GATmatic GA-600S User manual

GA-600S 3D Wheel Aligner User Manual

i

GA-600S

3D Wheel Aligner

User Manual

GA-600S 3D Wheel Aligner User Manual

ii

Copyright Information

Copyright ©2009~2013. All rights reserved. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording or otherwise, without the prior

written permission of our company. The information contained herein is designed

only for the use of this unit. We are not responsible for any use of this information as

applied to other units.

Neither we nor our affiliates shall be liable to the purchaser of this unit or third parties

for damages, losses, costs, or expenses incurred by purchaser or third parties as a

result of: accident, misuse, or abuse of this unit, or unauthorized modifications,

repairs, or alterations to this unit, or failure to strictly comply with our operating and

maintenance instructions.

We shall not be liable for any damages or problems arising from the use of any

options or any consumable products other than those designated as our Original

Products.

1 Precautions

Please read the User’s Manual and the Installation and Parts Manual carefully

before operating our 3D Series Wheel Aligner.

Only the qualified technician can operate the Wheel Aligner.

The operator must have knowledge of computer application and basic theory of

wheel alignment.

The power voltage of 3D series wheel aligner is AC110~240V±10% 50±1Hz /

60±1Hz. The power outlet must be a Three PIN socket and its earth pin

must be well grounded. If the power voltage is not stable, please purchase and

use AC voltage stabilizer.

3D series wheel aligner is operated with image sensing; by analyze target images

recorded by high-resolution video camera. Avoid reflect Infrared light or direct

sun light to the targets.

3D series wheel aligner is high precision equipment; special care should be taken

during installation and operation to prevent the casing from being distorted and

the internal parts from being damaged.

Install the lift according to the lift specifications before installing 3D series wheel

aligner. Check the lift regularly for fixedness and levelness to ensure personal

safety and correct measurement. Remove the obstacles around the lift for

convenient operation.

Don’t place 3D series wheel aligner on a vibrated object or an oblique surface.

Avoid direct sunlight and moisture.

Avoid splashing water on the surface of 3D series wheel aligner, for it may cause

permanent damage to the system.

GA-600S 3D Wheel Aligner User Manual

iii

The targets are major components for wheel alignment, be careful in storage or

operation. Clean the dirt with neutral detergent or ethanol.

Accurate calibration is made during manufacturing, and the design doesn't require

calibration work for a few years, install 3D series wheel aligner according to the

user/installation manual. Do NOT move the column, open or adjust cameras, or

else the warranty is expired automatically, and end user will bear the cost of

damage.

Video cameras are high precision parts; the filters shall be kept clean.

Turn off the power after operation. Check all bolts and parts after maintenance,

and tighten the slackened bolts and parts in turn for safety.

Check the packing list before installing. Do not hesitate to contact us or our

distributors for any questions.

2 General Safety Instructions

The chassis measurement system may only be used to measure vehicle axles

according to specifications.

Only trained professional may operate the system.

Safety equipment may not be removed and/or disabled.

Repairs may only be performed by trained customer service personnel.

Arbitrary modifications of the system exclude any liability by our company for

any resulting damages.

Any work on the electrical installation may only be performed by electricians.

The wheel aligner system may not be operated in explosion- prone

surroundings.

The operator must provide appropriate fire protection measures at the

measuring platform. In particular, any flammable or self- combusting items

(such as cloths soaked in solvents or oil) and fluids, or foreign items and other ignition

sources, should not be stored in the tool trolley.

GA-600S 3D Wheel Aligner User Manual

iv

Obligation by the operator to be considerate and avoid negligent

acts:

The equipment was designed and constructed with consideration to required

harmonized standards, as well as additional technical specifications. It therefore

corresponds with the current state of technology and provides the maximum

standard in safety during the operation.

The machine safety, however, can only be implemented during the operation, if all of

the required steps have been taken. The operator of the machine has the obligation

to plan these actions and check their compliance.

The operator must specifically verify that:

The machine is only used according to specifications.

The machine is only operated in perfect operational condition and that the safety

equipment is routinely inspected as to their operational condition.

The necessary personal safety equipment for operating, maintenance and repair

personnel is available and being worn.

The operating instructions are always in a legible condition and are completely

available at the machine location.

The machine is only operated, maintained and repaired by qualified and authorized

personnel.

This personnel is instructed routinely in all pertaining questions of work safety and

environmental protection, and knows the operating instructions, especially the

safety instructions contained therein.

All safety and warning labels attached to the machine are not removed and are

legible.

3 Concrete safety instructions and applied symbols

Concrete safety instructions are provided in the following operating instructions

which will point out any unavoidable remaining risks during the machine operation.

These remaining risks contain hazards for:

Persons

Product and machine

The environment

GA-600S 3D Wheel Aligner User Manual

v

Basic safety measures during normal operations:

The machine may only be operated by trained and authorized personnel who know

the operating instructions and capable of working with the equipment!

Prior to switching the machine on, check and verify that:

Only authorized personnel are located within the working range of the machine.

No one can be injured when the machine is activated!

Check the machine for visible damages prior to use and verify that it is only operated

in perfect condition!

Report any problems immediately to the supervisor!

Prior to each operating start, check and verify that all safety equipment operates

perfectly!

Basic safety measures during service and maintenance:

Adhere to the inspection and maintenance intervals specified in the operating

instructions!

Block access to the work area of the machine to unauthorized

personnel prior to performing maintenance or repairs! Attach or set up

a warning sign that points out maintenance or repair work!

Pull the power plug prior to any maintenance or repair work or switch

off the main switch for the power supply and secure with a lock, if the

power supply is installed.

The key to this lock must be in the hands of the person that is

completing the maintenance or repair work! Only use perfect load

suspension and lifting equipment when replacing heavy machine parts!

Properly dispose of environmentally hazardous lubricants, coolants or

cleaning agents!

Working on the electrical equipment:

Repairs on electrical equipment of the machine may only be performed

by trained electricians!

Re-attach any loose connections!

Immediately replace damaged lines/cables!

Always keep housings of electrical equipment closed! Access is only

permitted for authorized personnel with key/tools!

Never spray the housing of electrical equipment with a hose when

cleaning!

GA-600S 3D Wheel Aligner User Manual

vi

Observe environmental regulations:

The legal regulations for waste prevention and proper

recycling/disposal must be adhered to for all operations on and with

the machine.

Especially during installation, repair and maintenance operations,

water-polluting materials, such as: Lubricants and oils - hydraulic oils

- coolants.

Solvent-containing cleaning liquids may not pollute the ground or

reach the sewage system!!

These materials must be stored, transported, collected and disposed

of in suitable containers!

GA-600S 3D Wheel Aligner User Manual

vii

Table of Content

1 Trademark Information ..................................................................................................................... i

2 Copyright Information ...................................................................................................................... ii

3 Precautions ............................................................................................................................................ii

4 General Safety Instructions .......................................................................................................... iii

5 Concrete safety instructions and applied symbols .............................................................. iv

Chapter 1 Introduction .............................................................................................................................1

1. 1 Definition ...................................................................................................................................... 1

1. 2 When wheel alignment will be needed .............................................................................1

1. 3 Major alignment parameter .................................................................................................. 1

1. 3. 1 Camber ............................................................................................................................ 1

1. 3. 2 Toe-in ................................................................................................................................2

1. 3. 3 Steering Axle Inclination .......................................................................................... 3

1. 3. 4 Caster ............................................................................................................................... 3

1. 3. 5 Toe-out on turn .............................................................................................................4

1. 3. 6 Thrust Angle .................................................................................................................. 4

1. 3. 7 Wheelbase diff. ............................................................................................................. 5

1. 3. 8 Track Width Diff. ...........................................................................................................5

1. 3. 9 Left (right) lateral offset (angle) ...........................................................................5

1. 3. 10 Axle Offset (angle) ...............................................................................................5

1. 3. 11 delay (angle) ...............................................................................................................6

1. 3. 12 Included angle ............................................................................................................6

1. 4 Function and feature ................................................................................................................6

1. 5 Tech Specs ................................................................................................................................... 7

1. 6 Requirements on Surroundings ...........................................................................................7

1. 7 Working Principle .......................................................................................................................8

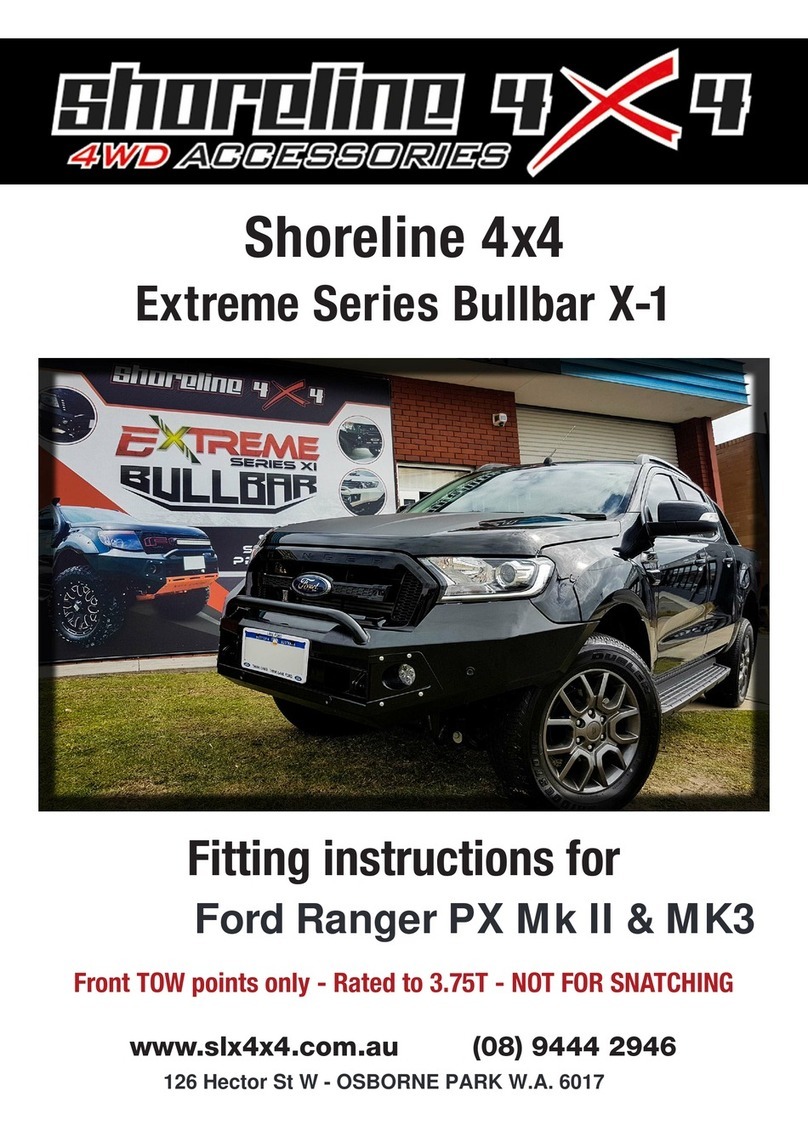

Chapter 2 Hardware Structure ..............................................................................................................1

2. 1 Overall Structure ....................................................................................................................... 1

2. 2 Target and Clamps ....................................................................................................................2

2. 3 Communication Cable ............................................................................................................. 2

2. 4 Turntable and passing bridge ...............................................................................................2

2. 5 Steering wheel holder ............................................................................................................. 3

2. 6 Brake pedal depressor ............................................................................................................ 3

Chapter 3 Basic Operation Procedure ................................................................................................ 1

3. 1 Precheck ........................................................................................................................................1

3. 2 Alignment Measurement ........................................................................................................ 1

3. 3 Adjustment .................................................................................................................................. 1

3. 4 Test Run ........................................................................................................................................ 1

GA-600S 3D Wheel Aligner User Manual

viii

Chapter 4 Operation Instruction .......................................................................................................... 1

4. 1 Preparation before test ........................................................................................................... 1

4. 2 Software Operation .................................................................................................................. 1

4. 2. 1 Alignment Measurement ...........................................................................................2

4. 2. 2 System Management ................................................................................................. 8

4. 2. 3 General Setting ...........................................................................................................14

4. 2. 4 Print Report .................................................................................................................. 15

4. 2. 5 Help Information ........................................................................................................16

4. 2. 6. Exit ................................................................................................................................. 16

Chapter 5 Frequent asked question ..................................................................................................17

5. 1 Computer Operation .............................................................................................................. 17

5. 1. 1 Computer can not boot ........................................................................................... 17

5. 1. 2 Can not enter WINDOWS 7 desktop ..................................................................17

5. 1. 3 Mouse/keyboard not functional ........................................................................... 17

5. 1. 4 Printer not functional ............................................................................................... 17

5. 1. 5 Can not run wheel aligner software ...................................................................17

5. 2 Standard measurement ........................................................................................................17

5. 2. 1When turn steering wheel, there’s no camera/target block prompt when

block rear targets. ....................................................................................................................17

GA-600S 3D Wheel Aligner User Manual

1-1

Chapter 1 Introduction

1.1 Definition

3D series wheel alignment system is to test wheel parameters and provide reference of

manufacturer specs, by compare the two set of parameters, operator can adjust the

vehicle wheel parameters to reasonable range, make the vehicle wheels in good

condition and avoid unreasonable tire worn.

1.2 When wheel alignment will be needed

At the following circumstance, wheel alignment will be necessary:

Vehicle pull to one side when release steering wheel.

Uneven tire worn.

Steering wheel too heavy, too light or shake when driving at high speed.

After tire change, chassis parts replacement.

After collision.

After 3000 km’s drive of new car.

At regular vehicle maintenance.

1.3 Major alignment parameter

Wheel alignment angles are relative angle of the chassis parts, which makes the

vehicle running stable and reduce tire worn.

Major wheel alignment angle include: Camber, Toe, Caster, SAI, Toe-out on Turn.

GA-600S 3D Wheel Aligner User Manual

1-2

1. 3. 1 Camber

Camber is the leaning of the wheel inwards or outwards from the vertical. If the

road wheel leans outwards from the vertical, it has positive camber and when leaning

inwards from the vertical - negative camber, looking from the front or rear of the

vehicle. See Fig.1.1. Camber is measured in degrees. Without camber, the wheels

will tilt to the inside at full load; increase the possibility of uneven tire worn. Hence, this

parameter can extend the life of tire and related axis.

Figure 1.1 Figure 1. 2

1. 3. 2 Toe-in

The toe setting is the amount by which the front or rear wheels point inwards or

outwards at the front of the wheel in relation to each other (see Fig.1.2). When the

wheels point inwards they are said to toe-in. Toe-in figures are given a positive value.

Conversely when the wheels point outwards they are toe-out and the figures are shown

as a negative value.

The purpose of correct toe is to ensure that the wheels run parallel when the vehicle is

driving. An incorrect toe setting may affect the stability and controllability of the

vehicle.

GA-600S 3D Wheel Aligner User Manual

1-3

1. 3. 3 Steering Axle Inclination

Steering Axle Inclination (SAI) is the angle of steering axis and vertical line (vehicle

front view). As show in Figure 1.3. Correct Kingpin Inclination can equalize the loads

applied on bearings so that the life of bearings can be prolonged and the controllability

of steering is improved. Without the inclination, the controllability of the steering may

be affected; further more, the vehicle weight and the ground counterforce may cause

significant stress in the axle and finally damage the axle. Correct inclination of king pin

is also helpful for the vehicle to restore its straight-ahead position after steering.

Kingpin Inclination is determined when the vehicle suspension is designed. It is not

service adjustable.

Figure 1. 3 Figure 1. 4

1. 3. 4 Caster

Caster is the tilting of the kingpin either forwards or backwards from vertical, as viewed

from side of the vehicle. See Figure 1. 4. When the king pin is tilted backwards from the

vertical, caster is positive. When the king pin is tilted forwards, caster is negative.

Caster angle influences the directional stability of the steering. To increase the

tendency of the steering to self-centre, the steering will normally be designed with

positive caster. Normally caster angle of a vehicle is between 1~4 degrees.

GA-600S 3D Wheel Aligner User Manual

1-4

1. 3. 5 Toe-out on turn

Toe-out on turns is defined as the difference of the steering angle between the two

front wheels when turning left or right by 20°. see Figure 1.5.When the vehicle turns,

the inner wheel angle is always bigger than the outer wheel, difference is about 2

degrees, the purpose is to make the vehicle turn by referenced to the instant center

point of the extend line of back axis.

Figure 1. 5 Figure 1. 6

1. 3. 6 Thrust Angle

Definition: The angle between the vehicle’s centerline and the vehicle thrust line. When

driving, the front wheels and the rear wheels should pull to the same side if the thrust

angle is not zero. When thrust line is at the left side of the vehicle’s centerline, the

thrust angle is positive, otherwise is negative. The existence of the thrust angle causes

the vehicle’s rear body pull to one side. In order to drive the vehicle straight-ahead, the

front wheels have to turn to the direction of thrust line. If thrust angle compensation is

not done for front toe, the steering wheel must be turned to one side when driving

straight-ahead. If rear toe can be adjusted, the thrust angle should be adjusted close

to zero. The direction of thrust line is the actual driving direction of the vehicle, which

is determined by rear toe. When the direction of thrust line doesn’t coincide with the

geometric centerline of the vehicle, the steering wheel must be turned by some

degrees to keep the vehicle driving straight-ahead, so that unbalance phenomenon of

the steering wheel is caused. At the same time, the traveling paths of rear wheels don’t

coincide with that of front wheels. This kind of phenomenon is called Rear Wheel

Lateral Move. If ignore the thrust line, the veracity of alignment cannot be ensured.

This is the main reason of the steering deflection. If you select the thrust line as the

measurement datum, you can perform the following operation procedures:

After adjusting rear toe to the specified value (OEM Specifications), the thrust line will

coincide with the vehicle’s centerline. For the vehicle with adjustable rear suspension,

rear toe should be adjusted to keep the thrust angle close to zero. No matter the

thrust angle is zero or not, the steering wheel can be adjusted balanced if you take the

thrust line as alignment datum. If rear toe cannot be adjusted, please adjust front toe,

and keep it be same with rear toe, and then set them to the angle by which the steering

wheel can be balanced.

GA-600S 3D Wheel Aligner User Manual

1-5

1. 3. 7 Wheelbase diff.

Wheelbase difference is defined as the angle between the joint line of the centre of two

rear wheels and that of the front wheels. It is positive when distance between the

centre of the right wheels is large than that of left wheels; and negative otherwise. If

the tread is available from the vehicle specifications, then the wheelbase difference can

be also expressed by angle. See Figure. 1.7.

+

+

Figure 1. 7 Figure 1. 8

1. 3. 8 Track Width Diff.

Track width (Tread) difference is defined as the angle between the joint line of the

ground-contact point of left wheels and that of the right wheels. It is positive when

distance between the centre of the rear wheels is large than that of front wheels; and

negative otherwise. If the wheelbases are available from the vehicle specifications,

then the tread difference can be also expressed by angle. See Figure 1.8.

1. 3. 9 Left (right) lateral offset (angle)

The offset of rear left (right) wheel and front left (right) wheel at the vehicle’s lateral

direction. When rear left (right) wheel is outside of front left (right) wheel, left (right)

lateral is positive, otherwise, it’s negative. The angle between the trust angle and the

left (right) front/back wheel center line is the left (right) lateral offset angle.

1. 3. 10 Axle Offset (angle)

The relative offset of front axle and rear axle at the vehicle’s lateral direction is defined

as Axle offset. When rear axle is more to the right side than front axle, axle offset is

positive, otherwise, it’s negative. The angle between the center line of the difference

angle and the trust angle is defined as axle offset angle.

GA-600S 3D Wheel Aligner User Manual

1-6

1. 3. 11 delay (angle)

The same axle’s relative offset in longitudinal direction of the vehicle is called the delay.

When the right wheel is behind of the left wheel on the same axle, the delay is positive,

otherwise, it’s negative. The angle between the wheel center line and the vehicle

longitudinal geometric center line vertical is called the delay angle.

1. 3. 12 Included angle

The sum of Kingpin inclination angle and camber angle is called the included angle.

1. 4 Function and feature

All new three dimension computer visual measurement: adopted high performance

camera to automatically detect the alignment parameter. The equipment was

calibrated at production, does not need on-site calibration at installation.

Electric component free target: no electric component or wiring on the target,

which ensure the equipment to be more convenient and durable.

3D (Fixed Height) wheel aligner can be installed at any height according to user’s

interest.

3D (Auto Focus) wheel aligner can detect the lift position and follow the lift up and

down, to ensure the equipment always in best working height.

Extremely simplified test procedure.

Complete parameter measurement: Capable of test of front/rear toe-in, front/rear

camber, thrust angle, caster, SAI/Kingpin, wheelbase, track (thread) etc.

Large database: More than 20000 records of vehicle all over the world, and user

can add data at will.

Historical data storage for client management.

Real-time help system.

GA-600S 3D Wheel Aligner User Manual

1-7

1.5 Tech Specs

Power Supply: AC 110/220V 50/60 Hz

Computer Host: Lenovo/Dell (or all in one computer)

Monitor: 18. 5 inch color monitor (all in one computer comes with 23

inch monitor)

Toe-in 0~+_20 degree.

Camber 0~+_8 degree.

SAI/Kingpin 0~+_20 degree.

Caster 0~+_20 degree.

Thrust Angle 0~+_5 degree.

Rim diameter 10 ~ 23 inch

Caution

WE preserve the right to change design without prior notification.

The measure range can only be assure when operate the wheel aligner

according to this user manual.

1. 6 Requirements on Surroundings

Ambient temperature:0~50℃

Relative humidity: ≤85%

Light condition: No direct Infrared light to the targets

Lift platform height difference: front/end height difference < 2mm

GA-600S 3D Wheel Aligner User Manual

1-8

1. 7 Working Principle

3D series wheel aligner working principle is as show in figure 1. 9. The entire system

can be divided into two categories: data acquisition and data processing.

Figure 1. 9

Data acquisition category consists of 2 high definition cameras and 4 targets. Left and

right side camera get target image and send to data processing citatory. Target was

mounted onto the wheel via clamps.

Data processing category is the core component of 3D wheel aligner, consist of

computer system, power supply system and interface. The function is to realize

operator’s instruction, automatically guide the measurement, and calculate data and

display together with manufacture data, at the same time, guide the operator to do

adjustment on the vehicle. Finally, print out the report.

Since 3D series wheel alignment system need to compare tested data with

manufacturer data, and provide guidance of adjustment, database is very important to

provide reference data. 3D series wheel aligner database covers over 20000 records of

vehicle data worldwide. At the same time, 3D series wheel aligner system provides

function for operator to input and save customized data.

Computer

Keyboard,

mouse

Printer

Monitor

Camera (L)

Camera(R)

Target(R)

Target (L)

GA-600S 3D Wheel Aligner User Manual

2-1

Chapter 2 Hardware Structure

2. 1 Overall Structure

3D series wheel aligner mainly consist of column assembly, lateral beam

assembly(include 2 sets of camera assembly), cabinet, computer host, monitor, printer,

targets, clamps, communication cables, turntables, steering wheel holder, brake pedal

depressor etc. as show in Figure 2. 1.

GA-600S 3D Wheel Aligner User Manual

2-2

3D Series Wheel Aligner

2. 2 Target and Clamps

3D series wheel aligner has 4 targets (come together with 4 clamps), is a key

component for acquire raw data of wheel alignment (Figure 2. 2), Cameras will capture

target image for data processing. On the back of the target, there’s identification label

for target position.

Figure 2. 2

2. 3 Communication Cable

3D series wheel aligner has two cables between computer and lateral beam, one is USB

data cable, another one is power supply cable, shall keep them in good condition to

avoid damage to the entire alignment system.

2. 4 Turntable and passing bridge

3D series wheel aligner comes with 2 mechanical turntables, as show in figure2. 2.

Turntable shall be placed on the front wheel position on the lift, each turntable has a

passing bridge, to ensure vehicle move smooth when do rolling compensation.

GA-600S 3D Wheel Aligner User Manual

2-3

Figure 2. 3

2. 5 Steering wheel holder

3D series wheel aligner equipped with a steering wheel holder, as show in figure 2. 4.

The steering wheel holder is mainly used when do rolling compensation.

Figure 2. 4

2. 6 Brake pedal depressor

3D series wheel aligner equipped with a brake pedal depressor, as show in figure 2. 5.

it’s used to press down the brake pedal, to prevent vehicle from moving at certain

measurement stage, e.g., caster swing.

GA-600S 3D Wheel Aligner User Manual

3-1

Chapter 3 Basic Operation Procedure

3. 1 Precheck

Ask the owner for vehicle drivability problems, symptoms, and wheel alignment history,

and find out vehicle information such as make, model and year, etc. Check each chassis

part carefully, include dust cover, bearing, rock arm, tripod-ball, shock absorber, tie rod

ball and steering mechanism, for any loose or wear. Then check to see if the tire

pressure, tire treads of the left and right wheels are alike. Perform the wheel alignment

checking after the initial condition is known. If the measuring values do not accord with

the specifications given in the databank, the wheel alignment should be adjusted. After

finishing the wheel alignment, test the vehicle to see if the abnormal conditions are

eliminated. Re-adjust the wheel alignment if necessary.

3. 1 Alignment Measurement

After precheck, can start alignment measurement.

3. 3 Adjustment

In the alignment measurement, based on the measurement results, combined with the

actual vehicle alignment fault phenomena, with reference of the OEM specs, to make

corresponding adjustments according to the actual situation.

3. 4 Test Run

The vehicle shall be test derived, after alignment adjustment, to confirm if the fault

phenomena are eliminated. Otherwise, shall redo the adjustment.

Table of contents

Other GATmatic Automobile Accessories manuals