-8-

4.2 CONTENTS OF PACKAGE

WARNING

4. INSTALLATION

4.1 MOVING & INSTALLING THE LATHE

The machine must not be plugged in and the power switch must be in the OFF position untill

installation is complete.

1. When moving the lathe, DO NOT use the headstock assembly, motor, tool rest or tailstock as this may damage the

machine. Hold under the lathe’s bed to lift and move the machine. Straps or battens placed under the lathe bed can

also be used to move the machine.

2. Position the machine on a solid stand, or bench, that is located in an area that has ample space in front and in back

of the lathe for working and moving around the lathe.

3. For best power and safety, the lathe should be plugged directly into a dedicated grounded electrical outlet that is

within the supplied cord length of the machine. The use of an extension cord is not recommended.

4. Align the machine so that during use, any turning debris or kickback will not face aisles, doorways, or other work

areas that bystanders may be in. Do not locate or use the machine in damp or wet conditions.

5. Once in place in your shop, make sure that the machine is level. If possible, secure the machine, or stand to the floor,

or bench, with lag screws (not supplied). This will reduce any possible vibration during use.

A. Lathe Bed Assembly - including;

B. Motor Assembly

C. Headstock Assembly

D. Tool Rest Base Assembly

E. Tailstock Assembly

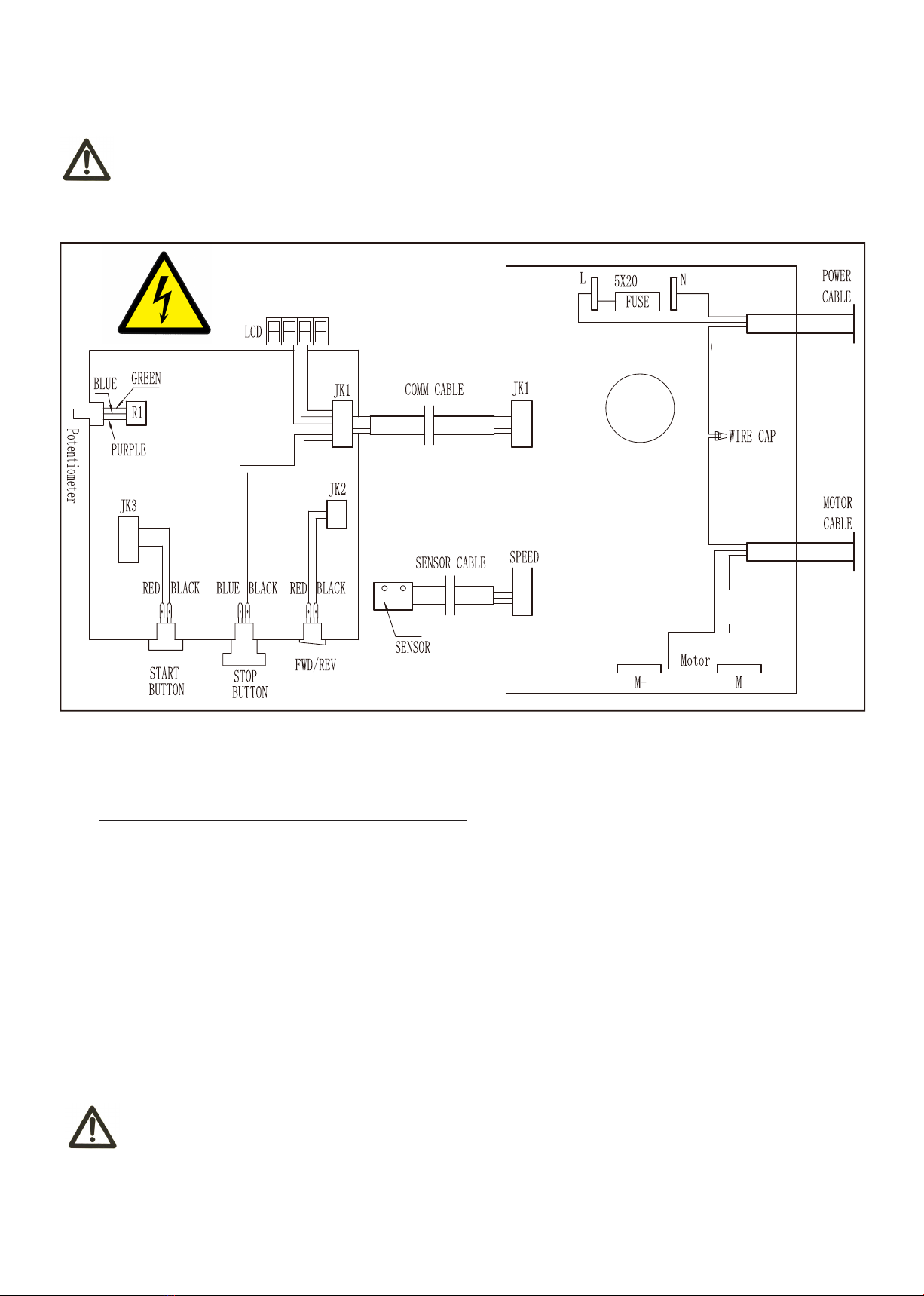

F. Electronic Controls

CONTENTS OF PACKAGE

LIST OF LOOSE PARTS

G. 3” Faceplate

H. 6” PRO Tool Rest

I. Spur Center

J. Live Center

K. Long Knockout Bar

L. Short Knockout Bar

M. Hex Wrenches (2.5, 3, 4, 5 mm)

N. Wrenches (38 & 46 mm)

O. Spanner Wrench (35 mm)

P. Tool Holder, Screws & Washers (2)

Q. Outboard Hand Wheel

R. Tailstock Hand Wheel

A

E

B

C

F

G

D

H

I

J

L

K

M

N

O

ADDITIONAL TOOLS REQUIRED FOR ASSEMBLY & ADJUSTMENTS

#2 Phillips Screwdriver Adjustable Wrench

P

NOTE: Lathe shown with Outboard Hand Wheel * on the

Headstock and Tailstock Hand Wheel ** installed.

Lathe is shown on the #70-920 Stand (sold separately)

***

Q

R

CONTENTS OF PACKAGE

A. Lathe Bed Assembly - including;

B. Motor Assembly

C. Headstock Assembly

D. Tool Rest Base Assembly

E. Tailstock Assembly

F. Electronic Controls

NOTE: Lathe shown with Outboard Hand Wheel * on the

Headstock and Tailstock Hand Wheel ** installed. Lathe is

shown on the Stand (sold separately)

LIST OF LOOSE PARTS

G. 3” Faceplate

H. 8” PRO Tool Rest

I. Spur Center

J. Live Center

K. Long Knockout Bar

L. Short Knockout Bar

M. Hex Wrenches (2.5, 3, 4, 5 mm)

N. Wrenches (38 & 46 mm)

O. Tool Holder, Screws & Washers (2)

P. Outboard Hand Wheel

Q. Tailstock Hand Wheel

A. Lathe Bed Assembly - including;

B. Motor Assembly

C. Headstock Assembly

D. Tool Rest Base Assembly

E. Tailstock Assembly

F. Electronic Controls

CONTENTS OF PACKAGE

LIST OF LOOSE PARTS

G. 3” Faceplate

H. 6” PRO Tool Rest

I. Spur Center

J. Live Center

K. Long Knockout Bar

L. Short Knockout Bar

M. Hex Wrenches (2.5, 3, 4, 5 mm)

N. Wrenches (38 & 46 mm)

O. Spanner Wrench (35 mm)

P. Tool Holder, Screws & Washers (2)

Q. Outboard Hand Wheel

R. Tailstock Hand Wheel

A

E

B

C

F

G

H

I

J

L

K

M

N

O

ADDITIONAL TOOLS REQUIRED FOR ASSEMBLY & ADJUSTMENTS

#2 Phillips Screwdriver Adjustable Wrench

P

NOTE: Lathe shown with Outboard Hand Wheel * on the

Headstock and Tailstock Hand Wheel ** installed.

Lathe is shown on the #70-920 Stand (sold separately)

***

Q

R

A. Lathe Bed Assembly - including;

B. Motor Assembly

C. Headstock Assembly

D. Tool Rest Base Assembly

E. Tailstock Assembly

F. Electronic Controls

CONTENTS OF PACKAGE

LIST OF LOOSE PARTS

G. 3” Faceplate

H. 6” PRO Tool Rest

I. Spur Center

J. Live Center

K. Long Knockout Bar

L. Short Knockout Bar

M. Hex Wrenches (2.5, 3, 4, 5 mm)

N. Wrenches (38 & 46 mm)

O. Spanner Wrench (35 mm)

P. Tool Holder, Screws & Washers (2)

Q. Outboard Hand Wheel

R. Tailstock Hand Wheel

A

E

B

C

F

G

D

H

I

J

L

K

M

N

O

ADDITIONAL TOOLS REQUIRED FOR ASSEMBLY & ADJUSTMENTS

#2 Phillips Screwdriver Adjustable Wrench

P

NOTE: Lathe shown with Outboard Hand Wheel * on the

Headstock and Tailstock Hand Wheel ** installed.

Lathe is shown on the #70-920 Stand (sold separately)

***

Q

R

A. Lathe Bed Assembly - including;

B. Motor Assembly

C. Headstock Assembly

D. Tool Rest Base Assembly

E. Tailstock Assembly

F. Electronic Controls

CONTENTS OF PACKAGE

LIST OF LOOSE PARTS

G. 3” Faceplate

H. 6” PRO Tool Rest

I. Spur Center

J. Live Center

K. Long Knockout Bar

L. Short Knockout Bar

M. Hex Wrenches (2.5, 3, 4, 5 mm)

N. Wrenches (38 & 46 mm)

O. Spanner Wrench (35 mm)

P. Tool Holder, Screws & Washers (2)

Q. Outboard Hand Wheel

R. Tailstock Hand Wheel

A

E

B

C

F

G

D

H

I

J

L

K

M

N

O

ADDITIONAL TOOLS REQUIRED FOR ASSEMBLY & ADJUSTMENTS

#2 Phillips Screwdriver Adjustable Wrench

P

NOTE: Lathe shown with Outboard Hand Wheel * on the

Headstock and Tailstock Hand Wheel ** installed.

Lathe is shown on the #70-920 Stand (sold separately)

***

Q

R

A. Lathe Bed Assembly - including;

B. Motor Assembly

C. Headstock Assembly

D. Tool Rest Base Assembly

E. Tailstock Assembly

F. Electronic Controls

CONTENTS OF PACKAGE

LIST OF LOOSE PARTS

G. 3” Faceplate

H. 6” PRO Tool Rest

I. Spur Center

J. Live Center

K. Long Knockout Bar

L. Short Knockout Bar

M. Hex Wrenches (2.5, 3, 4, 5 mm)

N. Wrenches (38 & 46 mm)

O. Spanner Wrench (35 mm)

P. Tool Holder, Screws & Washers (2)

Q. Outboard Hand Wheel

R. Tailstock Hand Wheel

A

E

B

C

F

G

D

H

I

J

L

K

M

N

O

ADDITIONAL TOOLS REQUIRED FOR ASSEMBLY & ADJUSTMENTS

#2 Phillips Screwdriver Adjustable Wrench

P

NOTE: Lathe shown with Outboard Hand Wheel * on the

Headstock and Tailstock Hand Wheel ** installed.

Lathe is shown on the #70-920 Stand (sold separately)

***

Q

R

A. Lathe Bed Assembly - including;

B. Motor Assembly

C. Headstock Assembly

D. Tool Rest Base Assembly

E. Tailstock Assembly

F. Electronic Controls

CONTENTS OF PACKAGE

LIST OF LOOSE PARTS

G. 3” Faceplate

H. 6” PRO Tool Rest

I. Spur Center

J. Live Center

K. Long Knockout Bar

L. Short Knockout Bar

M. Hex Wrenches (2.5, 3, 4, 5 mm)

N. Wrenches (38 & 46 mm)

O. Spanner Wrench (35 mm)

P. Tool Holder, Screws & Washers (2)

Q. Outboard Hand Wheel

R. Tailstock Hand Wheel

A

E

B

C

F

G

D

H

I

J

L

K

M

N

O

ADDITIONAL TOOLS REQUIRED FOR ASSEMBLY & ADJUSTMENTS

#2 Phillips Screwdriver Adjustable Wrench

P

NOTE: Lathe shown with Outboard Hand Wheel * on the

Headstock and Tailstock Hand Wheel ** installed.

Lathe is shown on the #70-920 Stand (sold separately)

***

Q

R

ADDITIONAL TOOLS REQUIRED FOR ASSEMBLY & ADJUSTMENTS

O

P

Q