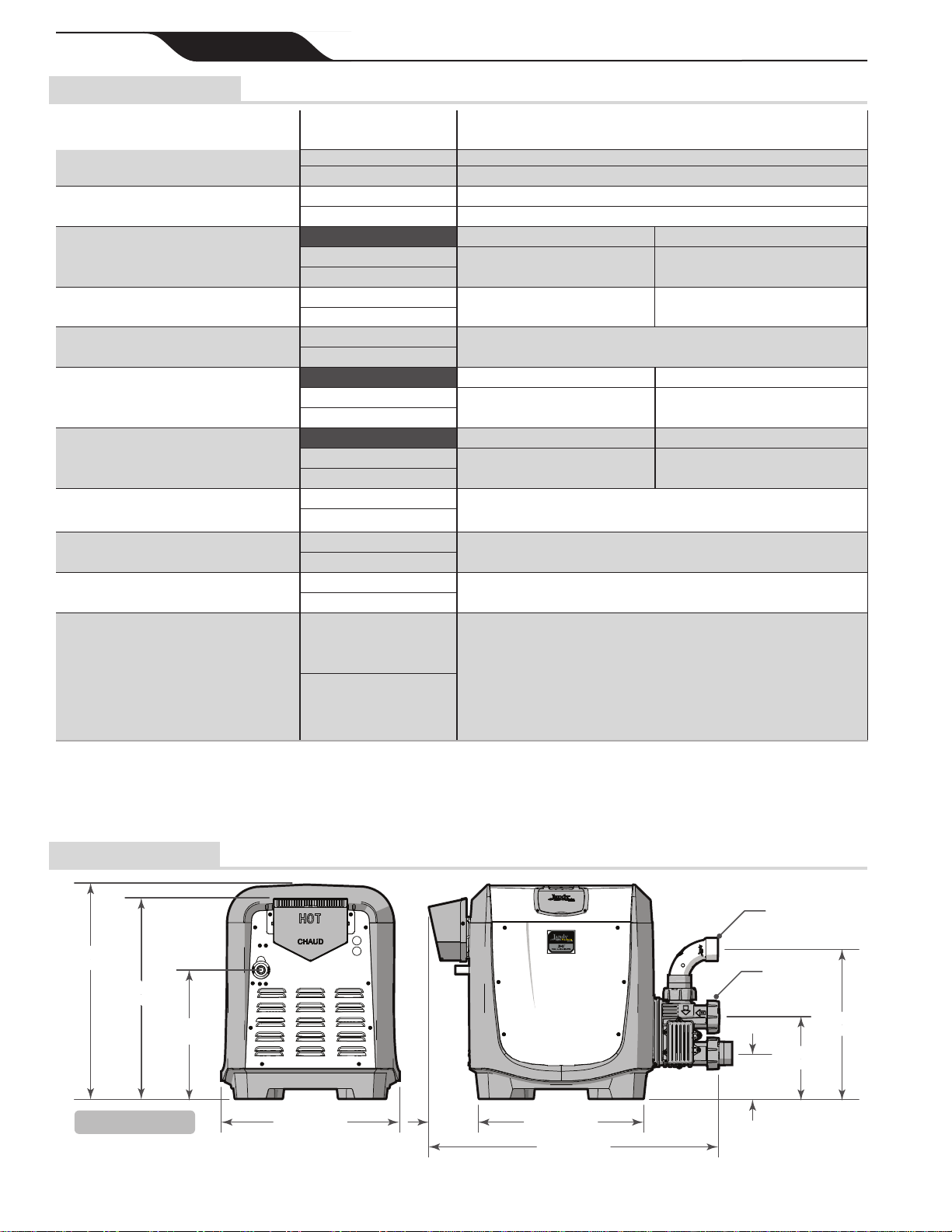

1.5 Specications ..................................................... 4

1.6 Dimensions......................................................... 4

1.7 CerticationCodesandStandards..................... 5

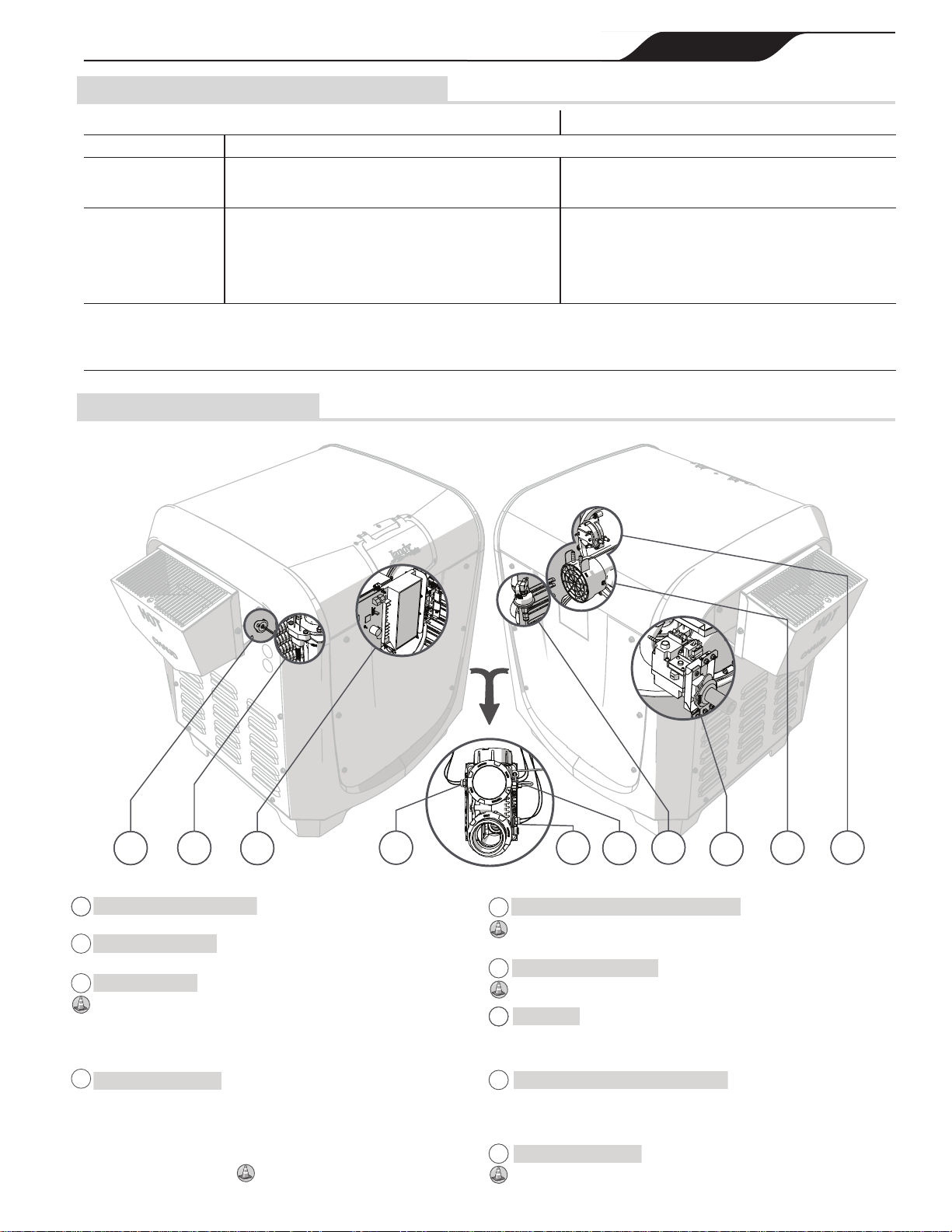

1.8 Heater Components........................................... 5

Section 2. Getting Started................................ 6

2.1 Package Contents.............................................. 6

2.2 Required Equipment........................................... 7

2.2.1 Tools................................................................................... 7

2.2.2 Materials............................................................................. 7

Section 3. Location Requirements.................. 8

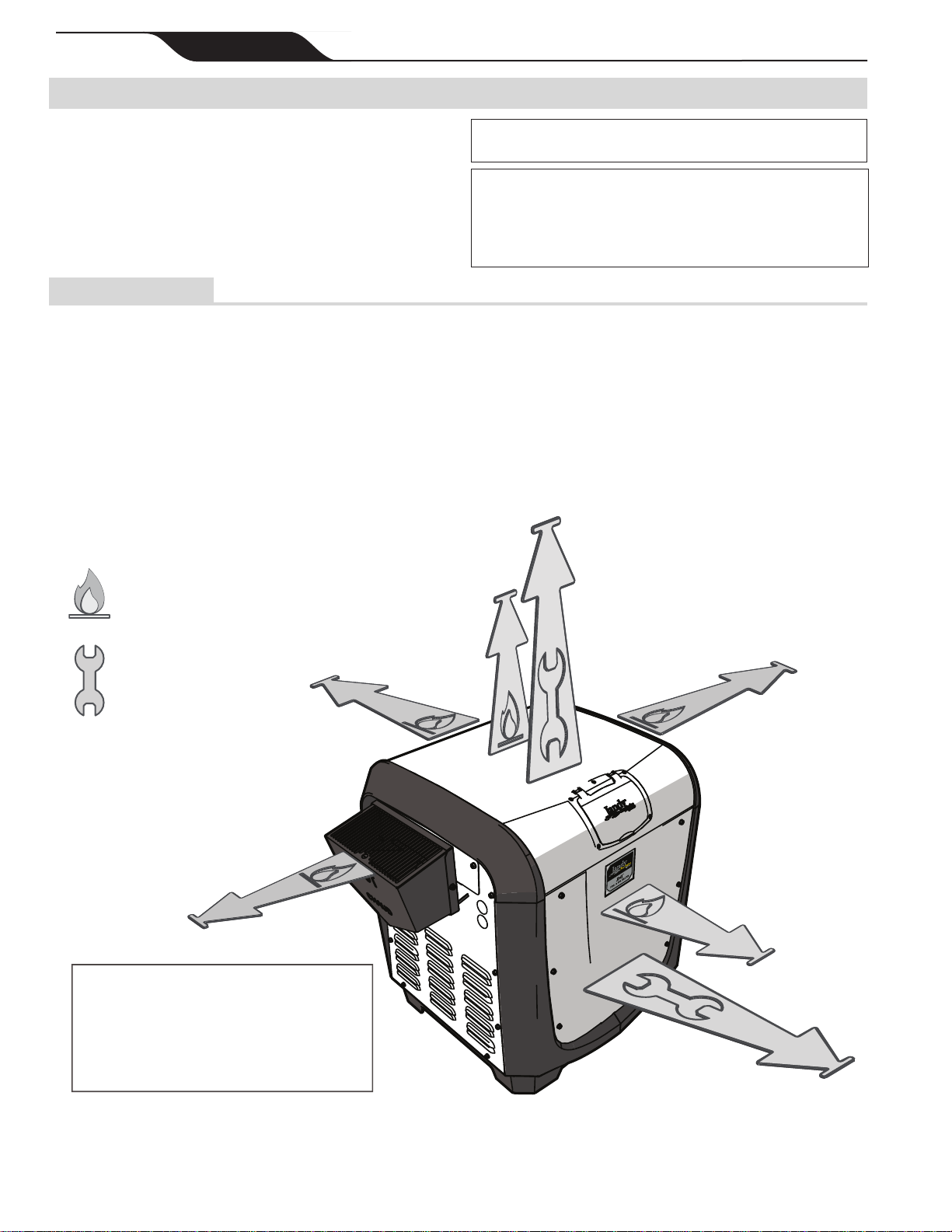

3.1 Clearances......................................................... 8

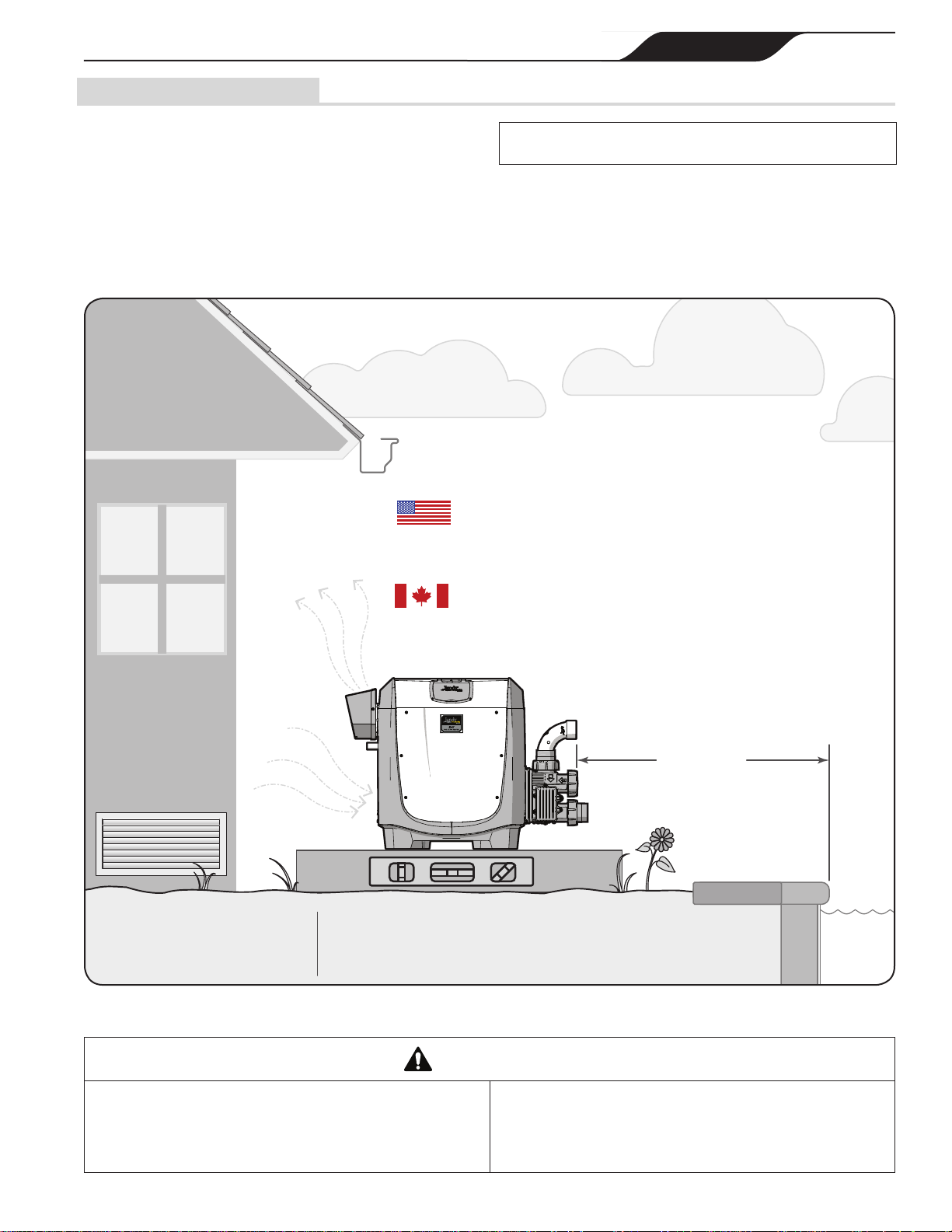

3.2 Outdoor Installation............................................ 9

3.2.1 Anchor Bracket Installation............................................... 10

3.3 Indoor and Outdoor Shelter Installation.............11

3.3.1 Combustion IntakeAir Supply...........................................11

3.3.2 Exhaust Venting ............................................................... 12

3.3.3 Indoor and Outdoor Shelter Exhaust Conversion............. 13

3.3.4 Indoor and Outdoor Shelter Exhaust Termination............ 14

3.3.5 PrecautionsAgainst Common Venting............................. 14

3.3.6 Inspection and Replacement

of Existing Vent System with New Components............... 14

Section 4. Gas Connections.......................... 15

4.1 Supply Gas Requirements ............................... 15

4.2 Inlet Gas Pressure Test.................................... 16

4.3 Gas Offset Pressure Test ................................. 16

4.3.1 Connect the Digital Differential Manometer...................... 17

4.3.2 Gas Offset Pressure Adjustment...................................... 17

4.4 Special Precautions for LP Gas........................ 18

Section 5. Water Connections....................... 18

5.1 Pump Sizing..................................................... 19

5.1.1 Manual Bypass Valve....................................................... 19

5.1.2 Pump Sizing for New Pool Construction:......................... 19

5.1.3 Pump Sizing for Replacement in an Existing Pool:.......... 19

5.2 Plumbing Connections ..................................... 20

5.2.1 Reversing Plumbing Connections.................................... 20

5.2.2 Optional Water Inlet Piping............................................... 20

5.3 Water Pressure Switch Adjustment.................. 21

5.4 Check Valve Installation................................... 22

5.5 Pressure Relief Valve Installation..................... 22

5.5.1 Install pressure relief valve kit # R0336101...................... 22

5.6 Auxiliary Components, Chlorinators,

Ozone Generators, and Sanitizing Chemicals . 23

Section 6. Electrical Connections................. 24

6.1 Service Access................................................. 25

6.2 Main Wiring Connections ................................. 25

6.3 Input Voltage and Conversion.......................... 25

6.4 Bonding............................................................ 26

Section 7. Optional Remote Controls........... 26

7.1 Connecting to a Remote Pool-Off-Spa Selector

(3-Wire Connection)......................................... 27

7.1.1 ConguretheControlPanel:............................................ 27

7.2 Connecting to an AquaLink® Control System

or Remote TSTAT (2-Wire Connection)............ 27

7.2.1 Install the Remote TSTAT:................................................ 27

7.2.2 ConguretheControlPanel:............................................ 27

7.3 “Smart” Communication via RS-485 ................ 28

7.3.1 To Restore Heater Control Panel Functionality

After Connecting to an External Controller.................................... 29

7.3.2 To return functionality to RS:............................................ 29

Section 8. Operating Instructions................. 29

8.1 IMPORTANT SAFETY INFORMATION............ 29

8.1.1 WHAT TO DO IF YOU SMELL GAS................................. 29

8.2 First-Time Start-Up Procedure ......................... 29

8.2.1 OPERATING INSTRUCTIONS ........................................ 30

8.2.2 If Ignition Is Unsuccessful................................................. 30

8.3 TO TURN OFF GAS TO THE HEATER ........... 30

8.4 Normal Operation............................................. 30

8.5 Operating the Controller................................... 32

8.5.1 Setting up Heater Options................................................ 32

8.5.2 Operating the Heater........................................................ 33

8.6 Shutting Down the Heater................................ 33

Section 9. Maintenance.................................. 34

9.1 Water Chemistry............................................... 34

9.1.1 Saturation Index............................................................... 34

9.2 Swimming Pool Energy Saving Tips................. 35

9.3 Winterizing........................................................ 35

9.4 Spring Start-up................................................. 35

9.5 Inspection and Service..................................... 36

9.5.1 Guidelines for Homeowner Inspection:............................ 36

9.5.2 Guidelines for Professional Inspection:............................ 36

Section 10. Troubleshooting ........................... 37

10.1 Common Problems........................................... 37

10.2 Service Diagnostic Messages.......................... 38

10.3 Ignition Control LED Service Codes................. 38

Section 11. Professional Service

and Maintenance .......................... 39

Section 12. Spare Parts.................................... 39

12.1 Major Components........................................... 39

12.2 Cabinet Assembly Spare Parts List

and Exploded Parts Diagram ........................... 40

12.3 Heat System Spare Parts List

and Exploded Parts Diagrams.......................... 41

12.3.1 Combustion Chamber Assembly...................................... 41

12.3.2 Burner Assembly.............................................................. 42

12.4 Water System Spare Parts List

and Exploded Parts Diagrams.......................... 43

12.5 Electrical System Spare Parts List

and Exploded Parts Diagrams ......................... 44