GENERAL SAFETY AND ACCIDENT PREVENTION

INSTRUCTIONS

With variations in machines, some of these statements may be contradictory as

regards the servicing. In these cases it is advisable to follow the standard guidelines!

Basic rules:

Before anyone starts up the wood chipper study the safety rules for commerce

and operation!

1. Pay attention to the references in this operations guide as they are general

legal safety and accident prevention instructions.

2. The minimum age for service personnel is 18 years, but for the purpose of

training, under supervision, 16 years.

3. Regarding the use of public transport routes heed the respective decisions of

the StVO. (lights, warnings etc.)

4. Ensure whilst using public transport routes the ejector does not damage the

views and that it is not projected into the roads!

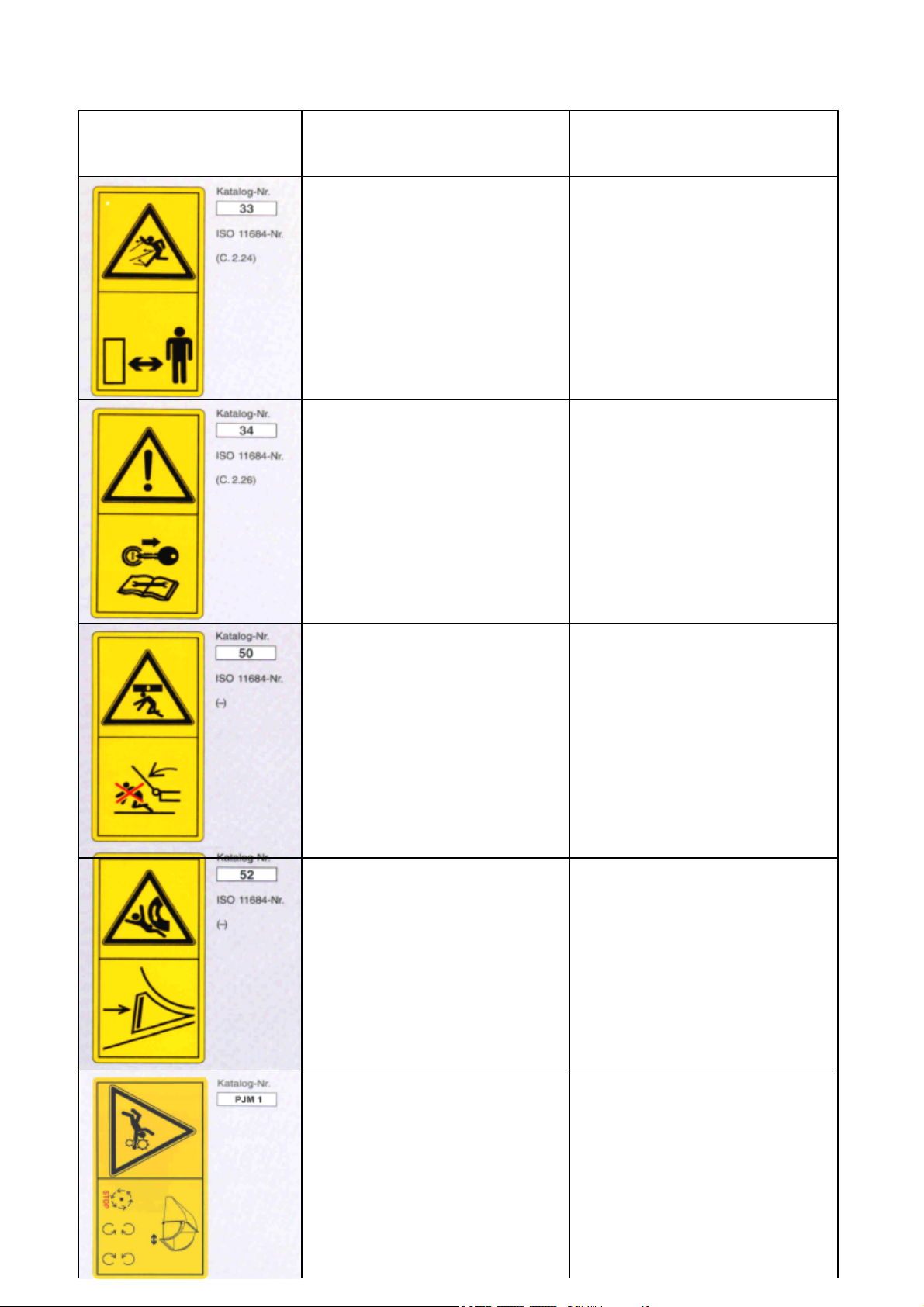

5. Before commencing work check that everything is in good working order.

Ascertain that all safety equipment is also in order. It is too late when the

machine is working!

6. The user is responsible for the welfare of others!

7. Stay away from the dangerous area of the machines!

8. Before starting a machine leave any dangerous areas!

9. Machines are not to be operated in enclosed areas!

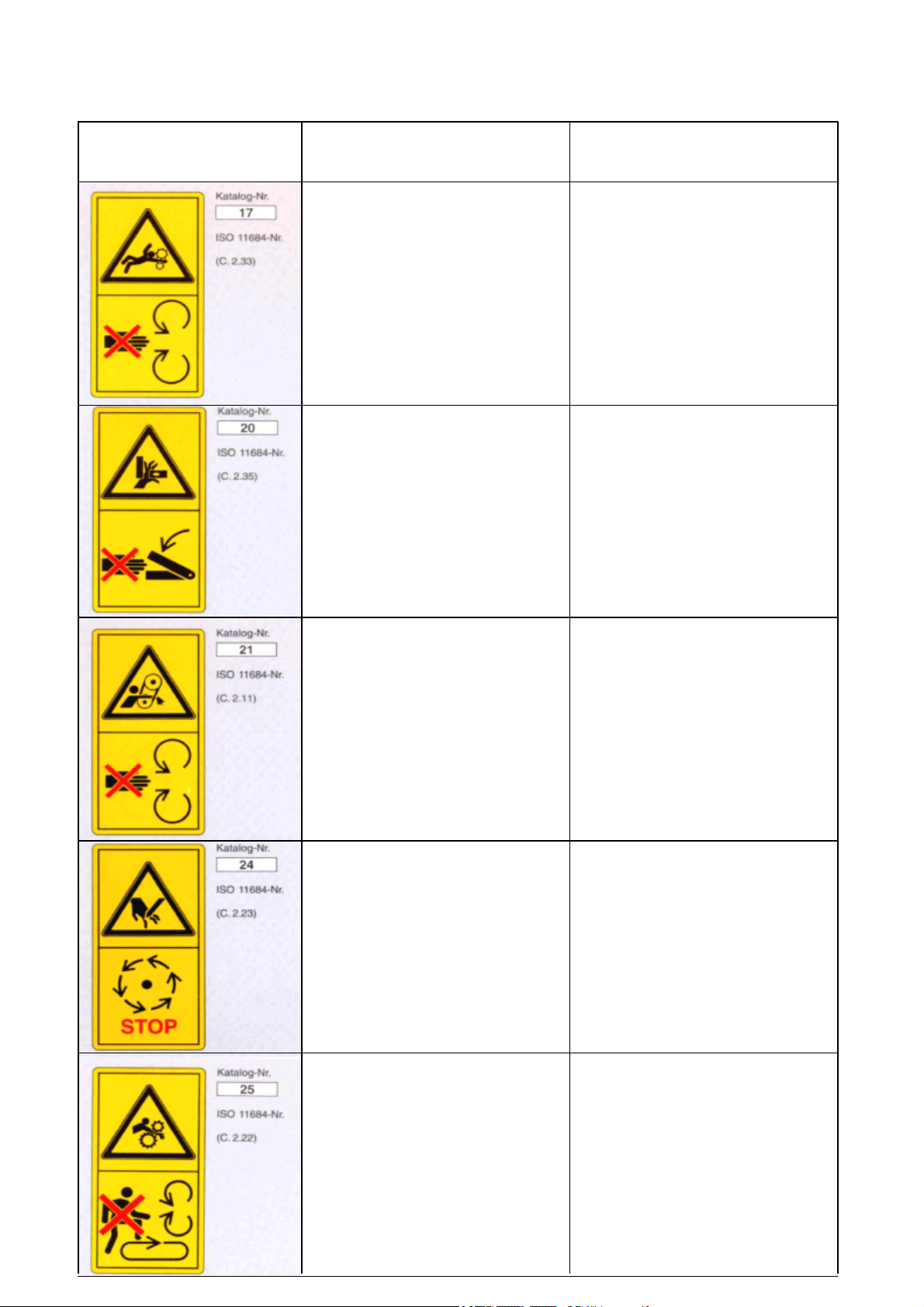

10. Employees clothing should be tight. Avoid loose clothing. Wear safe shoes,

protective eye, ear and head gear!

11. When leaving the machines ensure that they are unable to roll away and are

protected from unauthorised usage. (firm brakes activated, under-wedge in

place, power source switched off, ignition key removed.)

The Wood chipper as cultivation tool / supplement.

1. The operator alone is responsible for bringing in the machine and for its use in

traffic!

2. The chances of accidents occuring are significantly minimalised when the

wood chipper is coupled with the motor of another machine and when the

safety instructions are followed.

3. Before the construction and dismantling of the wood reducer by the three

steps outlined in the service instructions, bring the propulsion machine into

place, and ensure that it is switched off before any raising or lowering of the

machine is carried out!

4. Do not stay between the PTO and the tractor when the machine is running!

5. No one is allowed to halt the propulsion machine, the traction engine or

equipment, unless it is to stop the vehicle rolling away due to the parking brake

and/or the under-wedge being not properly in place.

6. Only put the pieces of the machine where they belong!

7. It is the function of the workers to control the breaking systems.

8. Pay attention to the maximum permissible support load of the adherent clutch!

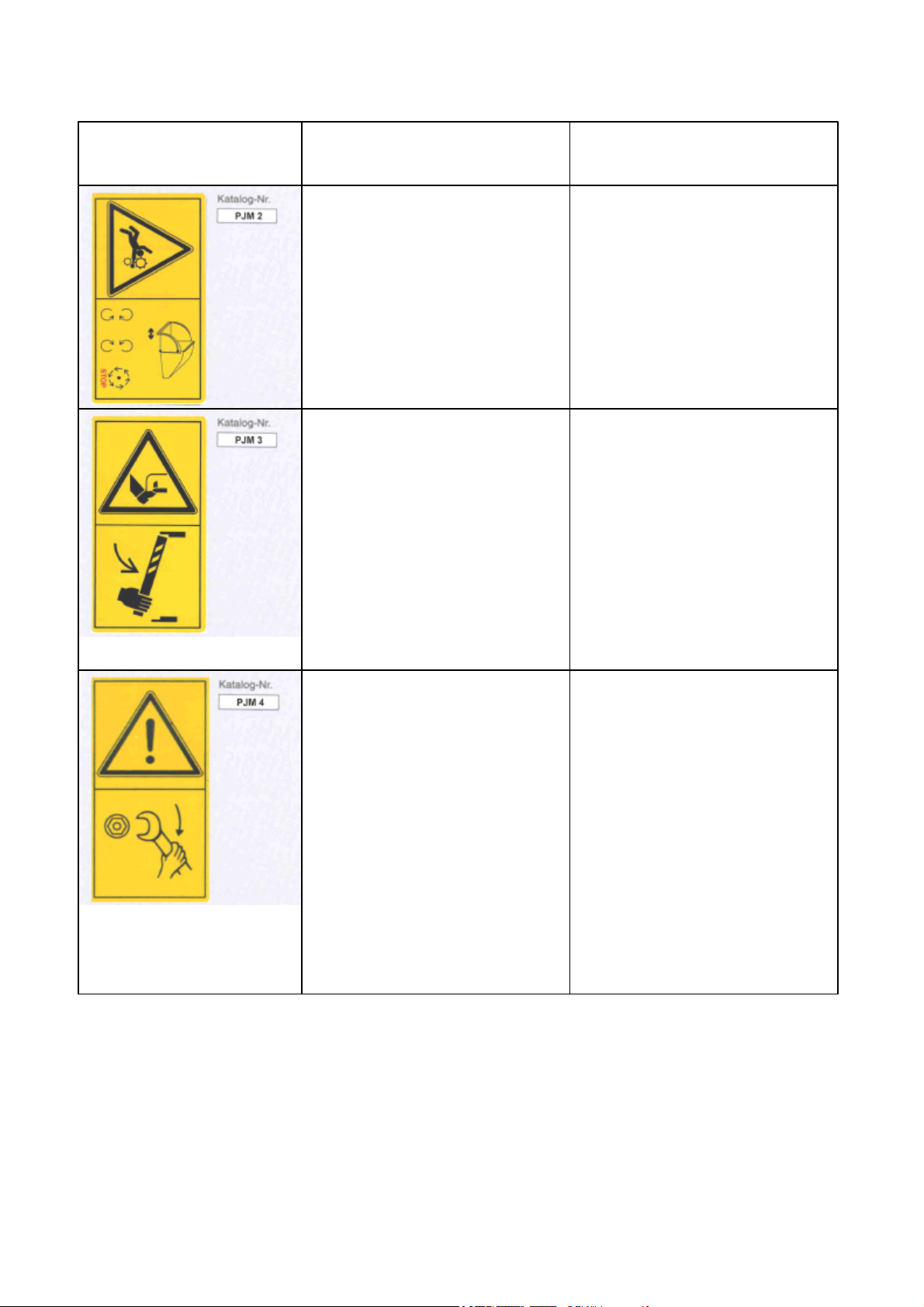

9. Take care with the difference betw een the markings of the hydraulic functions

of the propulsion machine and the wood chipper because if these are not

correctly placed, failures in the service of the machines will be exposed.( e.g.

forwards/backwards, raise/lower) – danger of accidents!