17. Pressure Testing

The maximum gas supply pressure for the regulator supplied on this appliance is

14" W.C, The test pressure for checking this regulator must be at least 6" W.C. for

natural gas, and at least 11" W.C. for LP. It isshipped from the factory set for natural

gas at 5" W.C.

This appliance and its individual shutoff valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures

in excess of 1/2 PSIG (3.5 k Pa).

This appliance must be isolated from the gas supply piping system by closing its

individual manual shutoff valve during any pressure testing ofthe gas supplypiping

system at test pressures equal to or less than 1/2 PSIG (3.5 k Pa).

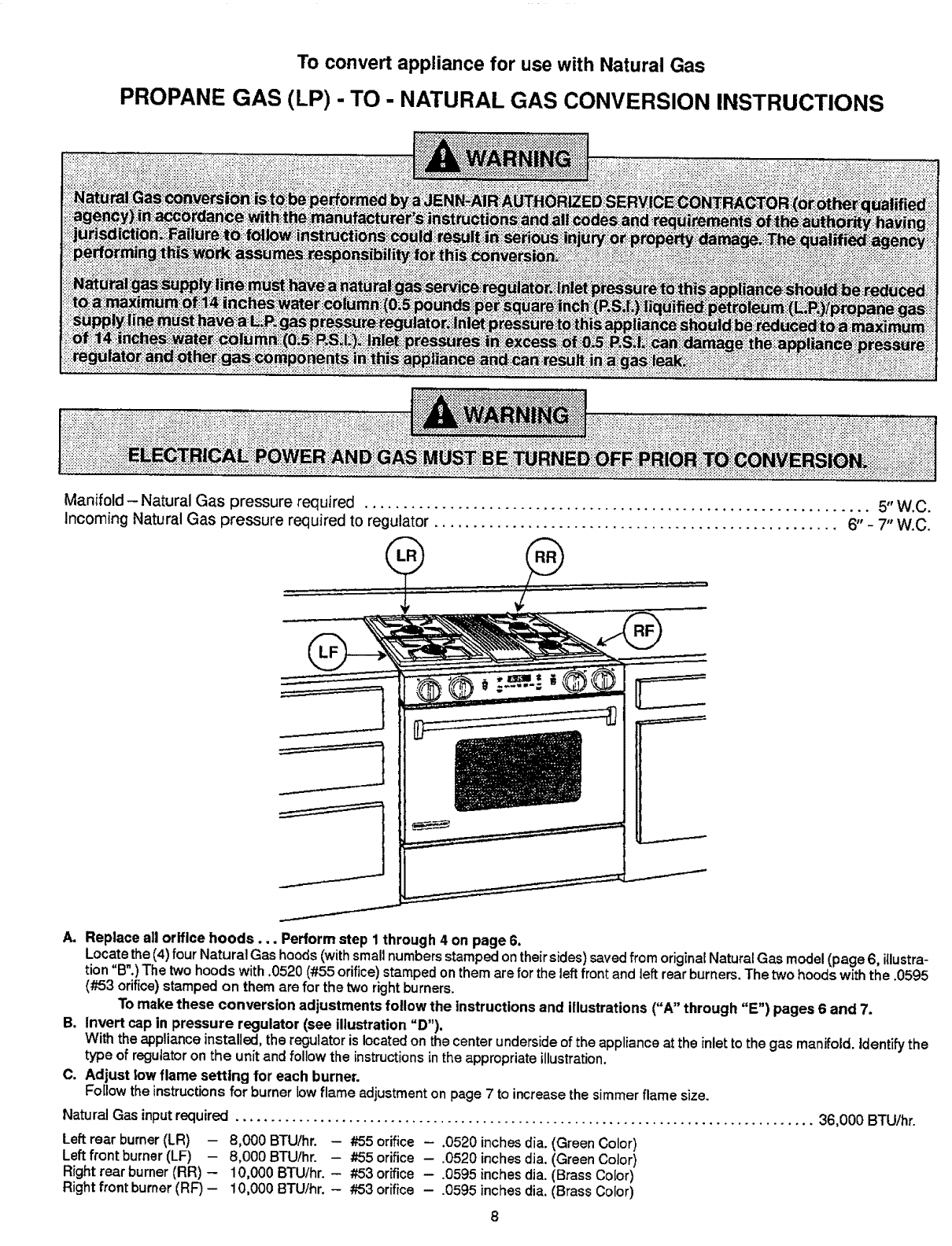

Appliance Pressure Regulator Conversion:

(see illustration "A")

Follow the instructions below to convert the regulator for use with LP gas. (This

appliance is shipped from the factory adjusted for use with natural gas.)

1, Unscrew the hex shaped cap from the neck of the regulator, (A wrench may be

required to loosen the cap.)

2. Within the cap is a plastic pin. Remove this pin from the cap by applying sideward

pressure to the pin, (See illustration,)

3. Invert the pin and snap it back into place within the cap by applying even finger

pressure at opposing edges of the pin's circular disc, The pin must be seated firmly

and squarely in the cap.

.Pin replacement may be most easily accomplished by placing the cap on aflat

horizontal surface, as shown in the illustration, and applying downward finger

pressure at the edges of the pin's disc.

4. Screw the cap securely back into place in the neck of the pressure regulator. (The

cap need not be wrench-tightened upon replacement. Firm finger tightening wilt

secure the cap.)

Appliance Pressure Regulator Conversion:

(see illustration "A")

To convert regulator to LP insert acoininto the slot inthe cap of the regulator and turn

counterclockwise to loosen. Reverse (invert) cap, push down and turn clockwiseto lock

in place. When finished, the marking"LP" should be visible inthe center well of the cap.

18. Conversion to LP Gas

This appliance is shipped from the factory equipped for use with natural gas. To

convert it from natural gas for use with LP gas, perform steps 1 through 4.

1, Remove natural gas orifice hoods. Remove LP orifice, (if so equipped) in tube

assemblies. Install color coded orifice hoods supplied.

(SEE LP GAS CONVERSION INSTRUCTIONS PAGE 7.)

2. Invert cap in convertible pressure regulator (if so equipped) located at entrance

to gas manifold.

3. Adjust air shutters on individual burners for proper flame appearance,

4. Adjust low flame setting at each burner by turning adjustment screw in center of

valve stem.

To make these conversion adjustments follow the instructions and

illustrations ("A" through "E").

This appliance is shipped from the factory with orifice hoods drilled for use with natural

gas. To convert from natural gas to LP, apply a 1/2" open-ended wrench to hex section

of orifice hood. TURN COUNTERCLOCKWISE TO REMOVE. Save the Natural Gas

orifice hoods just removed from this appliance for future use. Install color coded orifice

hoods supplied. (SEE GAS CONVERSION INSTRUCTIONS PAGE 7.) TURN

CLOCKWISE TO INSTALL. Hold dimension specified in illustration "B",

MAXITROL REGULATOR _Y=_A_

Rk_ERPRE_URE

B'DI_ B6EST0

C j_. LP APP...Y_Fdr¢;i_Mtf_IE RI_i,,AC_ INC_.

,

I_AHDPiN J _T lu,

ILLUSTRATION "A"

HARPER-WYMAN REGULATOR

The reversible cap is

labeled either"LP" or

"NAT" and is easiIy

recognized by the

raised center coin

slot (for Natural) or

the center well (for

LP).

ALTERNATE ILLUSTRATION "A"

1/2" OPEN END

WRENCH

TURN CLOCKWISE

TURN TO TIGHTEN

TO REMOVE ORIFICE HOOD

ILLUSTRATION "B"

TUBE ASSEMBLY

,._, ,j_,,-'- TUBE ASSEMBLY

OR,ROE

_._ _,,,--HOOD

DISCARDAND USE'--'--_

ORIFICE HOOD

FOR

SPECIFIED GAS.

5