3

Table of contents

Preface............................................................................................................................................................2

Use of this manual ...................................................................................................................................................2

Icons in this manual .................................................................................................................................................2

Service and technical support..................................................................................................................................2

1Lists of components and general information ...........................................................................................5

1.1 Lists of components .....................................................................................................................................5

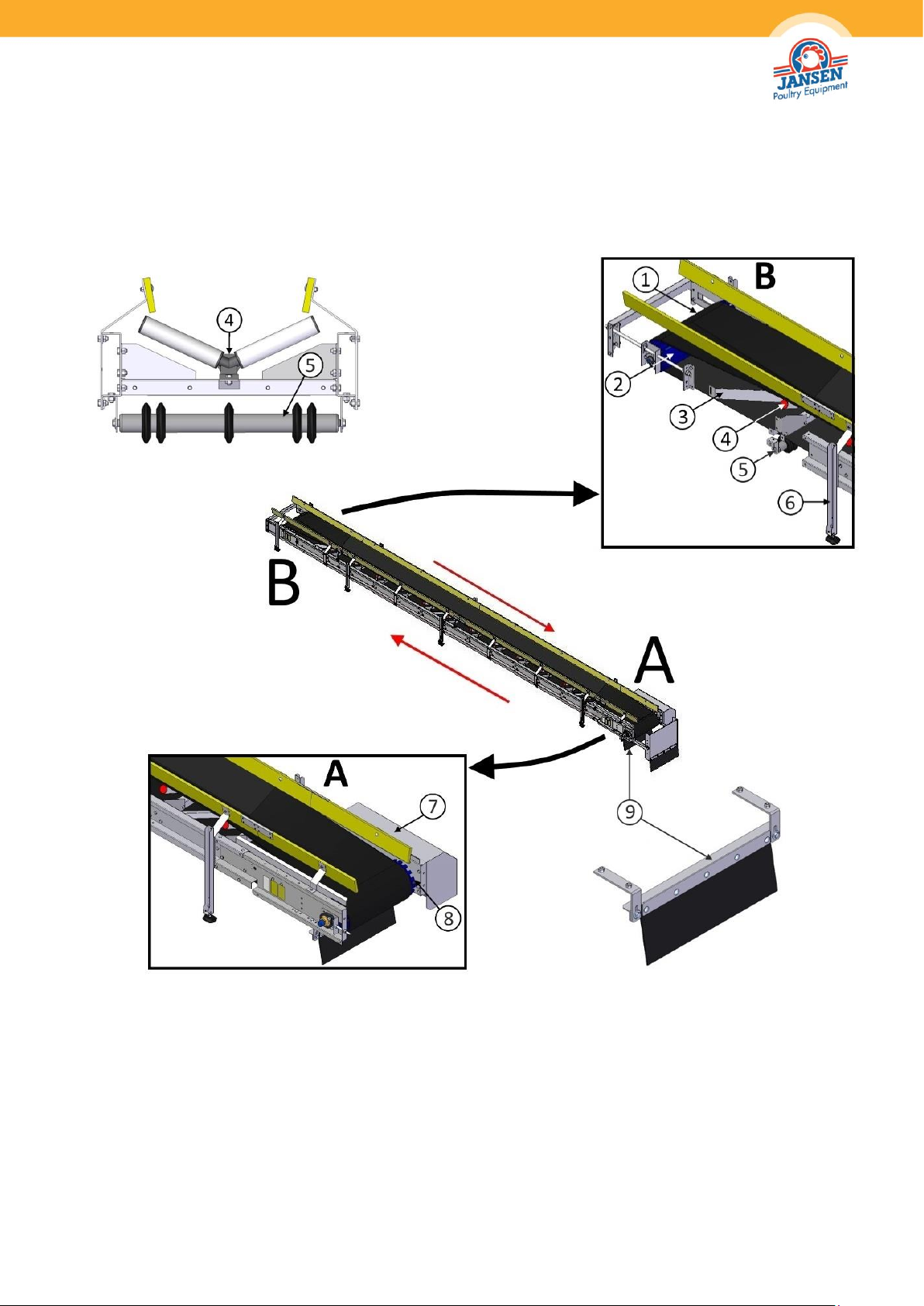

1.1.1 Horizontal manure removal belt ..........................................................................................................5

1.1.2 Horizontal manure removal belt with knee joint .................................................................................6

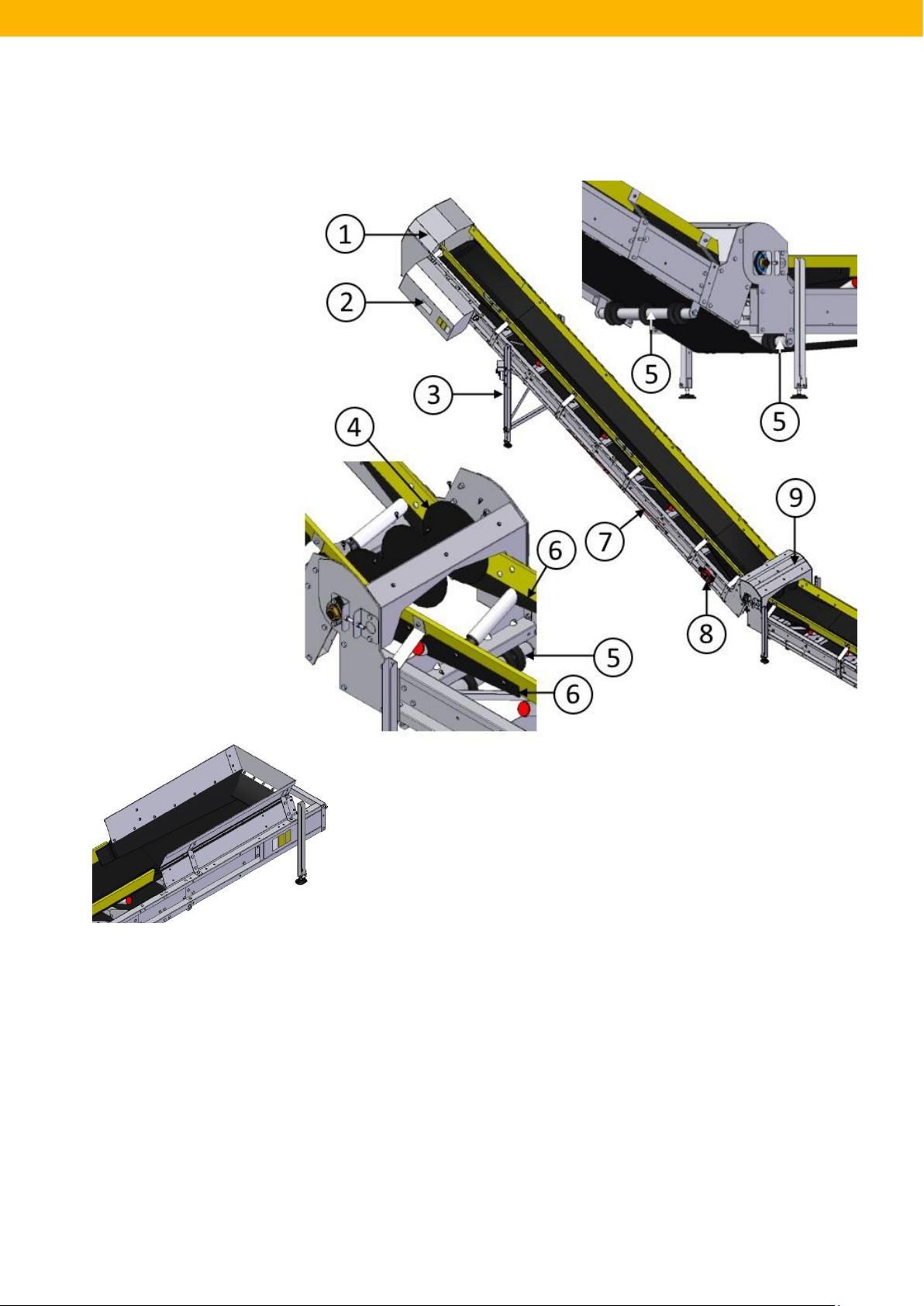

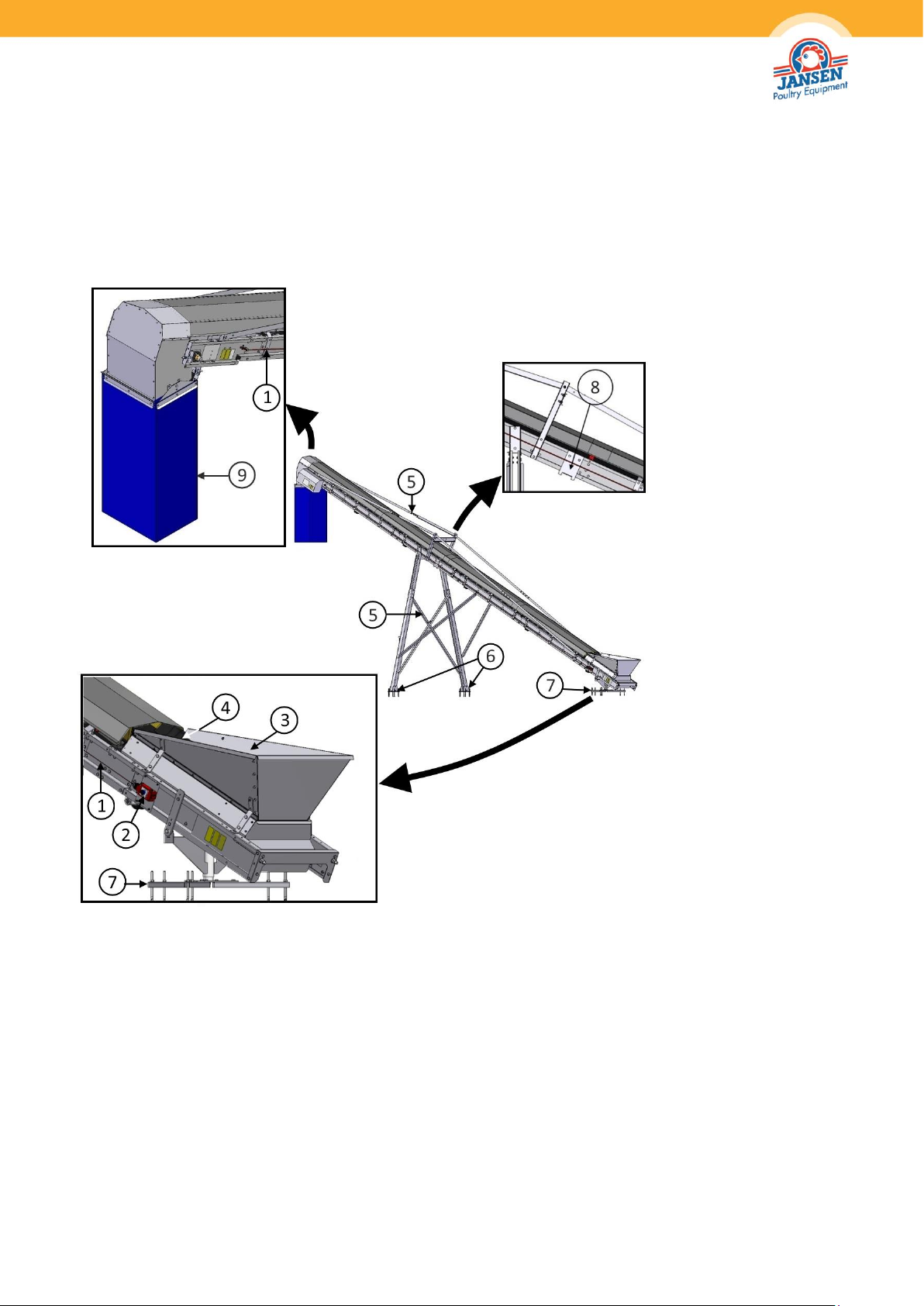

1.1.3 Manure elevating belt..........................................................................................................................7

1.2 List of article numbers..................................................................................................................................8

1.3 Middle sections per length of manure removable belt .............................................................................10

1.4 Installation order........................................................................................................................................11

1.5 Required tools for installation ...................................................................................................................11

2Mounting the frame............................................................................................................................... 12

2.1 Connecting the middle sections.................................................................................................................12

2.2 Connecting the knee joint (belt with knee joint)........................................................................................14

2.2.1 Upwards knee joint ............................................................................................................................14

2.2.2 Downwards knee joint........................................................................................................................15

2.3 Connecting the drive unit...........................................................................................................................16

2.4 Placing the legs of the horizontal parts (horizontal belt and belt with knee joint)....................................17

2.4.1 Fixed leg (horizontal belt and belt with knee joint)............................................................................17

2.4.2 OPTION instead of leg: wheel set (horizontal belt) ............................................................................18

2.5 Coupling the return unit.............................................................................................................................19

2.6 Placing the transport belt...........................................................................................................................20

2.7 Mounting the supporting rollers and tensioning the transport belt .........................................................22

2.8 Mounting the leg under the elevating part (belt with knee joint) .............................................................23

2.8.1 Fixed leg .............................................................................................................................................23

2.8.2 OPTION instead of leg: suspension ....................................................................................................24

2.9 Mounting the return unit support .............................................................................................................24

2.9.1 Mounting the swivel base (rotatable elevating belt) .........................................................................24

2.9.2 Mounting the wheel set (movable elevating belt) .............................................................................25

3Mounting the manure guiding parts .......................................................................................................26

3.1 Placing the funnel.......................................................................................................................................26

3.2 Mounting the side planks...........................................................................................................................27

3.2.1 Side planks in case of a funnel............................................................................................................27

3.2.2 Side planks in case there is no funnel.................................................................................................28

3.2.3 Side planks in case of a knee joint (belt with knee joint)....................................................................29

4Mounting the electrical parts .................................................................................................................31

4.1 Placing the motor.......................................................................................................................................31

4.2 Mounting the isolating switch....................................................................................................................32

4.3 If applicable: mounting the safety set........................................................................................................33

5Options.................................................................................................................................................. 35

5.1 Wall support or suspension (horizontal belt).............................................................................................35

5.1.1 Wall support (horizontal belt) ............................................................................................................35

5.1.2 Suspension in manure storage (elevating belt)..................................................................................36

5.1.3 Additional suspension point from wooden or steel purlins ................................................................36

5.1.4 Suspension in case of intermediate floor (horizontal belt).................................................................37

5.2 Overflow cap (elevating belt and belt with knee joint) .............................................................................37

5.3 Covers and water drainage strip................................................................................................................38