3. INSTALLATION GUIDE

If the TATIANA 997, ZELIA 908 and LEA 998, reach a height of more than 4 meters from floor to ceiling

then an Anti-Sway bracket must be installed to stabilize the installation and prevent oscillations which

might, in the long run, loosen fasteners.

If the EVA 992 and LINEA 914 reaches a height of more than 5 meters from floor to ceiling then an Anti-

Sway bracket is highly recommended.

Centred on the planned location of the replace, install a hearth made of approved non-combustible

material such as ceramic tiles, stone, masonry or concrete etc.

4. INSTALLING THE HEARTH NON-COMBUSTIBLE

7. INSTALLING ANTI-SWAY BRACKET

For added height (floor to ceiling), install the additional pipes (if required), onto the dropper box (using

the 3 screws TF M8x16).

Air intake is essential for the proper operation of the appliance, if installed in a well insulated/ 6 or

more star rated home. The air intake should be located in an area vented to the outdoors or in an area

exposed to non de-pressurised prevailing winds.

The air intake outlet should be located either directly in the chimney, or as close as possible to the

appliance. The air intake should be vermin proof.

MINIMUM FRESH AIR INTAKE

EVA 992, LINEA 914 AND TATIANA 997

• 300cm2

LEA 998 AND ZELIA 908

• 200m2

The connecting flue should not include more than two 45° offsets (i.e. more

than one non-vertical portion), the angle of these offsets should not exceed

45° with the vertical.

IMPORTANT: When a controlled mechanical ventilation includes an electric

extractor, it is absolutely necessary to stop operation of the replace. The

electric extractors of the kitchen, the bathroom, or the toilets, should also be

switched off when operating the replace.

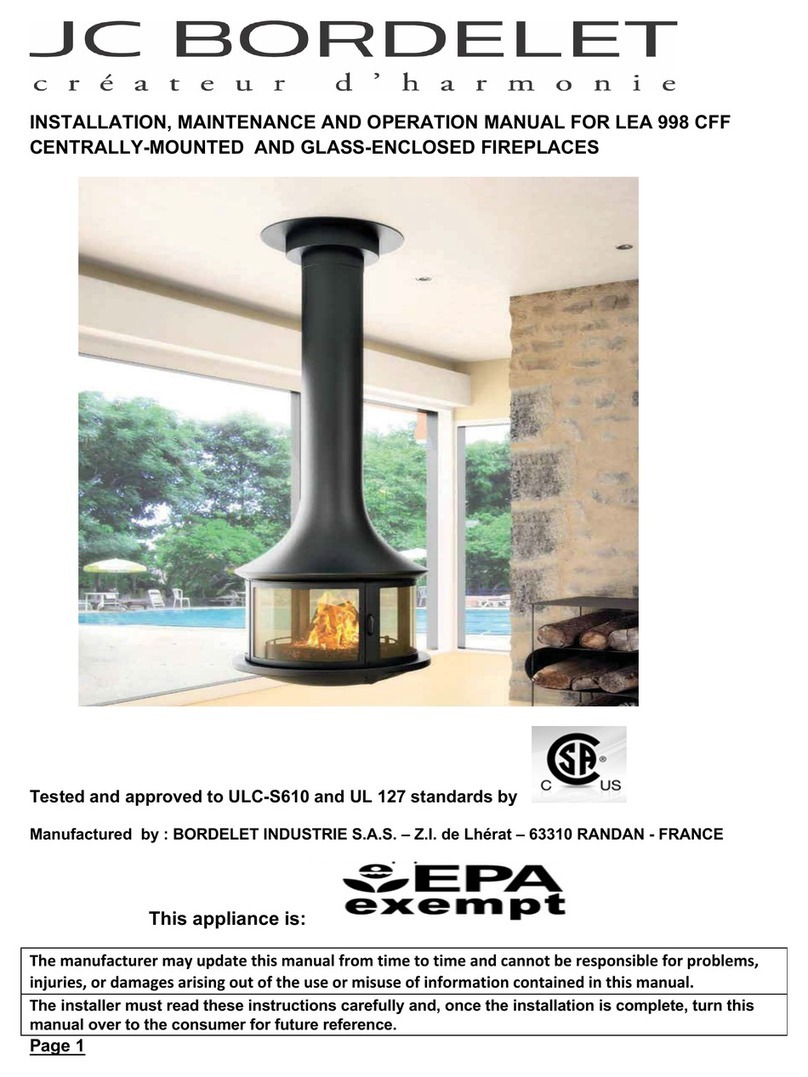

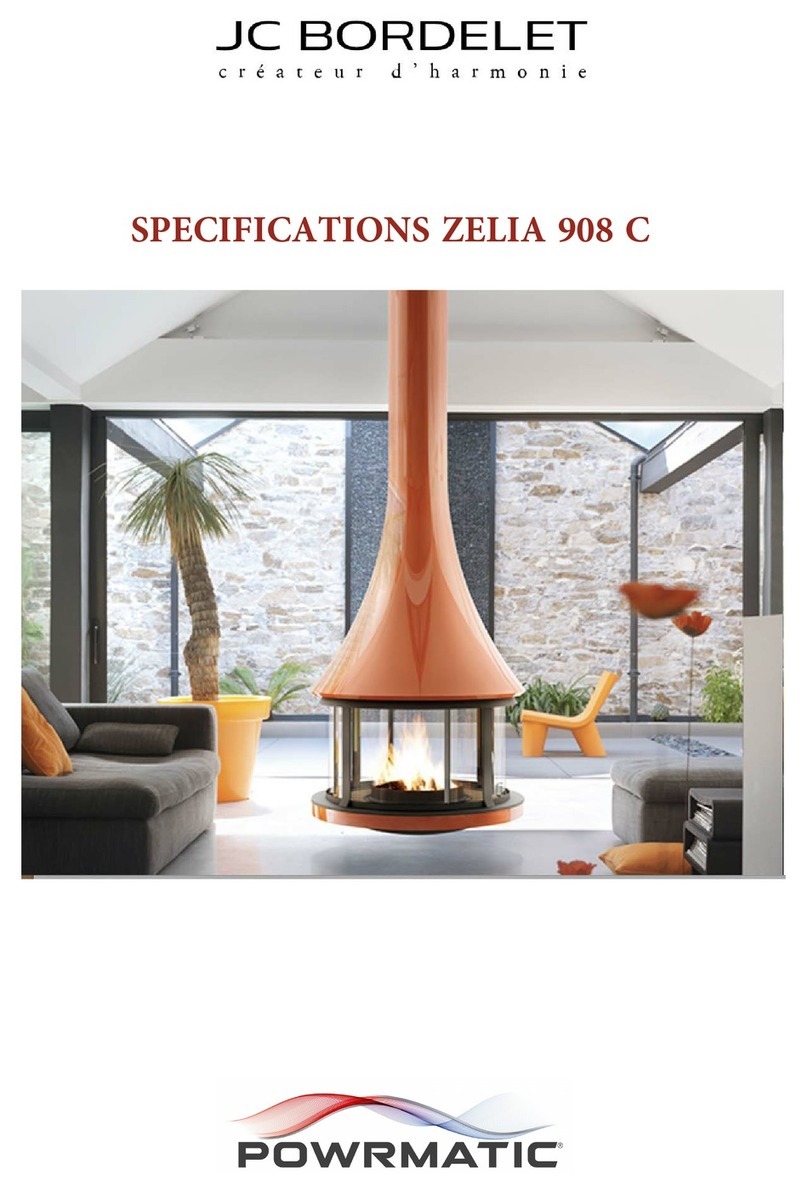

LEA 998, ZELIA 908 AND TATIANA 997

Install the LEA 998, TATIANA 997 and ZELIA 908 onto the dropper box (or the additional pipe if

requested) with the lower shelf of the replace 450 mm above the nished hearth.

INSTALLING THE FIREPLACE

5. INSTALLING THE INTERNAL COMPONENTS

2. INSTALLING THE ADDITIONAL PIPES 6. AIR INTAKE

3. 45° OFFSETS OF CONNECTING FLUES

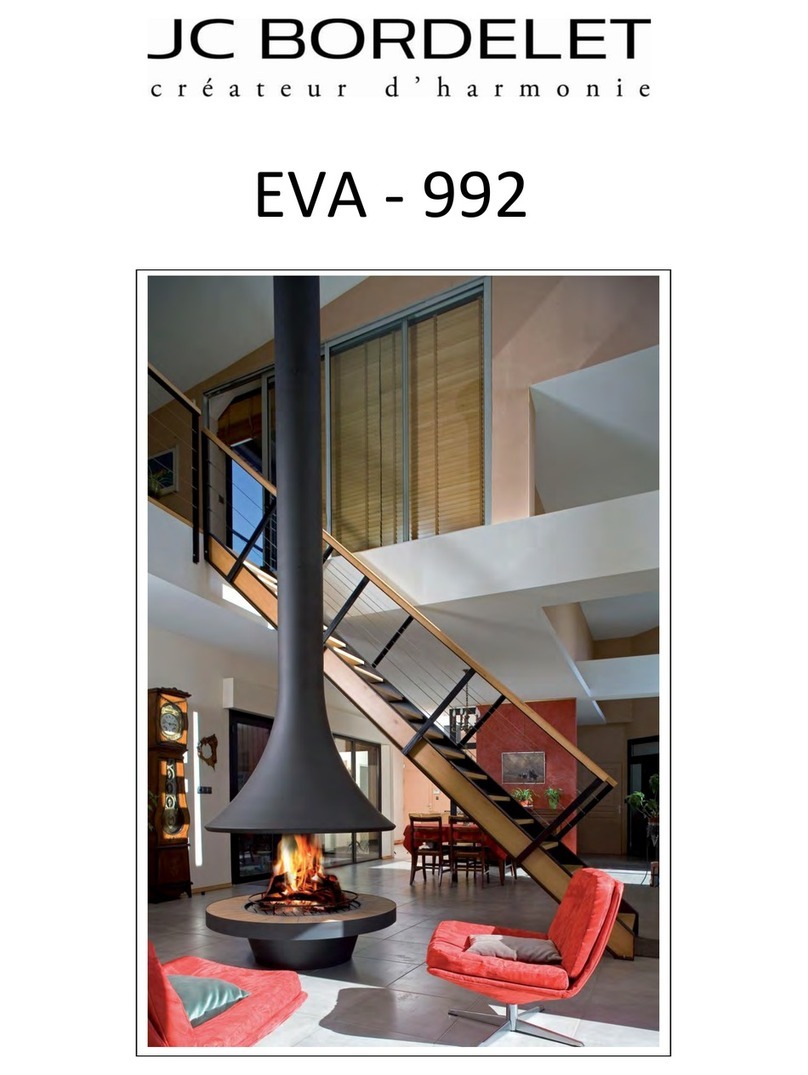

EVA 992 AND LINEA 914

Install the EVA 992 and LINEA 914 canopy onto the dropper box (or the additional pipe if required) with

the lower edge of the replace hood 820mm above the nished hearth. Make sure that all the fasteners

are tight. Centre the base of the EVA 992 and LINEA 914 on the non-combustible hearth in perfect

vertical alignment with the hood and bolt it down making sure that the exact 460mm clearance between

the canopy and the base is maintained.

TATIANA 997, LEA 998 and ZELIA 908

Install the baffle plate ensuring the flat surface is positioned upwards, proceed to gently position the

plate on the lugs located on the inside of the replace. Once in position ensure the plate sits securely,

the baffle plate should not rock or shift when touched if placed correctly. Install the ash pan and the ash

grate on the base of the replace, it should be noted an ash pan and baffle pleate is NOT supplied with

the TATIANA 997.

EVA 992 AND LINEA 914

Install the baffle plate ensuring the flat surface is positioned upwards, proceed to gently position the

plate on the lugs located on the inside of the replace. Once in position ensure the plate sits securely,

the baffle plate should not rock or shift when touched if placed correctly. Install the ash pan and the ash

grate on the base of the replace. Install the ring screw caps at the bottom of the base if necessary.

Install the 2 shutters at the bottom of the base, in case the replace is not connected to an air intake

from the floor.

3. INSTALLATION GUIDE

TYPE 1: WALL BRACKET

TYPE 2: CENTRAL BELT BRACKET WITH CABLE TIES

TYPES OF ANTI SWAY BRACKETS

MINIMUM

300MM FLUE

ANTI-SWAY BRACKET REQUIRED OPTION FOR 4000MM

HIGH(OR MORE) INSTALLATIONS

ADJUSTABLE

FASTENED BY SCREWS

TIGHTENING SCREWS

TIGHTENING NUTS