JD JDL-420 Series User manual

1

2

Content

Preface…………………………………………………………………………………………(2)

I Summary………………………………………………………………………………………(6)

II Safety instruction………………………………………………………………………(9)

III Installation……………………………………………………………………………(12)

IV Unwind--Feeder……………………………………………………………………………(16)

V Offset printing unit………………………………………………………………………(21)

VI Offset printing water and ink uints…………………………………………………(25)

VII Cold foil unit …………………………………………………………………………(52)

VIII Die cutting unit………………………………………………………………………(55)

IX Matrix unit…………………………………………………………………………………(65)

X Rewind unit……………………………………………………………………………………(69)

XI Lubrication system…………………………………………………………………………(74)

XII Maintenance……………………………………………………………………………… (79)

Annex I Manual for mounting plate

3

Preface

This manual is an operation manual about Jiangxi Zhongjing Group JDL-420 multi-

function web printing machine. The control process of accessories and third-party

equipments is only for reference, such as electrical control, sample table, alcohol

box, bending plate machine, laminate machine, UV and water cooling equipment.

【Notes on special security】

For your safety and the protection of the machine, please be sure to read the manual

and all the accompanying information on other related equipments before installing,

running, maintaining and checking. Make sure the operator in charge of the operation

reads and understands the instructions.

Please be familiar with related knowledge, safety information and notes about all

equipments before use.

The machine can only be operated by people who can meet the intellectual and

physical requirements of machine operation.

1、Notes on intallation

(1)The installation and commissioning of the machine must be carried out by our

own specialists or by our authorized specialists.

(2)The operating environment has an important influence on the quality of print

samples. So a good operating environment can reduce the occurrence of failures. The

installation and use environment shall meet the requirements of the production of

specialized equipment. ( For details, please refer to the requirements in Chapter

III, "Installation and Use Environment of Machine".)

(3)The requirements of lifting and level when installation must be done strictly in

accordance with the requirements of (Chapter III Installation)

(4)This model uses alcohol plating, alcohol, printing ink, printing paper, grease

and other flammable goods. The printing workshop requires good fire prevention

measures and no fireworks.

2、Notes on electrical appliances

(1)For details on electrical safety of machines, please refer to the "Manual of

Electrical Operation".

(2)Touching exposed high-voltage lines can be extremely damaging with electric

shocks.

4

3、Notes on starting, operation, maintenance

(1)The machine must be used by operators who are specially trained and specialized

in rotating trademark printing machines.

(2)All operations and maintenance on the central console, machinery, electrical

appliances and third-party equipments must only be performed by persons who are

fully familiar with the operation, maintenance and repair of the machine and who are

aware of the danger.

(3)Safety precautions relating to other related equipments, accessories and third-

party equipments, for details in the annexes, the safety instructions about other

related equipments, and third-party equipments and all information attached to other

related equipments.

4、The machine is ready to run when the bell is ringing. All manual operations

must be stopped and withdrawn from the dangerous position immediately.

5、Notes on disusing

When the machine is discarded, please treat it as industrial waste.

【USE】

1、Material

⑴、JDL-420 model series multi-function web printing machines are suitable for

printing adhesive, coated paper, offset paper, cardboard, plastic film and so on.

If there are any special materials, it must be confirmed by us before printing

⑵、Paper size and thickness should not exceed or be lower than the values

indicated in the manual. The paper stiffness must be within the range of general

printing materials. Printing ink should be commercial rotation UV ink, light oil

or glue.

2、Technical conditions without defects

⑴、Machines, accessories and third-party equipments can only be operated without

defect technical conditions. All protective devices on the machine and all safety

devices in the printing workshop must be complete and functional.

3、Modifications are not allowed.

It is prohibited to modify, add or refurbish the machine without the permission of

the manufacturer of the machine. For example, replacing software, installing new

features, changing machine parameters and electronic control are not allowed.

4、Comply with operating instructions

5

⑴、The use includes complying with operation and maintenance instructions provided

by the manufacturer, which also applies to external parts and third-party equipments.

⑵、All operations on central consoles, machines and third-party equipments can only

be performed by personnel who are fully familiar with the operation, maintenance and

repair of the machine and who are aware of the danger.

⑶、The machine is only available to those in charge who are specially trained to

specialize in web printing. Responsibility and distribution of tasks must be clear

and supervised.

5、Abide by the law

Comply with the laws and regulations of the country concerning labor safety,

environmental protection and use of equipment. Printed products, publications, and

etc. shall comply with the relevant provisions of the country's intellectual

property protection law, public publications, and etc.

6、Irresponsible matters

For your safety and the protection of the machine, please read the instructions in

details before using the machine. During use, you should operate the machine

strictly according to instructions of the Manual, especially pay more attention to

the safety notes.

Any use that is not mentioned here or is used out of the above is not an expected

usage. For example, the modification,joint and the idling of the installed machine

affect the normal function of the machine, or the unrestricted use, or the skipping

of the safety equipment, or failure to use the machine in accordance with the

parameters specified in the instruction manual, The operation of machines that do

not comply with the requirements of the instructions for use is within the scope of

unexpected use.

We do not allow any claims for any unexpected usage, personal injury, or damage to

the machine.

7、Printing output

The reference to 150 m/min refers to technically possible capabilities, but it is

not actually achieved in daily production, depending on the parameters beyond our

control. For example, the operator's proficiency, printing materials, printing

plates, ink and preparation of the printing environment, etc..

6

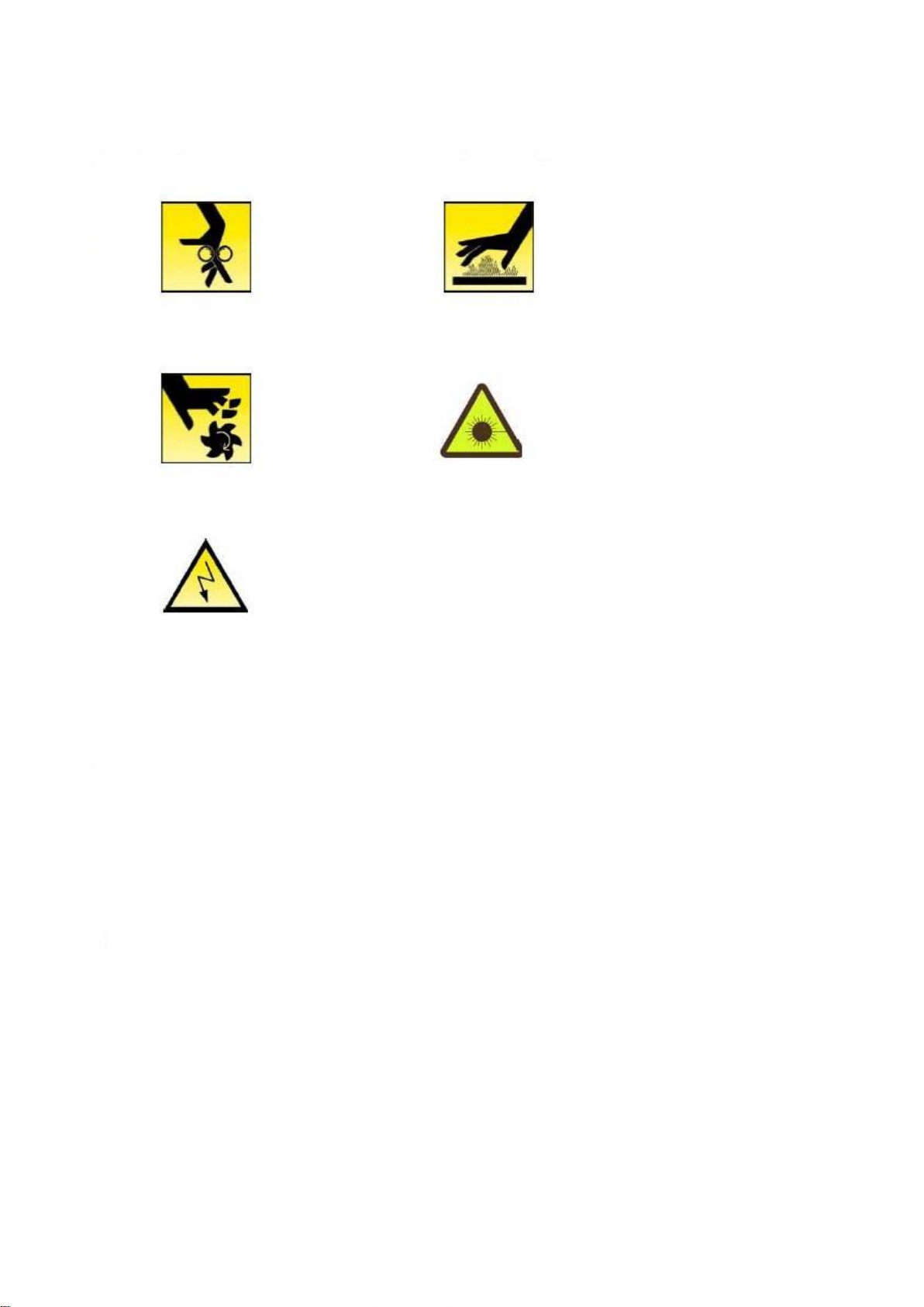

Warning sign

Watch your

fingers

High surface

temperature

Rotating

sharp

objects

Don’t look

directly

Dangerous

Electricity

7

I Summary

一、Use

JDL-420 model series continuous PS plate composite trademark printing presses are

suitable for printing adhesive, coated paper, cardboard, aluminum foil and

plastic film. The machines adopt unit type modular combination, which can be used

in 4-8 color printing. Each unit can be chosen any printing methods in offset,

flexo, screen, and cold foil. They adopt shaftless drive configuration, automatic

registration system and pre-registration system, in order to ensure accurate

registration with high speed (150m/min) and low rate of spoiled products. They

are ideal machines to print high-grade products, daily chemical products, wine

labels, medicine labels, packaging boxes, adhesive labels and so on.

二、Specifications

Printing speed

150m/min

Printing units

4-8 units

Max.Pinting repetition length

635mm

Min. Pinting repetition length

469.9mm

Max.web width

420mm

Min.web width

210mm(paper)315mm(film)

Max.printing width

410mm

Web thickness

0.06~0.35mm

Max.unwinding diameter

1000mm/350Kg

Max.rewinding diameter

1000mm/350Kg

Max. unwinding and rewinding diameter of

cold foil

600mm/40Kg

Offset plate thickness

0.3mm

Blanket thickness

1.95mm

Flexo plate thickness

1.14mm

Thickness of double sided adhesive

0.5mm

Margin

3mm

Total power

See machine installation diagram

Voltage

Three phases, 380V±10%

Control voltage

220V

Frequency

50Hz

8

Main machine size(length*width*height)

13000X2220X2280

Net weight

Offset printing units

2270Kg/unit

Unwinding unit

1400Kg

Die cutting and matrix units

1350Kg

Rewinding unit

920Kg

Cases size

Offset printing units

2380X1850X1900

Unwinding unit

2585X2370X1900

Die cutting and matrix units

2380X1850X2300

Rewinding unit

2380X1850X1300

Control table

1800X900X2000

Main power cabinet

1200X600X2200(2 pcs)

UV main power cabinet

850X600X2000(2 pcs)

Sticker machine

1200X700X1650

Bending machine

1600X1000X1250

Air compressor

1600X650X1200

Alcohol tank

650X550X1100

三、Features

1. Combination printing and unique sharing platform technology. It can be combined

with offset printing, flexo printing, screen printing, cold foil, super glazing,

laminating and other printing processes. Various printing processes can be combined

arbitrarily according to the requirements of different printing products. It is

suitable for various types of label printing.

2. Large printing area is 410 X 635mm and maximum printing perimeter can be up to

635mm. The maximum speed can reach 150m/min. Whether it is a large quantity order or

big label job, you can handle it easily.

3. It can print many kinds of printing materials, such as paper, plastic film, metal

foil. The thickness is from 0.06mm (film) to 0.35mm (cardboard).

4. Shaftless drive: The whole machine adopts the servo drive technology from

unwinding to printing, die-cutting to rewinding. The servo drive is been applied to

unwinding and rewinding units, so that the printing tension can be controlled more

accurately. The printing tension adopts closed loop control system, which is driven

9

by servo motors separately. Offset plate rollers, blanket rollers, impression

rollers, ink and water are all been driven by the servo motors, which is stable

operation and high precision. It can reduce ink bar without gears.

5. Automatic registration system, especially for more than one unit, registration

system is better than others. Its registration adjustment precision is to 0.01mm.

The axial and radial registration can be adjusted automatically and simultaneously.

The registration can be in the right place within two printing circumference.

6. Preset registration function: to install the plate roller before printing, then

press the start button, the plate roller will automatically look for the zero

position for registration. Registration requirements can be achieved without manual

adjustment. It improves efficiency, saves a lot of materials and labor costs.

7. Portable sleeve technology. The plate and blanket sleeve of magnesium aluminum

alloy can change the printing format and type easily. The operation is simple and

the maintenance cost is low.

8. It can adjust the parameters of the machine at any time through a digital handle,

store and call datum of each production working orders in printing management center.

The datum contain the optimal state of the machine during production. These datum

will be used to set the machine state when the order is stored and called. In

addition to boot, shutdown, speed control, counting and other basic functions, it

can achieve all the control of the printing machine, and perform work storage and

call, offset water and ink can be controlled automatically, registration control and

real-time detection.

10

II Safety instruction

一、Safety instruction

1. The printing press shall be operated and used by trained professionals. The

installation and commissioning of the machine must be carried out by our own

specialists or by our authorized specialists.

2. For your safety and the protection of the machine, please read the instructions

in details before using the machine. During use, you should operate the machine

strictly according to instructions of the manual, especially pay more attention to

the safety notes.

3. Our company shall not accept any claims for any personal injury or damage caused

by any use of the machine not in accordance with the parameters specified in the

instructions and for the operation of the machine not in accordance with the

provisions of the instructions.

4. The ignition point of the printing ink must be higher than 21 °C. Thickness of

substrate: 100-200 μm

二、Management standard

1. Please keep the manual next to the machine so that you can read it at any time

2. In addition to what is mentioned in the operation manual, the operation must

comply with the regulations on accident prevention and environmental protection

stipulated by local laws at the same time.

3. For safety reasons, staffs are required to wear clean work clothes. Sleeves and

chest buttons must be buttoned up, not open chest. Ladies must wear hair caps to

enter the workshop.If ladies do not wear hair caps, they are not be allowed to

operate the machine. It is strictly forbidden to use the machine in shoes, high

heels, earplugs, long skirts, long hair, and other violations of the relevant

operating rules

4. This model uses alcoholic system. Alcohol, printing ink, printing paper and

grease belongs to flammable items. If the machine is placed in a closed space, pay

attention to the flammable gas concentration and ensure air exchange timely to

avoid spontaneous combustion or explosion. The printing workshop must make good

fire prevention measures and strictly prohibit fireworks.

5. Compliance with safety and warning instructions on the machine.

11

6. Modification, addition or replacement of any devices that may affect safety is

forbidden.

7. Spareparts must be purchased in accordance with the technical requirements

specified by the manufacturer or authorized manufacturers

8. Software programs of control systems are prohibited to change. If changing, our

company shall terminate any liabilities immediately.

9. It is forbidden to place flammable or explosive or solvent coated rags next to

UV lamps to avoid explosion.

10. UV lamps produce harmful rays that damage the skin and eyes of the human body.

So it is prohibited to open the safety cover during the operation of the machine.

11. UV lamps produce ozone, so ventilation systems must be installed. The maximum

amount of indoor ozone is not allowed to exceed 0.1 ppm.

三、Security notes

1. Normalize operations to avoid any breach of safety regulations

2. The necessary precautions must be taken to use the machine in safe and secure

conditions.

3. The machine can only be operated if the safety protection device is working

properly. Such as: removable safety devices, emergency stop devices, soundproofing

and exhaust systems.

4. The machine must be checked for damage at each shift, and any changes must be

reported to the company in time. If necessary, it must be shut down and locked

immediately.

5. You must check the safety of the device at least once before starting.

6. The yellow device can only be unloaded when the device is replaced. After the

device is removed, the device must be reinstalled. Power must be turned off before

this operation can be performed.

7. The temperature of the plant in which the machine is located must not exceed 36º

C. High temperature will affect the life of the electrical equipment and increase

the surface temperature of the substrate.

8. UV lights and drying equipment must be turned off before cleaning equipment.

9. Only after the power is turned off, the safety cover can be removed.

10. Only personnel with relevant electrical qualifications are allowed to open the

cabinet door.

12

11.The filter of the ventilation system must be kept clean. Otherwise, the function

of the system will be reduced, and the air flow to the heating element will be

reduced, which may cause overheating or fire.

12.The temperature of UV lamp tube and oven cover shell is high, watch out for

scald.

13.Only experienced personnel are allowed to adjust, maintain, inspect equipment

and replace parts.

14.When maintaining and repairing the equipment, be sure to turn off the power and

lock the main switch to prevent inadvertent turning on the power.

15.After the machine is overhauled, maintained or repaired, the safety cover must

be reinstalled and checked immediately.

16.In the case of downtime during the printing process(for example, due to the

breaking of the tape or high temperature alarm, etc.), the UV lamp must be turned

off to prevent the tape from overheating and burning.

13

III Installation

一、Working environment, transportation and storage requirements

The operating environment of the machine has an important influence on the quality

of printed materials. A good operating environment can reduce the occurrence of

faults. The installation and use environment of the machine shall conform to the

requirements of the production of web printing machine.

1.In the process of transportation and storage takes safety measures, such as dust-

proof, earthquake-proof, collision-proof, fire-proof, corrosion-proof, Rust-proof

and other measures.

2.Workshop ground should take moisture-proof and shock-proof measures. Design of

doors and windows should be moisture-proof, or the use of wind curtains to block the

flow of outside air into the workshop to avoid the impact on the balance of ink.

3.When the printing press is installed, it should take safety measures, such as

dust-proof, earthquake-proof, fire-proof, heat, ventilation, lighting,

dehumidification, noise reduction and other measures. Room air should not include

acids, salts and corrosive gases. Best relative humidity 55 % -65 %, no condensate

water. The installation of the machine is conducive to the arrangement between the

various processes and the logistics direction is reasonable.

4.The installation temperature of the machine is not more than 37 °C, the constant

ambient temperature is conducive to the stability of the printing quality, the

optimal temperature range of 20 ± 2 °C.

5.The min. installation distance between electric cabinet and wall is 0.8 meters,so

as to ensure heat dissipation, ventilation and easy maintenance.

6.Power voltage is 380V. Fluctuation is less than 10 %. Frequency is 50Hz. For areas

surrounded by large electrical equipment, it should install automatic voltage

control power with 100KW. This machine uses communication methods to connect and

control various units. It is necessary to prevent strong magnetic interference

around it, such as high-voltage lines, microwave transmission stations. If necessary,

the factory building must take metal network shielding measures.

二、Installation

1、Installation preparation

Build the foundation according to drawings (there are some differences because of

different options). Before pouring concrete, please pre-bury the cable pipe or make

a good line groove for laying the wire.

14

If the machine is installed upstairs, the bearing capacity of the building must not

be less than 2 T/m².The machine seat must pass through a load-bearing beam. The

weight of the load-bearing beam is calculated by multiplying the weight of the

machine by 1.2 times (load coefficient).

For plant foundations filled with soft soil areas or original farmlands / lakes, the

thickness of the foundation must be increased by 500MM to prevent irregular

settlement and affect the accuracy and life of the machine.

2、Installation

(1) Connect each module unit according to the schematic diagram of the machine.

(2) Calibrate machine level and adjust support bolts on machine base to find machine

level.

Gradienter specification: 0.02/1000

Calibration Level Requirements:

Longitudinal level (in the direction of the length of the machine) is not greater

than: 0.08/1000

Transverse level is not greater than 0.04/1000

The degree of parallelism between the leveling units is not greater than 0.03.

【Notes】:

①、In order to increase the stability of the machine, the closer the seat is to the

ground, the better.

②、After installing and putting into operation about 70-80 shifts, the level of the

machine should be re-adjusted to check the changes after the foundation is pressed.

(3)、Fixed expansion screws in offset printing units.

(4)、Connect UV, Refrigerator,alcohol tank and control table.

(5)、Connect ventilation.

(6)、Connect lubricating tubing.

(7)、Clean rust resistant oil.

(8)、Connect electrical wires (for details, please refer to the "Electrical Section

of the Manual")

(9)、Test run (see test run before installation and operation).

三、Test run

1.Long-distance transportation may lead to loosening of certain wiring screws and

lead to poor contact resulting in control failure. The user is required to re-check

15

and tighten the terminal screws of all components and terminal rows before turning

on the power.

2.Before test run, all parts of the machine shall be fully inspected for connectors,

fasteners, fastening screws, tapers, opening pins, Stoppers, etc., to prevent

accidents caused by loose or falling parts that may occur during transportation.

3.According to the lubrication instructions, add the necessary lubricant to the fuel

tank and oil cup, and use the oil gun to fill each artificial injection point.

4.Check if the power feed phase sequence is correct or not.

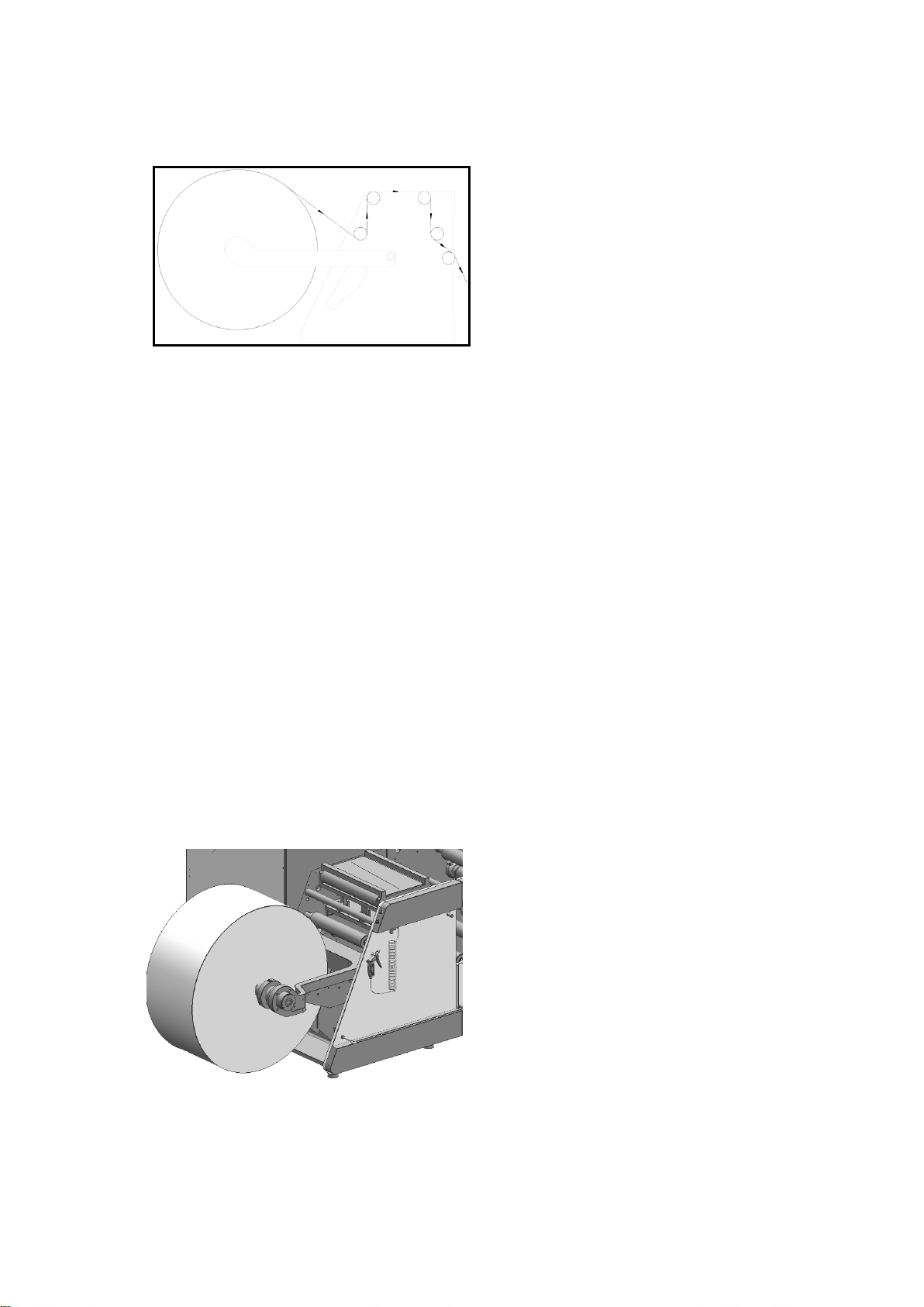

5.According to the paper route shown in Figure 3-1, put on the paper tape, click the

machine, confirm that there is no problem, and then you can carry out various

preparations before printing test.

16

Figure 3-1

17

IV Unwind--Feeder

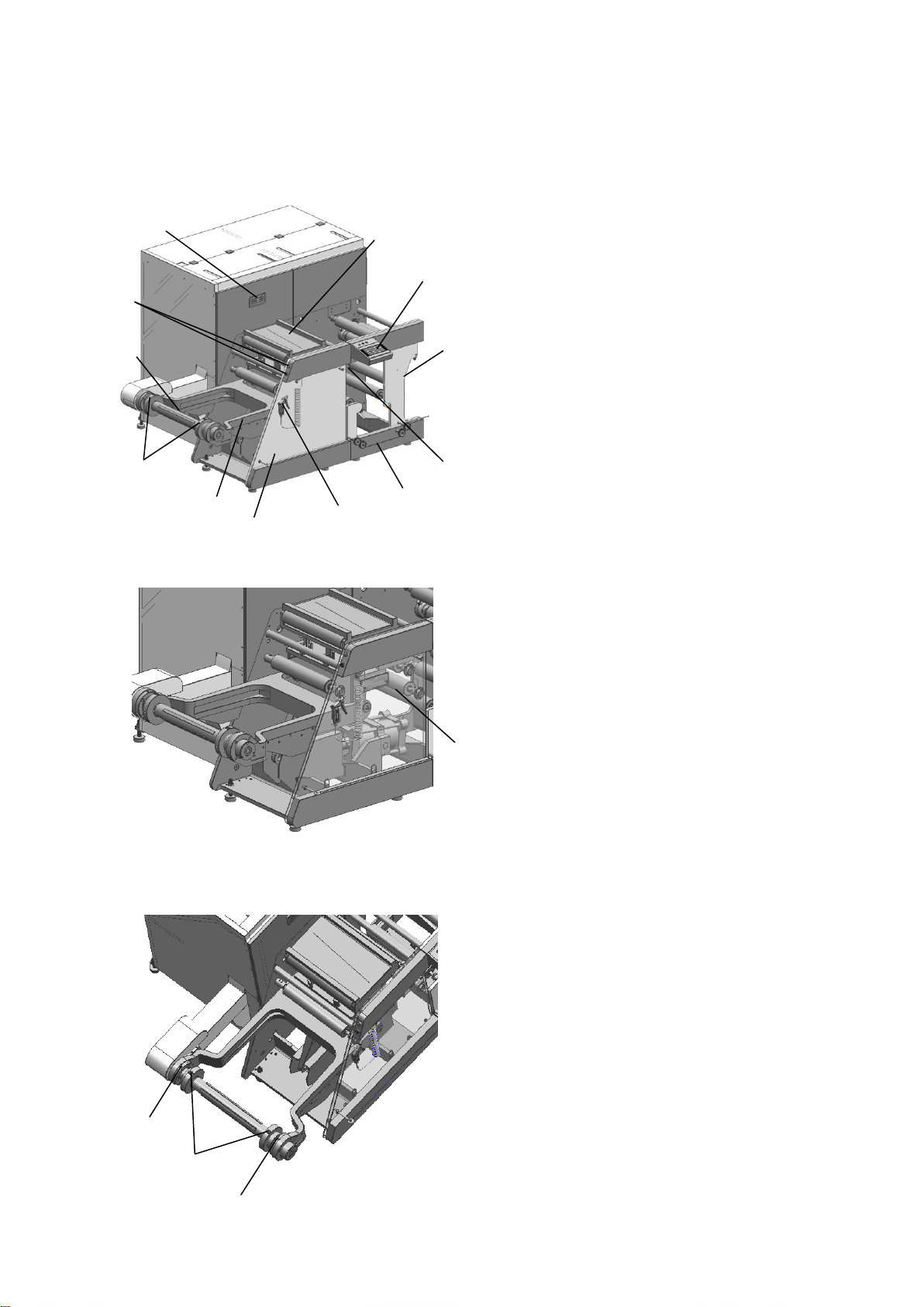

一、Overview of the structure

二、Unwinding unit

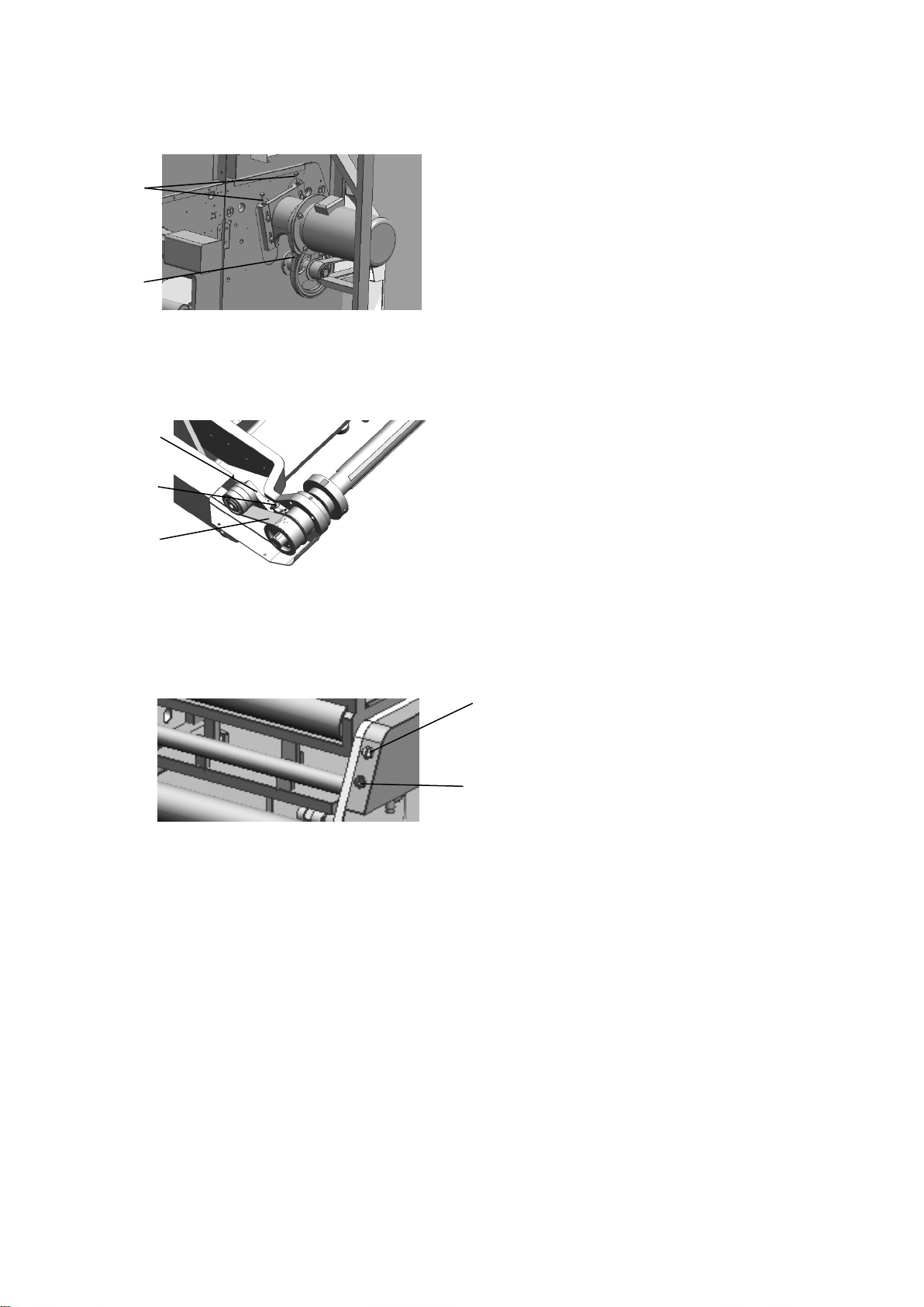

2.1 Lift Arm and air cylinder

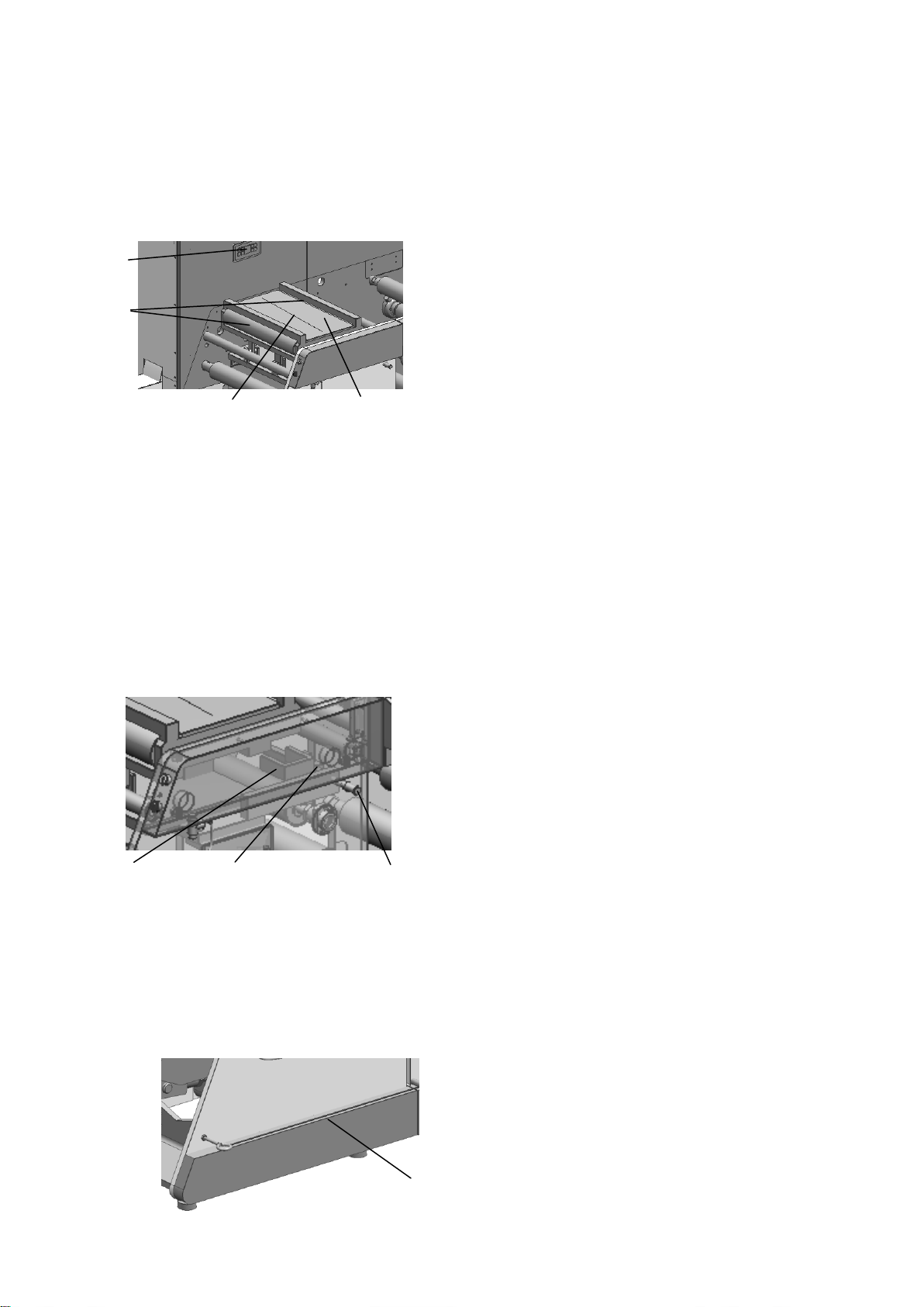

2.2 Support bearings

1 Unwinding unit

2 Lifting arm

3 Support bearings

4 Unwinding gas fluctuation shaft

5 Unwinding lift arm lift/drop button

6 Scrolling edge operation screen

7 Sheet laying table

8 Unwind-feeder operation screen

9 Feeder

10 Control paper adjustment

11 Emergency stop wires and cables

12 Air gun

2

4

3

5

4

3

2

1

1 Release button (Inner ring)

2 Mark Point(Outer Ring)

Two support bearings are installed on the

lifting arm to support the gas fluctuation

shaft equipped with paper rolls. Support

bearings consist of outer and inner rings.

The support bearing is fixed to the

lifting arm through the outer ring, and

the inner ring can rotate and push along

the shaft. Only when the release button on

the inner ring is aligned with the mark

point on the outer ring, the release

button can be pressed, the inner rings of

the two bearing are respectively pushed

outwards / inwards to remove / lock the

gas increase axis. The design of bearing

can prevent the accidental fall off of the

gas fluctuation shaft.

1 Lift arm supports air cylinder

Lift arm is used to support pre-printing

scroll by gas fluctuation shaft. Air cylinder is

used to support lift arm. If the air supply is

insufficient, the lifting arm will remain in its

current position. And then, as a safety

precaution, it drops very slowly. It prevents

injury to the operator and prevents damage to

the lifting arm. The role of the air cylinder

itself is used to stop the bottom of the lifting

arm.

1

1

2

2

12

2

3

5

4

6

7

8

9

10

11

1

18

2.3 Unwinding main motor belt tensioning

2.4 Unwinding drive belt tensioning

2.5 Lift and drop function of lifting arm

1. adjusting screws

2. circle-arc tooth Synchronous belt

Keep the arc tooth synchronous belt

tight during running by adjusting the

screw so as to ensure the best

running state.

1. Tensioning support

2. adjusting screws

3. circle-arc tooth Synchronous belt

By adjusting the adjustment screw on

the tensioning support, circle-arc

tooth Synchronous belt is kept tight

during running in order to ensure the

best running state.

1. lift button

2. drop button

Lift / Drop Button is used to lift /

drop a pre-printed paper roll through

a lift arm

1

2

1

2

1

2

3

19

2.6 Scrolling edge control and sheet laying

table

2.7 Emergency stop

1.Scrolling edge operation screen

2.Edge control roller

3.Cut line

4. Sheet laying table

The paper edge can be adjusted by

scrolling edge control. Place the

paper roll in the middle of the

printing unit when entering the

printing unit to begin printing.

The paper roll edge control

includes sheet laying table, where

the ends of different paper rolls

can be connected. After the new

paper roll is installed, the paper

is passed through the first edge

control roller controlled by the

paper roll edge, and the end of

the old and new paper roll is

respectively cut off along the

cutting line on the table. Through

the operation panel, scroll edge

control can be set up and related

operations

1

2

3

1. Fine-tuning handle

2. Sensor support

3. Sensor

Sensor support is used to

regulate the side of scroll edge

control. To make the adjustment

more precise, fine-tuning

handles can be used as needed.

1

1. Emergency stop wires and

cables

Emergency stop wires and

cables are installed at the

lower end of the machine's

operating side. If the

operator wants to stop the

entire machine, it will be

activated.

1

2

3

4

20

2.8 unwinding unit paper route

2.9 Installation of scroll

Rotate the inner rings of the two

bearing bearings so that the release

button is aligned with the mark point,

press the release button, pushthe inner

rings to the outside and take downthe

gas fluctuation shaft, and let airbag

release. Then, the gas fluctuation shaft

is penetrated into the inner hole of the

pre-printed scroll. According to the

scale on the gas fluctuation shaft, the

paper is correctly installed. The air

fluctuation is inflated by air gun and

the scroll is fastened. Press the lifting

armto lift / drop the operating button,

so that the lifting arm is in a suitable

position, and the inner ring of the two

bearings is rotated to align the release

button with the marking point. The

scroll installed on the gas fluctuation is

placed into the center hole, and the

inner ring ofthe two bearing is

respectively pushed to lock the gas

fluctuation shaft. Press the lift /drop

operation button to keep the lift arm in

a horizontalposition.

Table of contents