KTI-63517A3

SETUP INSTRUCTIONS

ThisisthesafetyalertsymbolusedfortheSETUPINSTRUCTIONSsectionofthismanualtoalertyoutopotentialpersonal

injury hazards. Obey all instructions to avoid possible injury or death.

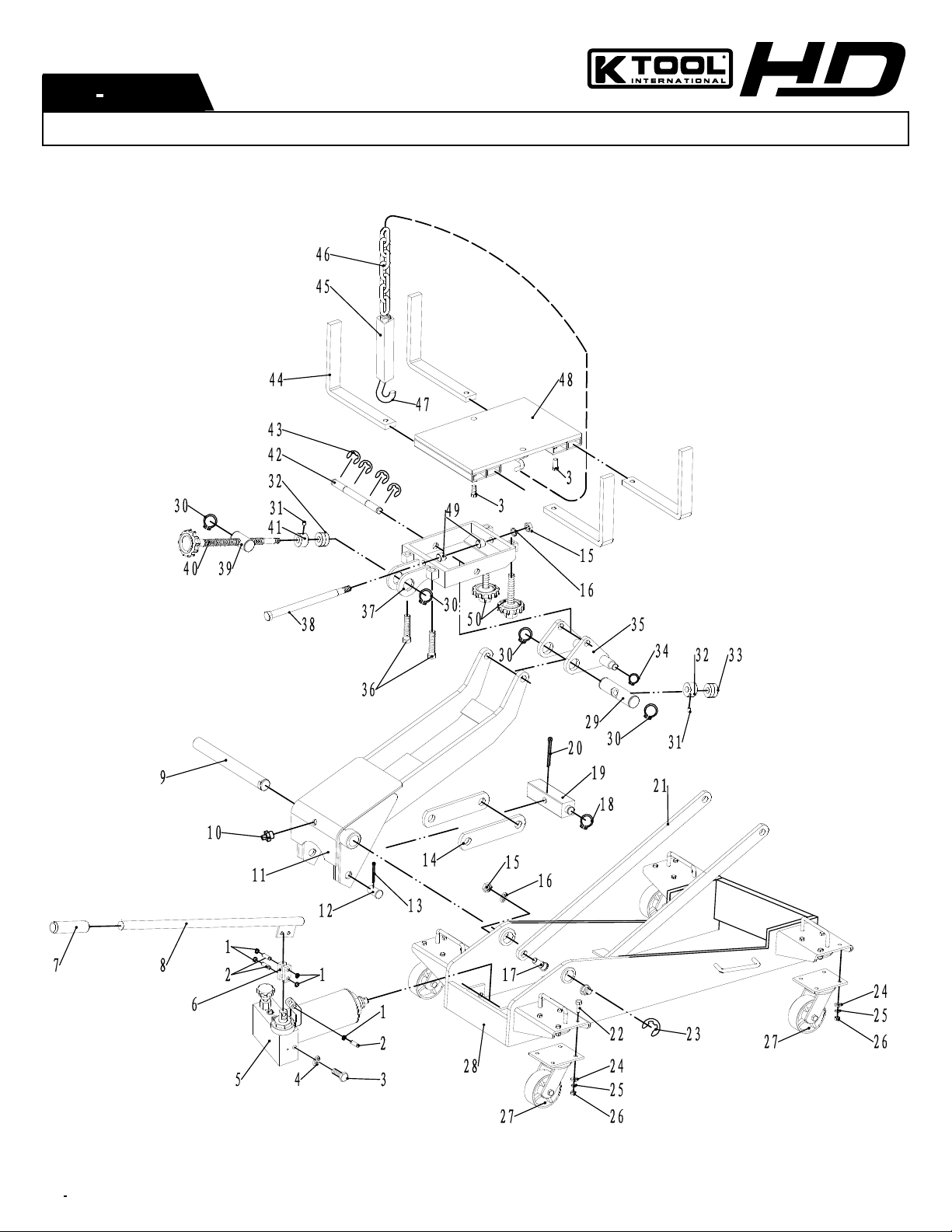

1. Refertotheexplodedviewdrawingonpage5toidentifyjackcomponents.

2. The#3-7and#3-13fingersmustbeinstalledinthe#3-8saddlewiththe#3-6bolts,#3-9washersand#3-10wingnutsas

shown in the exploded view drawing.

3. The#3-4chainsmustbeattachedtothe#3-7fingersasshownintheexplodedviewdrawingandsecuredtothefingerswith

the#3-1bolts,#3-2washers,#3-3lockwashersand#3-5nutsprovided.

4. Assemblethe#3-16chainhookstothe#3-15adaptorboltswiththe#3-14wingnutsasshowninthedrawing.

5. Securethe#3-15adaptorboltstothetworemaining#3-13fingersusingthe#3-12washersand#3-11nuts.

6. Airmaygettrappedinthehydraulicsystemduringfreightandhandling.

PURGING AIR FROM THE HYDRAULIC SYSTEM:

a. Rotatethereleaseknob#1-21atthetopofthebody#1-10inaclockwisedirectionuntiltight.

Nowturnitinacounterclockwisedirectiontwofullturns.

b. Activatethehandle#1-45about15times.

c. Rotatethereleaseknob#1-21atthetopofthebody#1-10inaclockwisedirectionuntiltight.

d. Activatethehandle#1-45untiltheliftarm#29israisedtomaximumheight.Youshouldexperienceafullpumpstrokewith

each incremental pump.

e. Repeatsteps"a"through"d"untilallairispurgedfromthesystem.

OPERATING INSTRUCTIONS

ThisisthesafetyalertsymbolusedfortheOPERATINGINSTRUCTIONSsectionofthismanualtoalertyoutopotential

personal injury hazards. Obey all instructions to avoid possible injury or death.

1. Liftthevehicletothedesiredworkheight,andsupportthevehicleinaccordancewiththeliftmanufacturer'srecommendedlifting

and support procedures.

2. Positionthetransmissionjackdirectlyunderthetransmission.Turntheknob#1-21allthewayinaclockwisedirectionuntilit

stops.Pumpthehandle#1-45,andthesaddle#3-8willstarttorise.Raisethesaddletoaheightveryclosetothecenterof

balance point of the transmission, but do not touch the transmission.

3. Loosenthefourbolts#3-6thatsecurethefourngers#3-7and#3-13tothesaddle#3-8.Thengers#3-7and#3-13canbe

adjustedinandouttohelppositionthetransmissiononthesaddle.Nowgentlyraisethesaddlesoitsupportsthetransmission.

Adjustthefourngersinpositionagainstthetransmission,andtightenthebolts#3-6thatsecurethengerstothesaddle.Fore

and aft saddle tilt adjustments and side to side adjustments are necessary to properly position the transmission on the saddle.

Theseadjustmentscanbemadebyrotatingthetwoknobs#18.

4. Thechain#3-4shouldbepulledoverthecenterofbalanceportionofthetransmissionandsecuredonthechainhooks#3-16.

Rotatethewingnuts#3-14totakeuptheslackinthechain#3-4andsecurethetransmissiontothesaddle#3-8.

5. Removethetransmissionfromtheengineaccordingtoinstructionsinthevehicleservicemanual.

6. Oncethetransmissionhasbeendisconnectedfromtheengine,veryslowlyturnthejack'sreleaseknob#1-21ina

counterclockwisedirectiontomakesurethejack'ssaddle#3-8andtransmissiondonothanguponanyundervehicle

components,wiring,fuellines,etc.Continuetolowerthejackallthewaydown.

7. Remembertosecurethetransmissiontothesaddlebeforeinstalling,andfollowthevehiclemanufacturer'sinstallation

instructions.

PREVENTATIVE MAINTENANCE

ThisisthesafetyalertsymbolusedforthePREVENTATIVEMAINTENANCEsectionofthismanualtoalertyouto

potential personal injury hazards. Obey all instructions to avoid possible injury or death.

1. Alwaysstorethejackinawellprotectedareawhereitwillnotbeexposedtoinclementweather,corrosivevapors,abrasive

dust, or any other harmful elements. The jack must be cleaned of water, snow, sand, grit, oil, grease or other foreign matter

before using.

2. Thejackmustbelubricatedperiodicallyinordertopreventprematurewearingofparts.Ageneralpurposegreasemustbe

applied to all zerk grease ttings, caster wheels, elevator arm, handle base pivot bolts, release mechanism and all other

bearing surfaces.