VLA-C-SB2 For Pull Back

Step 7:

Unscrew one of the eyebolts and move to the center

hole of the bar. Tighten permanently (Figure 10).

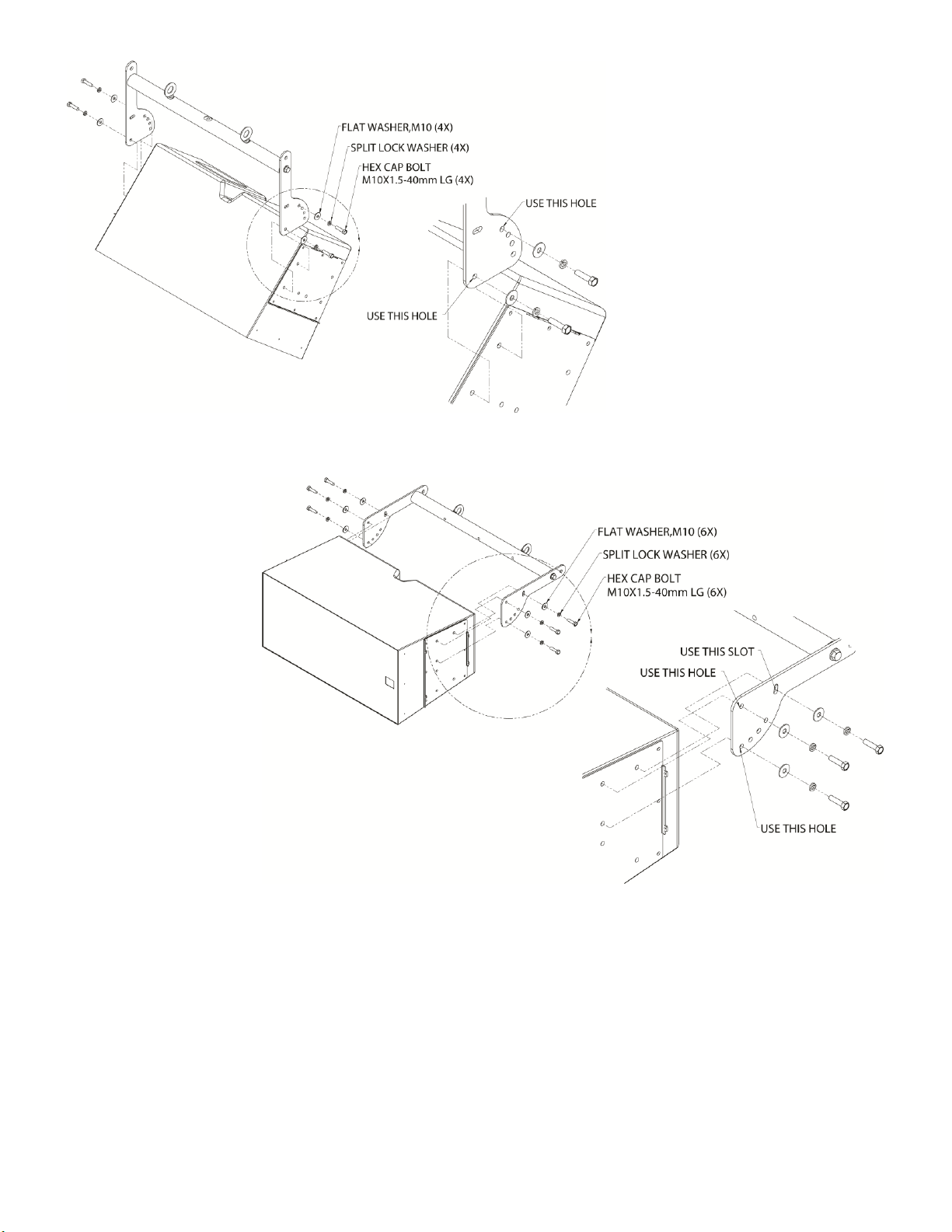

Step 8:

90 Degrees Position

Remove and discard the existing 3 bottom screws

from the speaker’s mounting holes where the (VLA-

C-SB2) bracket will be attached.

Step 9:

Position the (VLA-C-SB2) bracket’s side

mounting plate on the speaker’s mounting

holes, align holes, then secure using the

provided M10 hex bolts, split lock washers

and flat washers (Figure 11).

Step 10:

Tighten screws permanently. Reference

Torque = 30-35 ft/lb

Step 11:

0 Degrees Position

Remove and discard the existing 2 bottom

screws from the speaker’s mounting holes

where the (VLA-C-SB2) bracket will be

attached.

Step 12:

Position the bracket’s side mounting plate

on the speaker’s two bottom mounting

holes, align holes then secure

using the provided M10 hex

bolts, split lock washers and flat

washers. (Figure 12).

Step 13:

Tighten screws permanently.

Reference Torque = 35-40 ft/lb

Step 14:

Attach load rated pull back

cable to the center eyebolt of

the bracket. Slightly loosen the

end bolts holding the round

cross bar so that the crossbar

will naturally rotate axially, and

the eyebolt is in-line with the

direction of pull. Re-tigthen

bolts. Reference Torque = 45-

55 ft/lb (Figure 13).