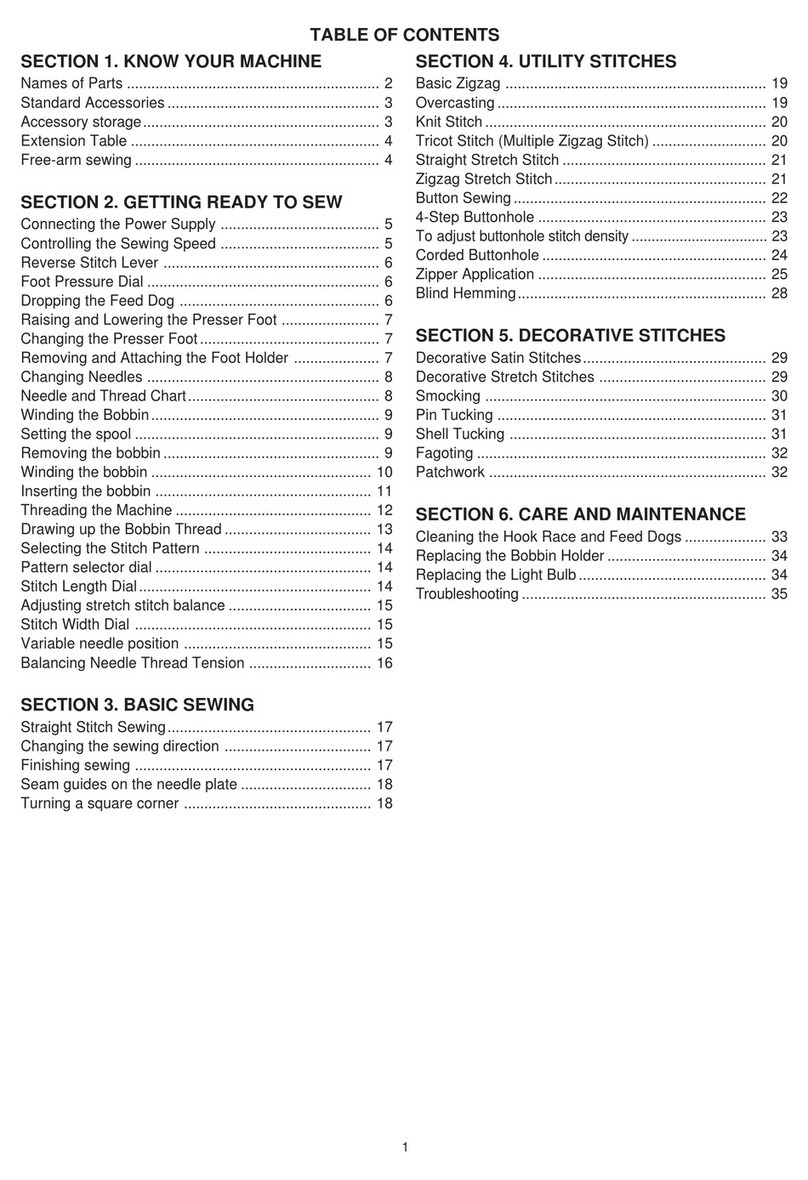

INDEX

What to do when .............................................................................................................................. 1 - 3

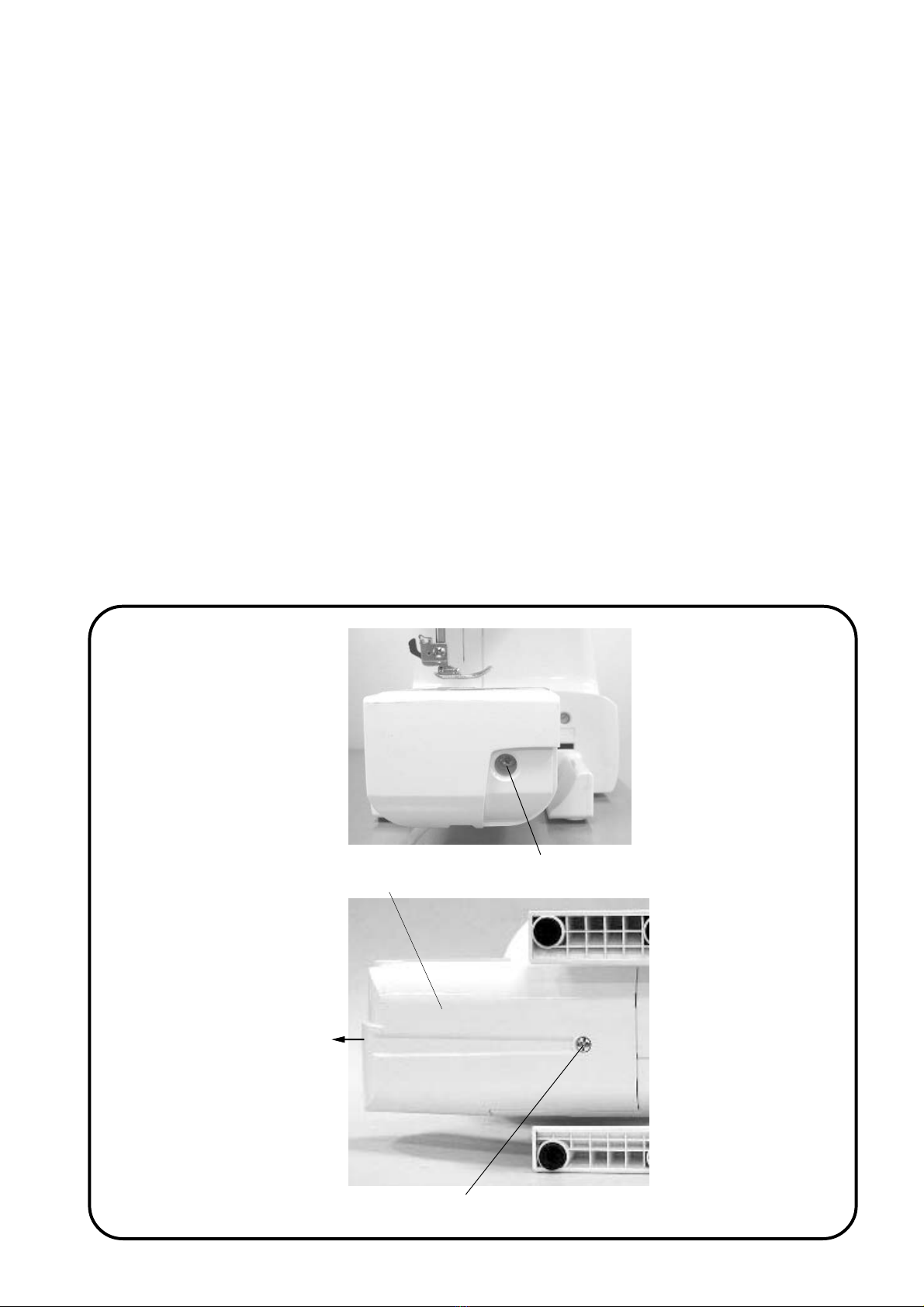

Changing External Parts

Face Cover ............................................................................................................................................. 4

Free-arm Cover ...................................................................................................................................... 5

Front Cover ....................................................................................................................................... 6 - 7

RearF Cover ........................................................................................................................................... 8

Mechanical Adjustment

Presser Bar Height ................................................................................................................................. 9

Needle Drop Position ........................................................................................................................... 10

Adjustment of Hook Timing .................................................................................................................. 11

Adjustment of Needle Bar Height ......................................................................................................... 12

Clearance between Needle and Tip of Hook Rotary ............................................................................ 13

Feed Dog Height .................................................................................................................................. 14

Feed Dog Adjustment (Only for model 3160QDC) ............................................................................... 15

Top Tension .......................................................................................................................................... 16

Replacing the Electronic Components

Circuit Board-A connection .................................................................................................................. 17

Self-diagnostic Test ......................................................................................................................... 18-22

Circuit Board-A ................................................................................................................................ 23-24

Driving Motor ........................................................................................................................................ 25

Switching regulator Unit ....................................................................................................................... 26

Adjusting Buttonhole Lever Position ..................................................................................................... 27

Parts List ........................................................................................................................................ 28-41