4

EN

1.0 SAFETY PRECAUTIONS

1.1 THIS EQUIPMENT MUST ALWAYS BE OPERATED BY A QUALIFIED TECHNICIAN WHO

IS FAMILIAR WITH REFRIGERANT SYSTEMS, REFRIGERANTS, REFRIGERANT SAFETY AND

LOCAL REQUIREMENTS.

1.2 READ THIS MANUAL and become familiar with the specications and operation of this machine

prior to use.

1.3 WEAR APPROPRIATE SAFETY PROTECTION APPAREL such as gloves, eye protection and

foot protection when working on refrigeration systems.

1.4 REFRIGERANT VAPOUR CAN BE HAZARDOUS AND ITS BYPRODUCTS CAN BE LETHAL

- work only in well ventilated areas. When working indoors, ensure there is adequate airow in the

workspace and install a separate circulation fan if necessary. DO NOT WORK IN AN ENCLOSED

AREA without special safety equipment as appropriate for the conditions.

1.5 KNOW THE PROPER SAFETY AND HANDLING REQUIREMENTS for the refrigerant being

recovered by reviewing the Material Safety Data Sheets (MSDS) and the temperature - vapour

pressure information.

1.6 PERFORM LEAK DETECTION in accordance with recommended practice only. For best results

use only a refrigerant detector such as the JAVAC D-TEK or TEK- Mate. NEVER USE OXYGEN for

this process as it can become an explosive mixture in the presence of oil and pressure.

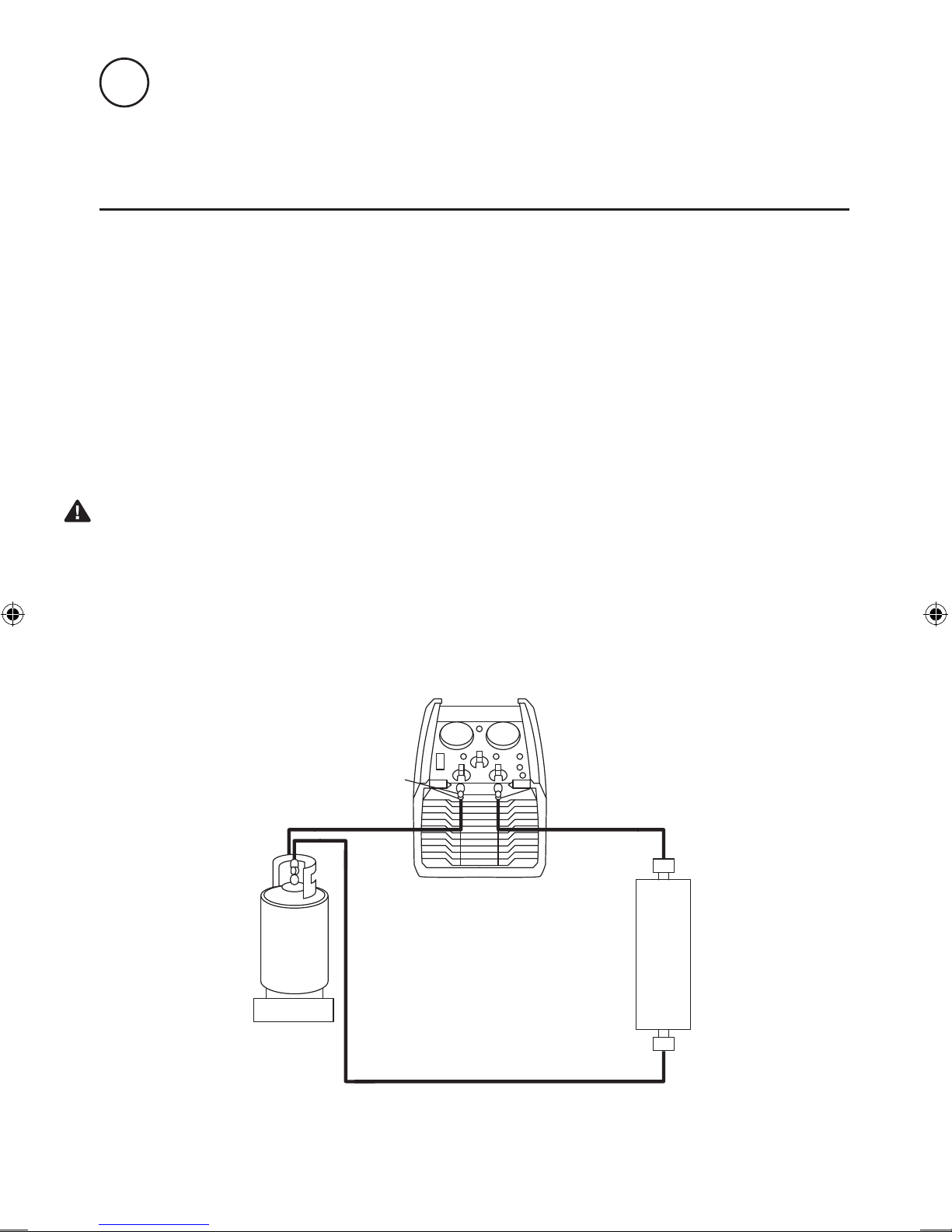

1.7 NEVER OVERFILL A STORAGE CONTAINER. The use of a refrigerant scale, such as the

JAVAC Pro-Charge, is required to prevent overll. OVERFILLED CYLINDERS CAN RUPTURE

EXPLOSIVELY!

1.8 STORE REFRIGERANTS in a cool, dry place.

1.9 SEPARATE DIFFERENT REFRIGERANTS. Avoid mixing refrigerants by using sepa-rate storage

cylinders and lters for each type recovered.

1.10 OPEN SERVICE OR CYLINDER VALVES SLOWLY to ensure that all connections are tight and

there is no danger.

1.11 DISCONNECT POWER before moving or servicing the recovery unit. CAUTION - these units

should be opened only by a technically qualied person who has been trained in basic electronics

and refrigeration. The risk of ELECTRIC SHOCK and exposure to HOT compressor parts is possible

if the unit is opened.

1.12 WARNING - TO REDUCE THE RISK OF FIRE, EXTENSION CORDS SHOULD NOT BE USED

with this equipment as the wiring can overheat under conditions of high current draw. If an extension

cord is absolutely necessary, its length should be as short as possible and it should contain size 16

AWG (1.291 mm) or larger wiring.

XTRULTRA-2 A5 safety-operation-manual.indd 4 01/02/2018 15:42