9

JBL Professional

VP SERIES SYSTEMS SPECIFICATIONS

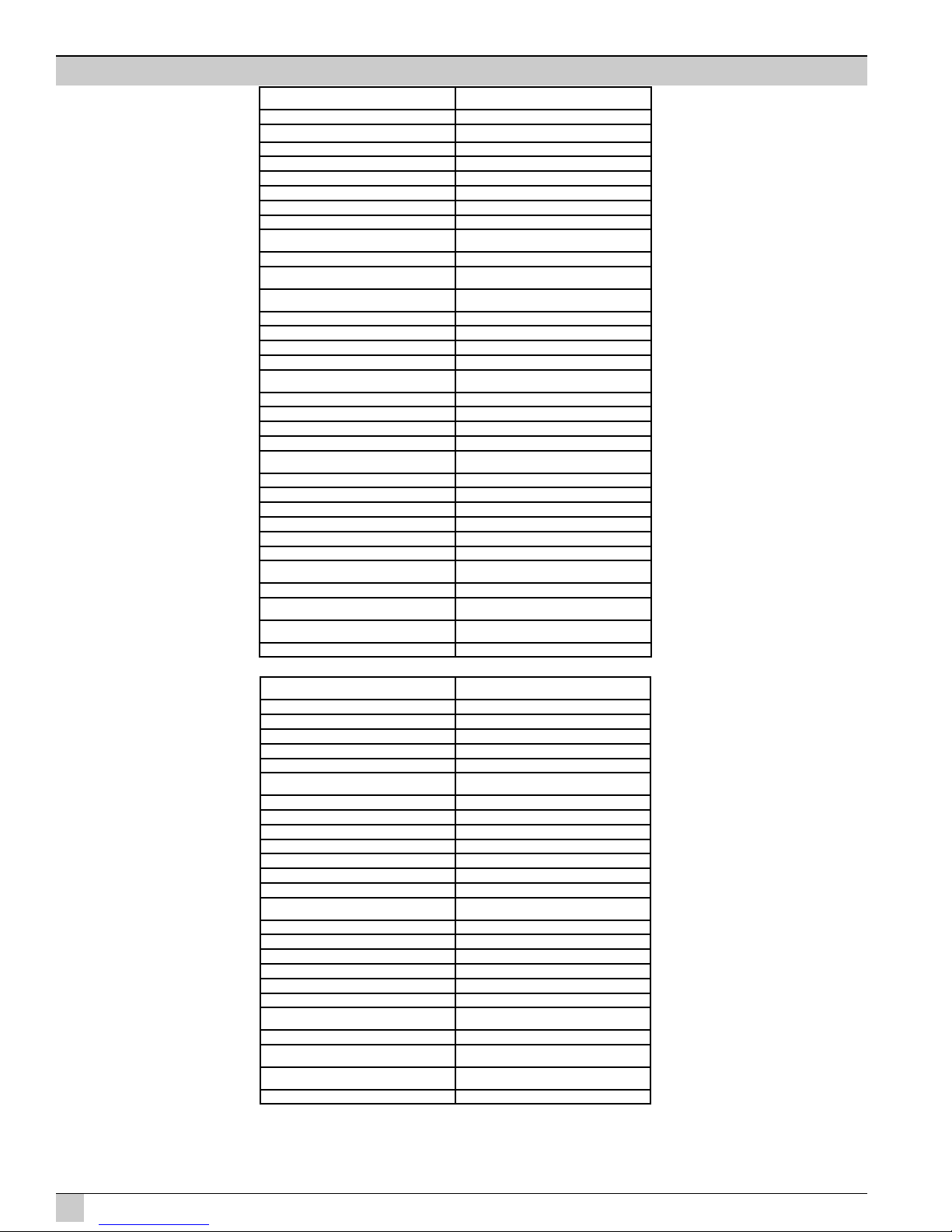

VP7215/64DP

Specifications:

Frequency Response (+/-3dB): 60 Hz - 18 kHz

Frequency Range (-10dB): 45 Hz - 20 kHz

Coverage Pattern: 60° x 40° rotatable waveguide

Directivity Factor (Q): 15.8

Directivity Index (DI): 12 dB

Max Peak Output: 137 dB SPL 1m

Transducer Section:

Low Frequency Section: JBL 2265G, 381 mm (15 in) dia., 76 mm (3 in) Dual

Coil neodymium Differential Drive®, Direct Cooled

Bandpass Nominal Impedance: 4 ohms

High Frequency: JBL2452H-SL, 100 mm (4 in) titanium damped

diaphragm, 1.5 in. exit.

Bandpass Nominal Impedance: 8 ohms

System:

DP2 Internal Amplification Output (at nominal load): 2200 Watts Peak (1100 Watts Continuous)

DP2 Output (Continuous IEC shaped pink noise

into rated load impedance):

750LF/350HF Watts

DP2 Output Section: 2-Channel, Class I

Audio Input Connector: XLR with loop-through

Network Control Connector: Ethernet, RJ45 (DPAN, DPCN options)

Signal Processing: DSP based, resident in Input Module.

System Management: DSP based limiters for mechanical and thermal

protection

AC Power Operating Range: Auto Select 90-132VAC/216-264VAC, 50/60 Hz

AC Line Voltage: 50/60 Hz, Auto-Detect; 120V/240V (-15%, +10%)

AC Input Connector: Neutrik PowerCon

AC Loop-Thru: Neutrik PowerCon

AC Current Requirement: 6A per system at 120V, 3A per system at 240V

Enclosure:

Box Construction: 5/8 in. multi-ply exterior grade Baltic birch.

Internally braced. Black DuraFlex™ finish.

Suspension System: 6 standard air-cargo 3 in. track and 14 M10 fittings.

Grille: 14 Gauge Black, powder-coated perforated steel

with foam backing.

Dimensions (H x W x D): 765.3 x 447.6 x 523.5 mm

30.13 x 17.62 x 20.61 in.

Net Weight: 38.6 kg (85 lb)

VP7215/95DP

Specifications:

Frequency Response (+/-3dB): 60 Hz - 18 kHz

Frequency Range (-10dB): 45 Hz - 20 kHz

Coverage Pattern: 90° x 50° rotatable waveguide

Directivity Factor (Q): 12.6

Directivity Index (DI): 11 dB

Max Peak Output: 137 dB SPL 1m

Transducer Section:

Low Frequency Section: JBL 2265G, 381 mm (15 in) dia., 76 mm (3 in) Dual

Coil neodymium Differential Drive®, Direct Cooled

Bandpass Nominal Impedance: 4 ohms

High Frequency: JBL2452H-SL, 100 mm (4 in) titanium damped

diaphragm, 1.5 in. exit.

Bandpass Nominal Impedance: 8 ohms

System:

DP2 Internal Amplification Output (at nominal load): 2200 Watts Peak (1100 Watts Continuous)

DP2 Output (Continuous IEC shaped pink noise

into rated load impedance):

750LF/350HF Watts

DP2 Output Section: 2-Channel, Class I

Audio Input Connector: XLR with loop-through

Network Control Connector: Ethernet, RJ45 (DPAN, DPCN options)

Signal Processing: DSP based, resident in Input Module.

System Management: DSP based limiters for mechanical and thermal

protection

AC Power Operating Range: Auto Select 90-132VAC/216-264VAC, 50/60 Hz

AC Line Voltage: 50/60 Hz, Auto-Detect; 120V/240V (-15%, +10%)

AC Input Connector: Neutrik PowerCon

AC Loop-Thru: Neutrik PowerCon

AC Current Requirement: 6A per system at 120V, 3A per system at 240V

Enclosure:

Box Construction: 5/8 in. multi-ply exterior grade Baltic birch.

Internally braced. Black DuraFlex™ finish

Suspension System: 6 standard air-cargo 3 in. track and 14 M10 fittings

Grille: 14 Gauge Black, powder-coated perforated steel

with foam backing.

Dimensions (H x W x D): 765.3 x 447.6 x 523.5 mm

30.13 x 17.62 x 20.61 in.

Net Weight: 38.6 kg (85 lb)

VP7212/64DP

Specifications:

Frequency Response (+/-3dB): 63 Hz - 18 kHz

Frequency Range (-10dB): 47 Hz - 20 kHz

Coverage Pattern: 60° x 40° rotatable waveguide

Directivity Factor (Q): 15.8

Directivity Index (DI): 12 dB

Max Peak Output: 136 dB SPL 1m

Transducer Section:

Low Frequency Section: JBL 2262G, 304 mm (12 in) dia., 76 mm (3 in) Dual

Coil neodymium Differential Drive®, Direct Cooled

Bandpass Nominal Impedance: 4 ohms

High Frequency: JBL2452H-SL, 100 mm (4 in) titanium damped

diaphragm, 1.5 in. exit.

Bandpass Nominal Impedance: 8 ohms

System:

DP2 Internal Amplification Output (at nominal load): 2200 Watts Peak (1100 Watts Continuous)

DP2 Output (Continuous IEC shaped pink noise

into rated load impedance):

750LF/350HF Watts

DP2 Output Section: 2-Channel, Class I

Audio Input Connector: XLR with loop-through

Network Control Connector: Ethernet, RJ45 (DPAN, DPCN options)

Signal Processing: DSP based, resident in Input Module.

System Management: DSP based limiters for mechanical and thermal

protection

AC Power Operating Range: Auto Select 90-132VAC/216-264VAC, 50/60

AC Line Voltage: 50/60 Hz, Auto-Detect; 120V/240V (-15%, +10%)

AC Input Connector: Neutrik PowerCon

AC Loop-Thru: Neutrik PowerCon

AC Current Requirement: 6A per system at 120V, 3A per system at 240V

Enclosure:

Box Construction: 5/8 in. multi-ply exterior grade Baltic birch. Inter-

nally braced. Black DuraFlex™ finish

Suspension System: 6 standard air-cargo 3 in. track and 14 M10 fittings.

Grille: 14 Gauge Black, powder-coated perforated steel

with foam backing.

Dimensions (H x W x D): 701.8 x 383.8 x 523.5 mm

27.63 x 15.11 x 20.61 in.

Net Weight: 35.4 kg (78 lb)

VP7212/95DP

Specifications:

Frequency Response (+/-3dB): 63 Hz - 18 kHz

Frequency Range (-10dB): 47 Hz - 20 kHz

Coverage Pattern: 90° x 50° rotatable waveguide

Directivity Factor (Q): 12.6

Directivity Index (DI): 11 dB

Max Peak Output: 136 dB SPL 1m

Transducer Section:

Low Frequency Section: JBL 2262G, 304 mm (12 in) dia., 76 mm (3 in) Dual

Coil neodymium Differential Drive®, Direct Cooled

Bandpass Nominal Impedance: 4 ohms

High Frequency: JBL2452H-SL, 100 mm (4 in) titanium damped

diaphragm, 1.5 in. exit.

Bandpass Nominal Impedance: 8 ohms

System:

DP2 Internal Amplification Output (at nominal load): 2200 Watts Peak (1100 Watts Continuous)

DP2 Output (Continuous IEC shaped pink noise

into rated load impedance):

750LF/350HF Watts

DP2 Output Section: 2-Channel, Class I

Audio Input Connector: XLR with loop-through

Network Control Connector: Ethernet, RJ45 (DPAN, DPCN options)

Signal Processing: DSP based, resident in Input Module.

System Management: DSP based limiters for mechanical and thermal

protection

AC Power Operating Range: Auto Select 90-132VAC/216-264VAC, 50/60

AC Line Voltage: 50/60 Hz, Auto-Detect; 120V/240V (-15%, +10%)

AC Input Connector: Neutrik PowerCon

AC Loop-Thru: Neutrik PowerCon

AC Current Requirement: 6A per system at 120V, 3A per system at 240V

Enclosure:

Box Construction: 5/8 in. multi-ply exterior grade Baltic birch.

Internally braced. Black DuraFlex™ finish

Suspension System: 6 standard air-cargo 3 in. track and 14 M10 fittings.

Grille: 14 Gauge Black, powder-coated perforated steel

with foam backing.

Dimensions (H x W x D): 701.8 x 383.8 x 523.5 mm

27.63 x 15.11 x 20.61 in.

Net Weight: 35.4 kg (78 lb)