2.2 FEATURES:

2.2.1 Designed with the highest quality components and manufactured in an ISO-9001

Registered facility.

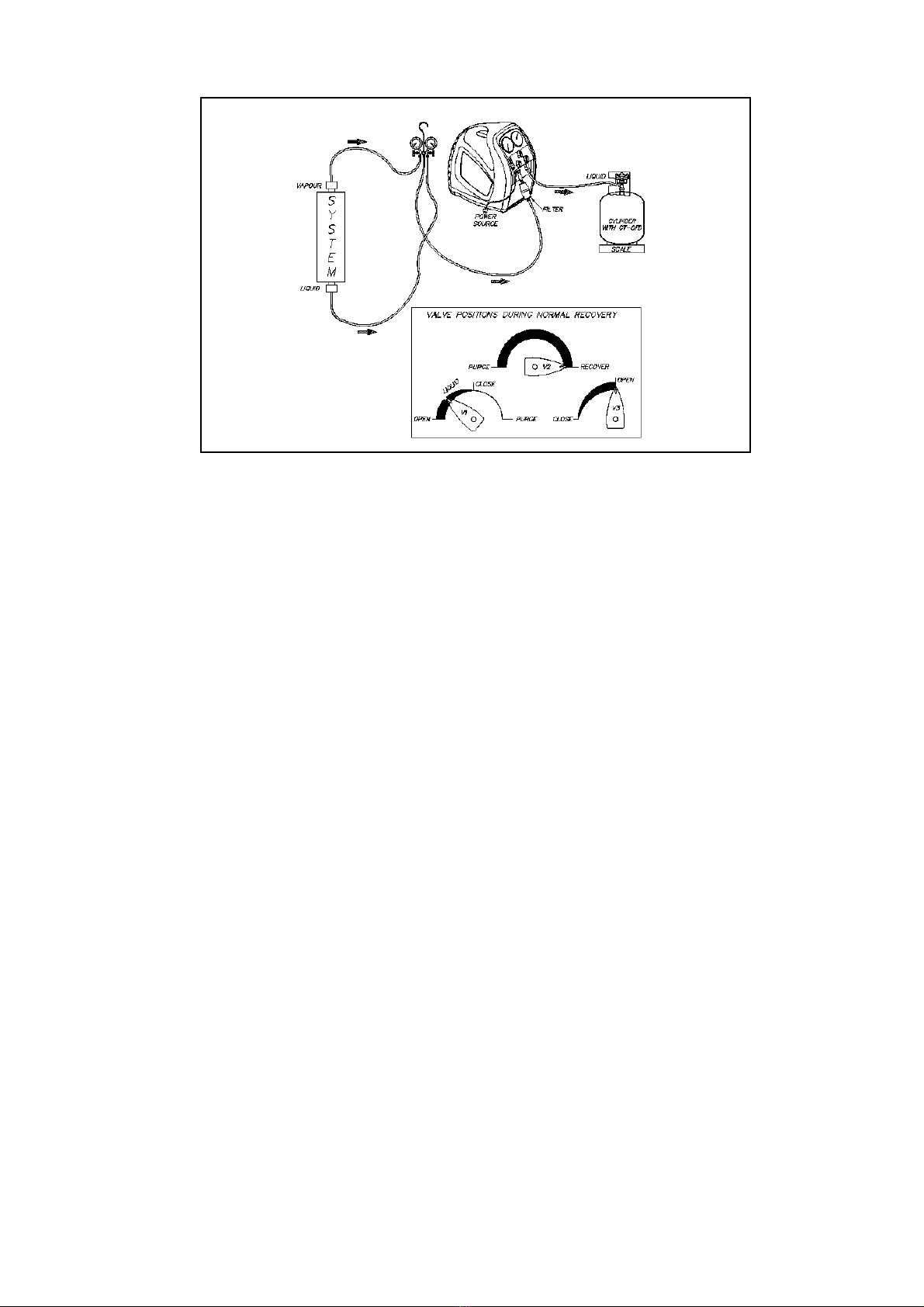

2.2.2 Factory fitted with an inlet particle filter, which traps contaminants. This filter is easy to

remove, clean or replace in the event of restricted flow.

2.2.3 Inlet (Suction) and Discharge pressure gauges allow the process to be monitored from

start to finish.

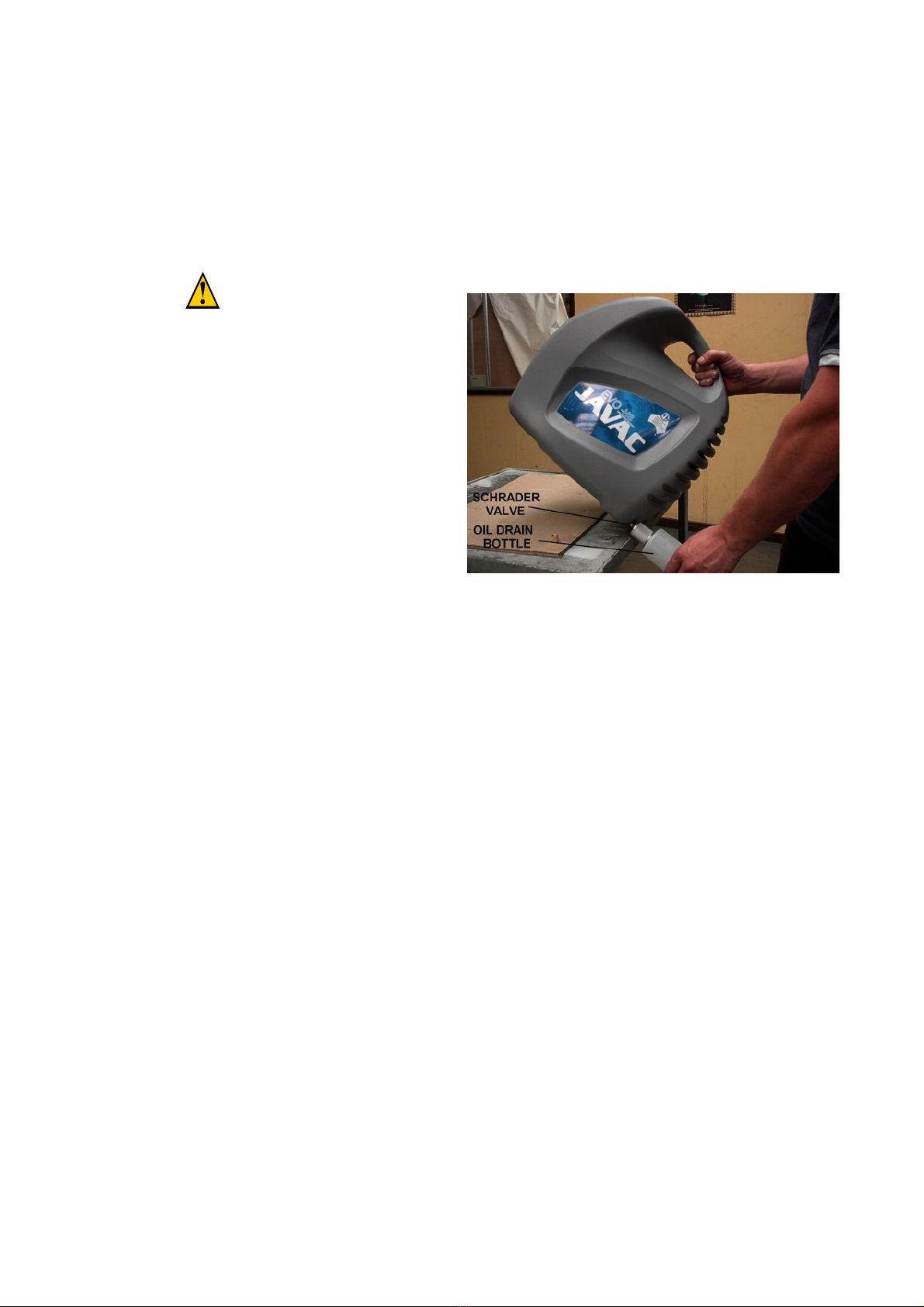

2.2.4 The unit’s lightweight and excellent balance makes it easy to transport to the job site

and into difficult locations. The handle is easy to grasp and the unit is exceptionally

well balanced.

2.2.5 The PURGE operation can be accomplished without changing hoses.

2.2.6 The high impact moulded case resists damage and is designed to protect the gauges,

valve knobs and hose connection ports from incidental damage caused during

operation, handling and storage.

2.3 WARRANTY:

2.3.1 Javac warrants your EVO-OS Refrigerant Recovery Machine to be free from defects of

materials or workmanship for two years from the date of purchase. Javac does not

warrant any machine that has been subjected to misuse, negligence, or accident, or has

been repaired or altered by anyone other than Javac. The EVO-OS is designed and

manufactured as a general recovery machine for intermittent operation. For instances

in commercial applications involving high duty cycles or continuous running the EVO-

OS is warranted for a period of 3 months from the date of purchase.

2.3.2 The manufacturer warrants the Compressor for a period of one year. To keep this

WARRANTY in force it is required that the standard filter and a filter drier be used on

the Inlet Port or Hose at all times to prevent particulates from entering the compressor.

FAILURE TO USE A FILTER WILL VOID THE COMPRESSOR WARRANTY.

2.3.3 Javac’s liability is limited to machines returned to Javac, return transportation prepaid,

not later than thirty (30) days after the warranty period expires, and which Javac

judges to have malfunctioned because of defective materials or workmanship. Javac’s

liability is limited to, at its option, repairing or replacing the defective machine or part.

2.3.4 This WARRANTY is in lieu of all other warranties, express or implied, whether of

MERCHANTABILITY or of FITNESS FOR A PARTICULAR PURPOSE or

otherwise. All such other warranties are expressly disclaimed.

2.3.5 Javac shall have no liability in excess of the price paid to Javac for the machine plus

return transportation charges prepaid. Javac shall have no liability for any incidental

or consequential damages. All such liabilities are EXCLUDED.