JEI Minibeast Cordless User manual

Unit 21 Empire Bus Park, Enterprise Way, Burnley, Lancs, UK, BB126LT

Phone: +44 1706 229490

www.jeiuk.com e-mail: [email protected].uk

OPERATOR’S MANUAL

CORDLESS DRILLING MACHINE

WITH ELECTROMAGNETIC BASE

Minibeast Cordless

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Equipment included ................................................................................................... 4

1.4. Dimensions................................................................................................................ 5

1.5. Design ....................................................................................................................... 5

2. SAFETY PRECAUTIONS.................................................................................................. 6

3. SYMBOLS......................................................................................................................... 9

4. STARTUP AND OPERATION..........................................................................................10

4.1. Tools compatible with drilling machine......................................................................10

4.2. Installing and removing the tool.................................................................................10

4.3. Application of a cooling system.................................................................................11

4.4. Installing and removing the cooling system...............................................................12

4.5. Checking the battery charge level.............................................................................12

4.6. Installing and removing the battery............................................................................13

4.7. Clamping surface requirements ................................................................................13

4.8. Securing the machine with a safety strap..................................................................15

4.9. Machine state indication............................................................................................15

4.10. Preparing................................................................................................................16

4.11. Drilling ....................................................................................................................17

4.12. Finishing the operation ...........................................................................................17

5. ACCESSORIES...............................................................................................................18

5.1. Battery charger ASC 145..........................................................................................18

5.2. Battery 18 V LiHD 4.0 Ah..........................................................................................18

5.3. Battery 18 V LiHD 10.0 Ah........................................................................................18

5.4. Pressure cooling system...........................................................................................18

5.5. Pipe attachment DMP 251 ........................................................................................19

5.6. Vacuum pad..............................................................................................................19

6. ENVIRONMENTAL PROTECTION..................................................................................20

7. DECLARATION OF CONFORMITY.................................................................................21

8. WARRANTY CARD..........................................................................................................22

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

3

1. GENERAL INFORMATION

1.1. Application

The Minibeast Cordless is a drilling machine designed to drill holes of diameters up to

36 mm (1.42″) with TCT annular cutters and up to 30 mm (1.18″) with HSS annular

cutters. The machine can also drill holes of diameters up to 12 mm (0.47″) by using

twist drill bits. It allows machining holes of diameters up to 30 mm (1.18″) by using

conical countersinks.

The drilling machine is battery powered. After charging the battery, it can work in

places that are not connected to the mains.

The electromagnetic base clamps the machine to ferromagnetic surfaces. This

assures that the operator is safe and the machine works correctly. A safety strap

protects the machine from falling in case of a clamping loss.

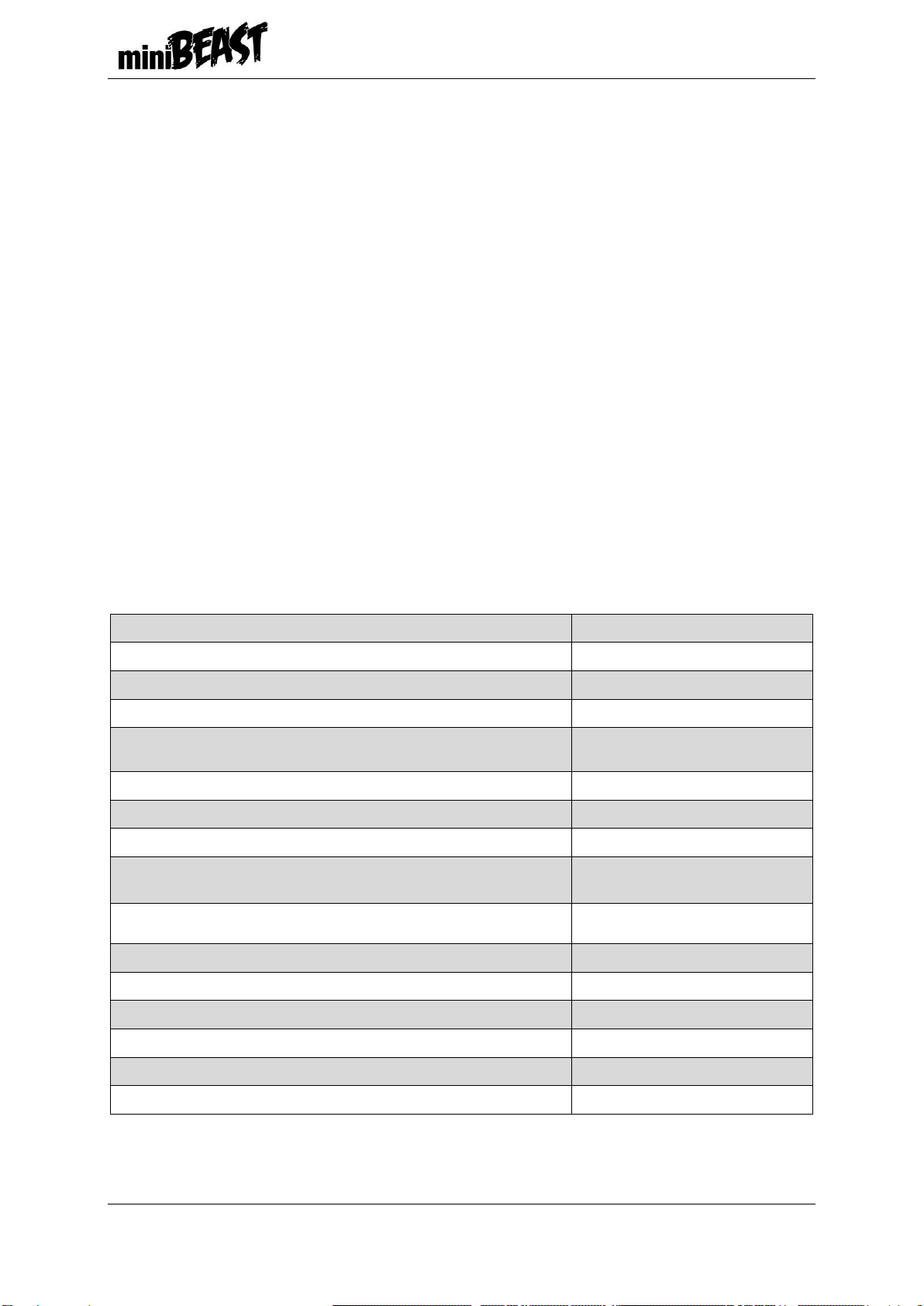

1.2. Technical data

Spindle shank

19 mm (3/4″) Weldon

Maximum drilling diameter with TCT annular cutter

36 mm (1.42″)

Maximum drilling diameter with HSS annular cutter

30 mm (1.18″)

Maximum drilling diameter with a twist drill bit

12 mm (0.47″)

Maximum diameter of a hole to be machined with a conical

countersink

30 mm (1.18″)

Maximum drilling depth

50 mm (1.97″)

Stroke

70 mm (2.76″)

Minimum workpiece thickness

6 mm (0.24″)

Electromagnetic base dimensions

80 mm × 160 mm × 38 mm

(3.15″× 6.3″× 1.5″)

Clamping force

(surface with the thickness of 25 mm and roughness Ra= 1.25)

7500 N

Voltage

18 V DC

Power

450 W

Protection level IP

IP20

Rotational speed with load

260 rpm

Required ambient temperature

0 –40 ⁰C (32 –104 ⁰F)

Weight with battery 4 Ah

11.5 kg (25.35 lbs)

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

4

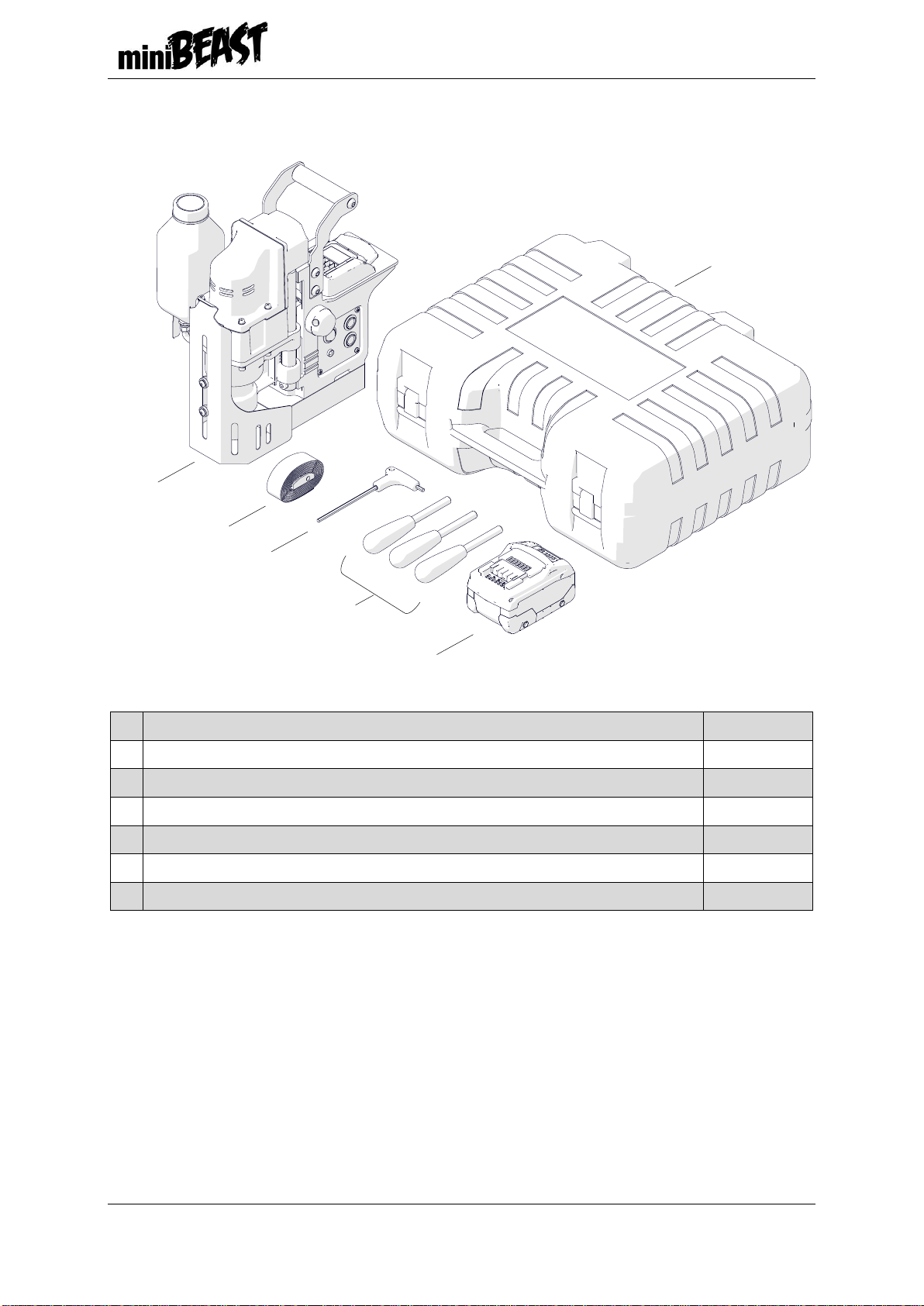

1.3. Equipment included

1

Drilling machine with cooling system

1 unit

2

Safety strap

1 unit

3

4 mm (0.16″) hex wrench with a handle

1 unit

4

Handle

3 units

5

Battery 18 V LiHD 4.0 Ah

1 unit

6

Box

1 unit

-

Operator’s Manual

1 unit

1

2

3

5

6

4

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

5

1.4. Dimensions

1.5. Design

Bottle valve lever

Chip guard

Spindle with arbor

Electromagnetic base

Hole for a safety strap

Control panel

Electromagnetic base switch

(MAGNET)

Motor STOP

Motor START

Feed shaft

Carrying handle

Battery

Battery lock

LED indicator

328 mm (12.91″)

316 mm (12.44″)

235 mm (9.25″)

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

6

2. SAFETY PRECAUTIONS

1. Before use, read this Operator’s Manual and complete training in occupational

safety and health.

2. Use only in applications specified in this Operator’s Manual.

3. Keep the machine and the battery away from children.

4. Keep the machine and the battery dry. Do not expose the machine to rain, snow,

or frost.

5. Do not expose the machine and the battery to fire or excessive temperature.

6. Set the MAGNET switch to ‘O’ before you install the battery and before you

move the machine. Use the carrying handle to move the machine.

7. Keep untrained people away from the machine.

8. Before each use,ensure the correct conditionof the machine, battery, and tools.

Make sure that the machine has all parts, and they are genuine, undamaged

and correctly installed.

9. Make sure to maintain correct conditions that may influence the operation of the

machine.

10.Do not stay below the machine that is put at heights.

11.Keep the work area well-lit, clean, and free of obstacles.

12.Make sure that the tool is correctly attached. Remove items from the work area

before you turn on the machine.

13.Do not use tools that are dull or damaged.

14.Remove the battery before you install or remove tools. Use protective gloves to

install and remove tools.

15.Remove the battery before you manually turn the spindle.

16.Do not remove the battery during operation of the machine.

17.Use annular cutters without the pilot pin only when you drill incomplete through

holes.

18.Drill with the chip guard lowered.

19.Do not drill/machine holes which diameter or depth differ from those specified

in the technical data.

20.Do not use in explosive environments or near flammable materials.

21.Do not use on surfaces that are rough, not flat, not rigid, or are covered with

rust, paint, chips, or dirt.

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

7

22. Always secure the machine with a safety strap. Use the safety strap to attach

the machine to a stable structure. Put the strap through the hole in the machine

body. In the horizontal position, attach the strap to the carrying handle. Do not

put the strap into the buckle from the front.

23.Use eye and ear protection and protective clothing. Do not wear loose clothing.

24.We do not recommend working on workpieces thinner than 6 mm (0.24″). The

clamping force depends on the workpiece thickness and is much lower for thin

plates.

25.Each time before you put the machine on the workpiece, grind the workpiece

with coarse-grained sandpaper. Make sure that the full bottom of the base

touches the surface.

26.Do not touch chips or moving parts. Do not let anything get caught in moving

parts.

27.After each use, clean the machine and the tool. Do not remove chips with your

bare hands.

28.Remove the battery before you do maintenance or install/remove parts.

29.Repair only in a service center appointed by the seller.

30.If the machine falls, is wet, or has any damage, stop the work, and immediately

send the machine to the service center for check and repair.

31.Do not leave the machine when it operates.

32.If you are not going to use the machine, remove the tool from the holder.

33.If you are not going to use the machine for an extended period, put anti-

corrosion material on the steel parts.

34.Use only original Promotech or CAS (Cordless Alliance System) batteries and

chargers with the following parameters:

Batteries: 18 V LiHD 4.0 Ah, 18 V LiHD 10.0 Ah

Chargers: ASC 145

35.Do not open the battery and do not short-circuit its contacts.

36.Do not allow the battery to be fully discharged. Do not leave the battery in the

machine.

37.Store the machine and battery in a safe and dry place. Do not store discharged

battery.

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

8

38.Acid flammable liquid may leak from defective battery. If the liquid comes in

contact with your skin or eyes, rinse them immediately with clean water and

seek medical attention.

39.When you transport the battery, familiarize yourself with hazardous goods

carriage regulations (UN 3480 and UN 3481).

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

9

3. SYMBOLS

Before using the machine, read the description of the following symbols.

Wear eye protection

Wear ear protection

Refer to instruction manual

Warning of flammable substances

Warning of corrosive substances

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

10

4. STARTUP AND OPERATION

4.1. Tools compatible with drilling machine

The drilling machine can be used with tools listed in the following table.

Tool

Maximum tool

diameter

Application

Tool holder

Turbo Tough, TCT

annular cutter

36 mm (1.42″)

Drilling through holes

19 mm (3/4″)

Weldon

Turbo Steel, HSS

annular cutter

30 mm (1.18″)

Turbo Steel, Twist drill

bit

12 mm (0.47″)

Drilling through and

blind holes

Turbo Steel, Countersink

30 mm (1.18″)

Countersinking and

chamfering holes

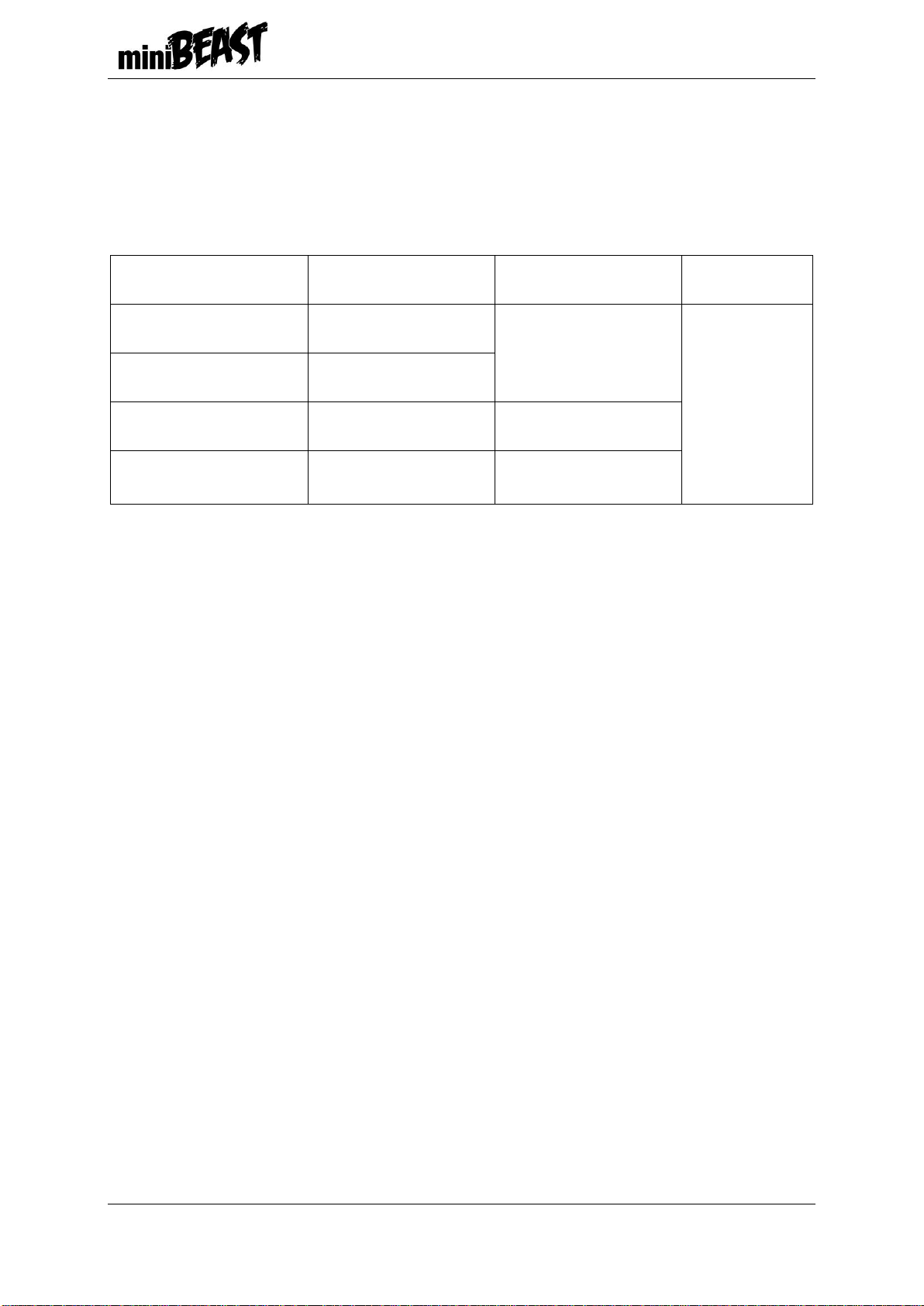

4.2. Installing and removing the tool

Remove the battery. Lift the chip guard (1). Turn the handles to the right (2) to lift the

motor. When you install the annular cutter –use gloves to put the correct pilot pin into

the cutter (3). Use a dry cloth to clean the spindle and the tool. Put the tool into the

spindle (4) so that the flat surfaces (5) align with the screws (6). Use the 4 mm hex

wrench to tighten the screws. To remove the tool, loosen the screws.

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

11

When you use an annular cutter, drill only through holes. Do not use

the pilot pin for incomplete through holes.

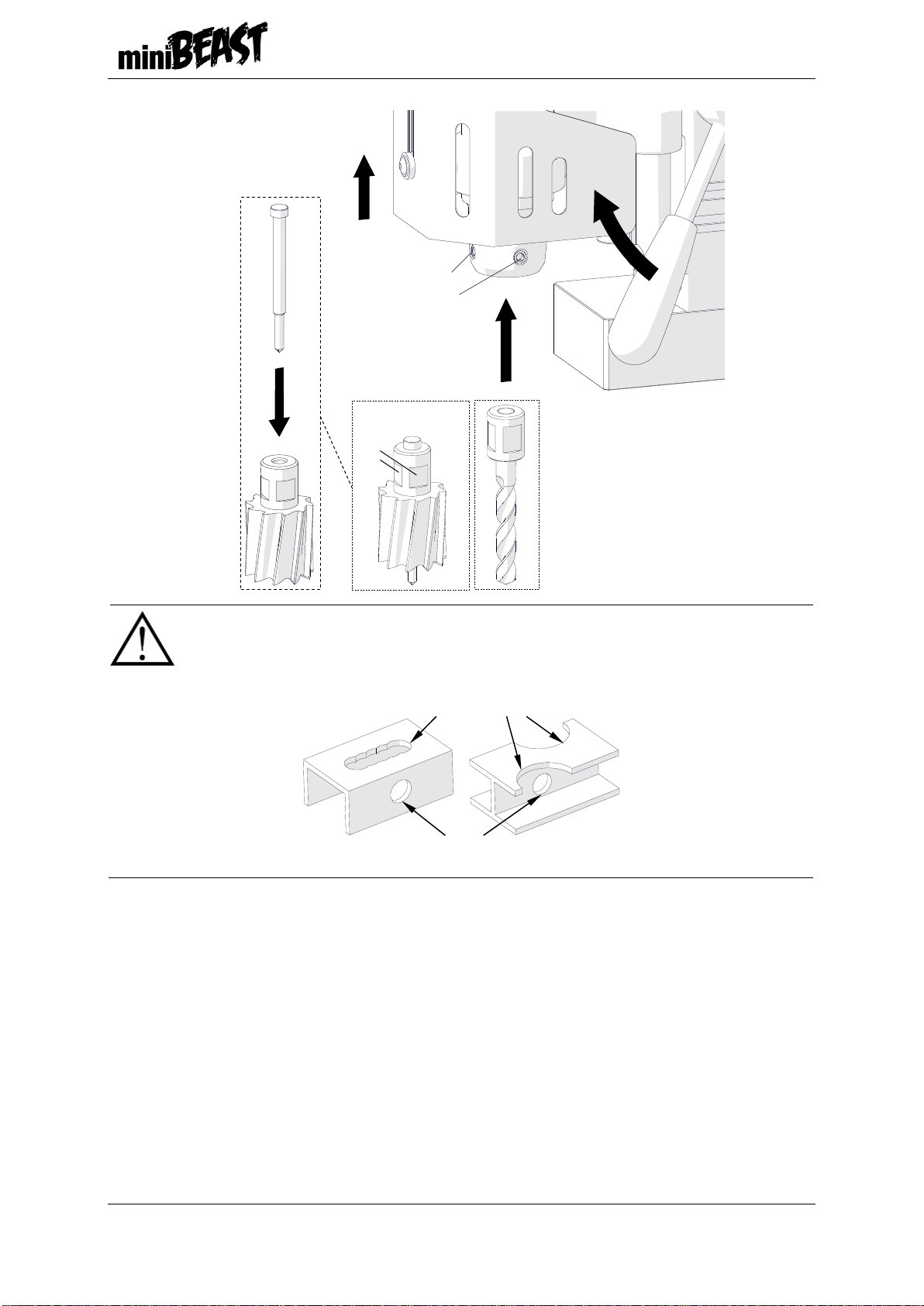

4.3. Application of a cooling system

The drilling machine is equipped with a gravity cooling system.

Install the cooling system when you drill vertically with an annular cutter. When you

use other tools or drill with an annular cutter in position other than vertical, use coolants

under pressure or in the form of spray or paste. Do not allow coolant to flow into the

motor.

Do not use pure water as coolant. You can use a mixture of water and drilling oil.

Complete through holes

Incomplete through holes

4

1

2

3

6

5

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

12

4.4. Installing and removing the cooling system

Remove the battery. Use lever to close the bottle valve. Put the bottle on the screws

(1). Attach the hose to the fitting (2). Check the operation of the cooling system. To do

this, loosen the bottle cap and open the valve using lever. Turn the handles to the left

to apply light pressure on the pilot pin. The coolant should fill the system and start

flowing from the cutter.

Remove cooling system in reverse sequence.

4.5. Checking the battery charge level

Charge the battery before first use.

To check the charge level, press the charge status button. If only one LED on the

charge indicator flashes green, charge the battery.

1

2

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

13

Do not charge fully charged battery.

Before charging the battery, read the charger manual.

4.6. Installing and removing the battery

Slide the battery in (1) until it locks into place. Press and hold the battery lock (2) to

remove the battery (3).

4.7. Clamping surface requirements

The ferromagnetic surface to which the drilling machine is clamped must be at least 6

mm (0.24”) thick.

4 LEDs light up green

≤ 100%

3 LEDs light up green

≤ 75%

2 LEDs light up green

≤ 50%

1 LED lights up green

≤ 25%

1 LED flashes green

charging required

1

2

3

Charge status button

Charge indicator

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

14

The clamping force of the electromagnetic base will be lower if the clamping

surface is thin, rough, not flat, not rigid, the voltage is lower than required, or the bottom

of the base is worn.

The force will be lower if there is rust, paint, chips, or dirt. The workpiece should

be ground with coarse-grained sandpaper and cleaned.

Some types of steel (non-ferromagnetic) do not conduct the magnetic

flux, therefore the machine cannot clamp onto them.

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

15

4.8. Securing the machine with a safety strap

Always secure the machine with a safety strap!

It prevents the machine from falling if it loses the clamping.

Attach the machine to a stable structure by putting the strap through the hole in the

machine body. Make sure that the strap is tight and not twisted. If the machine

detaches from the workpiece and hangs on the strap, replace the strap. Do not put the

strap into the buckle from the front.

4.9. Machine state indication

There is an LED indicator on the control panel that shows state of the machine.

LED indication

Machine state

Machine performance

Green is on

Sufficient clamping force

–

Green flashes

Low clamping force

High risk of losing clamping

Red is on

Discharged battery

Motor stops,

after a time of up to 15 minutes the

electromagnetic base turns off

Red flashes

Motor overload or clamping loss

Motor stops

CORRECT ✓

Vertical drilling

INCORRECT

Inverted drilling

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

16

4.10. Preparing

1. Clean steel parts, including the spindle, from the anti-corrosion material used to

preserve the machine during storage and transport.

2. Attach the handles to the feed shaft.

3. Put the machine on a workpiece.

4. Select the correct tool. Clean the spindle and the tool with a dry cloth. Install the

tool in the arbor.

5. For vertical drilling with an annular cutter install the cooling system and fill it with

coolant. Make sure that the cooling system works correctly.

6. Install the battery.

7. Set the MAGNET switch to ‘I’ to turn on the clamping. Check the LED indicator

to see if the clamping force is sufficient.

The operator takes full responsibility for working with low clamping

force.

8. Secure the machine with the safety strap.

9. Turn the handles to the left to put the tool above the workpiece.

10.Lower the chip guard to cover the tool.

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

17

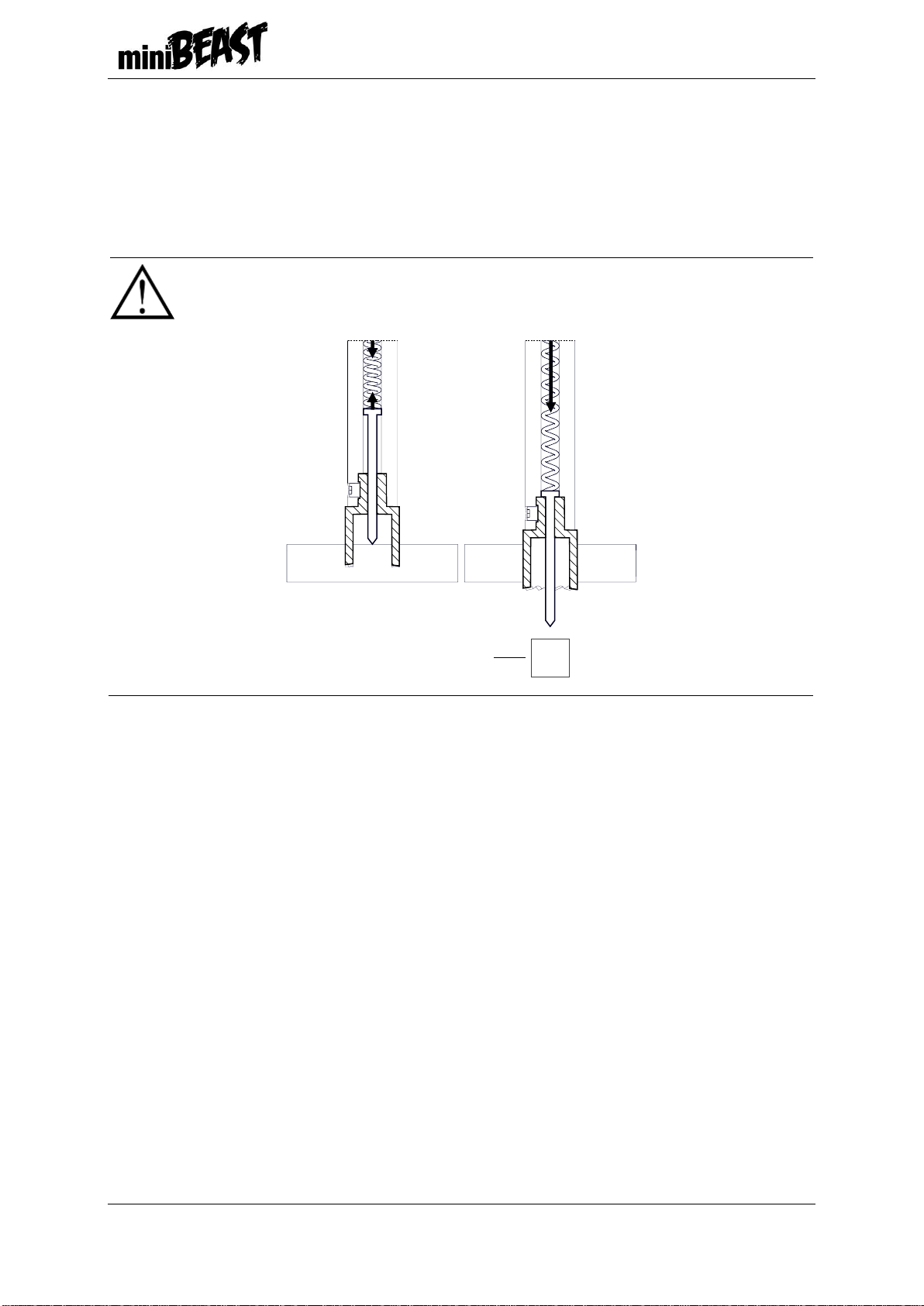

4.11. Drilling

1. Press the Motor START button to start the motor.

2. Turn the handles to the left to put the tool into the workpiece. Do not change the

position of the drilling machine while making the hole.

When the annular cutter goes through the workpiece, the slug core is

pushed out with a large force.

3. After the hole is made, retract the tool from the workpiece. Press the Motor

STOP button to stop the motor.

4. Before you move the machine, set the MAGNET switch to ‘O’ to turn off the

base.

4.12. Finishing the operation

1. Turn off the motor and the base.

2. Remove the battery.

3. Clean the drilling machine and the tool.

4. Remove the machine from the work area.

5. If the cooling system is installed, remove the remaining coolant. To do this,

tighten the bottle cap, close the valve, and then press the pilot pin. Remove the

cooling system.

6. With gloves on, remove the tool from the arbor.

7. Put the machine in the box.

Slug core

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

18

5. ACCESSORIES

5.1. Battery charger ASC 145

Part number:

LDW-0738-10-00-30-0 (EU)

LDW-0738-04-00-30-0 (UK)

LDW-0738-06-00-30-0 (AUS/NZ)

LDW-0738-24-00-30-0 (USA/CND)

5.2. Battery 18 V LiHD 4.0 Ah

Part number:

AKM-0738-10-00-01-0

5.3. Battery 18 V LiHD 10.0 Ah

Part number:

AKM-0738-10-00-02-0

5.4. Pressure cooling system

Capacity: 2 liters

Part number:

UKL-0440-16-00-00-0

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

19

5.5. Pipe attachment

For pipes with diameters: 80 –250 mm (3.15″–9.84″)

Internal dimensions: 95 × 211 mm (3.74″× 8.31″)

Part number:

JEICB-S

5.6. Vacuum pad

Allows you to clamp the machine to flat non-ferromagnetic surfaces. Can be supplied

from an ejector with the compressed air or from a vacuum pump.

Part number (vacuum pad, supply hose):

JEI-VPAD

Part number (vacuum pump with safety reservoir):

AGR-0541-10-20-00-0 (EU)

AGR-0541-10-10-00-0 (UK)

Part number (ejector):

ZSP-0587-11-00-00-0

Minibeast Cordless

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Drilling & Cutting Solutions is prohibited.

20

6. ENVIRONMENTAL PROTECTION

In accordance with the European Directive 2012/19/EU, this device is

marked with the symbol of the crossed-out waste bin. This marking means

that the equipment must not be disposed of with other household waste after

the service life. The user must return the product to a collection point for used electrical

and electronic equipment. The collectors of used equipment, including local collection

points, shops and municipal units create an appropriate system for returning such

equipment. Correct handling of used electrical and electronic equipment helps in

avoiding damage to health and the environment, which may result from the presence

of dangerous components and incorrect storage and processing of such equipment.

In accordance with the European Directive 2006/66/EC, the batteries are

marked with the symbol of the crossed-out waste bin. Below this symbol

there may be a chemical symbol of heavy metal present in the battery, if its

percentage is above: 0.0005% for mercury (Hg), 0.002% for cadmium (Cd), 0.004%

for lead (Pb). Batteries must not be disposed of with household waste and WEEE

waste. The user must return the battery to a collection point for used batteries. Before

returning the battery, discharge it*, remove it from the device and protect the contacts

with insulating tape. Returning the battery to the collection point reduces the negative

impact of its hazardous substances on human health and the environment, and

enables the recovery of raw materials and plastics in the recycling process.

* refers to undamaged batteries

Table of contents

Other JEI Drill manuals

Popular Drill manuals by other brands

Pro Work

Pro Work SMJ 500E operating instructions

Lumberjack

Lumberjack DP16-910B-VS operating manual

Ribitech

Ribitech PRKIT92FP User and maintenance manual

Parkside

Parkside PABS 10.8 A1 - MANUAL 6 Operation and safety notes

Graphite

Graphite 58G020 instruction manual

BGS technic

BGS technic 8471 instruction manual