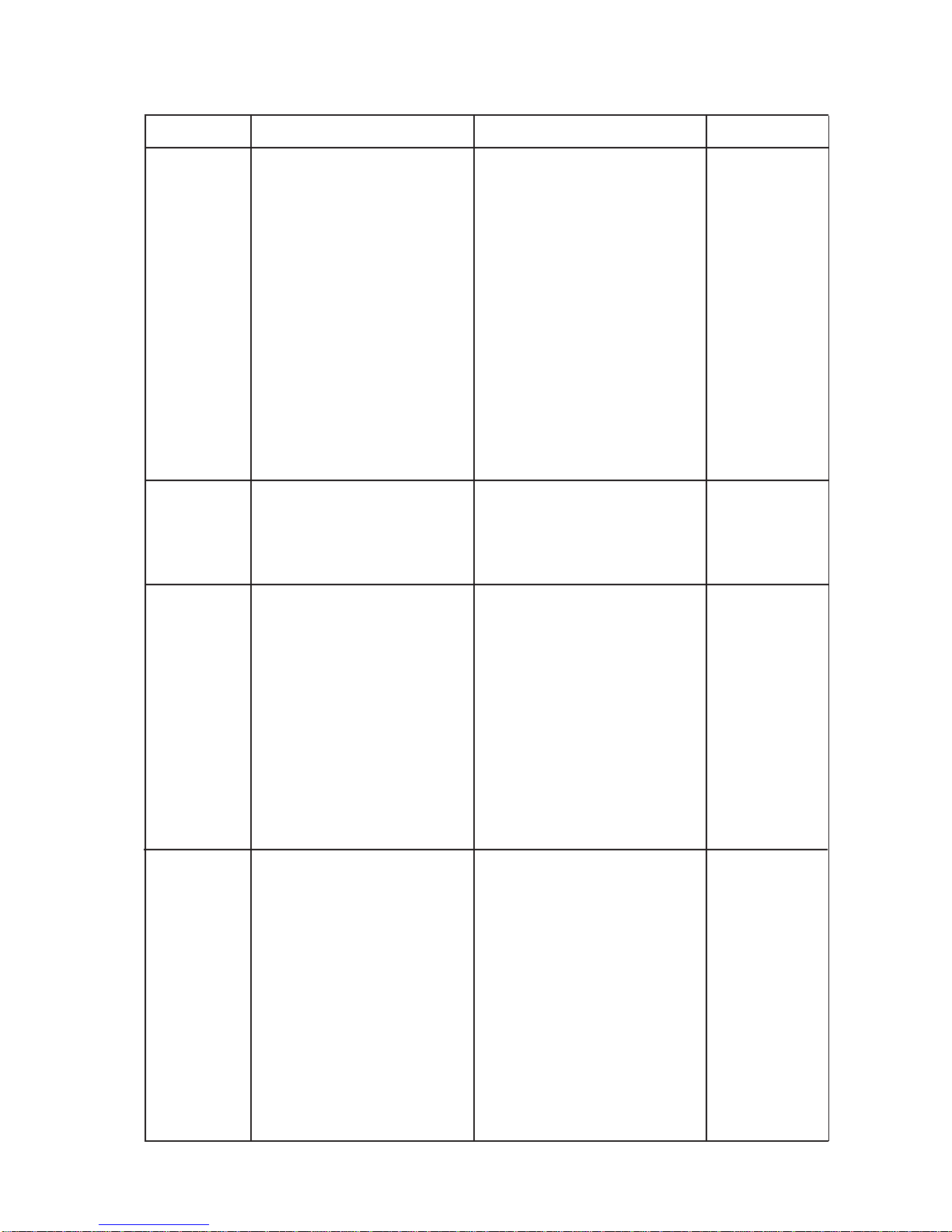

WHAT TO DO WHEN

CONDITION

1. Skipping

stitches

2. Fabric not

moving

3.Breaking

upperthread

4.Breaking

bobbin

thread

CAUSE

1. Needle is not inserted

properly.

2. Needle is bent or worn.

3. Incorrectly threaded.

4. Needle or thread is

inappropriate for fabric being

sewn.

5. Sewing on stretch fabric.

6. Inappropriateneedlebar

height.

7. Inappropriate needle to hook

timing.

8. Inappropriate needle to hook

clearance.

1. Incorrect feed dog height.

2. Thread on bottom side of

fabric is jammed up.

3. Feed dog teeth are worn.

1. Initial sewing speed is too

fast.

2. Thread path is incorrect.

3. Needle is bent or dull.

4. Upper thread tension is too

strong.

5. Needle size is inappropriate

for fabric.

6. Needle eye is worn.

7. Needle hole in needle plate is

worn or burred.

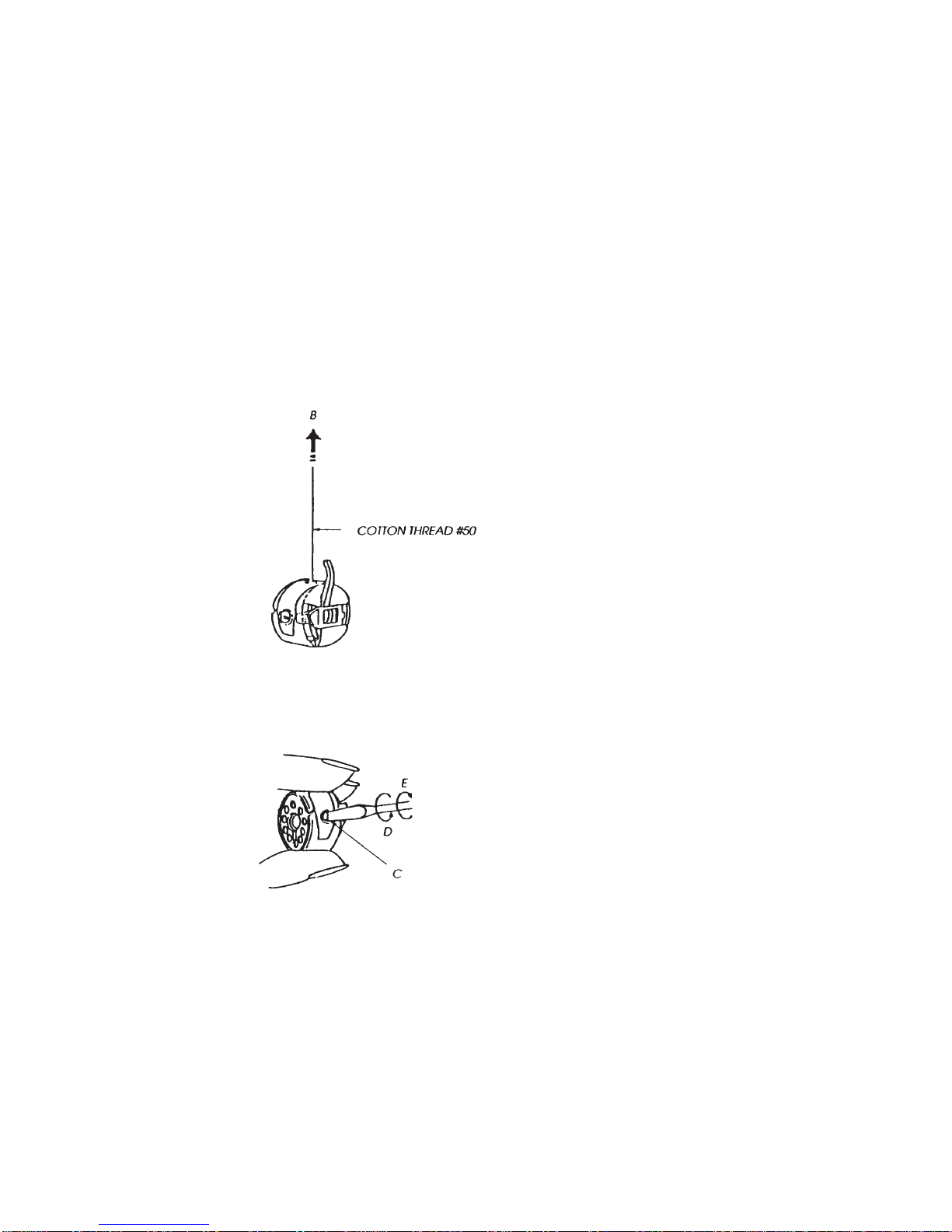

1. Incorrectly threaded bobbin

case.

2. Too much thread is around on

the bobbin.

3. Lint is stuck inside the bobbin

holder.

4. Thread quality is too low.

5. Thread is jamming around the

bobbin.

6. Bobbin thread tension is too

strong.

HOWTO FIX

Insert the needle properly.

Change the needle.

Rethread.

Use the recommended sewing

needle and thread.

Use a size 11 blue tip needle.

See mechanical adjustment

“Needle bar height”.

See mechanical adjustment “Hook

timing”.

See mechanical adjustment

“Clearance between needle and

hook”.

See mechanical adjustment

“Height of feed dog”.

Make sure to bring both needle and

bobbin thread under the foot when

starting sewing.

Change the feed dog.

Start with medium speed.

Use the proper thread path.

Replace with a new needle.

Adjust upper thread tension

correctly.

Use appropriate needle for fabric

and thread in use.

Change the needle.

Repair the hole or replace the

needle plate.

Thread bobbin case correctly.

Adjust the pos1tion of stopper.

Clean the hook race.

Change to a high quality sewing

thread.

Clear out the jamming thread.

Adjust bobbin thread tension

correctly.

REFERENCE

P.14

P15

P12.13

P11

P.6

P.7

1