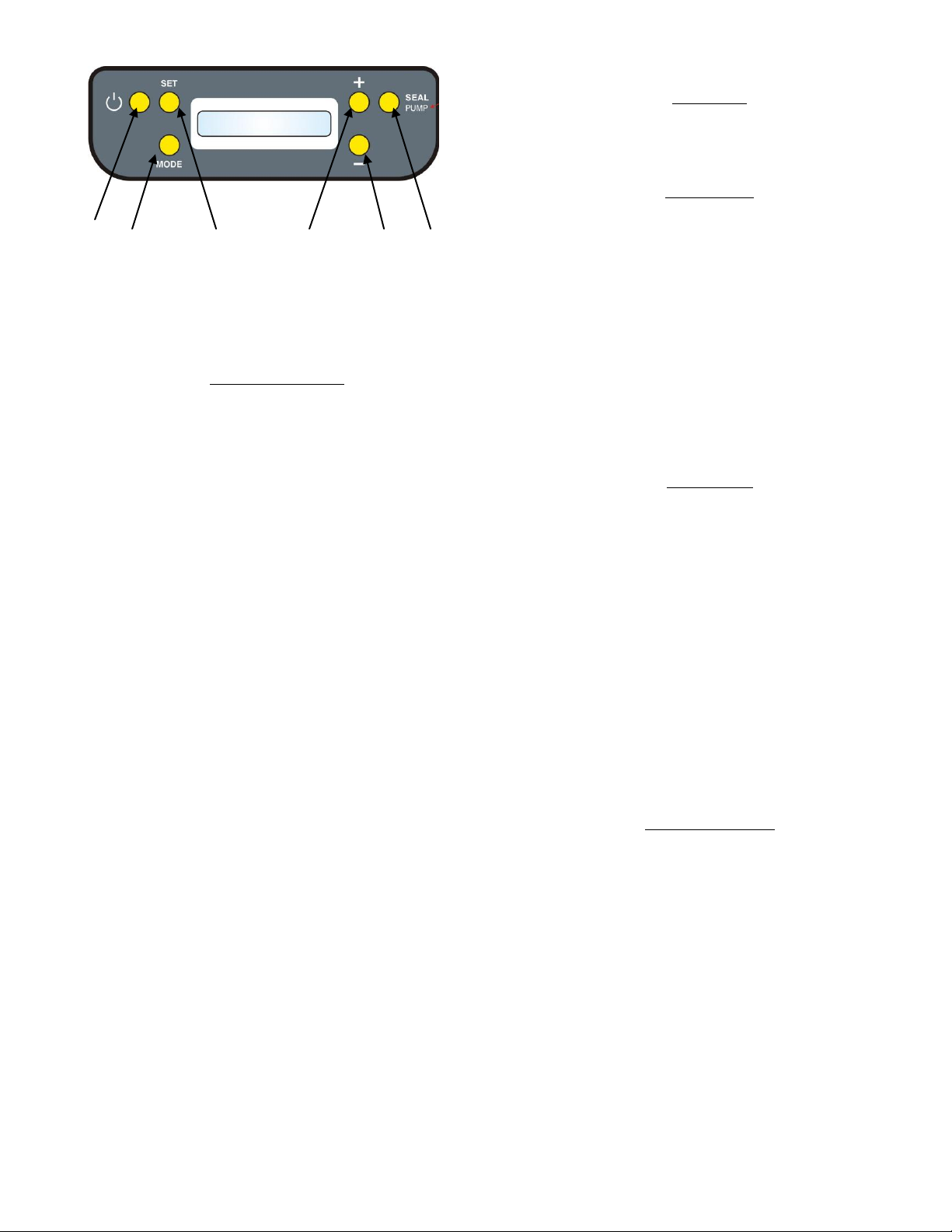

To view the chosen language, press the 'SET key" (3)

for 2 sec., or wait for a few seconds (the machine will

automatically set the language).

OPERATING MODES

VACUUM PACKAGING WITH AUTOMATIC CYCLE

With the machine on, press the "MODE key" (2)

repeatedly until the wording “automatic cycle” is

shown. You are now in the automatic cycle operating

mode.

Insert the product to be packaged into the bag.

Place the bag about 1 cm inside the lower part of the

decompression chamber - the chamber is delineated by

the gasket. Make sure that the bag content does not go

between the bag and the sealing bar.

Closing the lid, the suction pump will start

automatically; apply a slight pressure until it closes

onto the bag opening. The lid can be released after 2

secs.

The display will show the “vacuum level” from 0 to 8.

The optimum vacuum level is achieved when the

display shows the wording “vacuum level: 7”.

At the end of the vacuum process, the bag sealing

resistance turns on automatically. The display will show

the wording “sealing” and the numerical sealing value

set will decrease until 0. Then the pump will stop and

the lid will open automatically.

The machine is now ready to process another bag.

VACUUM PACKAGING WITH MANUAL CYCLE

This operating mode can be used to obtain a partial vacuum

in bags when the packaged food might be damaged by

over-compression of the bag (e.g. soft, salad vegetables,

soft bread or cheese).

Switch on the machine, press the "MODE key" (2)

repeatedly until the wording “manual cycle” is shown.

You are now in the operating mode with manual cycle.

Insert the product to be packaged in the bag.

Place the bag about 1cm within the lower

decompression chamber area - the chamber is

delineated by the rubber gasket. Make sure that the

the part to be sealed is free from food or any

substance or product.

On closing the lid, the suction pump will start

automatically; press gently and wait for it to close onto

the bag opening, then realease it.

The display will start to scan the “vacuum level

starting” from 0 to a maximum of 8. Choose the

vacuum level required.

The air suction will stop when the operator presses the

“SEAL PUMP” key (6) to start sealing the bag.

Pressing the “SEAL/PUMP” key (6) the wording

“sealing” will appear on the display and the sealing

value chosen will decrease gradually to zero.

NOTE: the sealing operation interrupts immediately the

suction of air from the bag, though the suction pump

continues to work.

Depending on the operator’s promptness in pressing the

“SEAL PUMP” key (6) it is possible to avoid creating a total

vacuum in the bag, leaving a minimum quantity of air, for

example to prevent compressing or distorting the food.

Please, however, be reminded that the food is preserved

longer with the highest level of vacuum which occurs when

the display shows the wording “vacuum level: 7”.

The pump will stop and the lid will open automatically at

the end of the sealing process.

The machine is now ready to process another bag.

VACUUM PACKAGING WITH VACUUM ONL Y CYCLE

This operating mode can be used to create vacuum in

containers (provided by the manufacturer and described in

the optional accessories section for packaging liquid food or

products with a high liquid content.

With the machine on, press the "MODE key" (3)

repeatedly until the wording "vacuum only" is shown.

You are now in the operating mode with vacuum only

cycle.

Connect the vacuum tube to the suction fitting in the

lower chamber.

Place the food inside the container and close it with the

special container lid.

Rest the suction sensor in such a way as to close the

tub on the lid, making sure that the rubber ball is

inside the special tub on the lid itself.

Start suction with the "SEAL PUMP key" (6), without

closing the mobile lid.

The display will start to scan the "vacuum level” from 0

to 8.

The machine stops when the vacuum has been

created. At this point it is possible to remove the

sensor from the lid on the jar. It's a good rule to

slightly press the rubber ball with your fingers.

The optimum vacuum level is achieved when the

display shows the wording "vacuum level: 7".

The machine is now ready to process another bag or

jar.

This operating mode does not activate the sealing bar

(which does not need to work) to avoid that the user gets

burned accidentally touching the open the mobile lid.

To open a jar in which a vacuum has been created by this

system, merely push slightly with your finger the ball in the

lid. This will allow air back into the jar and you will be able

to remove the lid.

IMPORTANT

Always use bags proportionate with the product to be

vacuum packed, otherwise (e.g.: if a very large bag is used

for only a little product), the device will take longer to

complete the cycle.

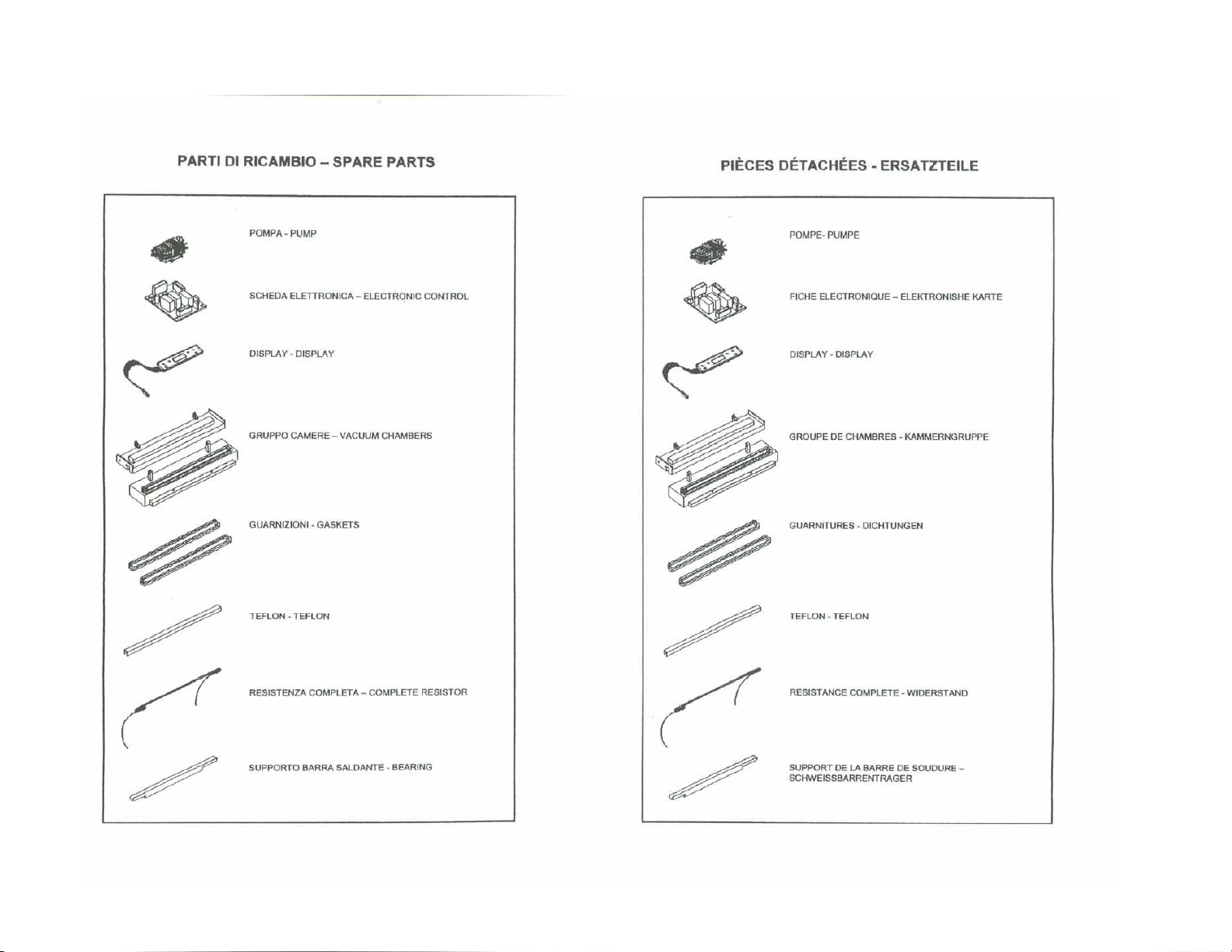

Therefore, after you have finished the sample bags

provided with the machine, select the most suitable bag

size for your packing needs from the attached list and order

the bags from the BESSER VACUUM retailers.

SEALING BAR TEMPERATURE SETTING

Sealing bar temperature adjustment takes place by

controlling the time the sealing bar stays on: the higher the

time the more the temperature increases, the lower the

time the more the temperature decreases.

Setting takes place using the "SET key" (3) as follows:

Press the "SET key" (3) for two seconds to view the

wording "temperature" on the display and the current

machine setting.

Press the "increase multifunction key (+)" (4) to

increase the sealing temperature (time), press the

decrease multifunction key (-)" (5) to decrease the

sealing temperature (time).