Jean Lebeniste MC1100B User manual

MODEL MC1100B

VARIABLE SPEED

WOOD LATHE

INSTRUCTION MANUAL

Please read and fully understand the instructions in this manual

before operation. Keep this manual safe for future reference.

Version: 2015.02.02

1

TECHNICAL DATA

Model number………………………………………………...………………………………………………… MC1100B

Speeds………………………………………………...…………………………..…………………………500-2000RPM

Distance between centers ………………………………………………….….…..………………. 1100mm(43in.)

Swing over bed………………………………………………………………………….…………………408mm(16in.)

Drive spindle through hole……………….……………………………….…………………………..…………10mm

Tailstock spindle through hole……………………………………………..……………………………………10mm

Tailstock spindle travel….…………………………………………………………………….……………………54mm

Headstock spur…………..………………………………………………………………spur center-Morse#2Taper

Tailstock center………..………………………………………………………Ball bearing center-Morse#2Taper

Net weight…………………………………………………….…………………………………………………….…132kgs

GENERAL SAFETY RULES

WARNING! WHEN USING ELECTRIC TOOLS BASIC SAFETY PRECAUTIONS SHOULD ALWAYS

BE FOLLOWED TO REDUCE THE RISK OF FIRE,ELECTRIC SHOCK AND PERSONAL INJURY,

INCLUDING THE FOLLOWING.

Read all these instructions before attempting to operate this product and save these

instructions.

SAFETY RULES

1. Keep work area clear

Cluttered areas and benches invite injures.

2. Consider work area environment

Do not expose tools to rain. Do not use tools in damp or wet locations. Keep work area well lit.

Do not use tools in the presence of flammable liquids or gases.

3. Guard against electric shock

Avoid body contact with earthed or grounded surfaces.

4. Keep other persons away

Do not let persons especially children involved in the work area and touch the tools or the

extension cord and keep them away from the work area.

5. Store idle tools

When not in use, tools should be stored in a dry locked up place out of reach of children.

6. Do not force the tool

It will do the job better and safer at the rate for which it was intended.

7. Use the right tool

Do not force small tools to do the job of a heavy-duty tool.

8. Dress properly

Do not wear loose clothing or jewelry, they can be caught in moving parts. Non-skid footwear is

recommended when working outdoors. Wear protective hair covering to contain long hair.

9. Use protective equipment

2

Use safety glasses. Use face or dust mask if cutting operations create dust.

10. Connect dust extraction equipment

If devices are provided for the connection of dust extraction and collecting equipment, ensure

these are connected and properly used.

11. Do not abuse the cord

Never yank the cord to disconnect it from the socket. Keep the cord away from heat oil and

sharp edges.

12. Secure work

Where possible use clamps or a vice to hold the work, it is safer than using your hand.

13. Do not overreach

Keep proper footing and balance at all times.

14. Maintain tools with care

Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories.

Inspect tool cords periodically and if damaged have them repaired by an

authorized service facility.

15. Disconnect tools

When not in use, before servicing and when changing accessories such as blades, bits and

cutters, disconnect tools from the power supply.

16. Remove adjusting keys and wrenches.

Form habit of checking to see that keys and adjusting wrenches are removed from the tool

before turning it on.

17. Avoid unintentional starting

Ensure switch is in "off" position when plugging in.

18. Use outdoor extension leads

When the tool is used outdoors, use only extension cords intended for outdoor use and so

marked.

19. Stay Alert

Watch what you are doing, using common sense and do not operate the tool when you are

tired.

20. Check damaged parts

Before further use of tool, it should be carefully checked to determine that it will operate

properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts, and any other

conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or replaced by an authorized

service center .

Have defective switches replaced by an authorized service center.

Do not use the tool if the switch does not turn it on and off.

21. Warning!

The use of any accessory or attachment other than that recommended in this instruction

manual may present a risk of personal injury.

22. Have your tool repaired by a qualified person

Repairs should only be carried out by a qualified person using original spare parts, otherwise

may result in considerable danger to the user.

3

Specific safety rules for the wood lathe

WARNING ! Do not operate your wood lathe until it is completely assembled and installed

according to the instructions.

1. For your own safety, read the entire instruction manual before operating the lathe.

2. Always wear eye protection.

3. Do not wear gloves, neckties, or loose clothing.

4. Tighten all locks before operating.

5. Do not mount a split workpiece.

6. Use the lowest speed when starting to cut a new workpiece.

7. Read the warning label attached to the wood lathe.

8. When turning a workpiece, always rough the wood to round form please. Stop wood lathe at

slow speed. If the lathe is runing so fast that it vibrates, there is a risk that the workpiece will

be thrown out or the tool jerked from your hands.

9. Always rotate the workpiece by hand before turning on the lathe. If the workpiece strikes the

tool rest, it could split and be thrown out of the lathe.

10. Do not allow the turning tools to bite into the wood. The wood could split or be thrown out

from the lathe.

11. Do not operate the lathe if it is rotating in the wrong direction.

The workpiece must always be rotating toward you.

12. Before attaching a workpiece to the faceplate, always rough it out to make it as round as

possible, this minimizes the vibrations while the piece is being turned. Always fasten the

workpiece securely to the faceplate, failure to do so could result in the workpiece being thrown

away from the lathe.

13. Position your hands so that they will not slip onto the workpiece.

14. Remove all loose knots in the stock before mounting it between the centers or on the

faceplate.

Save these safety rules!

Electrical information

Guidelines for using extension cords

WARNING! THIS WOOD LATHE IS FOR INDOOR USE ONLY. DO NOT EXPOSE TO RAIN OR

USE IN DAMP LOCATIONS.

Make sure your extension cord is in a good condition. When using an extension cord, be sure to

use one heavy enough to carry the current your product will draw. An undersized cord will

cause a drop in line voltage, resulting in loss of power and overheating. The table below shows

the correct size to use according to cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number, the heavier the cord.

4

Extension cord sizes shown assure a voltage drop of not more than 5% at rated load

of tool.

Ampere rating

(on name plate)

3

6

10

13

Extension cord length

Wire size mm²

7.5m

0.75

0.75

1.0

1.25

15m

0.75

0.75

1.0

1.5

22.5m

0.75

0.75

1.0

1.5

30m

0.75

0.75

1.25

1.5

45m

0.75

1.25

1.5

2.5

WARNING ! THIS TOOL MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR

FROM ELECTRICAL SHOCK.

SAVE THESE SAFETY RULES !

Assembly

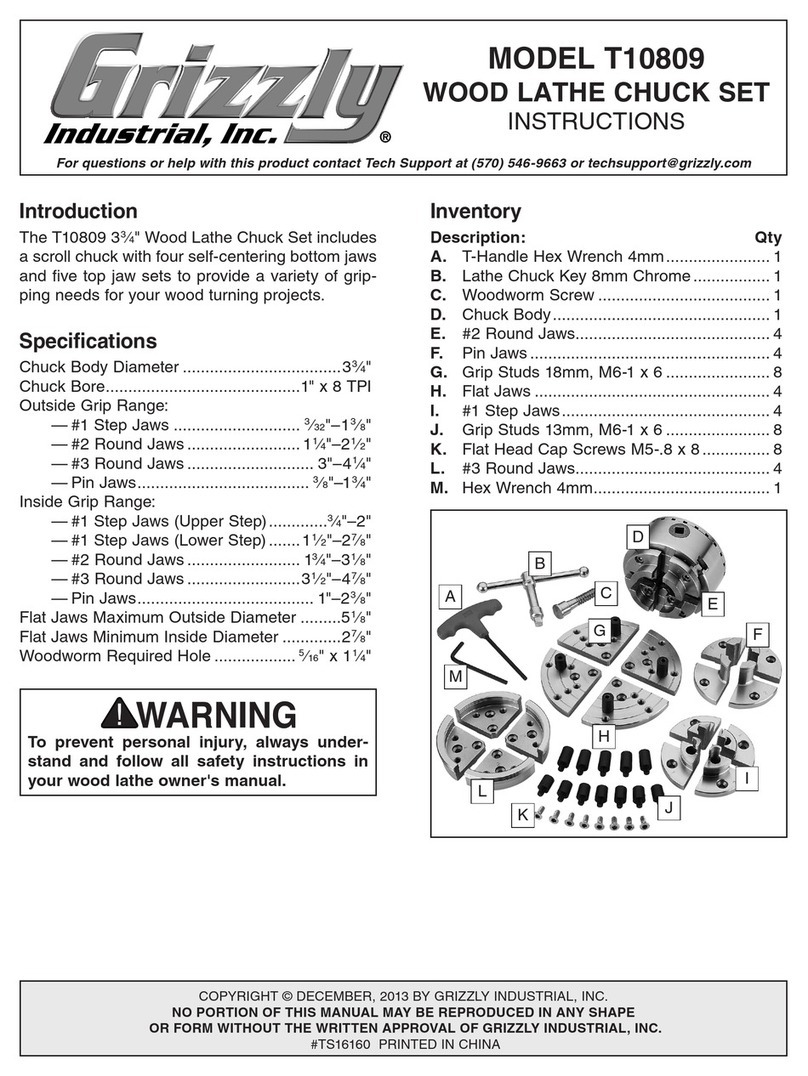

Unpacking (Fig 1)

1. Carefully remove the leg set and wood lathe from the carton.

CAUTION! THE WOOD LATHE IS VERY HEAVY AND MUST BE LIFTED WITH THE HELP OF 2

PEOPLE OR MORE. THE ASSEMBLY PROCESS REQUIRES 2 PEOPLE OR MORE TO SAFELY

ASSEMBLE THE LATHE TO THE LEG SET.

2. Separate the parts for the leg set from the parts of the lathe.

3. Lay out all parts and check them against the parts listed below. Examine all parts carefully.

WARNING! IF ANY PART IS MISSING OR DAMAGED, DO NOT PLUG THE WOOD LATHE IN

UNTIL YOU HAVE REPLACED THE MISSING OR DAMAGED PART.

For you safety, complete the assembly of the lathe before plugging it into the power supply.

5

1. Lathe bed assembly

2. Face plate

3. Headstock spur center

4. Tailstock cup center

5. Push rod

6. Flat wrenches

7. Hex key

8. Instruction panel

9. Hex bolt

10. Front leg & rear leg

Assembly

Setting the lathe on the leg set (Fig 3)

1. Place the lathe bed assembly [1] on the leg set.

2. Position the headstock [2] assembly over the top

plate and align the holes in the bed [3] with the holes

in the top plate [4]. Set the headstock down carefully.

3. Align the tailstock assembly end of the lathe over the

top plate mounting holes and set it down carefully.

4. Insert the hex bolts [5] into the mounting

holes in each bed and tighten securely.

IMPORTANT! THE LEG SET MUST BE FASTENED TO THE SUPPORTING SURFACE.

Faceplate (Fig 4)

1. Remove the headstock spur from the spindle.

2. Thread the 6 inch diameter faceplate to the Spindle.

3. Mount the workpiece to the faceplate with the flat

head brass wood screws. Make sure the length of the

screws does not interfere with the cutting tools.

6

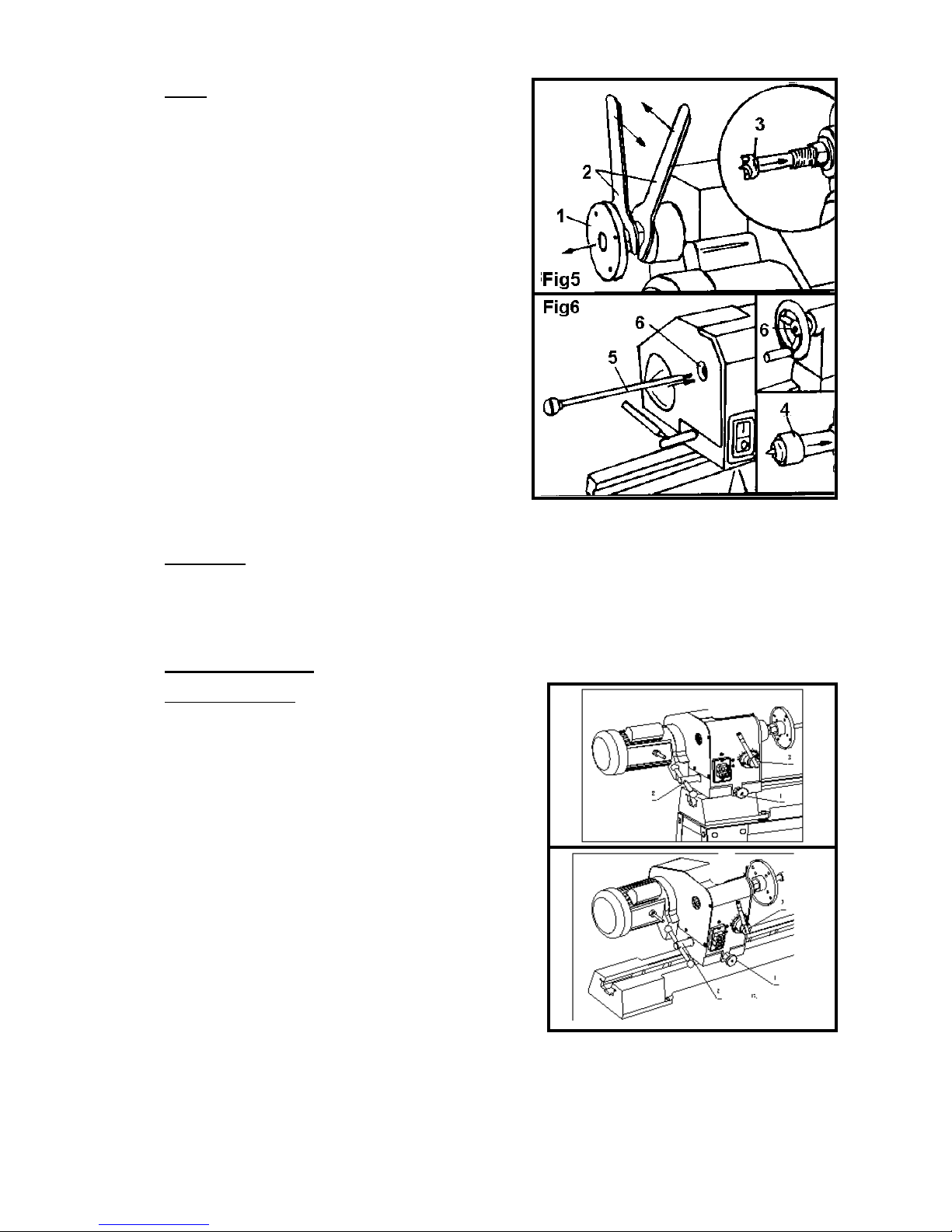

Spurs

1. Remove the faceplate [1] from the headstock spindle

using the two wrenches provided [2] to separate the

faceplate from the spindle nut. (Fig5)

2. Insert the headstock spur [3] in the spindle hole.

3. Insert the live center [4] in the tailstock hole. (Fig

6)

4. To remove either the headstock spur or the tailstock

center insert the push-out rod [5] into the hole [6] at

the opposite end of the headstock or tailstock. Remove

and store the rod in a safe location after use.

WARNING! Do not operate your wood lathe until it is completely assembled and adjusted

according to the instructions.

Adjustments

Headstock (Fig 7)

1. The headstock has 5 preset positions, 00 setting for all

spindle turning applications, 600/900/1200for use when

making face plate turnings, 1800for use for face plate

turnings when using the extension bed and tool rest.

2. To set the headstock at the desired position, you must

first turn the head lock handle [2] until you have

completed at least one rotation. (Fig 8)

3. Pull out the headstock release [1], rotate the entire

headstock clockwise to the desired position. The

headstock will be fixed in position when it clocks into one

of the five pre-set settings. Tighten the lock handle [2].

7

Operation

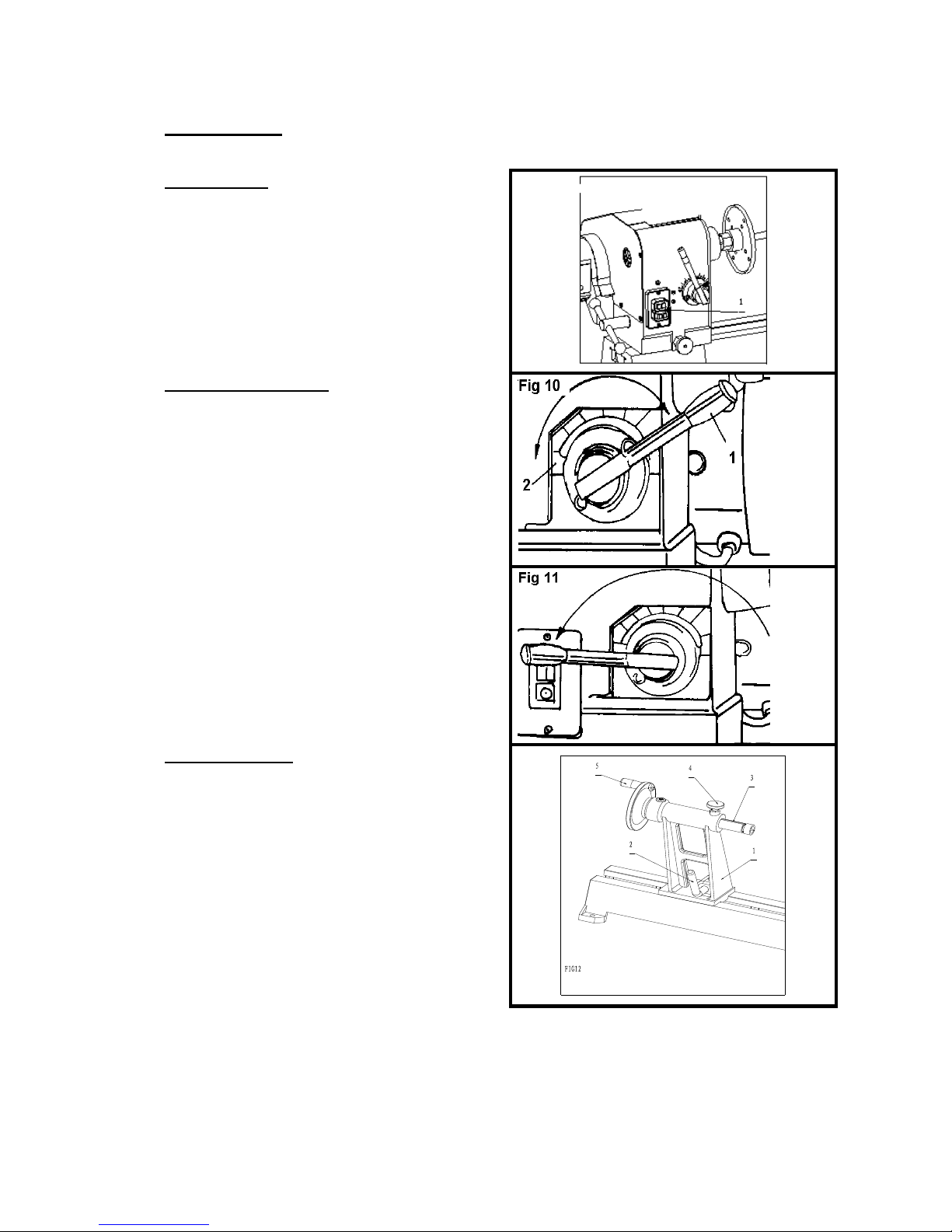

Switch (Fig 9)

The lathe is fitted with a no-volt switch. In the

event of a power supply failure the wood lathe

needs to be manually re-started by pushing the “I”

button on the switch.

Speed control (Fig 10)

1. The lathe motor must be running before you can

use the speed control lever.

2. The speed control lever can be turned to one of

ten fixed speeds. To set the speed, pull back on the

lever handle [1] and rotate the handle to the next

fixed speed. Use the index plate [2] to choose right

lathe speed.

3. Turn the lever clockwise to increase the speed

and turn counterclockwise to decrease the speed.

4. You must move the speed control lever to the

lowest speed setting before turning the switch off

(Fig 11), otherwise the motor may not start or be

damaged.

Tailstock (Fig 12)

1. Move the tailstock [1] by loosening the lock lever

[2] and pushing the tailstock to the desired position

on the bed. Lock by tightening the lock lever [2].

2. The spindle can extend up to 57mm from the

tailstock housing. You can move the tailstock

spindle [3] by loosening the spindle lock lever [4]

and then turning the hand wheel [5]. Lock the

levers [4] and [2] before operating lathe.

3. The tailstock spindle is hollow and can be

accessed from the hand wheel end. Use the

push-out rod to remove the center cup or to drill

holes through the center of a workpiece.

8

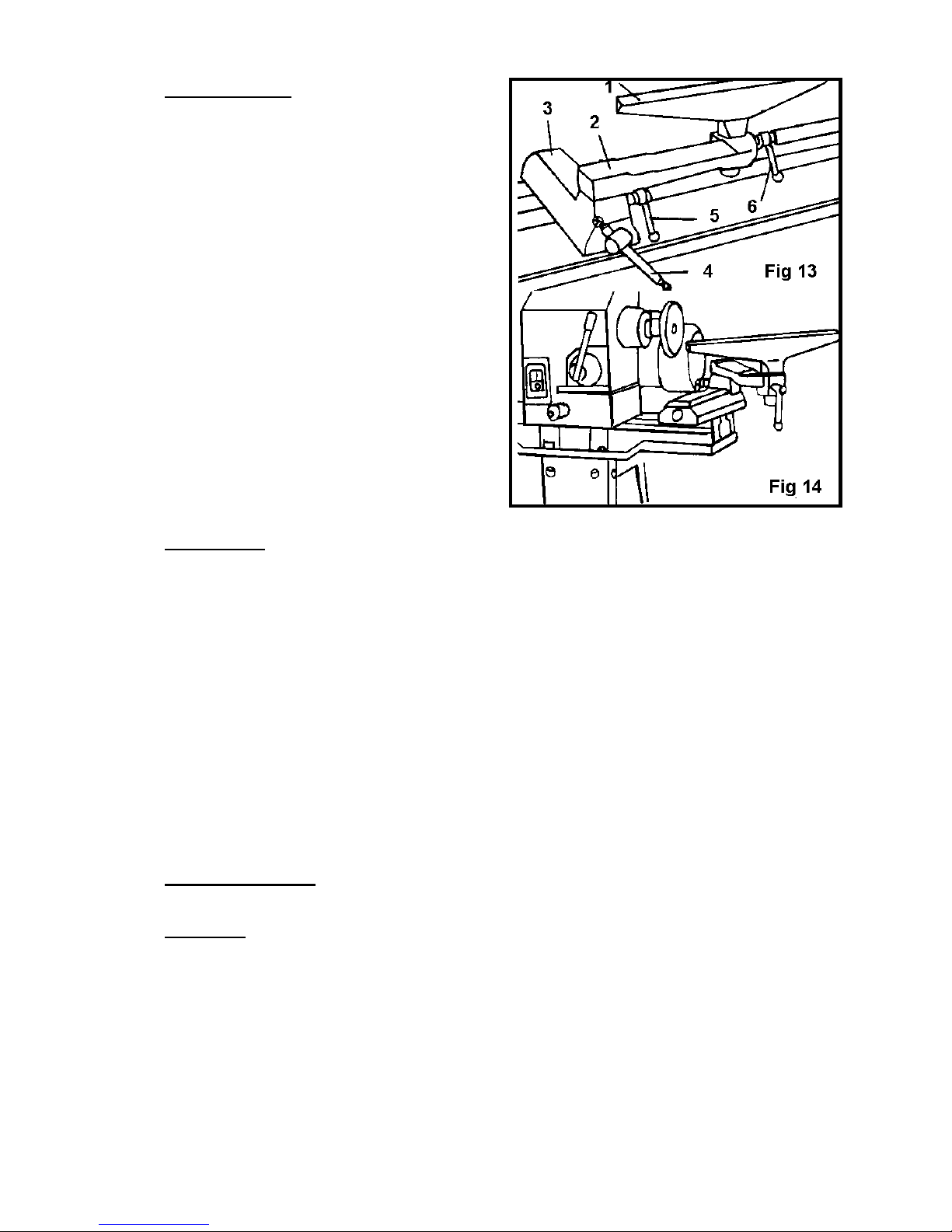

Tool rest (Fig 13)

1. The tool rest [1] can be used with or without the

arm [2].

2. To move the tool rest base [3], loosen the lock

lever [4], and move the base to the right or left and

back or front. Tighten the lever [4] when the tool

rest base is in the desired position.

3. When using the arm [2], make the necessary

adjustments using lick levers [5] and [6] to position

the tool rest.

4. Tighten all tool rest lever and handles [4-5-6]

and ensure there is adequate clearance between

the workpiece and the tool rest assembly before

turning the lathe on.

5. The tool rest can also be repositioned to the

extension bed for use on outboard turnings. (Fig

14)

IMPORTANT ! MAKE SURE THE TOOL REST IS ADJUSTED TO BE AS CLOSE TO THE

WORKPIECE AS POSSIBLE. ROTATE THE WORKPIECE BY HAND TO CHECK CLEARANCE BEFORE

TURNING THE LATHE ON.

Maintenance

WARNING! FOR YOUR OWN SAFETY, PUSH THE BUTTON "O" ON THE SWITCH AND REMOVE

THE PLUG FROM THE ELECTRICAL OUTLET BEFORE PERFORMING MAINTENANCE OR

LUBRICATION WORK ON THE LATHE.

1. Blow out dust accumulated inside the motor, housing, and bed assembly frequently.

2. A coat of automotive wax applied to the bed will help keep the surface clean and keep the

smooth movement of the tool rest and tailstock.

3. Periodic lubrication of the spring levers and other threaded parts will make these parts easier

to operate.

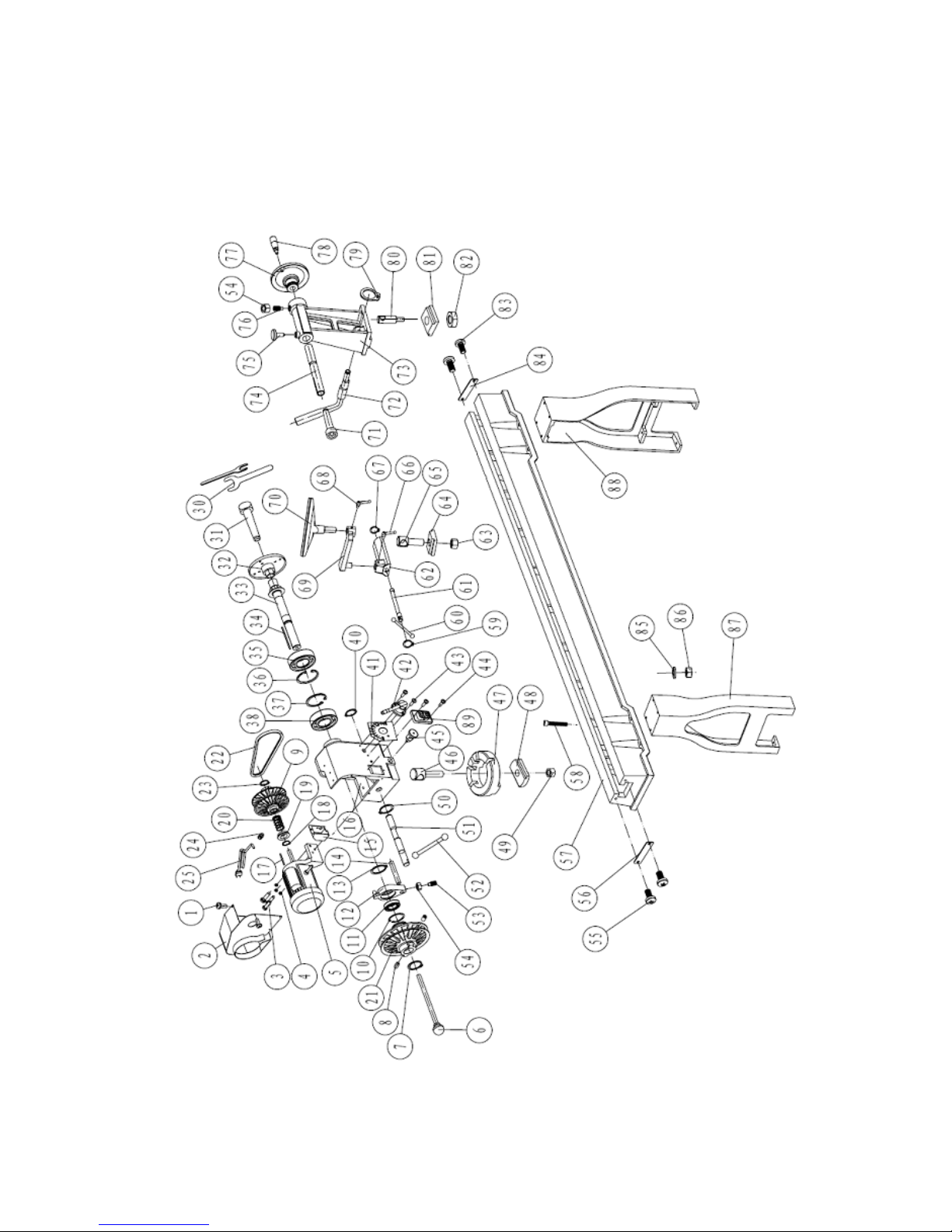

PARTS LIST

Part No

Description

Size

Q’ty

Part No

Description

Size

Q’ty

W1

Screw

M5X8

4

W50

“C” ring

24

1

W2

Cover –motor

1

W51

Lever

1

W3

Hex screw

M8X30

3

W52

Handle

1

W4

Washer

3

W53

Screw

M8x25

1

W5

Motor

1

W54

Nut

M8

2

W6

Pin-injection

1

W55

Screw

M5x12

2

W7

“C'' ring

24

1

W56

Plate

1

W8

Screw

M6

2

W57

Bed

1

W9

Motor Pulley Set, L&R

1

W58

Bolt

M8x35

8

W10

“C” ring

62

1

W59

“C” ring

19

1

W11

Bearing

6007

1

W60

Handle

1

W12

Bracket-Shifting Lever

1

W61

Shaft

1

W13

“C” ring

35

1

W62

Tool Rest Body

1

W14

Rack

1

W63

Nut

M18

1

W15

Switch Box

1

W64

Clamp

1

W16

Headstock

1

W65

Bolt-A

1

W17

Key 4x4x80

1

W66

Handle Assembly

1

W18

“C” ring

16

1

W67

“C” ring

19

1

W19

Sleeve

1

W68

Handle Assembly

1

W20

Spring

1

W69

Extension Tool Rest

1

W21

Spindle Pulley Set, L&R

1

W70

Tool Rest

1

W22

V-Belt 625

1

W71

Center

1

W23

“C” ring

16

1

W72

Shaft

1

W24

Plastic Jaw Nut M20x1.5

3

W73

Tailstock

1

W25

Power Wire

1

W74

Tail Spindle

1

W30

Wrench

2

W75

Quill Locking Screw

1

W31

Drive Center

1

W76

Cone Set Screw

1

W32

Disc

1

W77

Handle Wheel

1

W33

Spindle

1

W78

Handle

1

W34

Key 4x4x80

1

W79

“C” ring

10

1

W35

Bearing

6205

1

W80

Special Bolt

1

W36

“C” ring

52

1

W81

Clamp

1

W37

“C” ring

52

1

W82

Nut

M10

1

W38

Bearing

6205

1

W83

Screw

M5x12

2

W40

“C” ring

24

1

W84

Plate

1

W41

Label for Sped

1

W85

Washer

8

4

W42

Gear Assembly

1

W86

Nut

M8

4

W43

Screw

M5x12

2

W87

Leg

1

W44

Screw

M4x12

3

W88

Leg

1

W45

Angular setting assembly

1

W89

Switch

1

W46

Special Screw

1

W47

Index Bracket

1

W48

Clamp

1

W49

Nut

M18

1

10

PARTS DIAGRAM:

11

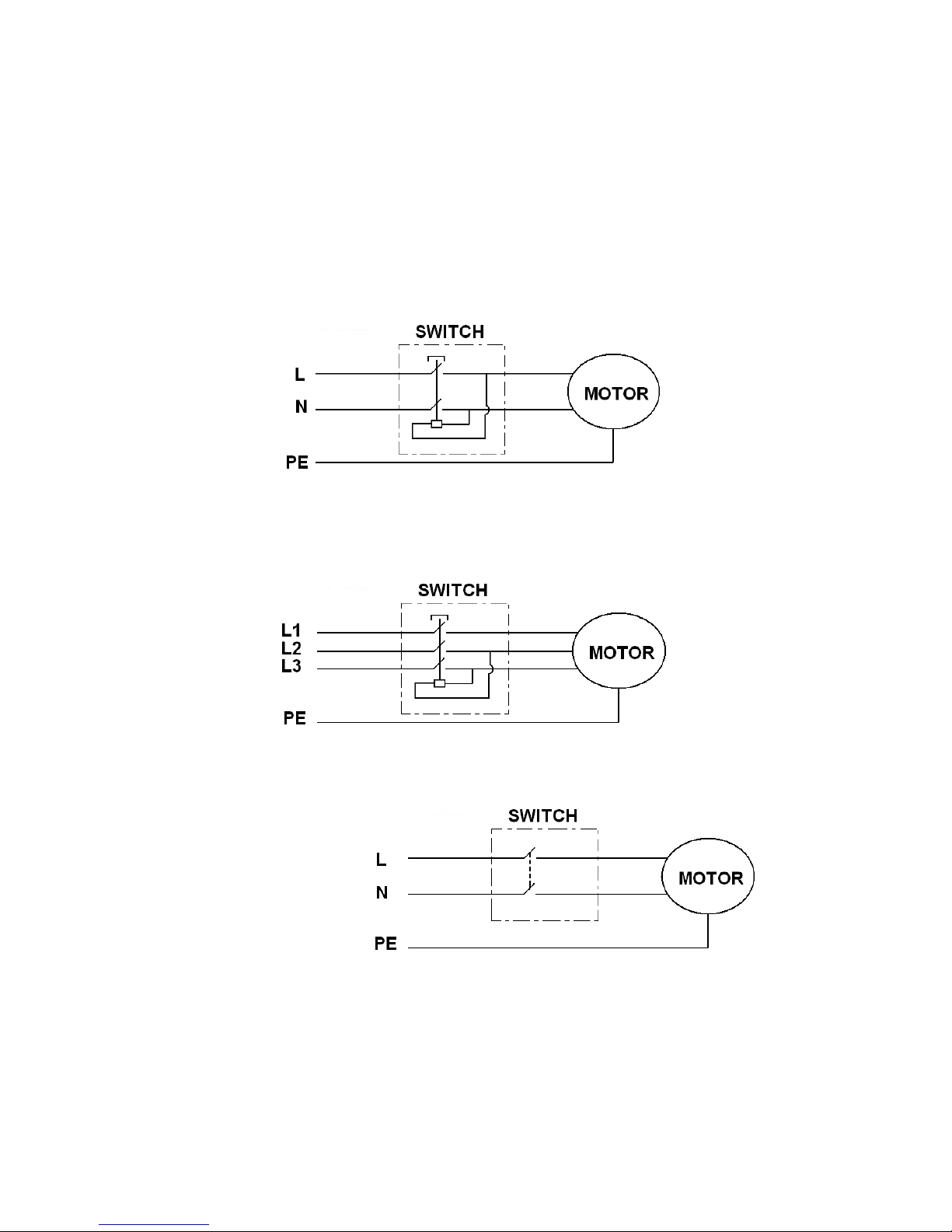

WIRING DIAGRAM:

1.220-240V/50Hz, 1 Phase

2.380-400V/50Hz, 3 Phase

3. 110-120V/60Hz, 1 Phase

Table of contents

Popular Lathe manuals by other brands

WoodFast

WoodFast WL1216B instruction manual

Climax

Climax BB4500 operating manual

Clarke

Clarke WOODWORKER CWL325V Operation & maintenance instructions

Gude

Gude GMH 2000 Translation of the original instructions

Scheppach

Scheppach 4902301901 Translation from the original instruction manual

tornos

tornos MultiDeco Series Equipment Logbook Assembly, operation and maintenance