Jenaer Antriebstechnik EtherCAT CANopen ECOVARIO 616 User manual

Installation and Operating Instructions

ECOVARIO® 616

ECOVARIO® 616 D

Subject to change without notice!

Installation and Operating Instructions ECOVARIO® 616, 616 D

3

Edition Comment

April 2013 Preliminary version for prototypes

July 2013 Preliminary version for UL certification

Nov 2013 French translation of safety instructions added because of UL requirements

June 2015 Series; added: Profinet interface, RFI suppression filter

Published editions:

All rights reserved:

Jenaer Antriebstechnik GmbH

Buchaer Straße 1

07745 Jena

No parts of this original instructions may be translated, reprinted or reproducted on microlm or in other

ways without written permission by Jenaer Antriebstechnik GmbH.

e content of this document has been worked out and checked carefully. Nevertheless dierences from the

real state of the hard and soware can never be fully excluded. Necessary corrections will be carried out in

the next edition.

ECOSTEP®, ECOVARIO® und ECOLIN® are registered trademarks of Jenaer Antriebstechnik GmbH, Jena.

BISS® is a registered trademark of iC-Haus GmbH, Bodenheim.

CANopen® is a registered community trademark of CAN in Automation e.V., Nuremberg.

EnDat® is a registered trademark of Dr. Johannes Heidenhain GmbH, Traunreut

EtherCAT® is a registered trademark and patented technology, licensed by Beckho Automation GmbH,

Germany.

HIPERFACE® is a registered trademark of SICK STEGMANN GmbH, Donaueschingen.

Windows® is a registered trademark of Microso Corporation in the United States and other countries.

Installation and Operating Instructions ECOVARIO® 616, 616 D

4Subject to change without notice!

Subject to change without notice!

Installation and Operating Instructions ECOVARIO® 616, 616 D

5

Inhalt

1 About this manual ......................................................................................................................... 7

2 Safety instructions ......................................................................................................................... 7

2.1 Signal words and Symbols used .................................................................................................................7

2.2 General notes................................................................................................................................................8

2.3 Dangerous voltages ......................................................................................................................................8

2.4 Danger by hot surfaces ................................................................................................................................ 8

2.5 Danger by unintentional mechanical movements...................................................................................9

2.6 Prescribed use............................................................................................................................................... 9

3 Legal notes.................................................................................................................................... 10

3.1 Terms of delivery..........................................................................................................................................10

3.2 Liability..........................................................................................................................................................10

3.3 Standards and directives..............................................................................................................................10

3.3.1 UL/CSA conformity according to UL 508C (under preparation).........................................................10

3.3.2 CE conformity ..............................................................................................................................................11

4 Technical Data.............................................................................................................................. 13

4.1 Equipment.....................................................................................................................................................13

4.2 Rated data of the power stage..................................................................................................................... 14

4.3 General technical data................................................................................................................................. 15

4.4 Order key.......................................................................................................................................................16

4.5 Suitable types of motors .............................................................................................................................. 17

4.5.1 ECOSPEED motors .....................................................................................................................................17

4.5.2 Direct linear motors ECOLIN® ..................................................................................................................17

4.5.3 DC servo motors..........................................................................................................................................17

5 Installation................................................................................................................................... 18

5.1 Mounting.......................................................................................................................................................18

5.1.1 Inportant notes............................................................................................................................................. 18

5.1.2 Dimensions ...................................................................................................................................................18

5.1.3 Assembly .......................................................................................................................................................19

5.2 Electrical Installation...................................................................................................................................20

5.2.1 Important notes............................................................................................................................................ 20

5.2.2 EMC compliant installation........................................................................................................................ 20

5.2.3 Connection diagram.................................................................................................................................... 21

5.2.4 Types of lines ................................................................................................................................................ 23

5.2.5 Operation with residual current devices...................................................................................................23

6 Interfaces...................................................................................................................................... 24

6.1 Overview .......................................................................................................................................................24

6.2 Control signals.............................................................................................................................................. 26

6.2.1 X1A, X1B: Digital inputs and outputs, 24 V............................................................................................. 26

6.2.2 X2A, X2B: Digital Inputs ............................................................................................................................27

6.3 Power interfaces ...........................................................................................................................................28

6.3.1 X4: Ballast resistor........................................................................................................................................28

6.3.2 X5A/X5B: Motor connection .....................................................................................................................30

6.3.3 X6 Power Connection..................................................................................................................................31

6.3.4 X7A, X7B: Brake...........................................................................................................................................32

6.4 Safety functions ............................................................................................................................................33

Installation and Operating Instructions ECOVARIO® 616, 616 D

6Subject to change without notice!

6.4.1 Restart lock / Safe torque o (STO)........................................................................................................... 33

6.5 Encoders........................................................................................................................................................36

6.5.1 2-Axis Servo Ampliers ECOVARIO 616 D: X11, X12: Encoder ......................................................... 37

6.5.2 1-Axis Servo Amplier ECOVARIO 616: X11, X12: Encoder............................................................... 39

6.6 Serial interfaces ............................................................................................................................................41

6.6.1 X13: RS485/RS232 interface with 2 Capture Inputs................................................................................41

6.6.2 X14: Parameterizing USB interface ...........................................................................................................44

6.7 X21: CAN interface......................................................................................................................................45

6.8 Optional interfaces.......................................................................................................................................46

6.8.1 X22: Designs with encoder emulation ......................................................................................................46

6.8.2 X22: Designs with PROFIBUS DP-V0 interface......................................................................................47

6.8.3 X22: Designs with Ethernet interface........................................................................................................49

6.8.4 X22: Designs with EtherCAT® interface....................................................................................................52

6.8.5 X22: Designs with Pronet interface.........................................................................................................55

7 Commissioning............................................................................................................................ 58

7.1 Important notes before commissioning.................................................................................................... 58

7.2 Control and display elements.....................................................................................................................58

7.3 Work schedule commissioning ..................................................................................................................59

7.3.1 State display...................................................................................................................................................60

7.3.2 Error messages.............................................................................................................................................. 61

7.3.3 Setting and querying displaying parameters via the keys....................................................................... 64

7.3.4 Bootloader mode..........................................................................................................................................64

8 Parameter setting......................................................................................................................... 65

8.1 User interface ECO Studio..........................................................................................................................65

8.2 Setting the current allocation to the both axes of the ECOVARIO 616 D ...........................................65

9 Accessories ................................................................................................................................... 66

9.1 Supplementary parts.................................................................................................................................... 67

9.1.1 Shield set........................................................................................................................................................67

9.2 Ballast resistors .............................................................................................................................................68

9.2.1 Ballast resistors 200 W (500 W cooled) .................................................................................................... 69

9.3 Mating connector sets .................................................................................................................................70

9.4 Cables............................................................................................................................................................. 71

10 Appendix...................................................................................................................................... 72

10.1 Glossary......................................................................................................................................................... 72

10.2 Index of formulae......................................................................................................................................... 74

10.3 Index of standards and directives ..............................................................................................................74

Subject to change without notice!

Installation and Operating Instructions ECOVARIO® 616, 616 D

7

1 About this manual

is original instructions describe the servo amplier range ECOVARIO® 6xx. It concerns to all persons

who project, install and commission ECOVARIO® 616 or ECOVARIO® 616 D drives.

Further information:

Soware commissioning: „ECO Studio Operation Manual ECOVARIO®, ECOSTEP®, ECOMPACT®“

Programming: manual „Object Dictionary ECOVARIO® and ECOSTEP®“, soware tool ECO Studio

Application Notes ECOVARIO® and ECOSTEP®

Motor data: Product catalogue „ECOSTEP®/ECOVARIO®/ECOLIN® Drives“.

is manual makes the following demands on qualied personnel:

Transport: Personnel trained in handling electrostatic sensitive devices

Installation: Electrotechnically qualied personnel who know the security directives of electrical enginee-

ring and automation

Setup/Commissioning: Qualied personnel with a broad knowlege of the elds of electrical engineering,

automation and drives.

Knowledge of machine safety legislation is compulsory.

2 Safety instructions / Consignes de sécurité

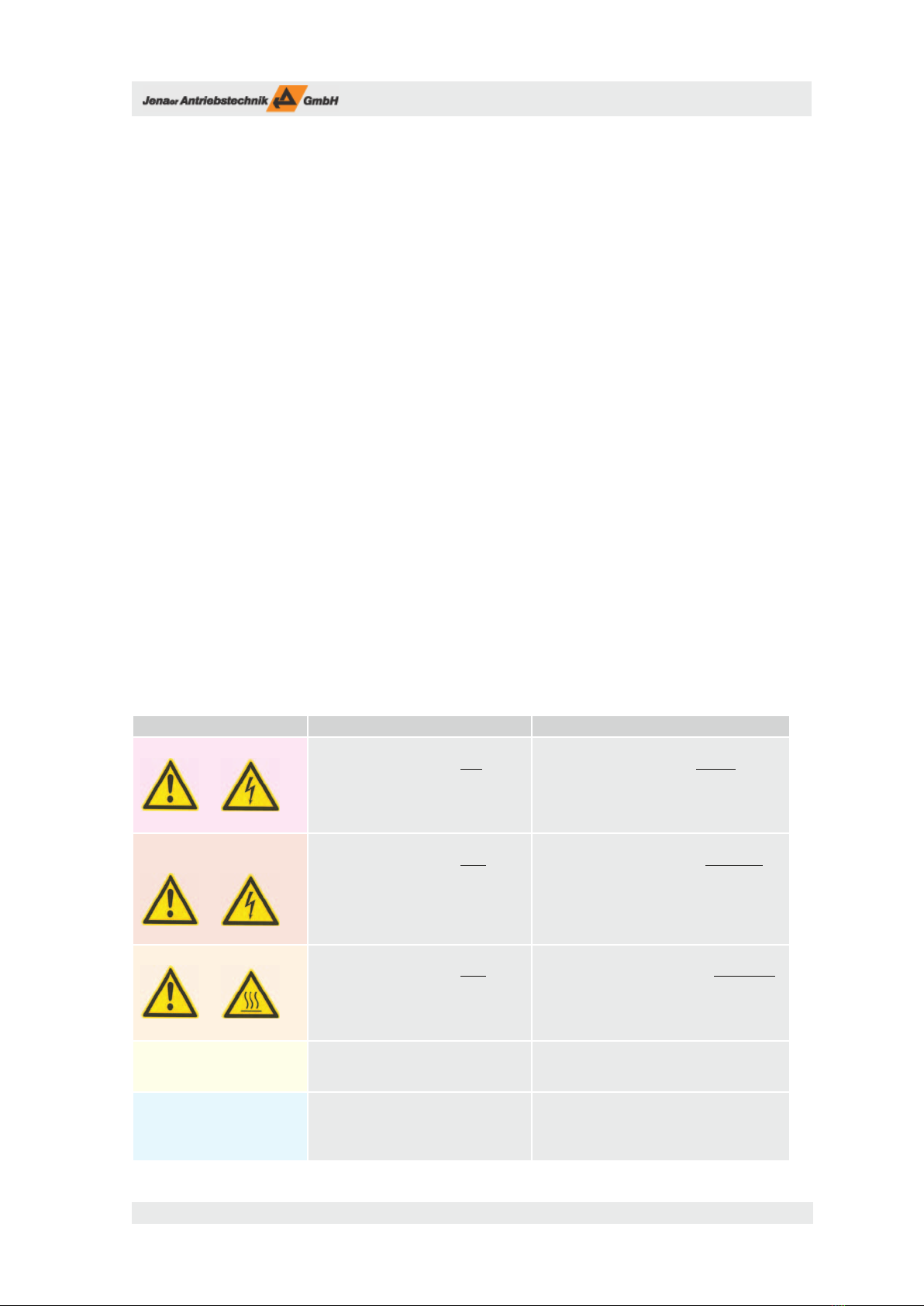

2.1 Signal words and symbols / Mots d‘avertissement et symboles

Table 2.1: Signal words and possible symbols / Mots d‘avertissement et symboles

Description Description

DANGER Warning about a dangerous situation.

Disregarding this warning will lead to

death or serious, irreversible injuries.

Left symbol: General danger

Right symbol: Dangerous electrical

voltages

Indique une situation dangereuse. Le non-re-

spect de l’indication de danger mènera à la mort

ou à des blessures graves ou irréversibles.

Pictogramme de gauche : indication générale de

danger

Pictogramme de droite : Danger du au courant électrique

WARNING /

AVERTISSEMENT

Warning about a dangerous situation.

Disregarding this warning may lead to

death or serious, irreversible injuries

Left symbol: General danger

Right symbol: Dangerous electrical

voltages

Indique une situation dangereuse. Le non-

respect de l’indication de danger peut mener à la

mort ou à des blessures graves ou irréversibles.

Pictogramme de gauche : indication générale de

danger

Pictogramme de droite : Danger du au courant

électrique

CAUTION / ATTENTION Warning about a dangerous situation.

Disregarding this warning may lead to

minor injuries

Left symbol: General

Right symbol: Hot surfaces

Indique une situation dangereuse. Le non-

respect de l’indication de danger peut mener

à des blessures légères.

Pictogramme de gauche : indication générale

Pictogramme de droite : Attention aux surfaces

chaudes

NOTICE / PRUDENCE Disregarding this note may lead to

damages of things.

Indique une situation qui, si elle n’est pas évi-

tée, peut mener à la détérioration de matériel.

INFO / INDICATION

Not a safety instruction. However:

Important information on the use of

the servo amplier.

N’indique pas de situation de danger, mais

une information importante par rapport à

l’utilisation de l’amplicateur de servomoteur.

Installation and Operating Instructions ECOVARIO® 616, 616 D

8Subject to change without notice!

2.2 General notes / Indications générales

CAUTION /

ATTENTION

Improper handling of the servo amplier may

lead lead to injuries and material damage.

Read this documentation carefully before you install

and commission the device. The technical data and

the information on connection requirements (name-

plate and documentation) have to be adhered to.

Only properly qualied personnel are permitted

to perform activities such as transport, installati-

on, setup and maintenance of the servo amplier

ECOVARIO®.

L’utilisation non conforme des amplicateurs de

servomoteurs peut entrainer des blessures et des

dégâts matériels.

Veuillez lire la documentation avant d’installer et de

mettre en route l’appareil. Les données techniques

ainsi que les informations concernant le raccordement

(Plaque constructeur et documentation) doivent abso-

lument être respectées.

Le transport, l’installation, la mise en service de

l’amplicateur de servomoteurs ECOVARIO® ne doivent

être réalisés que par du personnel autorisé et qualié.

CAUTION /

ATTENTION

The manufacturer of the machine must generate

a hazard analysis for the machine and take appro-

priate measures to ensure that unforeseen move-

ments cannot cause injury or damage to any per-

son or property.

In case of modications or retrots with components

of manufacturers other than Jenaer Antriebstechnik,

please contact us to clarify that those components

are suitable to be assembled with our devices..

Le fabricant d’une machine ou d’une installation

doit réaliser une analyse des risques et en tirer les

conséquences qui assurent une utilisation en toute

sécurité de l’ensemble de l’installation.

Lors de modication ou intégration de matériels

d’autres fabricants, merci de nous contacter pour que

nous puissions vérier la compatibilité de ces éléments

avec nos composants d’entrainement.

2.3 Dangerous voltages / Danger dus à des tensions dangereuses

DANGER Never open the units during operation. There

is danger of life or a risk of serious health and

material damage.

Covers and cabinet doors have to be kept closed

during operation. With the opening of the device all

warranty and liability claims against Jenaer Antriebs-

technik GmbH are void.

Ne pas ouvrir l’appareil pendant l’utilisation. Il y a

danger de mort ou danger de graves dommages à

la santé et au matériel.

Les capots et portes d’armoires électriques doivent

restés fermés pendant l’utilisation. L’ouverture de

l’appareil entraine la perte de toute garantie et respon-

sabilité de Jenaer Antriebstechnik GmbH.

WARNING /

AVERTISSEMENT

The protective earth conductor has to be proper-

ly applied before applying a voltage.

If the protective earth conductor is not connected, in

case of a failure e.g. the housing of the servo ampli-

er can be at hazardous voltage level.

Un raccordement à la terre réglementaire doit

obligatoirement être raccordé avant la mise sous

tension de l’appareil.

Si cette mise à la terre n’est pas raccordée, le boitier de

l’amplicateur de servomoteur peut, en cas de prob-

lèmes, mener de dangereuses tensions.

WARNING /

AVERTISSEMENT

Never undo electrical connections while they are

live! There is a risk of arcing. Arcs can cause injury

and damage contacts.

During operation logic and power connectors are

live.

Ne pas eectuer de débranchements sous tension.

Il y a danger d’arc électrique qui peut blesser des

personnes et endommager des contacts.

Pendant l’utilisation les conducteurs de pilotage et de

puissance conduisent des tensions dangereuses.

WARNING /

AVERTISSEMENT

Directly after disconnecting the servo amplier

from the power supply never touch parts of

the device which potentially could be live (e.g.

contacts).

Wait at least six minutes. Capacitors can still have

dangerous voltages present. To be sure measure the

DC link circuit and wait till it has fallen below 40 V.

Ne touchez pas de pièces de l’amplicateur de

servomoteurs directement après l’avoir débranché

de l’alimentation électrique qui peuvent être po-

tentiellement conducteur de tension (par exemple

des contacts).

Attendez au moins 6 minutes. Les condensateurs

peuvent rester chargés aussi longtemps de tension dan-

gereuse. Mesurez par sécurité les tensions entre circuits

jusqu’à qu’elles soient inférieurs à 40V.

Subject to change without notice!

Installation and Operating Instructions ECOVARIO® 616, 616 D

9

2.4 Danger by hot surfaces / Dangers dus à des surfaces chaudes

CAUTION /

ATTENTION

Hot surfaces may cause burns to the skin.

As the housing of the ECOVARIO 6xx serves

also as heat sink during operation the surface

temperature may rise to more than 70°C.

Des surfaces chaudes peuvent entrainer des brulures.

Le boiter de l’ECOVARIO sert également de radiateur, ceci

entraine qu’il peut atteindre des températures de plus de 70°C

pendant l’utilisation.

2.5 Danger by unintentional mechanical movements /

Dangers dus à des mouvements involontaires

DANGER Unintentional movements of motors,

tools or axes may lead to death or serious

injuries.

ECOVARIO® drives can produce strong mecani-

cal powers and high accelerations. Avoid sta-

ying in the danger zone of the machine. Never

switch o safety equipment! Emergency-o

equipment must be workable in all operation

modes, especially during setup and mainte-

nance. Malfunctions should be repaired by

qualied personnel immediately.

Des mouvements involontaires de moteurs, d’axes ou

d’outillages entrainent un danger de mort ou de bles-

sures.

Les entrainements ECOVARIO® peuvent engendrer de très

fortes accélérations mécaniques ainsi que des forces très éle-

vées. Il faut éviter de se trouver dans la zone de danger de la

machine. Des équipements de sécurité ne doivent jamais être

mis hors service. Des équipements d’arrêt d’urgence doivent

rester opérationnels dans tous les modes de fonctionnement,

aussi pendant la mise en service ainsi qu’en mode mainte-

nance. Des dérangements doivent être résorbés sans délai par

du personnel qualié.

2.6 Prescribed use / Utilisation conforme

e servo ampliers ECOVARIO® are components which are built into electrical equipment

or machines and can only be used as integral components of such equipment. e leakage

current of ECOVARIO® is higher than 3.5 mA. All notes about technical data and ambient

conditions have to be observed. Note the requirements concerning mounting position and

reserved space for ventilation given in chapter 5.1.3.

Using the unit in hazardous locations and in ambients containing oil, gas, vapours, dusts,

radiations etc. is prohibited if it is not explicitly allowed.

e manufacturer of the machine must generate a hazard analysis for the machine and take

appropriate measures to ensure that unforeseen movements cannot cause injury or damage

to any person or property.

L’amplicateur de servomoteurs ECOVARIO® est un composant de systèmes d’entrainement, il

doit être installé en en monte xe dans une armoire électrique prévue à cet eet. Le courant de

terre de l’ECOVARIO® est supérieur à 3,5 mA.

Toutes les indications de donnée techniques et conditions d’implantation doivent absolument

être respectées. Veuillez respecter les positions de montage et les espaces nécessaires à l’aération

indiqués dans le chapitre 5.1.3.

L’utilisation de l’appareil est interdite dans des environnements aux risques explosifs, environne-

ments huileux, acide, gazeux, vaporeux, poussiéreux, radiants, etc… s’il n’est pas expressément

autorisé pour ces milieux.

Le fabricant de la machine ou de l’installation doit établir une analyse des risques et en tirer les

conséquences qui garantissent une utilisation en toute sécurité.

Installation and Operating Instructions ECOVARIO® 616, 616 D

10 Subject to change without notice!

If one or more servo ampliers ECOVARIO® are built into machines or plants the intended

operation of the servo amplier is forbidden until it has been established that the machine or

plant fullls the requirements of the EC Machinery Directive 2006/42/EC and the EMC Di-

rective 2004/108/EC. Further EN 60204 and ENISO 12100 parts 1 and 2 have to be observed.

La mise en service d’une installation ou une machine où sont intégrés un ou plusieurs ECOVARIO®

est interdite jusqu‘à ce qu‘il ait été établi que toutes les dispositions des directives européennes et

des règles de sécurité de protection contre les accidents spéciques au pays d’implantation soient

remplies. En particuliers, il s’agit en premier ordre de la Directive Machines 2006/42/CE et de la

Directive CEM 2004/108/CE. Puis DIN EN 60204 et DIN EN ISO 12100, parties 1 et 2.

Safety function „Safe Torque O“, STO (cf. chapter 6.4.1) / Fonction de sécurité „Safe

Torque O “, STO, chapitre 6.4.1

e safety function STO must be integrated into a safety circuit that meets the demands of the

safety standards of EN 60204, EN ISO 12100-1 and -2 and EN ISO 13849-1. It must only be

activated when the motor is not longer rotating. Drives with a suspended load must have an

additional safe mechanical blocking.

La fonction de sécurité STO doit être intégrée dans un circuit de sécurité, les exigences des direc-

tives DIN EN 60204, DIN EN ISO 12100-1 et -2 et EN ISO 13849-1 sont susantes.

Elle ne doit être activée que si le moteur est arrêté et isolé de toute force s’exerçant sur lui (par

exemple des charges suspendues) qui doivent être bloquées avec un dispositif mécanique com-

plémentaire.

2.7 Foreseeable misuse of the safety function STO /

Mauvaises utilisation prévisibles de la fonction de sécurité STO

e safety function STO must not be used if the drive is to be made inactive for the following

reasons:

cleaning, maintenance and repair operations

long inoperative periods

In such cases the entire system should be disconnected from the supply by the personnel,

and secured (main switch).

in emergency-stop situations

In emergency-stop situations the main contactor is switched o (by the emergency-stop

button or the BTB-contact in the safety circuit).

La fonction de sécurité STO ne doit pas être utilisée

pendant la mise à l’arrêt pour travaux de nettoyage, de maintenance, de

réparation ainsi que pour de longues interruptions d’utilisation : Dans ces

cas, l’installation doit être mise hors tension par le sectionneur principal

dans une situation d’arrêt d’urgence : dans ce cas, un relais d’arrêt d’urgence doit mettre

l’installation hors tension.

Subject to change without notice!

Installation and Operating Instructions ECOVARIO® 616, 616 D

11

3 Legal notes

3.1 Terms of delivery

Our terms of delivery are based on the „e General Terms of Delivery for Products and Services of the Elec-

trical Industry“ (German: ALB ZVEI) of the Central Association of the Electrical and Electronics Industry

(ZVEI e.V.) in their current version.

3.2 Liability

e circuits and procedures in this manual are proposals. Every user has to check the suitability for every

special case. Jenaer Antriebstechnik GmbH is not responsible for suitability. Especially Jenaer Antriebstech-

nik is not responsible for the following damage causes:

disregarding the instructions of this manual or other documents concerning ECOVARIO®

unauthorized modications of drive, motor or accessories

operating or dimensioning faults

Improper use of the ECOVARIO® components

3.3 Standards and directives

ECOVARIO® are components intended to be built into machines or plants for industrial purpose.

e units meet the following standards:

DINEN61800-5-1: Adjustable speed electrical power drive systems – Part 5-1: Safety requirements; Elec-

trical, thermal and energy

DINEN61800-3: Adjustable speed electrical power drive systems – Part 3: EMC requirements and specic test methods

DIN EN 60204: Safety of machinery - electrical equipment of machines - Part 1: General requirements.

3.3.1 UL/CSA conformity according to UL 508C (under preparation) /

Conformité UL/CSA d’après UL 508C (en préparation)

If ECOVARIO® servo ampliers are to be used in countries where UL (Underwriters Laboratories Inc.) or

cUL conformity resp. is required the appropriate type has to be selected (cf. chapter 4.3 „Order key“).

For further information see UL le number E244038 at www.ul.com.

Si les amplicateurs de servomoteur ECOVARIO® sont installés dans des pays où l’ UL ou une conformité cUL

est requise, le type exact qui est requis doit être précisé lors de la commande on choisissant le type exacte (voir

chapitre 4.3 clé du type). Vous trouverez des informations complémentaires sous le numéro de chier UL -

E244038 sur la page web www.ul.com.

e UL(cUL) certication (UL 840 and UL 508C in this case) is related exclusively to the mechanical and

electrical design of the device. UL(cUL) certied servo ampliers are in accordance with the respective

american and canadian re regulations.

La certication UL(cUL) (Dans ce cas UL 840 et UL 508C) se rapporte exclusivement aux caractéristiques de

constructions mécaniques et électriques de l’appareil. Les directives UL(cUL) xent entre autres les exigences tech-

niques minimales pour appareils électriques pour prévenir les risques d’incendie qui émanent d’appareils électriques.

e installation and safety precautions in this documentation have to be observed.

Les indications d’installation et de sécurité de ce document doivent être respectées.

Installation and Operating Instructions ECOVARIO® 616, 616 D

12 Subject to change without notice!

3.3.2 CE conformity

ECOVARIO® servo ampliers are components that are intended to be built into electrical plant and ma-

chines for industrial use. e manufacturer of the machine is responsible that the machine or plant fullls

the requirements of the EMC directive.

e servo ampliers have been tested by an authorized testing laboratory in a dened conguration with the

system components which are described in this documentation.

Any divergence from the conguration and installation described in this manual means that you will be

responsible for carrying out new measurements to ensure that the regulatory requirements are fullled. For

servo ampliers with integrated safety function the conformity assessment is carried out according to the

EC machine directive 2006/42/EC.

Subject to change without notice!

Installation and Operating Instructions ECOVARIO® 616, 616 D

13

Jenaer Antriebstechnik GmbH •Buchaer Straße 1 •07745 Jena

Tel.: +49 (0) 3641/63376-0 •Fax: +49 (0) 3641/63376-99 Internet: www.jat-gmbh.de •E-mail: info@jat-gmbh.de

EG – Konformitätserklärung

EC –Declaration of Conformity

Hiermit erklären wir / Herewith we

Jenaer Antriebstechnik GmbH, Buchaer Str. 1, 07745 Jena, Deutschland

in alleiniger Verantwortung, dass das gelieferte Modell / declare under our own responsibility that the supplied

model of

Servoverstärker mit Sicherheitsfunktion ECOVARIO

®

616 xR-xx-xxx-xxx

Servo amplifier with safety function

den Anforderungen der

EG-Maschinenrichtlinie 2006/42/EC

entspricht.

complies with

EC Machinery Directive 2006/42/EC

Hierfür wurden die folgenden harmonisierten Normen angewendet / For this, the following harmonized standards

were applied:

EN 60204-1:2006, EN ISO 13849-1:2008

EN 61800-5-2:2007, EN 61800-5-1 / VDE160

EN 61800-3:2004

Das Produkt ist nach Artikel 2, Buchstabe c der Richtlinie

2006/42/EG als Sicherheitsbauteil definiert. Es ist ausschließlich für

den Einbau in eine Maschine bestimmt. Die Inbetriebnahme ist so

lange untersagt, bis die Gesamtmaschine, in die das Produkt

eingebaut werden soll, den Bestimmungen der Richtlinie

2006/42/EG entspricht.

Die Sicherheitshinweise der Betriebsanleitung sind zu beachten.

The products are defined as safety components according to directive

2006/42/EC. They are exclusively intended for installation in machines.

Operation is prohibited until it has been determined that the machines

in which these products are to be installed, conform to the directive

2006/42/EC.

The safety instructions of the manual are to be considered.

Ort, Datum der Ausstellung Geschäftsführer Dokumentationsverantwortlicher

(Place and date of issue) (General Manager) (Responsible for documentation)

Jena, 07.01.2013

Dipl.-Ing. (FH) Stephan Preuß Dipl.-Ing. Gerald Bobe

Installation and Operating Instructions ECOVARIO® 616, 616 D

14 Subject to change without notice!

4 Technical Data

4.1 Equipment

Features:

Supply voltage range from 200 to 528 VAC 3-phase

Integrated support for 1Vp-p SinCos encoder, incremental encoder

Integrated support for BISS B, BISS C or HIPERFACE protocol

Integrated encoder emulation

Support for second feedback input

Internal brake resistor; external brake resistor connector.

Safety:

Integrated Safe Torque O (STO) function according to EN 61800-5-2 SIL 2

Sucient isolation distances / creepage distances for safe galvanic isolation according to EN 61800-5-1

between the supply connectors / motor connectors and the signal electronics.

Overvoltage detection, short-circuit protection, phase failure supervision

Temperature monitoring of the servo amplier and of the motor

Motor overload protection: I2t monitoring.

Parameterization:

Commissioning soware ECO Studio with wizard functions.

Controller data:

Digital current, velocity, and position control with position, speed and torque limiting, minimum cycle

time for current control: 62,5 µs

Digital lter functions eective on resonant loads

Parameterisable velocity proles with jerk limiting

256 motion proles storable.

In-/outputs:

8 digital inputs per axis, includes 1 Enable input

3 digital outputs per axis, includes 1 Ready output

1 STO input per axis

1 STO output contact per axis.

Field bus interfaces (dependent on the selected option):

CANopen

EtherCAT

Probus DP

Pronet.

Subject to change without notice!

Installation and Operating Instructions ECOVARIO® 616, 616 D

15

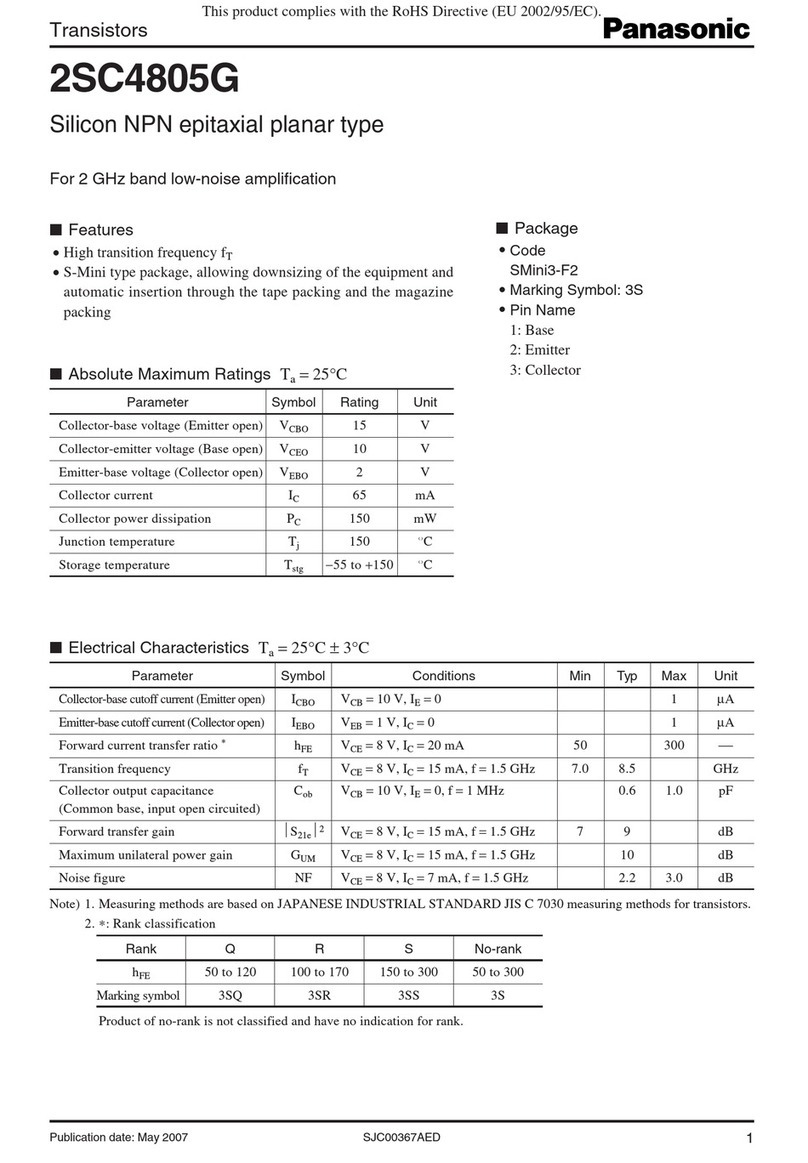

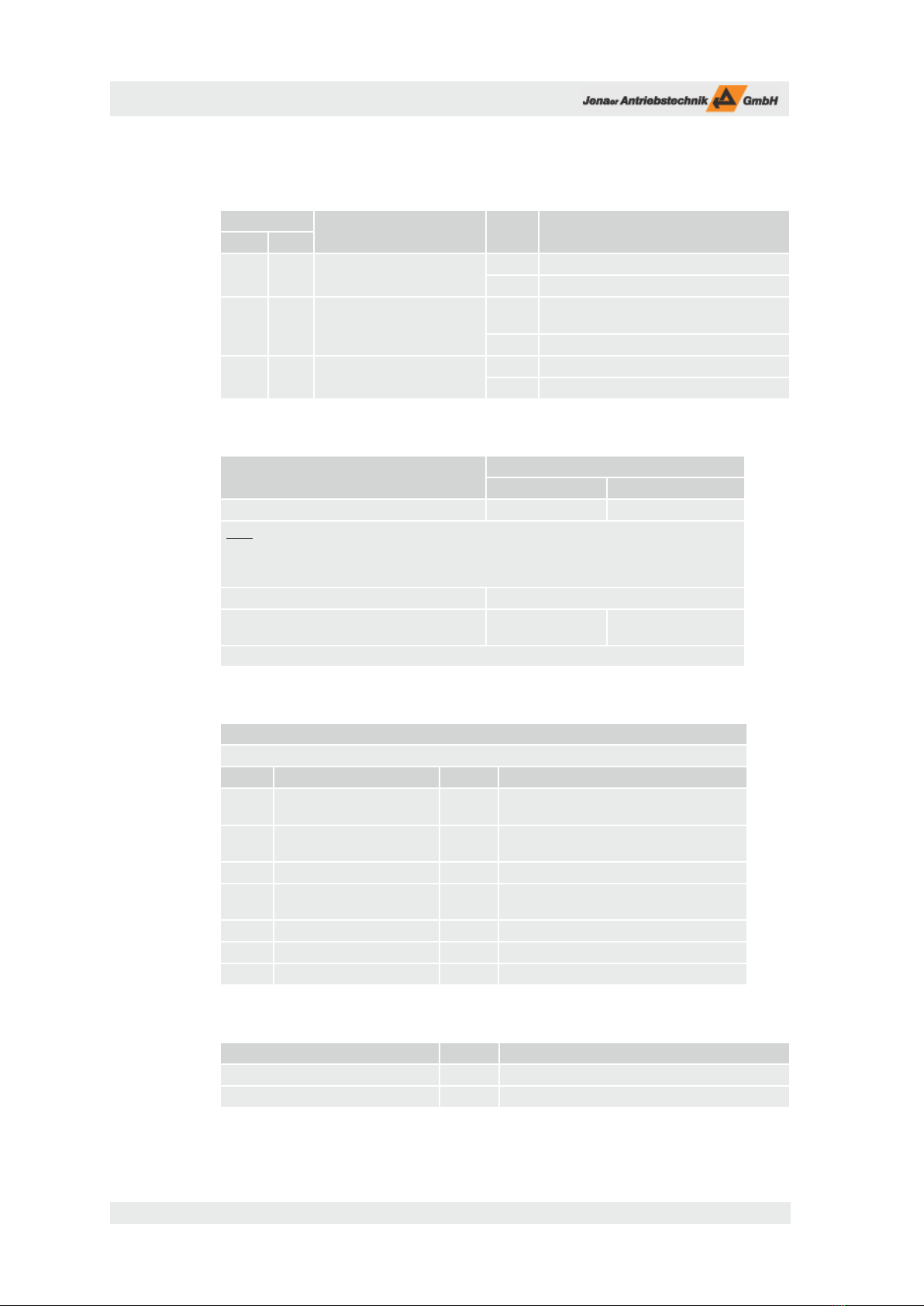

4.2 Rated data of the power stage

Table 4.1: Rated data of the power stage, AC supply at X6

Symb. Rated data Unit

616 AR 616 DR

3-phase AC supply

UNetz Rated supply voltage at AC input connector X6 VAC 3~ 400

(200 ... 528 V)

3~ 400

(200 ... 528 V)

fNLine frequency Hz 49 – 61 49 – 61

SNRated installed load kVA 8,2 8,2

PVN Rated losses W 280 280

UON Rated output voltage1) VAC 390 390

ION Rated output current4) total ARMS 3~ 8 3~ 8 3)

PON Rated output power1) total W 5400 5400 3)

Losses if diverging from nominal load: PV= PV0 + PVI + PVD

PV0 Basic losses W t.b.d. t.b.d.

PVI/IOCurrent-dependent losses per A W/A t.b.d. t.b.d.

PVD/POOutput power-dependent losses per 100 W W/100 W t.b.d. t.b.d.

Power stage

IOP Peak output current2) ARMS 3~ 16 3~ 16 3)

UBUSN Rated DC link voltage VDC 560 560

UBUSP Max. DC link voltage VDC 850 850

UPOvervoltage trip VDC 850 850

CLDC link capacity µF 470 470

EN-P Regenerated capacity Ws 96 96

RB EXT External ballast resistor Ω 40 40

PBP EXT Impulse power ext. ballast resistor kW 17 17

1) The data refers only to the internal data of the servo amplier. Modications of the input voltage due to line supply uctuations are not

taken into consideration. That means that with 15 % less input voltage the output data (UON, PON), on X5 have to be reduced by 15 %.

For motors with a low inductivity the motor dimensioning for the maximum velocity should be 25% to 50% below the specied voltages

(otherwise very high ripple current). For motors with a high inductivity even a higher reduction might be required in order to achieve an

acceptable dynamic performance.

At a heat sink temperature of more than 75 °C or at an ambient temperature of more than 40°C the power stage is switched o.

2) The DC link connection (X4) has no inrush-current limiting. Therefore appropriate circuits have to be integrated in the central power supply.

The power supply also has to be resistant against regenerated energy. It must regulate the DC link voltage during dynamic operation under

the limit UP

. If the regenerating energy (deceleration of the drive) is higher than the energy consumed by all units connected to the DC bus,

the power supply must have a load circuit.

3) For the 2-axis servo amplier ECOVARIO 616 DR the sum of the currents of both axes is listed here. The sharing to the axes can be parame-

terized.

4) Ambient conditions for cabinet dimensioning. The losses PVN refer to nominal operation with IONenn and the maximum output power PDC. In

case of deviations the losses can be estimated as shown here.

Installation and Operating Instructions ECOVARIO® 616, 616 D

16 Subject to change without notice!

4.3 General technical data

Table 4.3: General technical data, control signals

No. Control signal Unit

616 A 616 D

1 1 24 V supply (current draw

without outputs)

V24 ±10 %

A 0.8

8 16 Digital control signal inputs V0 ... 36 (Switching level: L->H: 11 V; H->L: 7 V

acc. to IEC 61131-2 type 3)

mA 10 (at 24 V)

3 6 Digital control signal outputs V 24

A 0.5

Table 4.4: General technical data, external fuses

616 AR 616 DR

AC supply

16 A (characteristic C)

16 A (characteristic C)

Note: When the device is used in an UL environment the overcurrent protection equipment has

to comply to UL489 (current ≤ 13 A) or UL Class CC (current ≤ 15 A, time delay current limiting)!

Alternatively a motor protection switch (self protecting motor controller, certified acc. to UL508,

type E) can be used.

24 V supply max. 12 A (fast)

external ballast resistance (not accessory resistors

DPRxx-xxx)1) t.b.d. t.b.d.

1) The accessory ECOVARIO®resistors DPRxx-xxx are intrinsically safe and therefore do not have to be fused

.

Table 4.5: General technical data, ambient conditions

Ambient conditions

ECOVARIO® is designed for ambient conditions of class 3K3 following EN 50178.

Symb. Condition Unit

TAAmbient temperature during

operation with nominal load

°C 5 – 40

Degree of humidity (not con-

densing)

% R. H. 5 – 85

p Air pressure mbar 860 – 1 060

Cooling the closed cubicle has to be sufficiently ven-

tilated.

h Installation altitude m up to 1 000 without restriction of power

Installation position The technical data refer to a vertical position.

Protection class IP20

Table 4.6: General technical data, dimensions and weight

Dimensions and weight Unit ECOVARIO® 616

Dimensions w x h x d mm 82 x 330 x 225

Weight of unit kg 4.0

Subject to change without notice!

Installation and Operating Instructions ECOVARIO® 616, 616 D

17

4.4 Order key

Table 4.7: Order key ECOVARIO® 6xx

ECOVARIO® x xx x x - x x - xxx xxx

No. of parameter set (three digits)

No. of firmware (three digits)

Approvals

A: CE, standard design

B - I: CE, special design

J: CE, UL, standard design

(UL approval under preparation)

K - Z: CE, UL, special design

(UL approval under preparation))

Type of field bus

A: CAN + RS485 + encoder emulation

B: CAN + RS232 + encoder emulation

F: CAN + RS485 + PROFIBUS DP-V0

G: CAN + RS232 + PROFIBUS DP-V0

H: CAN* + Profinet + RS485

I: CAN* + Profinet + RS232*

K: CAN + Ethernet + RS485

L: CAN + Ethernet + RS232

P: CAN + EtherCAT® + RS485

Q: CAN + EtherCAT® + RS232

Options

R: Safety function„Safe torque off“ (STO)

N: no option

Supply

A: 3-phase AC; 1-axis power stage

D: 3-phase AC; 2-axis power stage

Current rating (rms for 5 s)

16: max. 16 A

Voltage rating (DC bus)

6: max. 600V

Name of the unit

*) CAN/RS232 as service interface for ECO Studio only; no object dictionary acc. to CANopen DS402

Example ECOVARIO® 616 DR-AA-000-000:

ECOVARIO® servo amplier with:

max. 600 VDC DC link voltage

max. 16A output current (total)

AC supply 3-phase, 2-axis power stage

Safety function „STO“

CAN interface + RS485 interface

+ encoder emulation

CE appproval, standard design

Fig. 4.1: Name plate ECOVARIO®, dimensions 70 x 20 mm

Installation and Operating Instructions ECOVARIO® 616, 616 D

18 Subject to change without notice!

4.5 Suitable types of motors

With ECOVARIO® 6xx servo ampliers various types of motors can be operated. Rotative and linear 3-pha-

se motors of the motor series ECOSPEED and ECOLIN® as DC motors can be driven. e motors must be

equipped with encoders for commutation and for position and speed control. Incremental encoders, SIN-

COS encoders and absolute encoders can be evaluated.

It is not possible to drive motors with resolvers as measuring system.

e techical data in this manual refer exclusively to the servo motors mentioned in chap. 4.4.1 and 4.4.2.

If you want to drive DC motors with ECOVARIO® please contact our technical support (see http://www.

jat-gmbh.de/engl/service/service.html)

4.5.1 ECOSPEED motors

e motor series 60C, 80C, 110C and 150C contain rotative, 3-phase

low-pole servo motors with holding torques between 0.5 and 11 Nm.

For technical data and accessories for the motors see our product

catalogue „ECOVARIO®-/ECOMPACT®-/ECOSTEP® Drives“ or

our web site www.jat-gmbh.de

Fig. 4.1: Motor series 60C, 80C and 110C

4.5.2 Direct linear motors ECOLIN®

Series SLM contains iron core, 3-phase, encoder commutated syn-

chronous linear motors from 220 to 1450 N peak force. Series SLME

provides provides ironless direct linear motors from 150 N to 400 N

peak force.

For technical data and accessories of the motors see our product cat-

alogue „ECOVARIO®-/ECOMPACT®-/ECOSTEP® Drives“ or our

web site www.jat-gmbh.de.

Fig. 4.2: Direct linear motors SLM, SLME

4.5.3 DC servo motors

DC motors are not part of the delivery range of the Jenaer Antriebstechnik GmbH but can be operated with

ECOVARIO® ampliers. In this case we recommend strongly to contact our technical service.

e ECOVARIO® supports DC motors with brushes as well as brushless DC servo motors in conjunction

with RS422 compatible standard encoders.

Subject to change without notice!

Installation and Operating Instructions ECOVARIO® 616, 616 D

19

5 Installation

5.1 Mounting

5.1.1 Inportant notes / Informations importantes

Make sure that transport and storage did no damage to the units. /

Veillez à ce que le matériel n’a pas subi de dommages lors du transport ou du stockage.

e ambient air must not be polluted by dust, greases, aggressive gas etc. Eventually appro-

priate countermeasures have to be taken (installation of lters, frequent cleaning). /

L’air de ventilation ne doit pas être souillé (Poussière, graisses, gaz agressifs, etc.). Le cas échéant

prendre les mesures nécessaires intégration de ltres, nettoyage régulier)

e ECOVARIO with STO function has to be mounted in a cabinet which conforms to

protection class IP54 (or in a comparable environment) /

L’ECOVARIO avec fonction STO doit être monté dans une armoire électrique ou un environne-

ment équivalent qui présente un degré de protection minimum IP54.

Depending on the power losses an appropriate ventilation should be provided /

Il faut prévoir une ventilation susante pour compenser les pertes par échauement.

Observe the mounting spaces. / Les espaces libres doivent être respectés.

Use 60/75°C copper wire only. e accessory cables provided by Jenaer Antriebstechnik

fulll these requirements. /

N’utiliser que des câbles à âme cuivre qui résistent à une température de 60/75°C. Les câbles

proposés par Jenaer Antriebstechnik dans son programme d’accessoires, respectent ces exigences.

At installation locations with permanent vibrations or shocks damping measures should be

taken into consideration. /

Dans des implantions exposées à des vibrations continues ou des chocs, il faut vérier si des

mesure de réduction des phénomènes vibratoires doivent être prises.

5.1.2 Dimensions

330 mm

300 mm

375,5 mm

263 mm

15,6 mm

82 mm

225 mm

Fig. 5.1: Dimensions of ECOVARIO® 616 [mm], upper shield optional

330 mm

300 mm

375,5 mm

263 mm

15,6 mm

82 mm

225 mm

Installation and Operating Instructions ECOVARIO® 616, 616 D

20 Subject to change without notice!

5.1.3 Assembly

Basically, ECOVARIO® 6xx is intended for vertical mounting (motor connectors X5A, X5B on the bottom).

In this mounting position devices can be operated with built-in fan unit at ambient temperatures of up to

40°C. e ECOVARIO 6xx with STO function has to be mounted in a cabinet which conforms to protection

class IP54 (or in a comparable environment).

Cable clamps and side metal sheets assure that the connecting cables are laid EMC conform by connecting

the cable shield extensively to chassis earth.

e shields with cable clamps shown in g. 5.3 are available as accessories (see table 9.1). It is important that

the air ow is not disturbed by components above or below the servo ampliers. e distance between the

servo amplifers has to be at least 3 mm.

e surface of the mounting plate has to be conductive (e.g. zinc plated). Varnished mounting plates must

not be used.

INFO /

INDICATION

Make sure that no heat accumulation can

occur in the cabinet.

The servo amplier switches o at too high

temperatures in the cabinet (Error D02 or D03, =>

p. 57, Motor without torque).

Assurez une ventilation forcée suffisante de

l’armoire électrique.

L’amplificateur de servomoteur se coupe en cas de

température trop élevée dans l’armoire électrique

(Erreur D02 ou D03, => p. 57, Moteur sans couple).

Fig. 5.3: Mounting dimensions cabinet, width, minimum spacing [mm]

Kabelkanal

Kabelkanal

300

85

60

60

300 20

60

ECOVARIO®

616/616D

Kabelkanal

ECOVARIO®

616/616D

ECOVARIO®

616/616D

ECOVARIO®

616/616D

85

Cable conduct

Cable conduct

Cable conduct

This manual suits for next models

1

Table of contents

Popular Network Hardware manuals by other brands

NEC

NEC Aspire Series Networking manual

Lab.gruppen

Lab.gruppen NLB 60E Operation manual

Xentino

Xentino A405N Quick installation guide

Extron electronics

Extron electronics IP Link Accessory Power over Ethernet Inserter IPA T... Specification sheet

Ubiquiti

Ubiquiti PowerBeam PBE-5AC-400-ISO quick start guide

Crestron

Crestron Network Device PWE-4803RU installation guide