Jefferson JEFJKGAR03 User manual

User Manual

v.1.1

JEFJKGAR03

TROLLEY JACK

3 TONNE

2

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

3

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

1. Safety

IMPORTANT: READ ALL INSTRUCTIONS BEFORE USE

Regularly inspect and lubricate the jack to ensure it is in good

working order and condition. DO NOT use the jack if damaged

or a fault is suspected - check Section 6 Troubleshooting. If

necessary, immediately repair or replace damaged parts.

• Use recommended parts only, the use of unauthorised parts

may be dangerous and will invalidate your warranty.

• Ensure the work area is clean, tidy and free from unrelated

materials and has adequate lighting.

• Use jack on level and solid ground, preferably concrete.

Avoid tarmacadam since jack may sink in.

• Park the vehicle and apply hand brake (if automatic, place in

“Park” mode). Switch off the engine and place chocks under

the wheels.

• Ensure a minimum distance of 0.5m between vehicle and

static objects such as doors, walls, etc. to allow for tilting

during jacking.

• Ensure all persons are out of the vehicle before jacking.

DO NOT enter vehicle whilst it is supported on the jack or

axle stands.

• Check vehicle weight and recommended lifting points by

referring to the vehicle owner’s manual. Ensure the lifting

point is not corroded.

• Check lifting point is centred and stable on jack saddle (off

centre loads can slip). Position jack so as to avoid operating

it from under vehicle.

• Keep hands etc. clear of moving parts during raising and

lowering of the vehicle.

DANGER! Roadside wheel changing is hazardous. Be extra

vigilant, you may not be able to avoid jacking on tarmacadam.

Get everyone out of vehicle. NEVER go under vehicle. Traffic

may cause vehicle to rock. Use hazard warning lights. If in

doubt call professional help.

• When changing a wheel, slightly loosen wheel nuts/bolts

prior to jacking vehicle. Screw wheel nuts/bolts back before

lowering vehicle. Finally tighten when vehicle is fully lowered.

• Use a qualied person to lubricate and maintain the jack.

Conrm that only recommended hydraulic jack oil is used

during maintenance.

• DO NOT exceed the rated capacity of the jack and DO NOT

operate the jack beyond its maximum pump stroke.

WARNING! DO NOT allow the vehicle to move, or try to start

the engine, when the vehicle is jacked up.

• Ensure there are no persons or obstructions beneath the

vehicle before lowering.

• Clean and securely stow the jack with the ram in the down

position. DO NOT leave the ram extended. Ensure stowage

area is dry.

WARNING! Remember, it is very dangerous to go under a

vehicle supported by a jack even if additional supports are used.

DANGER! USE THE JACK FOR LIFTING ONLY, NOT

FOR SUPPORTING THE LIFTED LOAD. ALWAYS USE

ADEQUATELY RATED AXLE STANDS.

• DO NOT jack a vehicle if it may result in the spillage of fuel,

battery acid, or other dangerous substances.

• DO NOT place any part of your body under vehicle whilst

it is supported by the jack. Wait until adequately rated axle

stands have been correctly positioned.

• DO NOT use jack to support extensions or cradles.

DO NOT modify jack in any way. DO NOT use the jack

for any other purpose.

• DO NOT top up jack with brake uid. Use hydraulic oil only.

DO NOT adjust the safety overload valve.

• DO NOT go under a vehicle unless it is supported by

adequately rated axle stands. NOTE: Seek advice before

jacking caravans or trailers.

4

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

WARNING! BEFORE LIFTING ENSURE SECTION 1 SAFETY INSTRUCTIONS

ARE STRICTLY FOLLOWED.

1. Line up the holes in the two-piece handle and fasten with the assembly screw.

2. Loosen the location bolt at the side of the handle base. Insert jack handle and

tighten the bolt.

LIFTING

WARNING! ENSURE YOU PREPARE VEHICLE AND USE JACK ACCORDING TO

SECTION 1 SAFETY INSTRUCTIONS.

• Check that the ground upon which the jack will stand is level and solid.

• Position the jack saddle under the vehicle manufacturer’s recommended lifting point.

Position jack so as to avoid having to operate it from under the vehicle and so that

the handle can be moved up and down without hitting any part of the vehicle.

• Using the screw extension as necessary, raise the saddle to the lifting point. Ensure

that the saddle is correctly centred beneath the lifting point.

• Pump the handle up and down using full stroke until the required lift is achieved.

• Should the jack become overloaded, a safety overload valve will open, and stop the

vehicle from lifting.

• Lower the vehicle onto suitable axle stands before attempting any work.

LOWERING

• Ensure that the axle stands are removed and that there are no persons or obstacles beneath the vehicle,

or in the path of its descent.

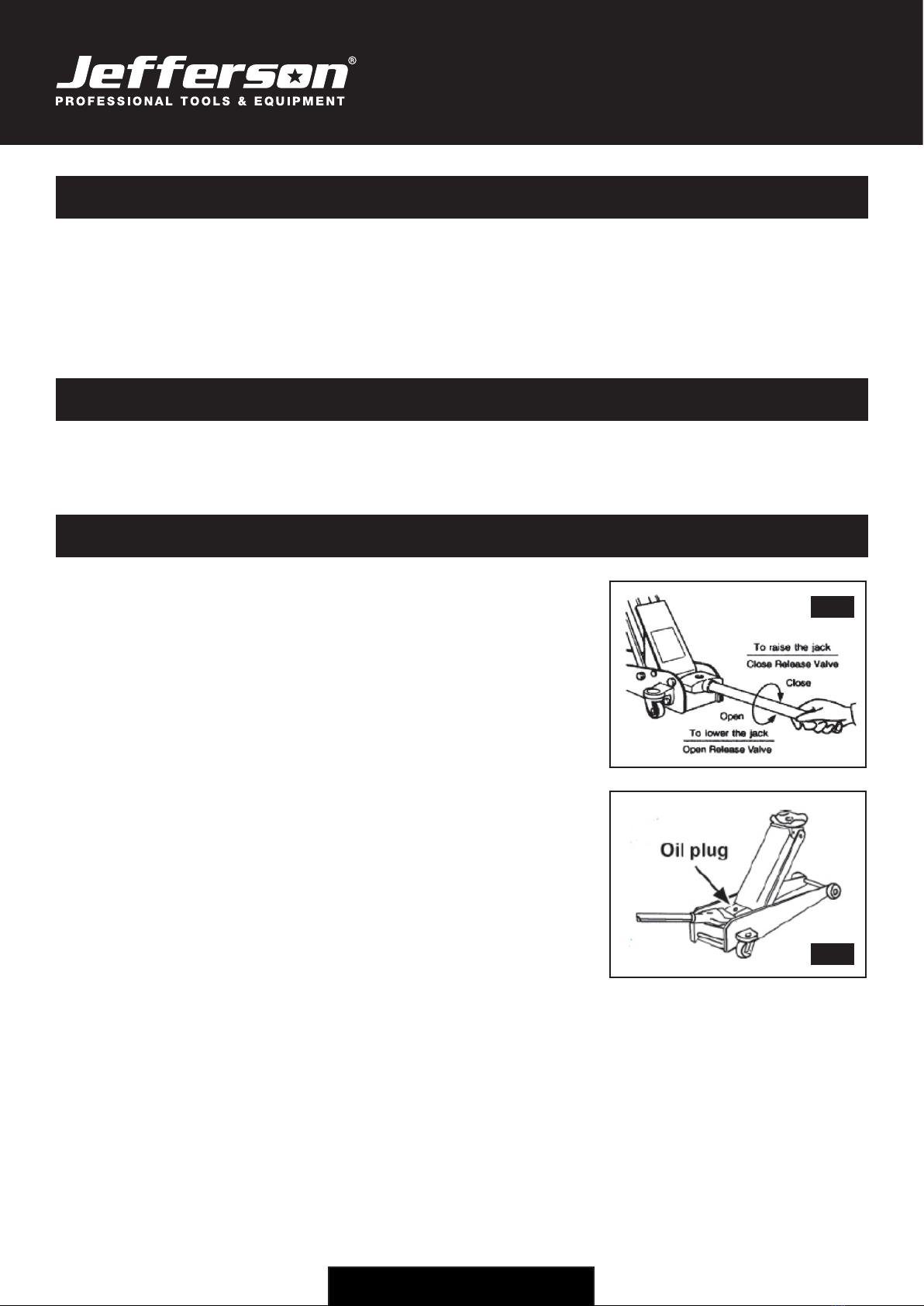

• The lowering speed is controlled by the amount the release valve is opened.

Turn valve anti-clockwise and lower slowly and carefully.

WARNING: DO NOT USE THE JACK IF YOU BELIEVE IT HAS BEEN SUBJECTED TO ABNORMAL LOAD OR SHOCK.

INSPECT AND TAKE APPROPRIATE ACTION.

• Before each use check for broken, cracked, bent, or loose parts. Also check for any visible damage to welds, ram,

pump, body and base.

• If any suspect item is found remove jack from service and take the necessary action to remedy the problem.

• Periodically check the pump piston and piston rod for signs of corrosion. Clean exposed areas with a clean oiled cloth.

2. Features

3. Specification

4. Operation

Model Number: JEFJKGAR03

Length: 630mm

Capacity: 3 Tonne

Weight: NW: 29.3Kg / GW: 31Kg

Minimum Height: 130mm

Maximum Height: 465mm

• Heavy-duty steel construction provides

stability and endurance

• Swivel saddle and rear casters allows

smooth manoeuvring

• Lifting range: 130mm to 465mm

• Hydraulic oil by-pass system protects

ram from being over-extended

• Twin pump mechanism for smooth &

quick lifting

• Built-in safety valve protects against

jack over-loading

Warning: This equipment is designed

for lifting purpose only, always use axle

stands and wheel chocks to support the

vehicle.

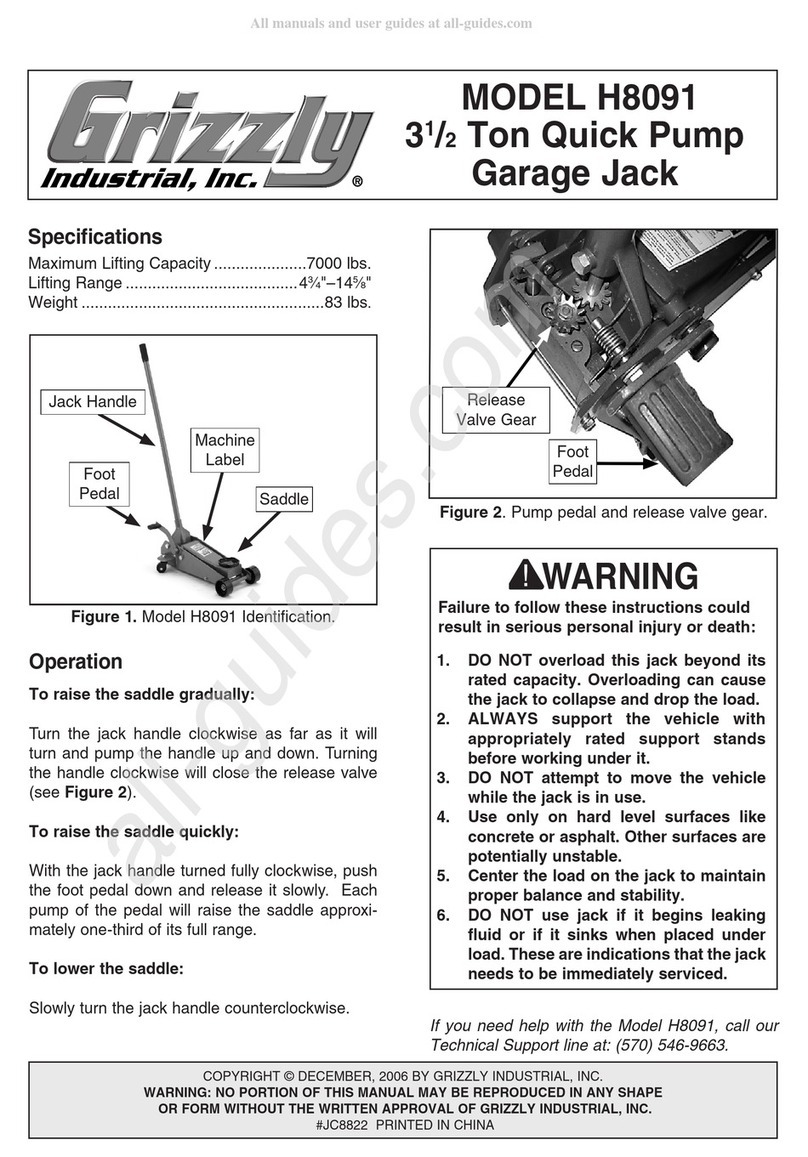

FIG. 1

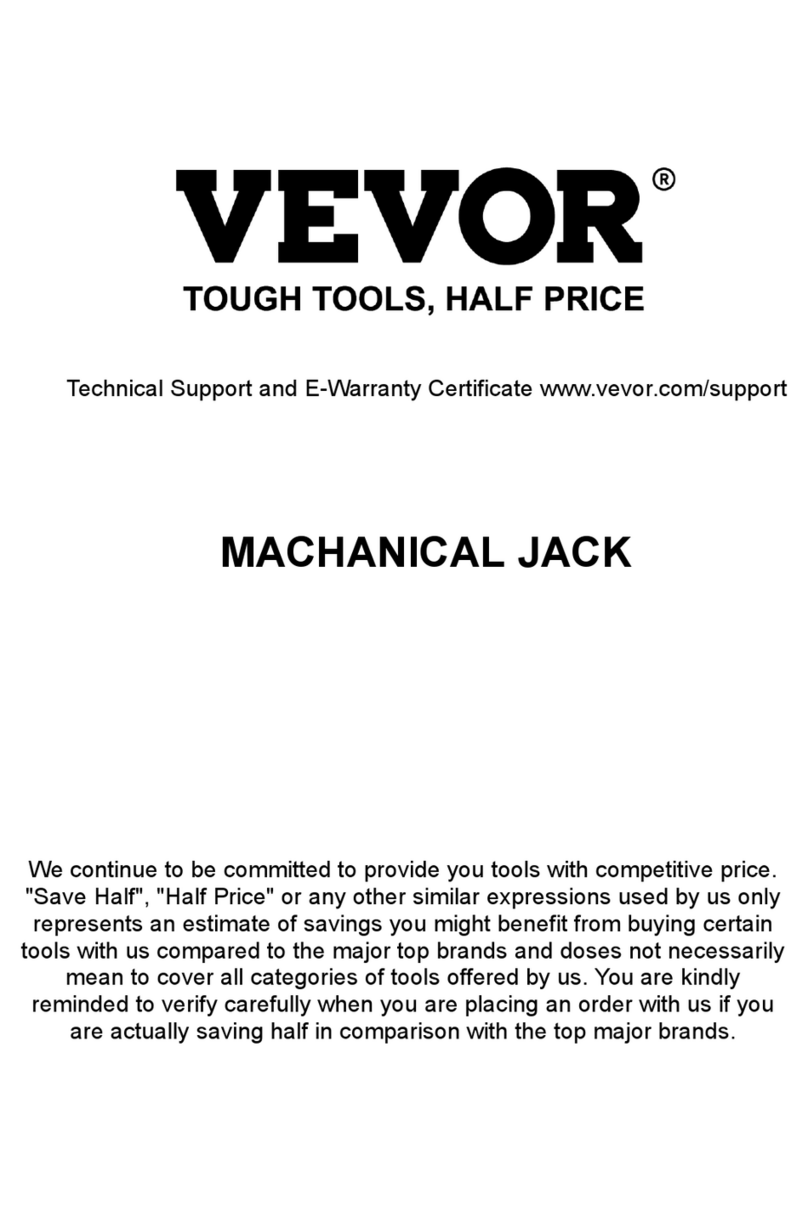

FIG. 2

5

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

5. Maintenance

6. Troubleshooting

IMPORTANT: ONLY FULLY QUALIFIED PERSONNEL SHOULD ATTEMPT MAINTENANCE OR REPAIR

WARNING: DO NOT USE BRAKE FLUID, OR ANY FLUID OTHER THAN HYDRAULIC JACK FLUID, AS TO DO SO MAY

CAUSE SERIOUS DAMAGE TO THE JACK AND WILL INVALIDATE THE WARRANTY!

• When the jack is not in use, the ram and piston must be in their lowest positions to minimise corrosion.

Remove the handle to inactivate jack.

• Keep the jack clean and lubricate all moving parts with acid free oil on a regular basis.

• To check the hydraulic oil level, fully lower the jack and remove the oil ller plug (Fig. 2). The correct oil level should be

approximately 5mm below the ller opening. If oil level is low, ll as required.

• After a year of extensive use, the oil should be replaced in order to extend the life of the jack. Drain the oil through the

ller plug opening. Make sure that no dirt is allowed to enter the jack or the fresh oil.

• To replace the oil ll as required. Pump unloaded jack 5 or 6 times to expel air and then ret the plug.

Note: Ensure waste oil is disposed of in accordance with local authority regulations.

TO PURGE AIR FROM THE SYSTEM

• Turn the handle counter clockwise one full turn to open.

• Pump the handle eight full strokes.

• Turn handle clockwise to close the valve.

• Pump the handle until the ram reaches maximum height and continue to pump several times to remove air trapped in the ram.

• Turn the handle counter clockwise one full turn and lower the ram to the lowest position. Use force on the saddle if necessary.

• Turn the handle clockwise to the closed position and check for proper pump action. It may be necessary to perform the above

procedure more than once to ensure all the trapped air is evacuated.

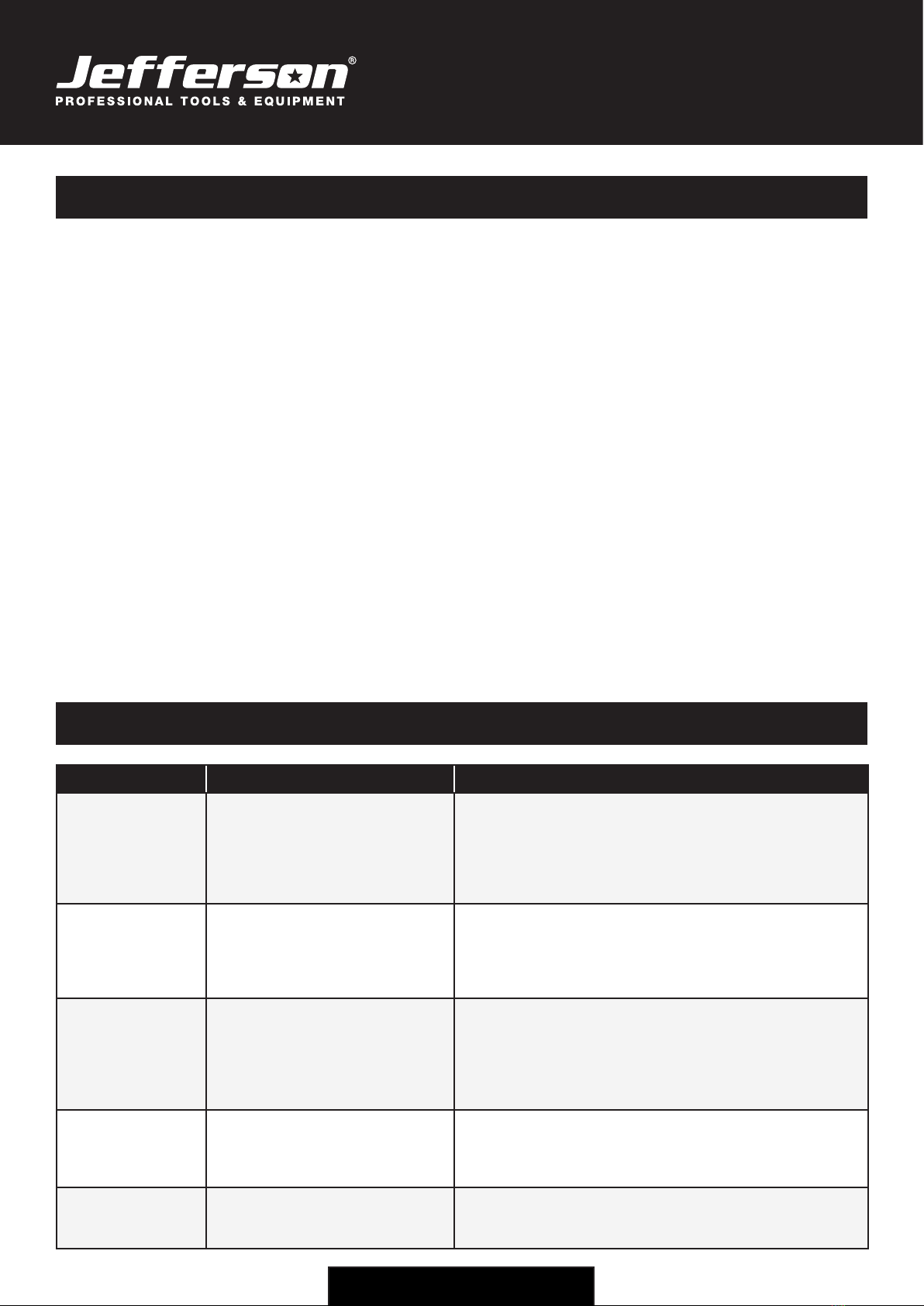

Symptom Possible Cause Corrective Action

Jack will not lift the

load

1. Overloaded

2. Oil level low

3. Release valve not correctly closed

4. Air in system

5. Packing worn or defective

1. Be sure to use jack with adequate capacity

2. Top up oil level

3. Check and close release valve

4. Open release valve and air vent (if fitted) and pump the handle

a few times. Close valve and re-try

5. Return jack to local service agent

Jack does not lift

high enough or feels

“spongy”

1. Low oil level

2. Worn seals

3. Air in system

4. Release valve not closed

1. Top up oil level

2. Return jack to local service agent

3. Open release valve and air vent (if fitted) and pump the handle

a few times. Close valve and re-try

4. Check and close release valve

Jack will not hold the

load

1. Release valve partially open

2. Dirt on valve seals

3. Air in system

4. Faulty seals

1. Check and close release valve

2. Lower jack, close release valve. Pull up lifting arm to full

height by hand. Open the release valve to lower arm

3. Open release valve and air vent (if fitted) and pump the handle

a few times. Close valve and re-try

4. Return jack to local service agent

Jack will not descend

to minimum height,

or will not remain in

lowered position

1. Ram damaged

2. Air in system

3. Release valve partially open

1. Contact local service agent

2. Open release valve and air vent (if fitted) and pump the handle

a few times. Close valve and re-try

3. Check and fully open release valve

Jack will not function

properly after trying

solutions above

1. Internal malfunction or structural

damage

1. Stop usage and contact an authorized repair centre

6

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

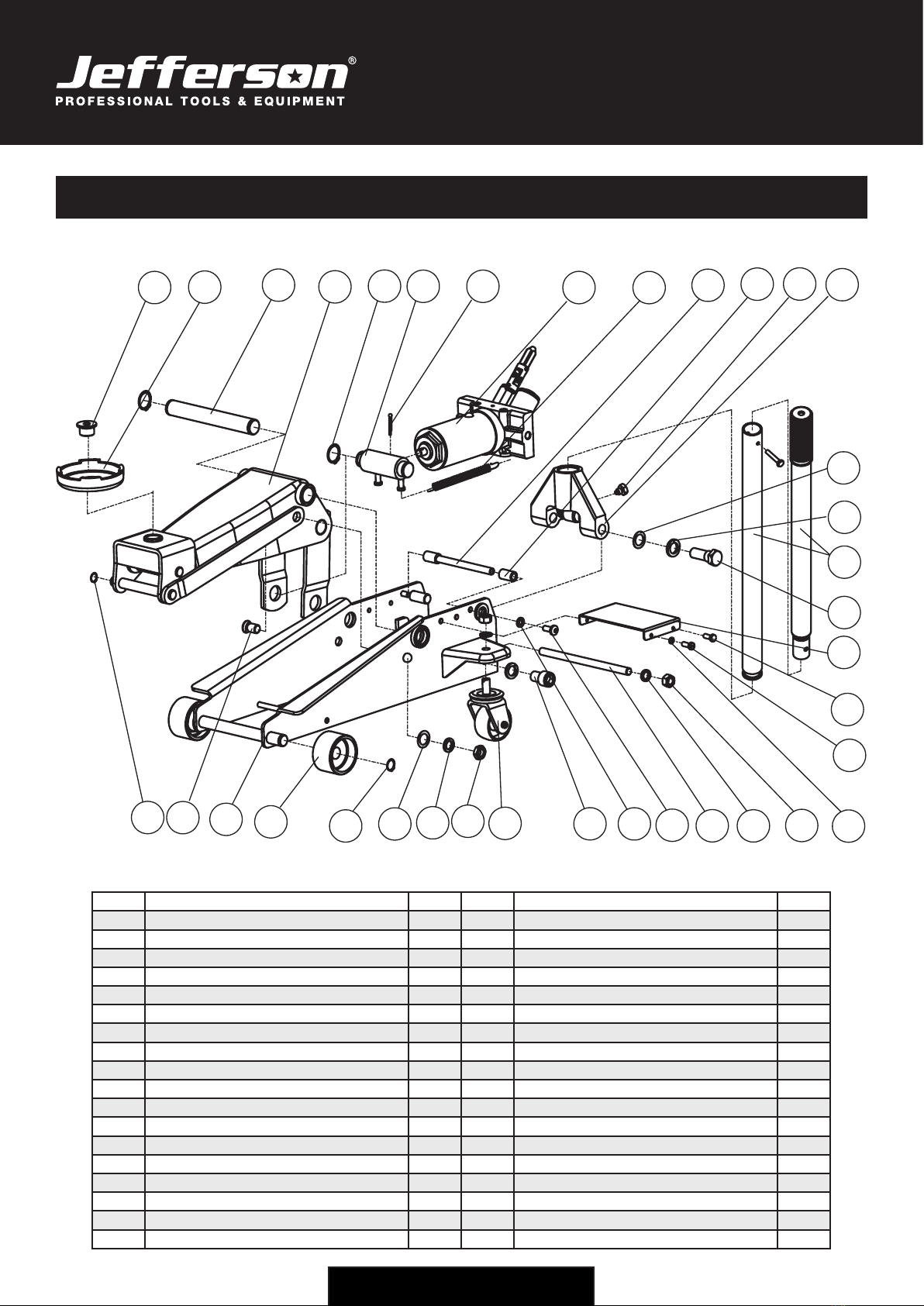

7. Parts Diagram

1

2

3

4

5

6

7

8

910 11 12 13 15 16 17 18 19 20 21 22 23 24

25

26

27

28

29

30

31

32

33

34

35

36

14

ITEM DESCRIPTION QTY ITEM DESCRIPTION QTY

1 Cylinder Assembly 1 19 Washer 8mm Diameter 2

2 Cotter Pin 1 20 Screw M8X16 2

3 Linkage 1 21 Back Shaft 1

4 Retaining Ring 4 22 Retaining Ring 6

5 Lifting Arm Assembly 1 23 Nut M12 4

6 Supporting Shaft 1 24 Washer 2

7 Saddle 1 25 Screw M6X10 2

8 Screw 1 26 Cover Plug 2

9 Retaining Ring 2 27 Cover Board 12

10 Linking Pin 2 28 Right Bolt 1

11 Wall Plate Assembly 1 29 Handle 2

12 Front Wheel 2 30 Washer 2

13 Retaining Ring 2 31 Shaft Gasket 1

14 Washer 2 32 Handle Socket 1

15 Retaining Washer 16 2 33 Screw 2

16 Nut M16 2 34 Rubber Sleeve 1

17 Rear Wheel Assembly 2 35 Handle Shaft 2

18 Bolt M12X25 2 36 Spring 1

7

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

ITEM DESCRIPTION QTY ITEM DESCRIPTION QTY

1 Screw 1 25 O Ring 2

2 O Ring 1 26 Plug 1

3 Spring 1 27 Screw 1

4 Spring Base 1 28 Safety Spring 1

5 Ball Bearing 5mm Diameter 6 29 Spring Base 1

6 Pump Piston 1 30 Ball Bearing 5mm Diameter 1

7 Circlip 2 31 Base 1

8 O Ring 2 32 Filter Tubing 2

9 Spring Base 1 33 Copper Washer 1

10 Spring Sleeve 1 34 O Ring 1

11 Spring 1 35 Circlip 1

12 Large Pump 1 36 Cylinder 1

13 Rectangular Seals 1 37 Y-Ring 1

14 Universal Joint Shaft 1 38 Back Supporting Ring 1

15 O Ring 2 39 Piston Cap 1

16 Spring Base 1 40 Piston Rod 1

17 Spring Sleeve 1 41 Sealing Ring 1

18 Spring 1 42 Housing 1

19 Small Pump 1 43 O Ring 1

20 Circlip 2 44 O Ring 1

21 O Ring 1 45 Screw Cap 1

22 Rectangular Seals 1 46 Oil Plug 1

23 Small Piston 1 47 Ball Bearing 6mm Diameter 1

24 Circlip 2

8

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will be free of defects

in workmanship or material. Jefferson shall, upon suitable notication, correct any defects, by repair or replacement, of any parts

or components of this product that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal operations,

improper care, service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is unavailable from

the end user, then the date of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

• All Jefferson Trolley Jacks

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a

minimum of 90 days cover or the remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form.

Online warranty registration is recommended as it eliminates the need to provide proof of purchase should

a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by repair or

replacement at an authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Jefferson will arrange

collection and transportation of any equipment returned under warranty. Upon inspection of the equipment, if no defect can be

found or the equipment is not covered under the terms of the Jefferson warranty, the customer will be liable for any labour and

return transportation costs incurred. These costs will be agreed with the customer before the machine is returned.

*Jefferson reserve the right to void any warranty for damages identified as being caused through misuse

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers. Jefferson's liability

under this warranty will not exceed the cost of correcting the defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of substitute equipment etc.)

caused by the defect or the time involved to correct the defect. This written warranty is the only express warranty provided by

Jefferson with respect to its products.

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved.

LIMITED WARRANTY STATEMENT

9

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their

nearest authorised Jefferson dealer where final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can complete the form

online and submit it to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your nearest

authorised Jefferson repair centre. On receipt of this form Jefferson will arrange to collect the equipment from you at the earliest

convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for collection, together

with a copy of the original proof of purchase. Please note that Jefferson cannot assume any responsibility for any damage

incurred to equipment during transit. Any claims against a third party courier will be dealt with under the terms & conditions of

their road haulage association directives.

Please note: Jefferson will be unable to collect or process any warranty requests without a copy of the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if the equipment is

defective and in need of repair and any repairs needed are covered by the warranty policy. In order to qualify for warranty cover all

equipment presented must have been used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent to the customer

(normally within 7 working days). Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will

invoice 1 hour labour time at £30 per hour plus return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is identified as the cause

of the problem, a minimum of 1 hour labour at £30 per hour plus carriage costs will be required before the equipment will be

despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer within 7 working

days upon receipt of the equipment at an authorised Jefferson Repair centre (subject to part availability). Where parts are not

immediately available Jefferson will contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your enquiry via email to

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are made without

guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or damage suffered from the use of

this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance with this data or suggestions infringes any patent.

Jefferson Tools® reserve the right to change product specifications and warranty statements without further notification. All images are for

illustration purposes only.

10

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

EC Declaration of Conformity

Name and address of manufacturer or authorised representative:

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester,

United Kingdom,

CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

We, Jefferson Professional Tools & Equipment, as the authorised European

Community representative of the manufacturer, declare that the following equipment

conforms to the requirements of the following Directives:

EN 1494:2000+A1:2008 (as amended)

Mobile or movable jacks and associated lifting equipment

2006/42/EC (as amended)

Machinery Directive

Equipment Category: Trolley Jack / Lifting Equipment

Product Name/Model: JEFJKGAR03 - 3 Tonne Trolley Jack

Maximum Load: 3 Tonne

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 21 March 2017

This technical document is held by: Jimmy Hemphill

Technical file holder's address as shown below

11

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

Parts & Servicing

For Jefferson approved replacement parts contact your

nearest dealer or contact Jefferson tools

Telephone: +44 (0)1244 646 048

Fax: +44 (0)1244 241 191

Email: [email protected]

12

USER MANUAL

JEFJKGAR03

3 TONNE TROLLEY JACK

www.jeffersontools.com

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester,

United Kingdom,

CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

Before attempting to use this product please

read all the safety precautions and operating

instructions outlined in this manual to reduce

the risk of personal injury.

IMPORTANT! SAFETY FIRST!

Table of contents

Other Jefferson Jack manuals

Popular Jack manuals by other brands

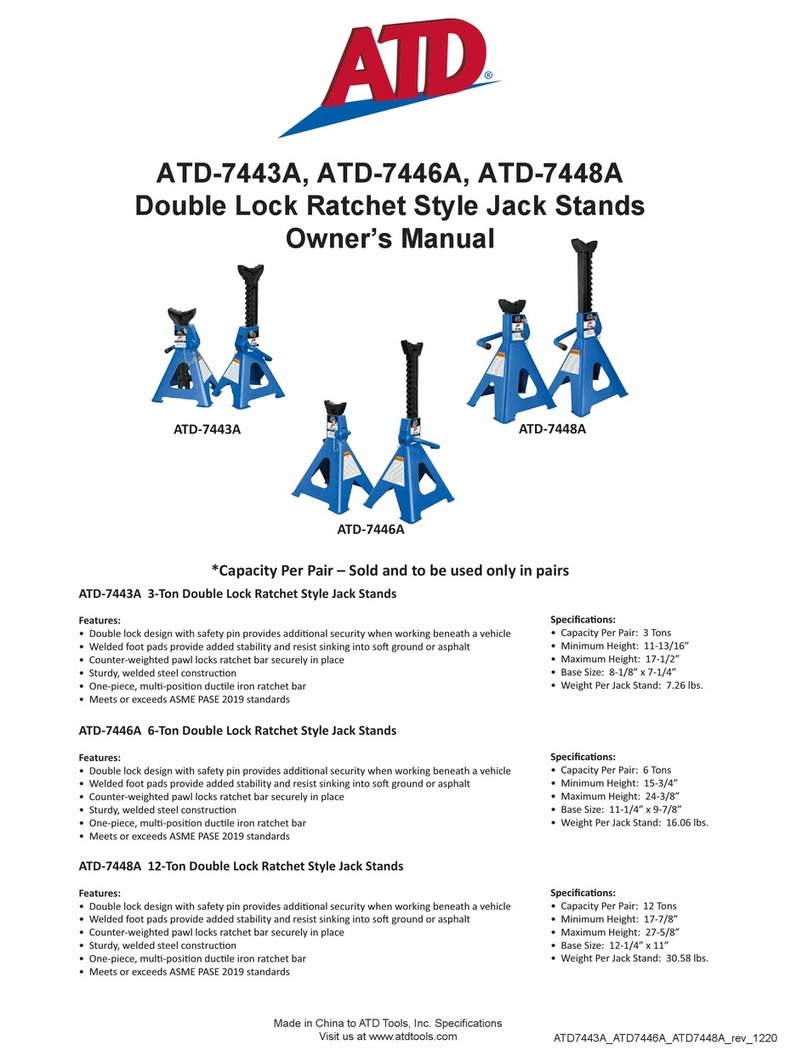

Black Hawk Automotive

Black Hawk Automotive BH7210 Operating instructions & parts manual

AUTO-XS

AUTO-XS ZQ2001 user guide

Cattini Oleopneumatica

Cattini Oleopneumatica YAK 330/S Operating and maintenance manual

Draper

Draper 28497 Original instructions

Winntec

Winntec BTJ2000 manual

Varan

Varan NEJKS-02 user manual