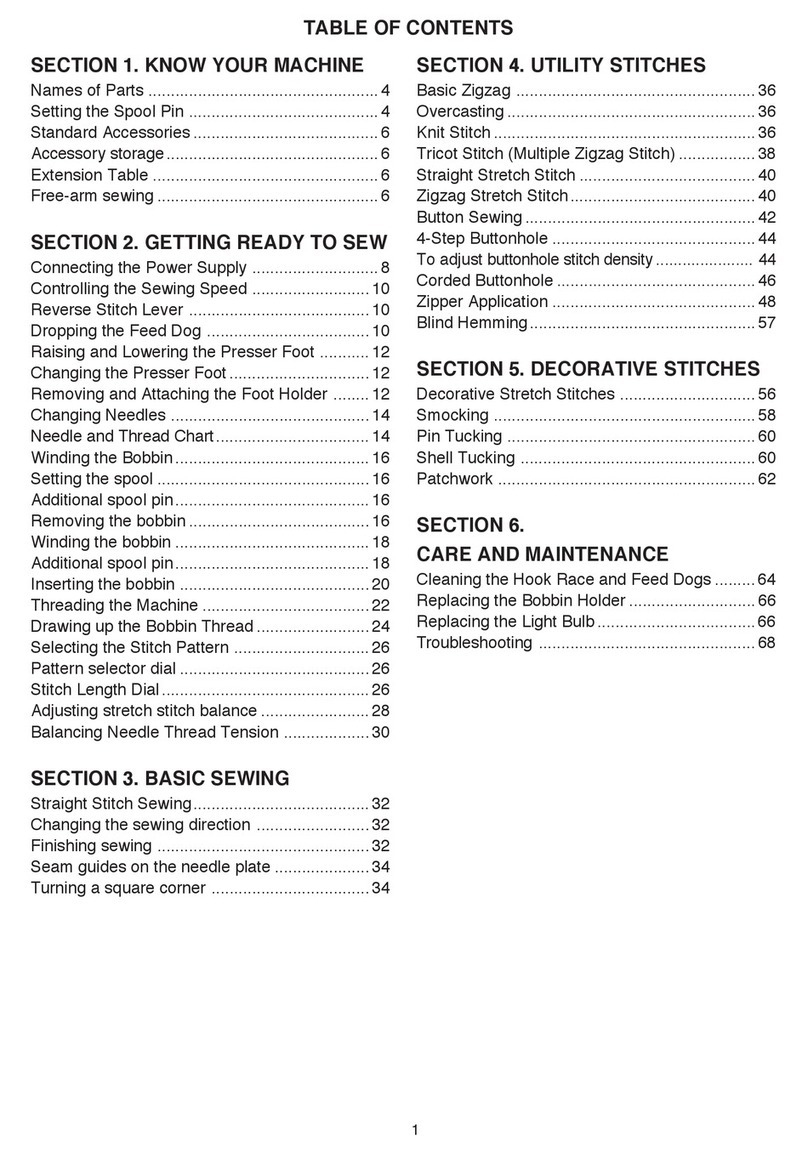

CONTENTS

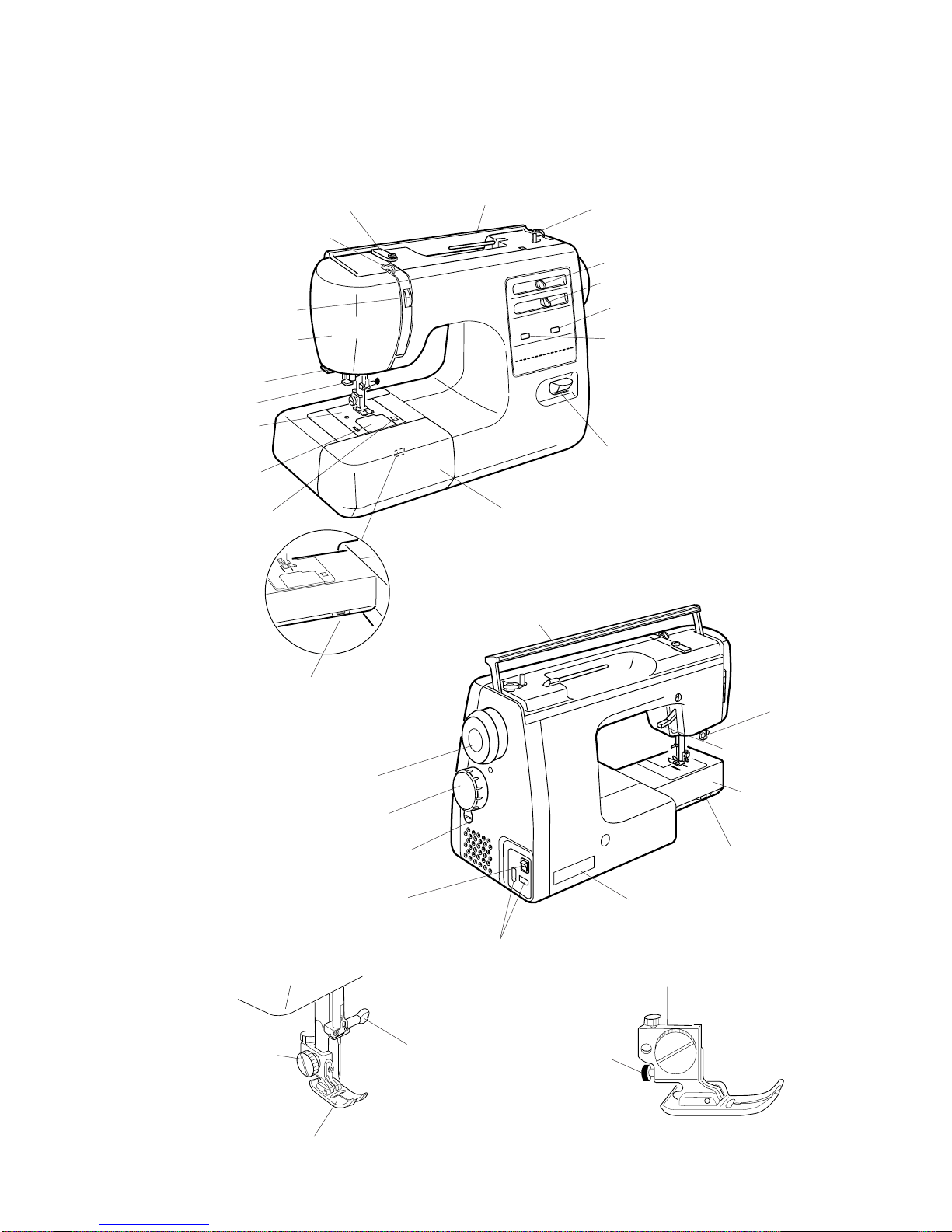

LOCATE AND IDENTIFYTHE PARTS ......................................................................... 1

WHAT TO DO WHEN .................................................................................................. 2-4

THREADING OF MACHINE ....................................................................................... 5-6

SERVICE ACCESS

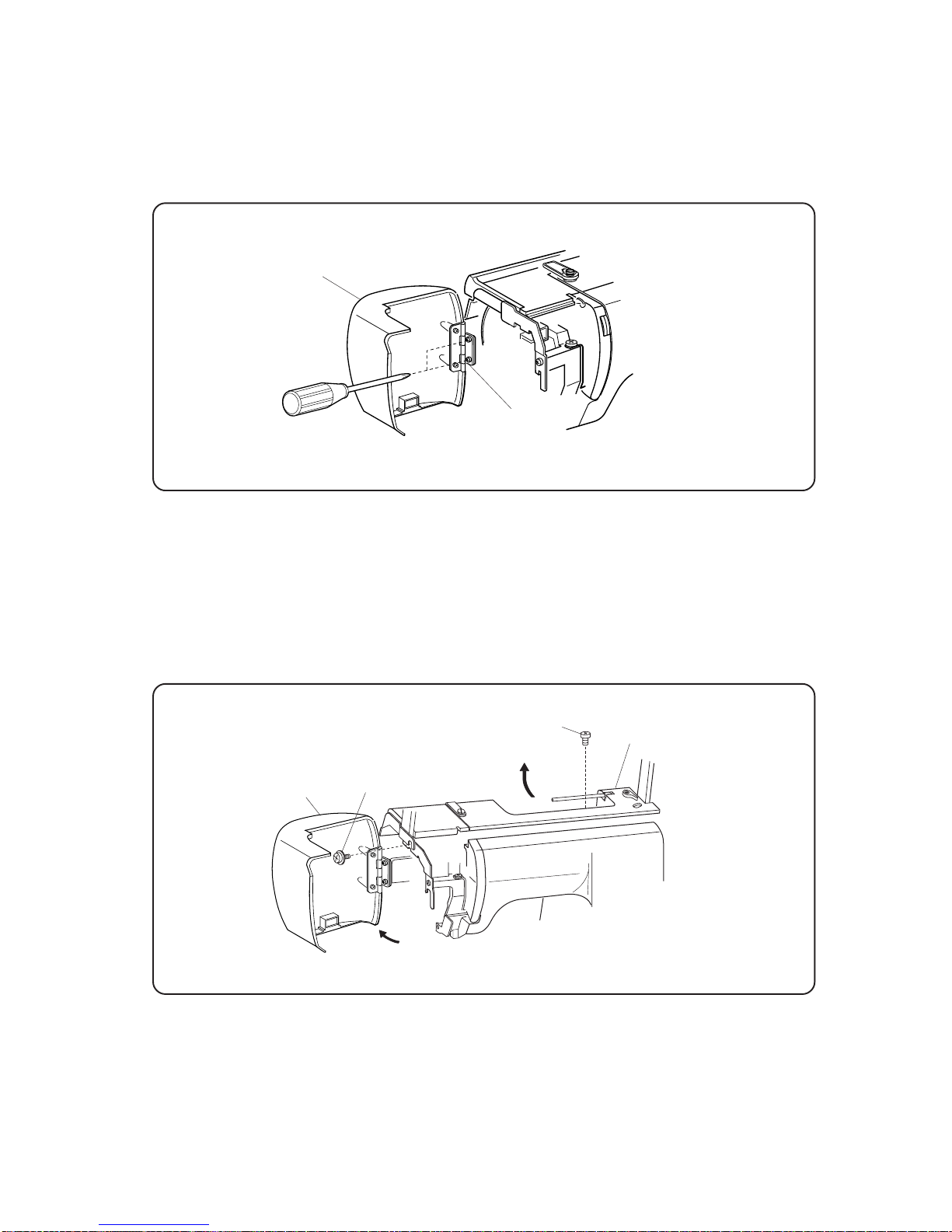

FACE COVER....................................................................................................... 7

TOP COVER......................................................................................................... 7

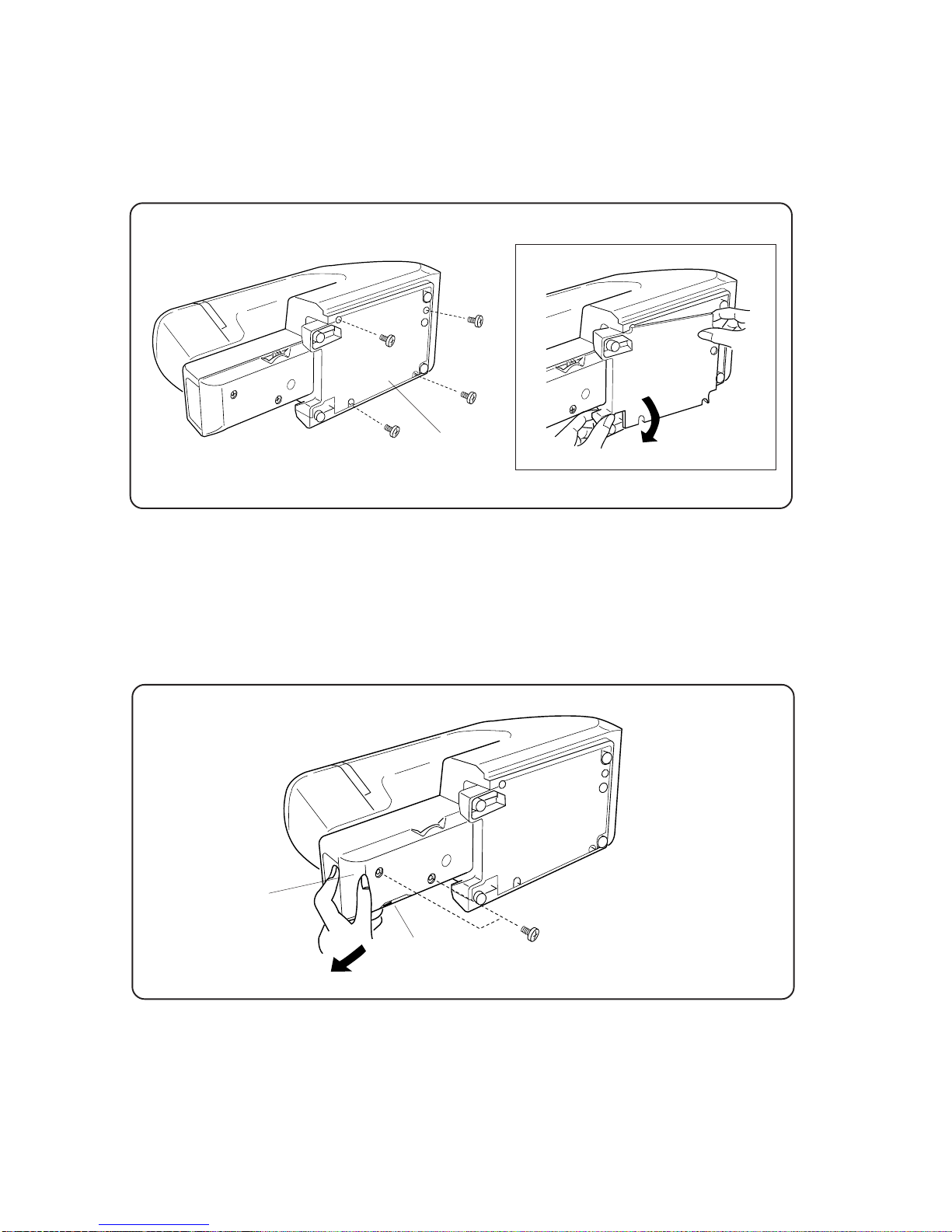

BASE PLATE ........................................................................................................ 8

BED COVER......................................................................................................... 8

BELT COVER ....................................................................................................... 9

FREE ARM COVER ............................................................................................. 9

FRONT COVER.................................................................................................... 10

REAR PANEL ....................................................................................................... 11

MECHANICAL ADJUSTMENT

TOP TENSION...................................................................................................... 12

PRESSER BAR HEIGHT AND ALIGNMENT....................................................... 13

NEEDLE SWING .................................................................................................. 14

STRAIGHT STITCHING .................................................................................. 15-16

DISTRIBUTION OF NEEDLE SWING............................................................. 17-18

STRETCH STITCH BALANCE........................................................................ 19-20

FEED DOG HEIGHT

................................................................................................ 21

NEEDLE BAR HEIGHT ........................................................................................ 22

NEEDLE TO HOOK TIMING................................................................................. 23

NEEDLE CLEARANCE TO HOOK ....................................................................... 24

BACKLASH (LOWER SHAFT GEAR) .................................................................. 25

BUTTONHOLE STITCH BALANCE ................................................................ 26-27

NEEDLE POSITION ........................................................................................ 28-29

ZERO FEEDING.............................................................................................. 30-31

BASIC NEEDLE POSITION ................................................................................. 32

BUTTONHOLE FUNCTION (1) ............................................................................ 33

BUTTONHOLE FUNCTION (2) ............................................................................ 34

REPLACEMENT AND ADJUSTMENT OF NEEDLE THREADER PLATE ........... 35

MOTOR BELT TENSION ...................................................................................... 36

OILING.......................................................................................................................... 37

WIRING OFTERMINAL BLOCK.................................................................................. 38

SPECIALTOOLS REQUIRED...................................................................................... 39

PARTS LIST............................................................................................................. 40-61