oport

bracket

is

secured

with

a

clamptothefront-to-rearbrace

;he

4350enclosure.Removalisaccomplishedby

unbolting

jclamp

from

theenclosurebrace,takingoutthefour

screws

'•ng

through

thebafflepaneltothehornflange,

and

lifting

^.ver/horn/bracketassembly

from

theenclosureThehorn

dbracketcanthenbeunbolted

from

thecompression

ver

Caution

To

avoidthepossibilityofpersonalinjury,besure

oroperiysupportthednver/horn/bracketassemblywhile

novingthe

mounting

screws

holdingthehorntothebaffle

iei.

sincetheassemblyweighsapproximatelyl3HKg[30lb)

*oconvertthe4350toright-handconfiguration,toehigh

quercydnve'/horn/bracketassembly

wilt

havetobe

archanged

with

itscorrespondingcoverplateonthe

right

of

bafflepanel.(The2405ultra-highfrequencydriverw:lialso

/e

tobeinterchanged

with

itsrespectivecoverplate,as

scribed

inthe

following

paragraphs)Thecoverplateis

;uredbehindthebaffle

panel

byfourmachine

screws

threaded

•>

T-nuts.

The

supportbracketmustbe

taken

offthednver/horn

;embly.rotatedt80°andreattachedtotherearflangeofthe

musingtheoriginalhardware(lockwasnersareusedunder

heads

oltnetwoooltsthatsecurethe©racket}Theentire

;emoiycanthenbeinsta'ieconthebaffiepanelandthe

jport

bracketclamp

bolted

totheinternalbraceonthe

right

e

ofthe

enclosure.

Finally,installthecoverplatebehindthe

•ncutoutonthe

left

sideofthebafflepaneiusingthe

screws

theiditinitsoriginallocation.

"-High

Frequency-The

2405ultra-highfrequencydriveris

,d

through

thebafflepanel

from

insidetheenclosureand

leldinplacebyfourmachine

screws.

To

achieve

tnedesired

persionpatternthe

unit

mustbepositionedsothatthe

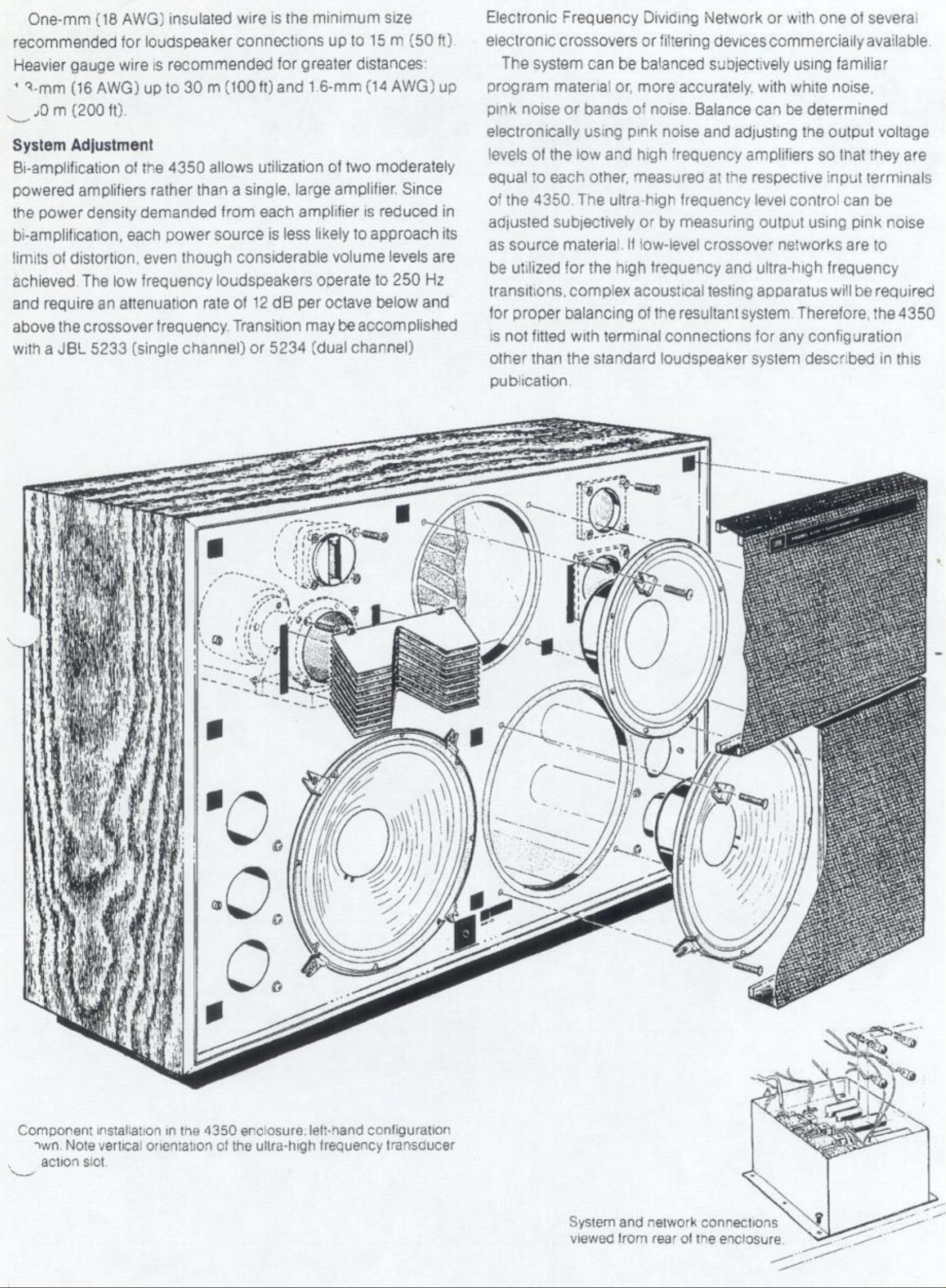

ractionslotisorientedvertically.

Vhen

movingthe2405totheright-handconfigurationthe

respondingcoverplateonthe

right

sideofthebaffiepanel

st

beremovedandreinstalledbehindtheopeningoriginally

:upiedbytheultra-nighfreauencydriverThecoverplateis

dmplace

with

tour

machine

screws

threadednto

T-nuts

The

ne

mounting

screws

aretobeusedtoinstallthecoverplate

the

left

sideofthebaffiepane!.

iding Network-Remove thetransducersaspreviously

icribed.

pull

theleadwires

from

themidrangesub-chamber

]

disconnectthe

input

leadstothedividingnetworkatthetab

inectorsattachedtothe

input

terminalsonthebackpanel,

detheenclosure.Theultra-highfrequencyieveicontrolis

untedona sub-panelsecuredtotnebackoftheenclosure

fiepanelby

two

machine

screws

extending

through

thepanel

)

threadedfasteners

To

gam

access

totnecontro

.

carefully

j|oftthe

serialized

foil

namepiate.removethe

mounting

ews

andplacetnecontrolassemblyonthe

bottom

ofthe

:losure.

Thenetworkitselfismountedonthe

bottom

pane;of

encosure

andisheldinplacebysixmachine

screws

and

Afterremovingthe

mounting

screws,

thenetworKano

molassemblycanoe

lifted

outoftheenclosure

through

er

ofthelowfreauencyloudspeakeropenings

e:

Malfunctionofthe

networK

ishighlyunlikely.

Since

the

namepiategenerallyisdestroyedirremoval,tt;snotrecom-

mendedthatthenetworkberemovedsimplyforthepurpose

ofinspection

Replacement-

Reverse

theremova:proceduretoreplacethe

system

components.

Mounting

screws

forall

devices

shouldbe

tightenedevenlyandiust

tight

enoughtopreventairleaks

AlthoughJBLloudspeakersareextremelyrugged,theconeandother

movingpartsaresubjecttoaccidentaldamage.

Exercise

extreme

cautionwhenever

using

a screwdriverorothertoolsIntheirimmediate

vicinity.Wheneverthehornisremovedfromthe

compression

driver,

themouthofthedriver

should

becoveredwith

plastic

tape.Anintense

magneticfieldexistsinthemoutholthedriver,andItisextremely

Importantthatforeignobjects

such

asIron

chips,

othermetallic

contaminants,

mountinghardwareortoolsbekeptfromthearea.

Maintenance

The

grilleclothisa double-knitpolyesterfabricselectedfor

acoustic

transparency,

beauty,physica'strength,color

fastness

andsod

resisiance

Itcanbecleanedbygentlydustingit

with

a

vacuum

cleanerStainscanberemovedbyusingaerosol

cieaners.

suchas

Texize

K2r Goddard'sDry

Clean,

or Pen

Champ

Quick

'n

Easy

accordingtoeacnmanufacturers

instructions.

Warning:Cleaningfluidsorother

solvents

should

notbe

used.

Although

theymayappeartoremovea stain,liquidcleanerswilldissolvethe

base

paintonthegrilleframebeneaththe

cloth,

resultinginpermanent

discoloration

ofthematerial.

Occasional

dusting

with

a

clean,

softclothwillmaintanthe

finishoftheenclosure

Since

both

thetexturedgrayandoiled

wainut

surfaces

aremoisture

resistant,

adamp

c<oth

willremove

moststains

Mild

detergentmaybeusedonthegrayfinishto

removesmudgesormorepersistent

stains.

Conventional

furniture

waxes

orpolishesshouldnotbe

used;

tneoiledwalnut

enclosure,

however,maybetreated

with

waxspecifically

formulatedforsuchsurfaces

The

walnutfinishmayappearto

age.

ordryoutastheoil

penetratesdeeperanddeeper

into

theveneeritmay,therefore

bedesirabletore-oiltheenclosuresurface

from

timetotime.

Witheachapplication,theoeautyofthefinishwillbecomemore

obvious,anda warm,richpatinawiileventualy beobtained

To

re-oila

JBL

oiledwalnutfinisnuseanyoneofme

severa

clear

oilfinishingpreparationsavailable

through

furnitureor

hardwareoutlets.Applya liberalamountoftheoreparationover

theentirefinishedsurfaceoftheenclosure.Intentofifteen

minuteswipeofftheremainingoil

with

a soft,

clean,

drycloth

Sma/

surface

scratches

can

usuallyberemovedbygently

rubbingthem

witn

veryfinesieelwool(4/0grade)ancapplying

oiltotheentirepanel

Very

deep

scratches,

dentsorotherserious

damageshouldoerepairedonlyoy

a

Qualifiedfurniturerefmtsner

Caution:

ImproperstorageofwipingragscouldresultInspontaneous

combustion.

Theyshouldbethrownawayorspreadouttodryina

well-ventilatedareabeforestorageor

disposal.