Contents

Safety Information, Instructions, and Symbols........................................................................ 1

Safety Information .............................................................................................................1

Classification ......................................................................................................... 1

Disconnecting from Line Power............................................................................. 1

Line Power Requirements ..................................................................................... 1

Fuse Type .............................................................................................................1

Laser Application...................................................................................................1

Safety Instructions.............................................................................................................2

Before Initializing and Operating the Unit.............................................................. 2

Operating the Unit ................................................................................................. 2

Safety Symbols .................................................................................................................3

Compliance ....................................................................................................................... 4

FCC Compliance ................................................................................................... 4

CE Compliance ..................................................................................................... 5

CSA / IEC Compliance .......................................................................................... 5

UL Compliance...................................................................................................... 5

General Information and Specifications ................................................................................... 6

General Information ..........................................................................................................6

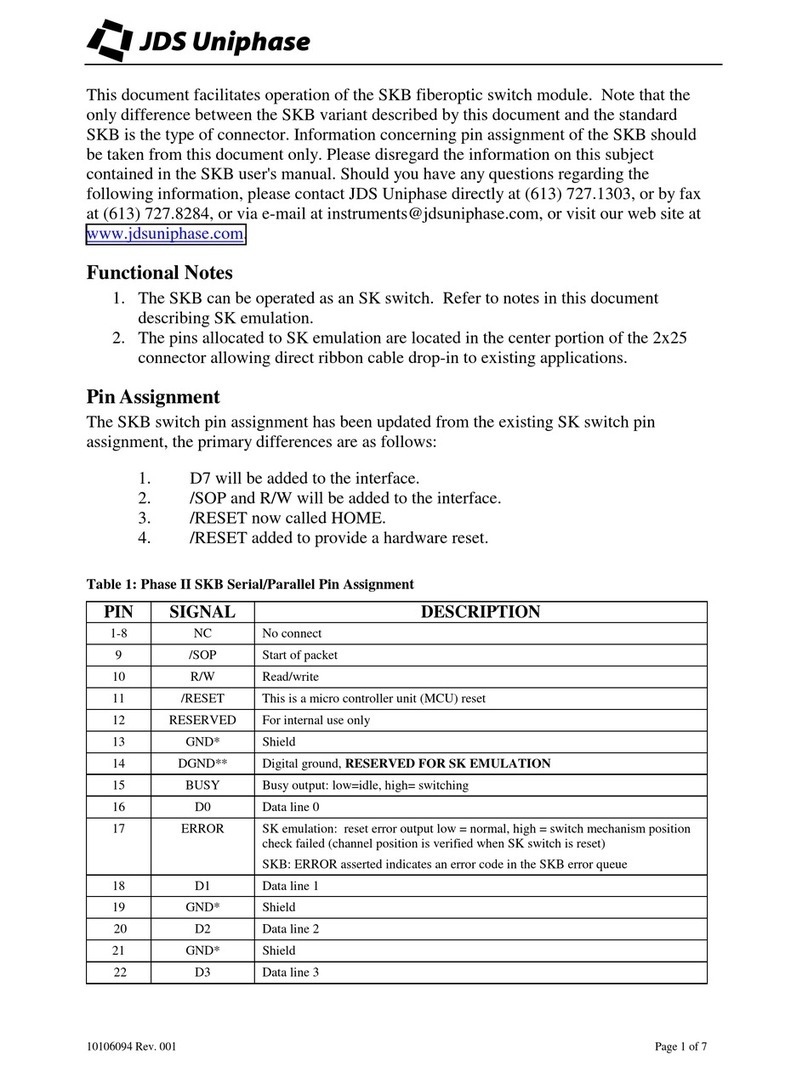

Multiple-Common (SCG-D) Switch Configuration ................................................. 7

Single-Step Multiple-Common (SCG-E) Switch Configuration .............................. 7

Multiple-Common Blocking (SCG-F) Switch Configuration ................................... 8

Key Features ......................................................................................................... 8

Applications ........................................................................................................... 8

Standard Accessories ...........................................................................................8

Specifications .................................................................................................................... 9

Getting Started .......................................................................................................................... 11

Before Initializing and Operating the Unit........................................................................11

Initial Inspection .............................................................................................................. 11

Operating Environment ................................................................................................... 12

Temperature........................................................................................................ 12

Humidity .............................................................................................................. 12

Ventilation............................................................................................................ 12

Storing and Shipping.......................................................................................................12

Claims and Repackaging ....................................................................................12

Returning Shipments to JDS Uniphase............................................................... 12

Cleaning Connectors.......................................................................................................13

Installing the Switch ........................................................................................................ 14

Operating and Maintenance Instructions ............................................................................... 15

Front Panel...................................................................................................................... 15

Operating Keys.................................................................................................... 16

Status LEDs ........................................................................................................16

Rear Panel ...................................................................................................................... 17

Making External Switch Module Connections ................................................................. 17

External Switch Module without TTL Input Controls............................................ 17

SD000343 Rev. A August 2000