TABLE OF CONTENTS

TO CHANGE THE FACE PLATE UNIT .................................................................................................. 1

TO CHANGE THE BELT COVER............................................................................................................2

TO CHANGE THE TOP COVER UNIT....................................................................................................3

TO CHANGE THE FRONT COVER UNIT...............................................................................................4

TO CHANGE THE FREE ARM COVER UNIT.........................................................................................5

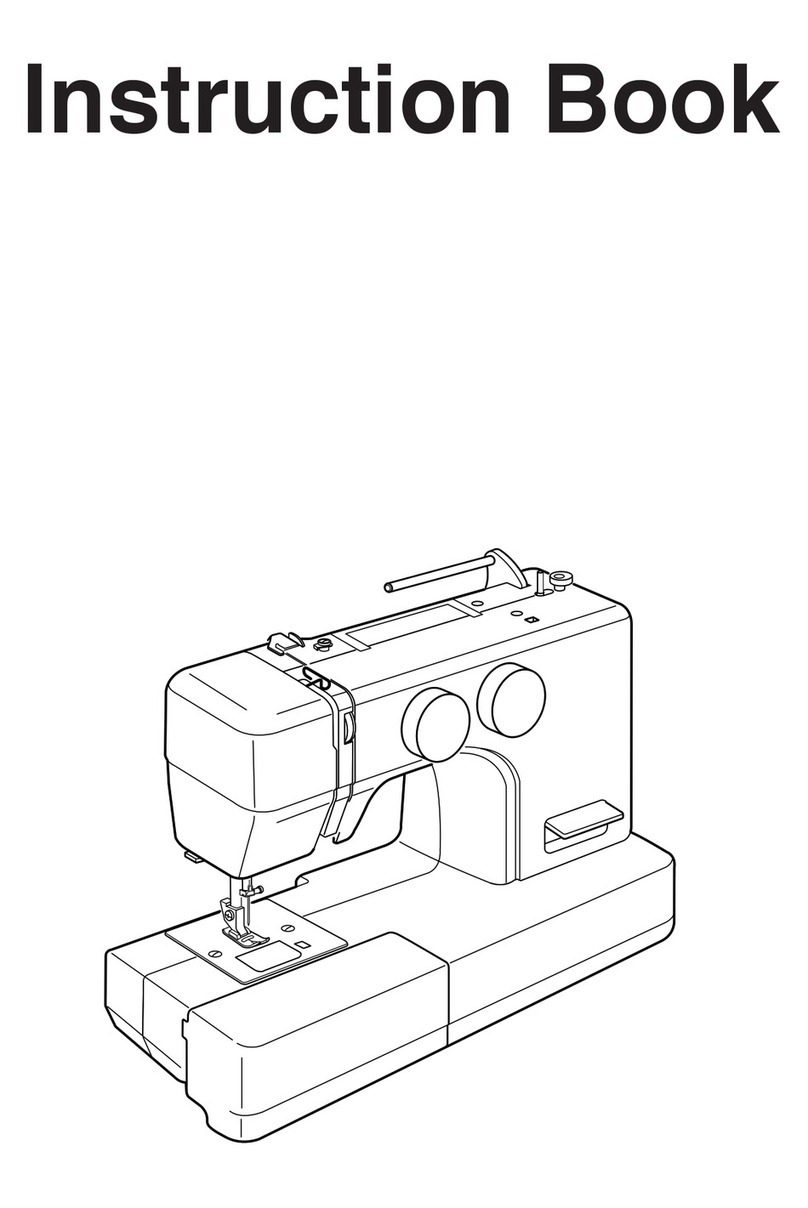

TO CHANGE THE MACHINE BASE.......................................................................................................6

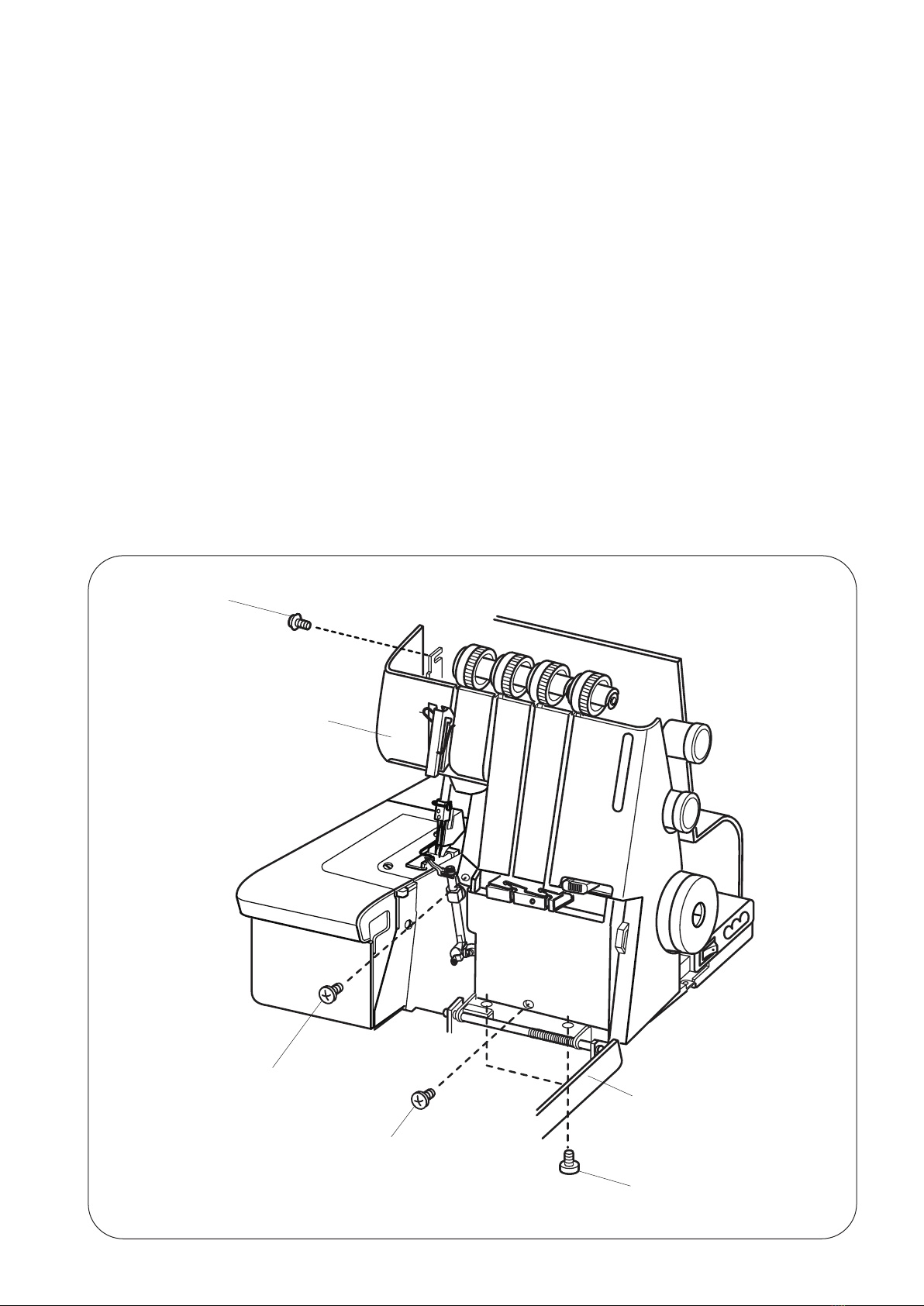

TO CHANGE THE MACHINE SOCKET..................................................................................................7

TO ADJUST THE MOTOR BELT TENSION............................................................................................8

TO ADJUST THE NEEDLE HEIGHT.......................................................................................................9

TO ADJUST THE PRESSER BAR HEIGHT..........................................................................................10

TO ADJUST THE FEED DOG HEIGHT ................................................................................................11

TO ADJUST THE TIMING OF THE NEEDLE AND THE FEED DOG ...................................................12

TO ADJUST THE TIMING OF THE NEEDLE AND THE UPPER KNIFE ..............................................13

TO ADJUST THE CLEARANCE BETWEEN THE NEEDLES AND

THE LOWER LOOPER/NEEDLE GUARDS ................................................................................14 to 16

TO ADJUST THE CLEARANCE BETWEEN THE NEEDLES AND

THE FIXED NEEDLE GUARD ..............................................................................................................17

TO ADJUST THE POSITION OF THE CHAINING FINGER .................................................................18

TO ADJUST THE POSITION OF THE UPPER LOOPER.....................................................................19

TO ADJUST THE TIMING OF THE NEEDLE AND THE LOWER LOOPER .........................................20

TO ADJUST THE TIMING OF THE UPPER AND LOWER LOOPERS.................................................21

TO ADJUST THE CLEARANCE BETWEEN THE LOOPERS ..............................................................22

TO ADJUST THE CLEARANCE BETWEEN THE NEEDLE AND THE UPPER LOOPER ...................23

TO ADJUST THE POSITION OF THE KNlVES ....................................................................................24

TO ADJUST THE POSITION OF THE LOOPER THREAD GUlDE ......................................................25

TO ADJUST THE STITCH LENGTH .....................................................................................................26

TO ADJUST THE THREAD TENSION DIALS.......................................................................................27

PARTS LIST .................................................................................................................................28 to 50