Page 7

1. In case of troubles consult with your salesman or call authorized service organized established distributor.

2. The warranty period amounts 12 month by use according to the regulations. The beginning of the warranty period is the date

of the rst purchase according to the original invoice or the original sales receipt. gemäß der Original-Rechnung bzw. dem Ori-

ginal-Kaufbeleg. Replacement deliveries or resale don‘t cause an extension of the warranty period.

3. Defects of the device which are due to mistakes in the manufacturing or the material, are removed within the warranty peri-

odfree of charge either by repair or replacement of the concerning parts. The Franz Janschitz Ges.m.b.H. decides at its own

judgement on the measure to the removal of the defect. The necessary expenditures for this purpose, like transport costs,

working costs or spare part costs are in a warranty case supported by the Franz Janschitz Ges.m.b.H. - the concerning pro-

duct rst has to be sent in, to proof if it is a case of warranty.

4. Not included in warranty are defects or disturbances, which are caused by:

• Damages by accident, abusive or improprer operation/assembly/installation/exposures, especially with disregard of the opera-

tion manual, the instructions for use, the instructions for installation or the safety instructions.

• Damages due to transport, carelessness, force majeure, inuence of weather, other natural phenomenons or the environment

of operation.

• Damages by the application of parts, which are not manufactured or expelled from Franz Janschitz Ges.m.b.H. or authorised

representatives of the Franz Janschitz Ges.m.b.H., as well as damages by the application of accessories which are not appro-

ved by the Franz Janschitz Ges.m.b.H.

• Damages due to service features/interventions/changes/modications, which are not made by the Franz Janschitz Ges.m.b.H.

or authorised representatives of the Franz Janschitz Ges.m.b.H.

• Damages due to normal wear and usual abrasion

• Damages due to disregard of the maintenance and cleaning operation according to the operation manual

5. The warranty also doesn‘t include:

• Device, destroyed by water or milk inow

6. Demands for the claim:

• The customer has to contact the Franz Janschitz Ges.m.b.H. within the warranty period

• The customer has to verify the beginning of the warranty period (date of purchase) by presentation of the original invoice or the

original sales receipt or a copy from it

• The customer has to provide a clearly description of the errors and also has to fulll the analysis of errors according to the

instructions

• The customer must send in the product completely and as delivered

• The customer has to ensure that the product is packed for the transport appropriately

7. Other rights, that are not mentioned in upper obligations of the manufacturer, especially responsibility for personal injury, are

excluded.

GARANTIE

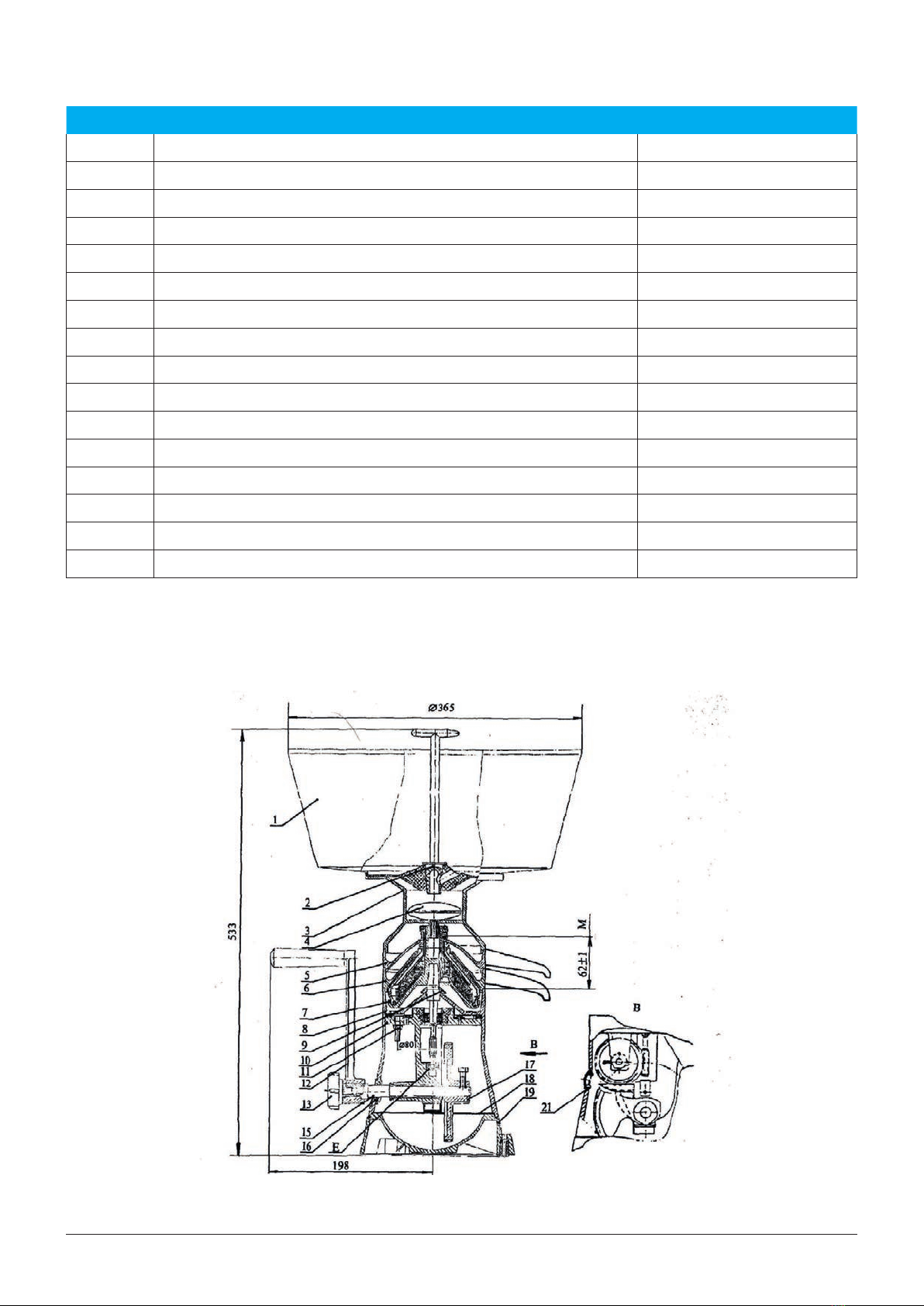

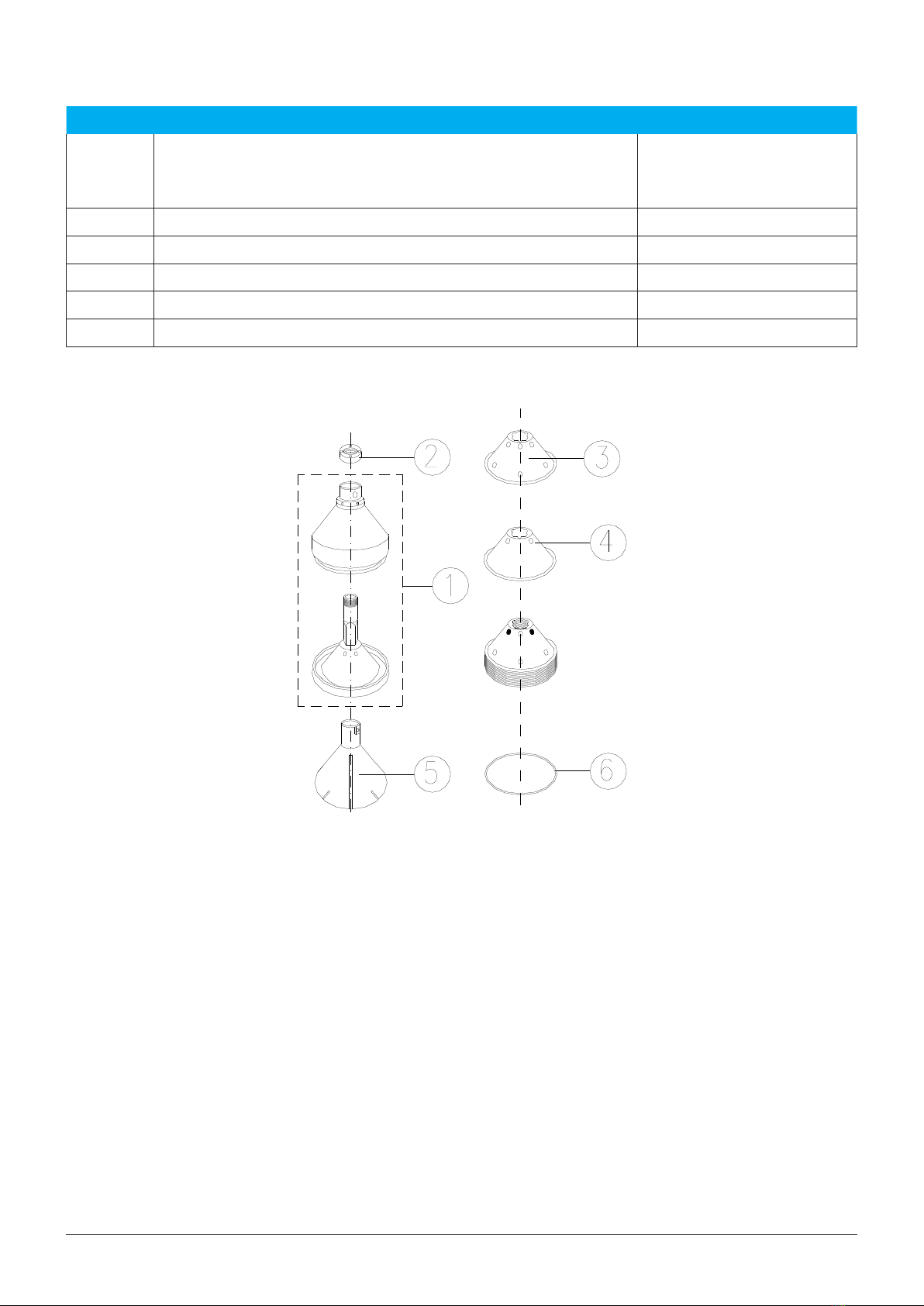

Fast and reliable shipment of spare parts is possible only if their description is clear enough. At the time of ordering please state

clearly:

• Type of cream separator.

• Serial number printed on label plate at the rare side of device.

• Part name and code number of wished spare part (data on the list of spare parts).

SPARE PARTS ORDERING