JEON DG Series User manual

Instruction Manual

D103761X012

March 2021

DG Series

Direct-Operated Regulators

Manual

DG Series Regulators

2

!

WARNING

Contents

1. Introduction ......................................................... 3

2. Specifications ........................................................ 3

3. Principle of Operation................................................. 7

4. Installation .......................................................... 9

5. Overpressure Protection .............................................11

6. Operating of Pressure Reducing Regulator..............................12

7. Operating of Backpressure Regulator ..................................12

8. Maintenance........................................................13

9. Pressure Reducing Regulator Disassembly ..............................14

10. Backpressure Regulator Disassembly .................................18

11. Parts Ordering .....................................................21

12. Part List ...........................................................21

Failure to follow these instructions or to properly install and maintain this equipment could result in an explosion, fire

and/or chemical contamination causing property damage and personal injury or death. Regulators must be installed,

operated and maintained in accordance with federal, state and local codes, rules and regulations and Emerson Process

Management Regulator Technologies Inc. (Emerson) instructions. If the regulator discharges process fluid or a leak

develops in the system, service to the unit may be required. Failure to correct trouble could result in a hazardous

condition. Call a qualified service person to service the unit. Installation, operation and maintenance procedures

performed by unqualified person may result in improper adjustment and unsafe operation. Either condition may result

in equipment damage or personal injury. Only a qualified person must install or service the DG Series regulator.

DG Series Regulators

3

!

WARNING

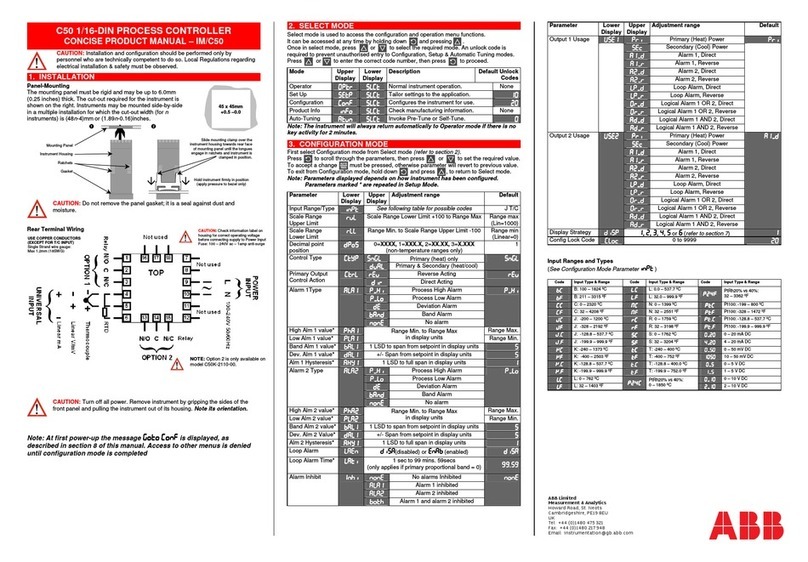

Table 1. Body Sizes and End Connection Styles

1. Introduction

Scope of the Manual

This instruction manual provides installation, adjustment, maintenance and parts ordering information for DG Series

direct-operated Pressure Reducing Series Regulators and Backpressure Series Regulators.

Description

DG Series are multipurpose direct-operated regulators that use fluid pressure to drive the actuator and automatically

maintains the outlet pressure or inlet pressure constant. They are available in Pressure Reducing (PRV) and Backpressure (BPV)

configurations to control outlet pressure or inlet pressure respectively. They have high-capacity, fast response, tight-shutoff,

superior control and stability and can be used in a variety of industrial gas and liquid applications such as: Nitrogen, Carbon

Dioxide, Natural Gas, Oil, Water, Methanol, Alcohol, Naphtha and similar media.

2. Specifications

Body Sizes and End Connection Styles:

See Table 1

Accuracy Class:

AC5 ~AC10

Shutoff Classification per ANSI/FCI 70-3-2004:

Class VI (Soft seat)

Construction Materials:

See Table 2

Maximum Inlet, Outlet and Emergency Casing Pressure(1):

See Table 3, DG Pressure Reducing Series

See Table 4, DG Backpressure Series

Control Pressure Range(1):

See Table 5, DG Series Pressure Reducing Regulator Spring

Set Range

See Table 6, DG Series Backpressure Regulator Spring Set Range

Maximum Setpoint of Pressure Reducing Regulator(1):

Low-Pressure Actuator (DOA330): 3.0 bar / 43 psig

High-Pressure Actuator (DOA180):

Nitrile (NBR) Diaphragm: 25 bar / 363 psig

Fluorocarbon (FKM) Diaphragm: 10 bar / 145 psig

Maximum Setpoint of Backpressure Regulator(1):

Low-Pressure Actuator (DOA330): 2.3 bar / 33.4 psig

High-Pressure Actuator (DOA180):

Nitrile (NBR) Diaphragm: 25 bar / 363 psig

Fluorocarbon (FKM) Diaphragm: 10 bar / 145 psig

Maximum Differential Pressures(1):

See Table 8

Flow and Sizing Coefficients:

See Table 9, Wide Open Flow and Sizing Coefficients

Temperature Capabilities(1):

Nitrile (NBR): -29 to 80°C / -20 to 176°F

Fluorocarbon (FKM): -7 to 120°C / 19 to 248°F(2)

Pressure Registration:

External

Down Stream Control Line Connection Size:

1/4 NPT

Maximum Pressure Over Setpoint to Avoid Internal

Parts Damage(1):

Low-Pressure Actuator: 0.6 bar / 8.7 psig or

1.3 times setpoint, whichever is larger

High-Pressure Actuator: 5.7 bar / 82.6 psig

Dimension and Estimated Weight:

See Table 7

To avoid possible personal injury, equipment damage or leakage due to escaping fluid do not stand on or apply an

external load to the actuator or any part of the regulator while working around the regulator.

DG SERIES PRESSURE REDUCING REGULATOR (PRV) DG SERIES BACKPRESSURE RAGULATOR (BPV)

BODY SIZES DN 25, 50, 80, 100 / NPS 1, 2, 3, 4

BODY END FLANGE CONNECTION STYLES CL150 RF, CL300 RF, GB PN 16/25/40

1. The pressure/temperature limits in this Manual or any applicable standard limitation should not be exceeded.

2. Fluorocarbon (FKM) is limited to 93°C / 200°F in hot water.

DG Series Regulators

4

Table 2. Construction Material

PART NAME STANDARD OPTIONS

Body WCB CF8M

Diaphragm/Sealing parts NBR FKM

Sleeve 316 SST 316 SST

Sleeve Guide 316 SST 316 SST

Cage 316 SST 316 SST

Inner Spring 316 SST 316 SST

Seat 316 SST 316 SST

Stem S31803 S31803

Table 3. Maximum Inlet/Outlet and Emergency Casing Pressure(1) - DG Series PRV

BODY

MATERIAL ACTUATOR ELASTOMER

TYPE

END

CONNECTION

MEDIUM

TYPE

TEMPERATURE

RANGE

MAXIMUM INLET

PRESSURE

MAXIMUM OUTLET

PRESSURE

MAXIMUM EMERGENCY

CASING PRESSURE

bar psi bar psi bar psi

WCB

Low-pressure

Actuator

DOA330

NBR ALL Gas or Liquid -29 to 80°C

15 218 3.7 53.7 3.7 53.7

FKM ALL Gas -7 to 120°C

Liquid -7 to 93°C

High-pressure

Actuator(1)

DOA180

NBR

CL150 RF Gas or Liquid -29 to 80°C 18.3 265 18.3 265 18.3 265

CL300 RF Gas or Liquid -29 to 80°C 30 435 30 435 30 435

PN16 RF Gas or Liquid -29 to 80°C 16 232 16 232 16 232

PN25 RF Gas or Liquid -29 to 80°C 25 363 25 363 25 363

PN40 RF Gas or Liquid -29 to 80°C 30 435 30 435 30 435

FKM ALL Gas -7 to 120°C 15 218 15 218 15 218

Liquid -7 to 93°C

CF8M

Low-pressure

Actuator

DOA330

NBR

CL150/300 RF

PN25/40 RF Gas or Liquid -29 to 80°C 15 218

3.7 53.7 3.7 53.7

PN16 RF Gas or Liquid -29 to 80°C 13.2 191

FKM

CL150/300 RF

PN25/40 RF

Gas -7 to 120°C 15 218

Liquid -7 to 93°C

PN16 RF Gas -7 to 120°C 12.1 175

Liquid -7 to 93°C 12.8 186

High-pressure

Actuator(1)

DOA180

NBR

CL150 RF Gas or Liquid -29 to 80°C 17.1 248 17.1 248 17.1 248

CL300 RF Gas or Liquid -29 to 80°C 30 435 30 435 30 435

PN16 RF Gas or Liquid -29 to 80°C 13.2 191 13.2 191 13.2 191

PN25 RF Gas or Liquid -29 to 80°C 20.6 299 20.6 299 20.6 299

PN40 RF Gas or Liquid -29 to 80°C 30 435 30 435 30 435

FKM

CL150/300 RF

PN25/40 RF

Gas -7 to 120°C 15 218 15 218 15 218

Liquid -7 to 93°C

PN16 RF Gas -7 to 120°C 12.1 175 12.1 175 12.1 175

Liquid -7 to 93°C 12.8 186 12.8 186 12.8 186

1. Maximum inlet, outlet and emergency pressures for constructions with Fluorocarbon (FKM) diaphragm are limited to 15 bar / 218 psig or the body rating limit, whichever is lower.

Table 4. Maximum Inlet/Outlet and Emergency Casing Pressure(1) - DG Series BPV

BODY

MATERIAL ACTUATOR ELASTOMER

TYPE

END

CONNECTION MEDIUM TYPE TEMPERATURE

RANGE

MAXIMUM INLET

PRESSURE

MAXIMUM OUTLET

PRESSURE

MAXIMUM EMERGENCY

CASING PRESSURE

bar psi bar psi bar psi

WCB

Low-pressure

Actuator

DOA330

NBR ALL Gas or Liquid -29 to 80°C

3.7 53.7 3.7 53.7 3.7 53.7

FKM ALL Gas -7 to 120°C

Liquid -7 to 93°C

High-pressure

Actuator(1)

DOA180

NBR

CL150 RF Gas or Liquid -29 to 80°C 18.3 265 18.3 265 18.3 265

CL300 RF Gas or Liquid -29 to 80°C 30 435 30 435 30 435

PN16 RF Gas or Liquid -29 to 80°C 16 232 16 232 16 232

PN25 RF Gas or Liquid -29 to 80°C 25 363 25 363 25 363

PN40 RF Gas or Liquid -29 to 80°C 30 435 30 435 30 435

FKM ALL Gas -7 to 120°C 15 218 15 218 15 218

Liquid -7 to 93°C

CF8M

Low-pressure

Actuator

DOA330

NBR

CL150/300 RF

PN25/40 RF Gas or Liquid -29 to 80°C

3.7 53.7 3.7 53.7 3.7 53.7

PN16 RF Gas or Liquid -29 to 80°C

FKM

CL150/300 RF

PN25/40 RF

Gas -7 to 120°C

Liquid -7 to 93°C

PN16 RF Gas -7 to 120°C

Liquid -7 to 93°C

High-pressure

Actuator(1)

DOA180

NBR

CL150 RF Gas or Liquid -29 to 80°C 17.1 248 17.1 248 17.1 248

CL300 RF Gas or Liquid -29 to 80°C 30 435 30 435 30 435

PN16 RF Gas or Liquid -29 to 80°C 13.2 191 13.2 191 13.2 191

PN25 RF Gas or Liquid -29 to 80°C 20.6 299 20.6 299 20.6 299

PN40 RF Gas or Liquid -29 to 80°C 30 435 30 435 30 435

FKM

CL150/300 RF

PN25/40 RF

Gas -7 to 120°C 15 218 15 218 15 218

Liquid -7 to 93°C

PN16 RF Gas -7 to 120°C 12.1 175 12.1 175 12.1 175

Liquid -7 to 93°C 12.8 186 12.8 186 12.8 186

1. Maximum inlet, outlet and emergency pressures for constructions with Fluorocarbon (FKM) diaphragm are limited to 15 bar / 218 psig or the body rating limit, whichever is lower.

DG Series Regulators

5

Table 5. DG Series Pressure Reducing Control Ranges

ACTUATOR SPRING PART

NUMBER SPRING COLOR BODY

MATERIAL

END

CONNECTION MEDIUM TYPE BODY SIZE

ELASTOMER/

TEMPERATURE

RANGE

SPRING CONTROL RANGE

bar psig

Low-pressure

Actuator

DOA330

ERSA01273A0 White WCB or CF8M PN 16/25/40 RF

ANSI 150/300 RF Gas all NBR (-29 to 80°C) 0.15 to 0.3 2.18 to 4.35

FKM (-7 to 120°C)

ERSA01286A0 Blue WCB or CF8M PN 16/25/40 RF

ANSI 150/300 RF

Gas all NBR (-29 to 80°C) 0.27 to 0.83 3.92 to 12

FKM (-7 to 120°C)

Liquid all NBR (-29 to 80°C) 0.3 to 0.83 4.35 to 12

FKM (-7 to 93°C)

ERSA01288A0 Yellow WCB or CF8M PN 16/25/40 RF

ANSI 150/300 RF

Gas all NBR (-29 to 80°C)

0.75 to 1.77 10.9 to 25.7

FKM (-7 to 120°C)

Liquid all NBR (-29 to 80°C)

FKM (-7 to 93°C)

ERSA01290A0 Red WCB or CF8M PN 16/25/40 RF

ANSI 150/300 RF

Gas all NBR (-29 to 80°C)

1.6 to 3 23.2 to 43.5

FKM (-7 to 120°C)

Liquid all NBR (-29 to 80°C)

FKM (-7 to 93°C)

High-

pressure

Actuator(2)

DOA180

ERSA01273A0 White WCB or CF8M PN 16/25/40 RF

ANSI 150/300 RF Gas DN 25 and

DN 50(1)

NBR (-29 to 80°C) 0.75 to 2.35 10.9 to 34.1

FKM (-7 to 120°C)

ERSA01286A0 Blue WCB or CF8M PN 16/25/40 RF

ANSI 150/300 RF

Gas

DN 25 and

DN 50(1)

NBR (-29 to 80°C) 2.2 to 6 31.9 to 87

FKM (-7 to 120°C)

DN 80 and

DN 100(1)

NBR (-29 to 80°C)

2.5 to 6 36.3 to 87

FKM (-7 to 120°C)

Liquid all NBR (-29 to 80°C)

FKM (-7 to 93°C)

ERSA01288A0 Yellow

WCB PN 16 RF

Gas all NBR (-29 to 80°C) 5.5 to 13.3 79.8 to 192.8

FKM (-7 to 120°C) 5.5 to 10 79.8 to 145

Liquid all NBR (-29 to 80°C) 5.5 to 13.3 79.8 to 192.8

FKM (-7 to 93°C) 5.5 to 10 79.8 to 145

CF8M PN 16 RF

Gas all NBR (-29 to 80°C) 5.5 to 11.2 79.8 to 162.4

FKM (-7 to 120°C) 5.5 to 10 79.8 to 145

Liquid all NBR (-29 to 80°C) 5.5 to 11.2 79.8 to 162.4

FKM (-7 to 93°C) 5.5 to 10 79.8 to 145

WCB or CF8M PN 25/40 RF

ANSI 150/300 RF

Gas all NBR (-29 to 80°C) 5.5 to 14.5 79.8 to 210

FKM (-7 to 120°C) 5.5 to 10 79.8 to 145

Liquid all NBR (-29 to 80°C) 5.5 to 14.5 79.8 to 210

FKM (-7 to 93°C) 5.5 to 10 79.8 to 145

ERSA01290A0 Red

WCB

ANSI 150 RF Gas all NBR (-29 to 80°C) 13.5 to 15.3 196 to 221.8

Liquid

PN 25 RF Gas all NBR (-29 to 80°C) 13.5 to 20.8 196 to 302

Liquid

CF8M

ANSI 150 RF Gas all NBR (-29 to 80°C) 13.5 to 14.3 196 to 207

Liquid

PN 25 RF Gas all NBR (-29 to 80°C) 13.5 to 17.2 196 to 249

Liquid

WCB or CF8M PN 40 RF

ANSI 300RF

Gas all NBR (-29 to 80°C) 13.5 to 25 196 to 363

Liquid

1. No white spring option is available when the PRV body size is DN 80 / NPS 3 or DN 100 / NPS 4, the blue spring range is 2.5 to 6 bar / 36.3 to 87.0 psig.

2. The maximum control pressure for fluorocarbon (FKM) construction is 10 bar / 145 psig.

DG Series Regulators

6

Table 6. DG Series Backpressure Control Ranges

ACTUATOR SPRING PART

NUMBER

SPRING

COLOR

BODY

MATERIAL

END

CONNECTION

MEDIUM

TYPE BODY SIZE ELASTOMER/TEMPERATURE

RANGE

SPRING CONTROL RANGE

bar psig

Low-pressure

Actuator

DOA330

ERSA01273A0 White WCB or CF8M PN16/25/40 RF

ANSI 150/300 RF Gas All NBR (-29 to 80°C) 0.15 to 0.32 2.18 to 4.64

FKM (-7 to 120°C)

ERSA01286A0 Blue WCB or CF8M PN16/25/40 RF

ANSI 150/300 RF

Gas All NBR (-29 to 80°C)

0.3 to 0.7 4.35 to 10.2

FKM (-7 to 120°C)

Liquid All NBR (-29 to 80°C)

FKM (-7 to 93°C)

ERSA01288A0 Yellow WCB or CF8M PN16/25/40 RF

ANSI 150/300 RF

Gas All NBR (-29 to 80°C)

0.6 to 1.4 8.7 to 20.3

FKM (-7 to 120°C)

Liquid All NBR (-29 to 80°C)

FKM (-7 to 93°C)

ERSA01290A0 Red WCB or CF8M PN16/25/40 RF

ANSI 150/300 RF

Gas All NBR (-29 to 80°C)

1.3 to 2.3 18.9 to 33.4

FKM (-7 to 120°C)

Liquid All NBR (-29 to 80°C)

FKM (-7 to 93°C)

High-pressure

Actuator(1)

DOA180

ERSA01286A0 Blue WCB or CF8M PN16/25/40 RF

ANSI 150/300 RF

Gas

DN25 &

DN50

NBR (-29 to 80°C)

2.1 to 5 30.5 to 72.5

FKM (-7 to 120°C)

DN80 &

DN100

NBR (-29 to 80°C)

FKM (-7 to 120°C)

Liquid All NBR (-29 to 80°C)

FKM (-7 to 93°C)

ERSA01288A0 Yellow

WCB PN16 RF

Gas All NBR (-29 to 80°C)

4.5 to 10 65.3 to 145

FKM (-7 to 120°C)

Liquid All NBR (-29 to 80°C)

FKM (-7 to 93°C)

CF8M PN16 RF

Gas All NBR (-29 to 80°C)

FKM (-7 to 120°C)

Liquid All NBR (-29 to 80°C)

FKM (-7 to 93°C)

WCB or CF8M PN25/40 RF

ANSI 150/300 RF

Gas All NBR (-29 to 80°C)

FKM (-7 to 120°C)

Liquid All NBR (-29 to 80°C)

FKM (-7 to 93°C)

ERSA01290A0 Red

WCB

PN16 RF

Gas All NBR (-29 to 80°C) 9.5 to 16 138 to 232

FKM (-7 to 120°C) 9.5 to 10 138 to 145

Liquid All NBR (-29 to 80°C) 9.5 to 16 138 to 232

FKM (-7 to 93°C) 9.5 to 10 138 to 145

PN25 RF

Gas All NBR (-29 to 80°C) 9.5 to 25 138 to 363

FKM (-7 to 120°C) 9.5 to 10 138 to 145

Liquid All NBR (-29 to 80°C) 9.5 to 25 138 to 363

FKM (-7 to 93°C) 9.5 to 10 138 to 145

ANSI150 RF

Gas All NBR (-29 to 80°C) 9.5 to 18.3 138 to 265

FKM (-7 to 120°C) 9.5 to 10 138 to 145

Liquid All NBR (-29 to 80°C) 9.5 to 18.3 138 to 265

FKM (-7 to 93°C) 9.5 to 10 138 to 145

CF8M

PN16 RF

Gas All NBR (-29 to 80°C) 9.5 to 13.2 138 to 191

FKM (-7 to 120°C) 9.5 to 10 138 to 145

Liquid All NBR (-29 to 80°C) 9.5 to 13.2 138 to 191

FKM (-7 to 93°C) 9.5 to 10 138 to 145

PN25 RF

Gas All NBR (-29 to 80°C) 9.5 to 20.6 138 to 299

FKM (-7 to 120°C) 9.5 to 10 138 to 145

Liquid All NBR (-29 to 80°C) 9.5 to 20.6 138 to 299

FKM (-7 to 93°C) 9.5 to 10 138 to 145

ANSI150 RF

Gas All NBR (-29 to 80°C) 9.5 to 17.1 138 to 248

FKM (-7 to 120°C) 9.5 to 10 138 to 145

Liquid All NBR (-29 to 80°C) 9.5 to 17.1 138 to 248

FKM (-7 to 93°C) 9.5 to 10 138 to 145

WCB or CF8M PN40RF

ANSI 300RF

Gas All NBR (-29 to 80°C) 9.5 to 25 138 to 363

FKM (-7 to 120°C) 9.5 to 10 138 to 145

Liquid All NBR (-29 to 80°C) 9.5 to 25 138 to 363

FKM (-7 to 93°C) 9.5 to 10 138 to 145

1.The maximum relief pressure for fluorocarbon (FKM) construction is 13 bar / 189 psig or maximum relief pressure of corresponding body, whichever is lower. The maximum control

pressure for fluorocarbon (FKM) construction is 10 bar / 145 psig.

DG Series Regulators

7

Table 7. Dimensions and Estimated Weight

BODY DIMENSION, mm / In. WEIGHT, Kg / Lbs

A B C D E

DN NPS DOA 180 DOA 330 DOA 180 DOA 330 DOA 180 DOA 330 PN16 PN25/40 CL150 CL300 DOA 180 DOA 330 DOA 180 DOA 330

Pressure Reducing Regulator

25 1 680 / 26.8 685 / 27 580 / 22.8 585 / 23 115 / 4.53 120 / 4.72 184 / 7.24 197 / 7.76 184 / 7.24 197 / 7.76 180 / 7.09 330 / 13 29 / 63.9 38 / 83.8

50 2 707 / 27.8 712 / 28.0 591 / 23.3 596 / 23.5 127 / 5.00 132 / 5.20 254 / 10.0 267 / 10.5 254 / 10.0 267 / 10.5 180 / 7.09 330 / 13 39 / 86 48 / 105.8

80 3 753 / 29.6 758 / 29.8 609 / 24.0 614 / 24.2 145 / 5.71 150 / 5.91 298 / 11.7 317 / 12.5 298 / 11.7 317 / 12.5 180 / 7.09 330 /13 59 /130 68 /150

100 4 816 / 32.1 801 / 31.5 639 / 25.2 624 / 24.6 175 / 6.89 180 / 7.09 352 / 13.9 368 / 14.5 352 / 13.9 368 / 14.5 180 /7.09 330 /13 83 /183 91.5 / 202

Backpressure Regulator

25 1 700 / 27.6 684 / 26.9 638 / 25.1 622 / 24.5 172 / 6.77 177 / 6.97 184 / 7.24 197 / 7.76 184 / 7.24 197 / 7.76 180 / 7.09 330 / 13 29.5 / 65.0 38 / 83.8

50 2 739 / 29.1 725 / 28.5 656 / 25.8 642 / 25.3 192 / 7.56 197 / 7.76 254 / 10.0 267 / 10.5 254 / 10.0 267 / 10.5 180 / 7.09 330 / 13 40.5 / 89.3 48 / 105.8

80 3 796 / 31.3 780 / 30.7 691 / 27.2 675 / 26.6 225 / 8.86 230 / 9.10 298 / 11.7 317 / 12.5 298 / 11.7 317 / 12.5 180 / 7.09 330 / 13 59.5 / 131 68 /150

100 4 855 / 33.7 846 / 33.3 727 / 28.6 718 / 28.3 262 / 10.3 267 / 10.5 352 / 13.9 368 / 14.5 352 / 13.9 368 / 14.5 180 / 7.09 330 / 13 83.5 / 184 92 / 203

Table 8. Maximum Differential Pressure of PRV

GAS LIQUID

Ratio range of inlet pressure over setting pressure: 1.2:1~20:1

Ratio range of inlet pressure over setting pressure:

1.2:1~10:1, need to meet the following at the same time:

Differential Pressure of PRV≤ (Inlet pressure + standard atmosphere pressure) x

Recover Factor Km(Km=0.7).

Table 9. Wide-Open Flow and IEC Coefficient

BODY SIZES WIDE-OPEN FLOW COEFFICIENT VALVE RECOVERY FACTOR, Km

DN NPS CvCg

25 1 16 529 0.7

50 2 59 1797 0.7

80 3 148 4345 0.7

100 4 240 6590 0.7

DG Series PRV is a direct-operated pressure reducing regulator. When operating, fluid flows from the inlet chamber, up

through the seat ring and cage and exits the outlet chamber. Downstream pressure is registered at the underside of the

diaphragm through an external sensing line that is connected to the lower diaphragm casing. The pressure under the actuator

diaphragm is balanced by the spring force acting at the topside of the diaphragm, through the action of the actuator stem,

the valve plug moves to or away from the seat ring to achieve pressure reducing and retaining. Downstream pressure is set by

turning the adjusting screw.

When downstream flow demand decreases, downstream pressure increases and the pressure registered under the actuator

diaphragm also increases. Spring force moves the diaphragm upward and the valve stem together with the valve plug move

towards the seat ring, decreasing fluid flow and downstream pressure is maintained at a new equilibrium state.

When downstream flow demand increases, downstream pressure decreases and the pressure registered under the actuator

diaphragm also decreases. Spring force now moves the diaphragm downward and the valve stem together with the valve plug

move away from seat ring, increasing fluid flow and downstream pressure is maintained at a new equilibrium state.

DG Series BPV is a direct-operated backpressure regulator. When operating, fluid flows from the inlet chamber through the

seat ring and cage and exits on the outlet chamber. Inlet pressure is registered at the underside of the diaphragm through an

external sensing line that is connected to the lower diaphragm casing. The pressure under the actuator diaphragm is balanced

by the spring force acting at the topside of the diaphragm. Through the action of the actuator stem, the valve plug moves to

or away from the seat ring to achieve pressure retaining. Upstream pressure is set by turning the adjusting screw.

When the inlet pressure is above the set pressure, the pressure registered at the actuator diaphragm increases. Spring force

moves the diaphragm upward and the valve stem together with the valve plug move away from seat ring, increasing fluid flow

and then it opens the backpressure regulator. Inlet pressure is maintained at a new equilibrium state.

When the inlet pressure is below the set pressure, the pressure registered at the actuator diaphragm decreases. Spring force

now moves the diaphragm downward and the valve stem together with the valve plug move towards the seat ring, decreasing

fluid flow and then it closes the backpressure regulator. Inlet pressure is maintained at a new equilibrium state.

3. Principle of Operation

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

FIRST STAGE

REGULATOR

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

INTERMEDIATE PRESSURE

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

FIRST STAGE

REGULATOR

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

INTERMEDIATE PRESSURE

DG Series Regulators

8

ADJUSTING SCREW

SPRING CASE

CONTROL SPRING

SENSING LINE

DIAPHRAGM

TRIM PARTS

BODY

OUTLETINLET

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 1. Operational Schematic of DG Series PRV

Figure 2. Operational Schematic of DG Series BPV

ADJUSTING SCREW

CONTROL SPRING

DIAPHRAGM

SENSING LINE

BODY

TRIM PARTS

SPRING CASE

VALVE SPRING

OUTLETINLET

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

DG Series Regulators

9

!

WARNING

!

WARNING

4. Installation

Personal injury or system damage may result if this regulator is installed, without appropriate overpressure

protection, where service conditions could exceed the limits given in the Specifications section and/or regulator

nameplate. Refer to Overpressure Protection section for recommendations on how to prevent service conditions from

exceeding those limits.

Additionally, physical damage to the regulator may result in personal injury or property damage due to escaping of

accumulated gas. To avoid such injury and damage, install the regulator in a safe location.

All vents should be kept open to permit free flow of gas to the atmosphere. Protect openings against entrance of rain,

snow, insects or any other foreign material that may plug the vent or vent line. Under enclosed conditions or indoors,

escaping gas may accumulate and be an explosion hazard. In these cases, the vent should be piped away from the

regulator to the outdoors.

General Installation Instructions

Installation of Pressure Reducing Regulator

Installing, operating and maintaining PRV should be performed by qualified personnel.

1. Before installing PRV:

• Check for damage which might have occurred during shipment.

• Inspect regulator body inlet and outlet ports and remove any dirt or foreign material that may be present.

• Blow out any debris or dirt in the tubing and the pipeline

• Check if the pressure in the pipeline is within the pressure range stated on the regulator nameplate.

• Make sure fluid flow through the regulator is in the same direction as the arrow on the body.

2. Install PRV away from fire source, vibration, water accumulation and ice formation areas and the environment

temperature should comply with the requirements. In low temperature areas, heat tracing measures may be considered

to heat the pipelines of the PRV in winter. At special occasions, such as installations in areas with heavy snow, may require

a hood or enclosure to protect the PRV from snow load and vent freeze over.

3. Body installed vertically with the actuator spring case pointing upward is required.

4. Do not forcefully install the regulator when connecting the inlet and outlet pipelines.

5. If a quick exhausting device or valve is to be installed downstream of the PRV, make sure to leave enough gas piping

volume between the PRV and the device to avoid sharp pressure drop due to rapid changing flow rates.

6. The filter should be installed on the upstream of the PRV and leave enough straight run of pipe downstream. Attach

a 14 mm / 0.55 in. OD sensing line with a 1/4 NPT fitting no less than 5 x DN (the nominal diameter of the pipework)

away from the PRV outlet port and at a point away from any source of turbulence and no less than 5 x DN (the nominal

diameter of the pipework) away from downstream block valve. When outlet pressure is at or above 0.5 bar / 7.25 psig,

gas velocity should not exceed 50 m/s. When outlet pressure is below 0.5 bar / 7.25 psig, gas velocity should not exceed

25 m/s. The nominal diameter of the pipework connecting the regulator shall not be smaller than the nominal diameter

of the regulator.

Note: Uninstall/Replacing any of the parts (Ex. Adjusting Screw, Spring etc.) is forbidden when the internal pressure of

regulator is not vent completely.

Note: Contact appropriate Emerson representative prior to removing or modifying restrictor (if used) in sense line.

Improper adjustment to restrictor can lead to instability in pressure reducing regulator.

Remove or isolate (utilizing blind flange) the regulator when the pipeline is undergoing pressure test or purging to avoid

damaging the regulator.

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

FIRST STAGE

REGULATOR

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

INTERMEDIATE PRESSURE

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

FIRST STAGE

REGULATOR

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

INTERMEDIATE PRESSURE

DG Series Regulators

10

Note: Optional Damper and Restrictor are available for various applications.

Figure 3. Installation Schematic for DG Series PRV

≥ DN 5 ≥ DN 5

≥ DN 10

FILTER UPSTREAM

BLOCK VALVE

PRESSURE

GAUGE DOWNSTREAM

BLOCK VALVE

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 4. Installation Schematic for DG Series BPV

Note: Optional Damper and Restrictor are available for various applications.

≥ DN 5

≥ DN 5

FILTER UPSTREAM

BLOCK VALVE

PRESSURE

GAUGE DOWNSTREAM

BLOCK VALVE

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

DG Series Regulators

11

!

WARNING

!

WARNING

DG Series Pressure Reducing Regulator (PRV)

DG Series pressure regulator have an outlet pressure rating lower than the inlet pressure rating. The recommended pressure

limitations are stamped on the regulator nameplate. Some type of overpressure protection is needed if the actual inlet

pressure can exceed the maximum operating outlet pressure rating. Over-pressuring any portion of the regulators beyond the

limits in the Specifications section may cause leakage, damage to regulator parts or personal injury due to bursting of pressure

containing parts.

Provide an external overpressure protection if inlet pressure will be high enough to damage downstream equipment.

Common methods of external overpressure protection include relief valves, monitoring regulators, shut-off devices and

series regulation.

Installation of Backpressure Regulator

Installing, operating and maintaining BPV should be performed by qualified personnel.

1. Before installing BPV:

• Check for damage which might have occurred during shipment.

• Inspect regulator body inlet and outlet ports and remove any dirt or foreign material that may be present.

• Blow out any debris or dirt in the tubing and the pipeline.

• Check if the pressure in the pipeline is within the pressure range stated on the regulator nameplate.

• Make sure fluid flow through the regulator is in the same direction as the arrow on the body.

2. Install BPV away from fire source, vibration, water accumulation and ice formation areas and the environment

temperature should comply with the requirements. In low temperature areas, heat tracing measures may be considered

to heat the pipelines of the BPV in winter. At special occasions, such as installations in areas with heavy snow, may require

a hood or enclosure to protect the BPV from snow load and vent freeze over.

3. Body installed horizontally with the actuator spring case pointing upward is required.

4. Do not forcefully install the regulator when connecting the inlet and outlet pipelines.

5. If a quick exhausting device or valve is to be installed downstream of the BPV, make sure to leave enough gas piping

volume between the BPV and the device to avoid sharp pressure drop due to rapid changing flow rates.

6. The filter should be installed on the upstream of the BPV and leave enough straight run of pipe upstream. Attach a

14 mm / 0.55 in. OD sensing line with a 1/4 NPT fitting no less than 5 x DN (the nominal diameter of the pipework) away

from the BPV on the upstream and at a point away from any source of turbulence and no less than 5 x DN (the nominal

diameter of the pipework) away from the upstream block valve. The nominal diameter of the pipework connecting the

regulator shall not be smaller than the nominal diameter of the regulator.

Note: Uninstall/Replacing any of the parts (Ex. Adjusting Screw, Spring etc.) is forbidden when the internal pressure of

regulator is not vent completely.

Note: Contact appropriate Emerson representative prior to removing or modifying restrictor (if used) in sense line.

Improper adjustment to restrictor can lead to instability in pressure reducing regulator.

Remove or isolate (utilizing blind flange) the regulator when the pipeline is undergoing pressure test or purging to avoid

damaging the regulator.

5. Overpressure Protection

Personal injury, equipment damage or leakage due to escaping accumulated gas or bursting of pressure-containing

parts may result if this regulator is:

• Over-pressured;

• Used with incompatible process fluid;

• Installed where service conditions could exceed the limits given in the specifications section and on the

appropriate nameplate; or

• Where conditions exceed any ratings of adjacent piping or piping connections.

To avoid such injury or damage, provide pressure-relieving or pressure-limiting devices to prevent service conditions

from exceeding those limits.

DG Series Regulators

12

!

WARNING

If the regulator is exposed to an overpressure condition, it should be inspected for any damage that may have occurred.

Regulator operation below the limits specified in the Specifications section and regulator nameplate does not preclude the

possibility of damage from external sources or from debris in the pipeline.

DG Series Backpressure Regulator (BPV)

Over-pressuring any portion of this equipment may result in equipment damage, leaks in the backpressure regulator or

personal injury due to bursting of pressure-containing parts. The system should be inspected after any overpressure condition.

The individual spring range of your backpressure regulator is stamped on the nameplate. Maximum inlet pressures depend

upon body materials and temperatures. See the Specifications section for the maximum inlet pressure of the valve. The valve

should be inspected for damage after any overpressure condition.

6. Operating of Pressure Reducing Regulator

To avoid possible personal injury, equipment damage or leakage due to escaping fluid, make certain the regulator is

installed as instructed in the Installation section.

Note: Pressure gauges must always be used to monitor downstream pressure during Startup.

Startup

1. Make sure bypass valve is closed. Open the system shutoff valve.

2. Slowly open the inlet block valve in front of the PRV.

3. Slightly open the outlet block valve behind the PRV.

4. When used in liquid service, the PRV has bleed design to exhaust the air (Figure 3) trapped under the actuator diaphragm

depending on medium type. Slowly unscrew the bleed plug to exhaust the air. Then, screw and tighten the plug.

Exercise caution always.

5. Keep in this position until pressure is stabilized.

6. Fully open the outlet block valve.

Note: The regulator is factory-set as specified on the order or at the midpoint of the spring range. The allowable spring range is

stamped on the nameplate. If a pressure setting other than the one specified is desired, be sure to change the pressure setting

by following the Adjustment procedure.

Pressure Adjustment

To change the outlet pressure, unscrew the jam nut and slowly turn the adjusting screw and set the outlet pressure to

the desired setting, screw the jam nut. Clockwise to increase the setting pressure. Counterclockwise to decrease the

setting pressure.

Shutdown

1. Close the inlet block valve.

2. Close the outlet block valve.

Note: To avoid internal damage due to reverse pressurization of main valve components, make certain pressure reducing

regulator outlet pressure is bled prior to inlet pressure.

3. Slowly open the outlet block valve to release downstream pressure.

4. Keep the outlet block valve open, release inlet pressure and all remaining pressure in PRV.

7. Operating of Backpressure Regulator

Startup

1. Make sure bypass valve is closed, open the system shutoff valve.

2. Slowly open the outlet block valve behind the BPV.

3. Slowly open the inlet block valve in front of the BPV

4. When used in liquid service, the BPV has bleed design (Figure 4) to exhaust the air trapped under the actuator diaphragm

depending on medium type. Slowly unscrew the bleed plug to exhaust the air. Then, screw and tighten the plug. Exercise

caution always.

Note: The regulator is factory-set as specified on the order or at the midpoint of the spring range. The allowable spring range is

stamped on the nameplate. If a pressure setting other than the one specified is desired, be sure to change the pressure setting

by following the Adjustment procedure.

DG Series Regulators

13

Figure 5. Diaphragm Case Figure 6. Spring Case

PLUG

ADJUSTING SCREW

VENT HOLE

LIQUID OPTION ONLY

!

WARNING

Pressure Adjustment

To change the inlet pressure, unscrew the jam nut and slowly turn the adjusting screw (Figure 6) and set the inlet pressure to the

desired setting, screw the jam nut. Clockwise to increase the inlet pressure. Counterclockwise to decrease the inlet pressure.

Shutdown

1. Close the upstream BPV inlet block valve.

2. Close the downstream BPV outlet block valve.

Note: To avoid internal damage due to reverse pressurization of main valve components, make certain pressure reducing

regulator outlet pressure is bled prior to inlet pressure.

3. Slowly open the outlet block valve to release downstream pressure.

4. Keep the outlet block valve open, release inlet pressure and the remaining pressure in BPV.

8. Maintenance

Personal injury, equipment damage or leakage due to escaping fluid may result if seals are not properly lubricated

or maintained. Due to normal part wear or damage that may occur from external sources, this regulator should be

inspected and maintained periodically. The frequency of inspection, maintenance and replacement of parts depend

upon the severity of service conditions or the requirements of local, state and federal regulations.

Regulators that have been disassembled for repair must be tested for proper operation before being returned to

service. Only parts manufactured by Emerson should be used for repairing Emerson regulators. Restart gas utilization

equipment according to normal start-up procedures.

Note: To protect against reduced performance, make certain vents are not plugged when conducting routine maintenance.

Before maintenance, close the inlet and outlet block valves and exhaust the gas pressure in the valve body and piping. When

removing or replacing parts such as the orifice or diaphragm, be careful not to damage them. Ensure movable parts can move

freely after reassembly. Recommission according to the Installation and Startup procedures. Ensure all connections are tight

and check for leaks. Emerson provides training for your maintenance personnel. For other information, consult your local

Sales Office.

Routine Maintenance

The frequency of routine maintenance should be given by end user’s management department depend on the medium type

and service condition to keep safety:

1. Make sure that there is no leakage on the regulator.

2. Observe the gauges to make sure that the pressure being controlled is sTable and at the correct set point.

3. Clean the outside of the regulator.

DG Series Regulators

14

CAUTION

All disassembly, trim change and reassembly steps in this section may be performed with the regulator in the main line.

The trim for the DN 80 and 100 / NPS 3 and 4 body sizes are heavy and may be awkward to remove or reinstall in some

valve/ pipeline orientations. Follow your company policy for lifting and handling heavy parts.

!

WARNING

To avoid possible personal injury from spring or pressure-loaded actuator, make certain the adjusting screw is

completely backed off or the spring case pressure is vented prior to disassembly. Otherwise, the spring load or loading

pressure could forcefully eject the spring case.

!

WARNING

Periodic Check

The frequency of periodic check should be given by end user’s management department depend on the medium type and

service condition to make sure the proper functioning of the regulator. Apart from monitoring the set pressure:

1. Check DG Series PRV lock up pressure every 1 to 3 months: Open the upstream valve, using the downstream pressure

gauge to monitor the pressure, slowly close the downstream valve, ensure that the downstream pressure does

not increase.

2. Check DG Series BPV lock up pressure every 1 to 3 months: Slowly increase the inlet pressure until the relieving pressure

starts to rise, then slowly decrease the inlet pressure until the valve closed, ensure the downstream pressure does

not increase.

3. Clean internal parts every 3 to 6 months like the Disk, Diaphragm, O-rings and Seat Ring. Give due diligence to check and

replace deformed and worn out seals upon necessary.

4. Check wear parts every 3to 6 months for damage and replace upon necessary, replace crush installed O-rings

after disassembly.

Replacing Nameplate

Be certain that the nameplates are updated to accurately indicate any field changes in equipment, materials, service conditions

or pressure settings.

9. Pressure Reducing Regulator Disassembly

To avoid personal injury resulting from sudden release of pressure, isolate the regulator from all pressure and

cautiously release trapped pressure from the regulator before attempting disassembly.

Failure to properly follow maintenance installation procedures when replacing parts could result in regulator damage,

personal injury and property damage from escaping process fluid or regulators separation during testing or after

reinstallation in the pipe line.

All O-rings, gaskets and seals should be lubricated with a good grade of general-purpose lubricant and installed gently rather

than forced into position. Refer to Table 10 for torque specifications. Refer to Figures 6, 8 and 9 while servicing Type DG

pressure reducing regulators.

Actuator Maintenance

Perform this procedure if it is desired to inspect or replace the diaphragm or other internal parts or if it is desired to change the

outlet pressure range of the regulator by changing the control spring.

If only maintenance and checking for non-trim parts under the regulator main-valve is needed, please go to step 18.

Replacing Main Valve Spring

1. Loosing Lock Nut (key 52), slowly loosing Adjusting Screw (key 53) and remove it from the Case Cover (key 51).

2. Slowly loosing Case Cover (key 51) and remove it from the Spring Case (key 49 for Low-Pressure Actuator, key 44 for

High-Pressure Actuator).

3. Remove Upper Spring Seat (key 50) and the Control Spring (key 48), replace the control spring if needed. If no other

maintenance work needed in the actuator and internal parts, please go to step 44.

4. If further maintenance needed, for Low-Pressure Actuator please go to step 5, For High-Pressure Actuator please go

to step 13.

DG Series Regulators

15

Table 10. DG Series Pressure Reducing Regulator Assembly Torque

PART NAME TORQUE (N•m)

1 In. 2 In. 3 In. 4 In.

Bolts (key 16), M8×25 25 to 30

Bolts (key 42), M8×25 Nuts (key 40), M8 28 to 32

Bolts (key 7) 26 to 36 60 to 75 54 to 74 94 to 128

Bolts (key 45), M8×15 25 to 30

Bolts (key 58), M12×45 Nuts (key 57), M12 61 to 74

Thin Nut (key 34), M10 16 to 19

Nut (key 60), M10 21 to 24

Locknut (key 29), M10 21 to 24

Plug (ERSA01628, key 5) 100 to 132

Replacing Low-Pressure Actuator Diaphragm

5. Slowly screw out and remove the Spring Case (key 49), loosen the Nut (key 40), remove the Washer (key 41) and Bolt

(key 42), Remove the Upper Casing (key 43) and Base (key 47) carefully.

6. Loosen Nut (key 45) and disassemble Base (key 47), remove and check O-ring (key 46), if necessary replace with new

spare parts.

7. Carefully loosen Lock Nut (key 60) and Thin Nut (key 34) in the middle of diaphragm. Remove Lower Spring Seat (key 37).

Remove Upper diaphragm plate (key 38) and Pin (key 66).

8. Taking out the Diaphragm (key 39) carefully, check if there is any damage or ageing. If needed, replace it with new

spare parts.

9. Take out the Diaphragm Head (key 36) carefully, check the O-ring (key 68) in the groove of Diaphragm Head (key 36),

replace it with new spare part if needed. If no further maintenance in trim parts or connection parts of actuator and body,

please go to step 34.

10. Loosen Bolt (key 16), Remove the Washer (key 17), taken out the Lower Casing Plate (key 35) slowly, remove the actuator

Lower Casing (key 33) from the main valve assemble carefully. Check the O-ring (key 63) and replace it with new spare

parts if needed.

11. Loosen the Bolt (key 64) with tools, take out the Washer (key 17), remove out the Connector Pad (key 62) slowly from the

Stem (key 18). Check the Bushing (key 25) and O-ring (key 15) if damaged, replace with new spare part if needed. If no

further maintenance of internal parts needed, please go to step 32.

12. If further internal parts maintenance is needed, please go to step 18.

Replacing High-Pressure Actuator Diaphragm

13. Slowly screw out and remove the Spring Case (key 44), loosen Nut (key 57), remove Washer (key 8) and Bolt (key 58),

Carefully remove Upper Casing (key 59).

14. Carefully loosen the Lock Nut (key 60) and Thin Nut (key 34) in the middle of diaphragm, take out the Lower Spring Seat

(key 37); Remove the Diaphragm Plate (key 55) and Pin (key 66).

15. Taken out the Diaphragm (key 56) Carefully, check if there is any damage or ageing. If needed, replace it with new

spare parts.

16. Remove the Diaphragm Head (key 36) carefully, check the O-ring (key 68) in the groove of Diaphragm Head, replace it

with new spare part if needed. If no further maintenance in trim parts or connection parts of actuator and body, please go

to step 40.

17. Loosen Bolt (key 16), remove Washer (key 17), remove the Lower Casing (key 54) from the main-valve assemble carefully.

Check the O-ring (key 15), replace it with new spare part if needed. If no further maintenance of internal parts needed,

please go to step 39.

Replacing Trim Parts

Perform this procedure when inspecting, cleaning or replacing individual internal trim parts.

18. Remove Plug (key 5), check the O-ring (key 6) in the groove of plug. Replace it with new spare part if needed.

19. Carefully remove the Nut (key 7) and Washer (key 9). Please avoid dropping internal parts, remove the body flange (key 2)

carefully, check the O-ring (key 3) in the contact corner of body and body flange and the O-ring (key 4) in the outer

groove of Sleeve Guide (key 10). Replace it with new spare part if needed. If no further maintenance of internal parts nee,

please go to step 30.

20. Slowly slide the Sleeve /Stem assemble out of the Sleeve Guide (key 10), Take out the Sleeve Guide (key 10) and Cage

(key 13), Check the O-ring (key 12) and Sliding (key 11) in the inner groove of the Sleeve Guide (key 10). Replace it with

new spare part if needed. If no maintenance of the Seat (key 19) needed, please go to step 27.

21. Loose the Seat (key 19) using suiTable tools and remove slowly and check the O-ring (key 14) in the contact area of Seat

(key 19) and Body (key 1), replace it with new spare parts if needed.

22. In the Sleeve/Stem assemble, Loosen Nut (key 29), Take out Washer (key 28) and Plate/Gasket (key 27), check the O-ring

(key 26), replace it with new spare part if needed.

23. Take out the Stem Bushing (key 22) from the body (key 1), check the O-ring (key 24, key 23) and Bushing (key 25), replace

it with new spare part if needed.

DG Series Regulators

16

!

WARNING

!

WARNING

!

WARNING

Personal injury, equipment damage or leakage due to escaping fluid may result if regulator bolts are not tightened to

proper load. Always tighten bolts in an alternating pattern.

Personal injury, equipment damage or leakage due to escaping fluid may result if regulator bolts are not tightened to

proper load. Always tighten bolts in an alternating pattern.

Personal injury, equipment damage or leakage due to escaping fluid may result if regulator bolts are not tightened to

proper load. Always tighten bolts in an alternating pattern.

Reassemble of the Pressure Reducing Regulator

Make sure all the parts which needed to be maintenance are properly handled or replaced, then perform the following procedure:

24. Lubricate the O-ring (key 26), And assemble it onto the groove of the Plate/Gasket (key 27), add the Washer (key 28) and

tighten the Nut (key 29) using torque values listed in Table 10.

25. Lightly lubricate the O-ring (key 23) and Bushing (key 25), assemble it on the inner groove of the Stem Bushing (key 22).

Lubricate the O-ring (key 24) and assemble it onto the outer groove of the Stem Bushing (key 22). Press the Stem Bushing

assemble into the stage hole on the top of Body (key 1) slowly until it reaches the stopping point.

26. Clean and purge the inner surface of the body, lubricate the O-ring (key 14) and put it on the corner of the mating faces of

the body and Seat. Put the Seat (key 19) on the inner stage of the Body (key 1), please make sure the O-ring (key 14) are

not damaged.

27. Assemble the Cage (key 13) onto the groove of the Seat (key 19).

28. Lubricate the O-ring (key 12) and Sliding (key 11), assemble them onto the inner groove of the Sleeve Guide (key 10) and

carefully put the Stem/Sleeve assemble in step 24 into the Sleeve Guide (key 10).

29. Put the Stem/Sleeve/Sleeve Guide assemble onto the stage of the Cage. And let the Stem (key 18) go through the hole of

Body (key 1), Please make sure there is no damage or scratch of the Stem during the process.

30. Lubricate the O-ring (key 4) and assemble it onto the outer groove of the Sleeve Guide (key 10); Lubricate the O-ring

(key 3) and put it onto the stage corner of the Body (key 1). Assemble the Bonnet (key 2) onto the body (key 1), please

make sure all the bolting holes are aligned. Lubricate the screw of the Bolt (key 7), connect the Bonnet and Body using

Bolt (key 7) and Washer (key 9), tighten the bolt in an alternating pattern using the torque listed in Table 10.

31. Lubricate the O-ring (key 6) and assemble it onto the Plug (key 5), Screw the Plug (key 5) into the hole of Bonnet (key 2)

carefully, using the torque values listed in Table 10.

If no maintenance of the internal parts, actuator and Control Spring, then the reassemble procedure ends here.

For the assemble procedure of Low-Pressure Actuator, please go to step 32.

For the assemble procedure of High-Pressure Actuator, please go to step 39.

32. Lubricate the O-ring (key 15), assemble it onto the outer groove of the Body (key 1); (For DN100/NPS 4 please skip the

following procedures in this step and go to step 33 directly), Lubricate the Bushing (key 25) and press it into the hole on

the protrusion part of the Connector Pad (key 62); Let the Connector Pad (key 62) go through the Stem carefully and

assemble it onto the Body (key 1) carefully. Make sure all the bolt holes are aligned. Connect the Connector Pad (key 62)

and Body (key 1) using the Bolt (key 64) and Washer (key 17), tighten the Bolt (key 64) in an alternating pattern using the

torque value listed in Table 10. Lubricate the O-ring (key 63) and put it onto the groove of Connector Pad.

33. Put the actuator Lower Casing (key 33) onto the Connector Pad Carefully. Make sure the bolt holes are aligned and check

the direction of the signal connection port. Put the Lower Casing Plate (key 35) onto the Lower Casing (key 33) and make

sure the bolt holes are aligned. Lubricate the Screw of Bolt (key 16), Fix the Lower Casing (key 33) and Lower Casing Plate

(key 35) onto the Connector Pad (key 62) using the Bolt (key 16) and Washer (key 17). Tighten the bolt with the torque

listed in Table 10.

34. Lubricate the O-ring (key 68) and assemble it onto the inner groove of Diaphragm Head (key 36); Let the Stem (key 18) go

through the Diaphragm Head (key 36), Press the Diaphragm Head (key 36) until it reaches the Lower Plate (key 35).

DG Series Regulators

17

!

WARNING

Personal injury, equipment damage or leakage due to escaping fluid may result if regulator bolts are not tightened to

proper load. Always tighten bolts in an alternating pattern.

35. Lubricate the flange facing of Lower Casing (key 33) and the groove sealing face of Diaphragm Head (key 36), assemble

the Diaphragm (key 39) onto the lower plate carefully. Make sure the pin holes on lower plate and diaphragm are aligned

and make sure the bolts holes on diaphragm and bolts holes on flange faces are aligned. Assemble the Pin (key 66) into

the pin hole carefully. Lubricate the groove sealing side of the Diaphragm Upper Plate (key 38), let it go through the Stem

(key 18), align the pin hole side to the Pin (key 66) and assemble it onto the upper side of Diaphragm (key 39). Assemble

the Lower Spring Seat (key 37) onto the upper side of Diaphragm Upper Plate (key 38). Lubricate the Screw at the end of

Stem (key 18), Tight the Thin Nut (key 34) and Nut (key 60) using the torque value listed in Table 10.

36. Lubricate O-ring (key 46) and put it onto the groove of the Base (key 47), lubricate the screw of Bolt (key 45). Fix the Base

(key 47) onto Upper Casing (key 43) using the Bolt (key 45).

37. Lubricate the flange face of Upper Casing (key 43), Assemble the Upper Casing/Base Assemble on to the diaphragm

(key 39) carefully, make sure the bolts holes are aligned. Lubricate the screw of Bolt (key 42), connecting the Upper and

Lower Casing using the Bolt (key 42), Nut (key 40) and Washer (key 41). Tight the bolts in an alternating pattern using the

torque value listed in Table 10.

Note: Exercise care to ensure that the diaphragm (key 39) is not pinched, twisted or wrinkled while compressing between the

upper and lower diaphragm casings (keys 43 and 33).

38. Lubricate the screw on the end of Spring Case (key 49) which side has no bleed hole. And Screw it into the Base (key 47).

Then go to step 44.

39. Lubricate O-ring (key 15) and assemble it onto groove at the end of the Body (key 1); put the actuator Lower Casing

(key 54) onto the body (key 1) carefully, make sure all the bolting holes are aligned and check the direction of the signal

connection port; lubricate the screw of the Bolt (key 16), fix the Lower Casing (key 54) onto the Body (key 1) using Bolt

(key 16) and Washer (key 17). Tight it with the torque value listed in Table 10.

40. Lubricate O-ring (key 68) and assemble it onto the inner groove of Diaphragm Head (key 36); Let the Stem (key 18) go

through the Diaphragm Head (key 36) and press the Diaphragm Head (key 36) until it reaches the Lower Casing (key 54).

41. Lubricate the flange face of Lower Casing (key 54) and the sealing groove face of Diaphragm Head (key 36), assemble

the Diaphragm (key 56) onto the lower plate carefully. Make sure the pin holes on lower plate and diaphragm are aligned

and make sure the bolts holes on diaphragm and bolts holes on flange faces are aligned. Assemble the Pin (key 66) into

the Pin hole carefully. Lubricate the groove sealing side of the Diaphragm Upper Plate (key 55), Let it go through Stem

(key 18), align the pin hole to the Pin (key 66) and assemble it onto the upper side of the Diaphragm (key 56). Assemble

the Lower Spring Seat (key 37) onto the upper side of the upper plate (key 55). Lubricate the screw on the top of the Stem

(key 18), tight it using the Thin Nut (key 34) and Nut (key 60) with the torque value listed in Table 10.

42. Lubricate the flange face of Upper Casing (key 59), assemble it onto the Diaphragm (key 56) carefully, make sure the

Bolt holes are aligned. Lubricate the screw of the Bolt (key 58), connect the Upper / Lower Casing using Bolt (key 58), nut

(key 57) and Washer (key 8). Tight it in an alternating pattern using the torque value listed in Table 10.

Note: Exercise care to ensure that the diaphragm (key 56) is not pinched, twisted or wrinkled while compressing between the

upper and lower diaphragm casings (keys 59 and 54).

43. Lubricate the screw on the end of Spring Case (key 49) which side has no bleed hole. And Screw it into the screw of Upper

Casing (key 59).

44. Coat the two ends of Control Spring (key 48) with grease and put it correctly inside the Spring Case (key 49). Coat the

raised face of Upper Spring Seat (key 50) with grease and put it onto the top end of spring.

45. Coat the screw on Adjusting Screw (key 53) with grease, slowly screw in Lock Nut (key 52) and then screw in the Adjusting

Screw (key 53) into the threaded hole of Case Cover (key 51).

46. Lubricate the screw on the top of Spring Case (key 49), Screw in the Case Cover assemble into the top of Spring Case

(key 49) slowly and then screw in Adjusting Screw (key 53) to a proper position.

DG Series Regulators

18

CAUTION

!

WARNING

!

WARNING

10. Backpressure Regulator Disassembly

To avoid personal injury resulting from sudden release of pressure, isolate the regulator from all pressure and

cautiously release trapped pressure from the regulator before attempting disassembly.

Failure to properly follow maintenance installation procedures when replacing parts could result in regulator damage,

personal injury and property damage from escaping process fluid or regulators separation during testing or after

reinstallation in the pipe line.

All disassembly, trim change and reassembly steps in this section may be performed with the regulator in the main line.

The trim for the DN 80 and 100 / NPS 3 and 4 body sizes are heavy and may be awkward to remove or reinstall in some

valve/ pipeline orientations. Follow your company policy for lifting and handling heavy parts.

To avoid possible personal injury from spring or pressure-loaded actuator, make certain the adjusting screw is

completely backed off or the spring case pressure is vented prior to disassembly. Otherwise, the spring load or loading

pressure could forcefully eject the spring case.

Table 11. DG Series Backpressure Regulator Assembly Torque

PART NAME TORQUE (N•m)

1 In. 2 In. 3 In. 4 In.

Bolts (key 16), M8×25 25 to 30

Bolts (key 42), M8×25 Nuts (key 40), M8 28 to 32

Bolts (key 13) 26 to 36 60 to 75 54 to 74 94 to 128

Thin Nut (key 34), M10 16 to 19

Nut (key 60), M10 21 to 24

Bolts (key 45), M8×15 25 to 30

Bolts (key 58), M12×45 Nuts (key 57), M12 61 to 74

Nuts (key 29), M10 21 to 24

All O-rings, gaskets and seals should be lubricated with a good grade of general-purpose lubricant and installed gently rather

than forced into position. Refer to Table 11 for torque specifications. Refer to Figures 7, 8 and 9 while servicing Type DG

pressure reducing regulators.

Actuator Maintenance

Perform this procedure if it is desired to inspect or replace the diaphragm or other internal parts or if it is desired to change the

outlet pressure range of the regulator by changing the control spring.

Replacing Main Valve Spring

1. Loosing Lock Nut (key 52), slowly loose Adjusting Screw (key 53) and remove it from Case Cover (key 51).

2. Slowly loose Case Cover (key 51) and remove it from Spring Case (key 49 for Low-Pressure Actuator, key 44 for

High-Pressure Actuator).

3. Remove Upper Spring Seat (key 50) and Control Spring (key 48), replace the control spring if needed. If no other

maintenance work needed in the actuator and internal parts, please go to step 39.

4. If further maintenance needed, for Low-Pressure Actuator please go to step 5, for High-Pressure Actuator please go to

step 11.

DG Series Regulators

19

Replacing Low-Pressure Actuator Diaphragm

5. Slowly screw out and remove Spring Case (key 49), loosen Nut (key 40), remove Washer (key 41) and bolt (key 42),

carefully remove Upper Casing (key 43) and Base (key 47).

6. Loosen Nut (key 45) and disassembly the Base (key 47), remove and check the O-ring (key 46), replace it with new spare

part if needed.

7. Carefully Loosen the Lock Nut (key 60) and Thin Nut (key 34) in the middle of diaphragm, take out Lower Spring Seat

(key 37); remove the Diaphragm Plate (key 38) and Pin (key 66).

8. Remove the Diaphragm (key 39) carefully, check if there is any damage or ageing, replace it with new spare part

if needed.

9. Take out the Diaphragm Head (key 36) carefully, Check the O-ring (key 68) in the groove of Diaphragm Head, replace it with new

spare parts if needed. If no further maintenance in trim parts or connection parts of actuator and body, please go to step 29.

10. Loosen Bolt (key 16), remove Washer (key 17), remove the Lower Casing Plate (key 35) slowly. Remove the actuator Lower

Casing (key 33) from the top of Bonnet (key 12) carefully. Check the O-ring (key 15), replace it with new spare part if

needed. If no further maintenance of internal parts needed, please go to step 28, if further maintenance of internal parts

needed, please go to step 16.

Replacing High-Pressure Actuator Diaphragm

11. Slowly Screw out and remove the Spring Case (key 44), loosen Nut (key 57), remove Washer (key 8) and Bolt (key 58),

remove Upper Casing (key 59) carefully.

12. Carefully loosen the Lock Nut (key 60) and Thin Nut (key 34) in the middle of diaphragm, take out the Lower Spring Seat

(key 37), remove the diaphragm plate (key 55) and Pin (key 66).

13. Remove the Diaphragm (key 56) carefully, check if there is any damage or ageing, replace it with new spare part

if needed.

14. Carefully remove the Diaphragm Head (key 36), check the O-ring (key 68) in the groove of Diaphragm Head, replace it with

new spare parts if needed. If no further maintenance in trim parts or connection parts of actuator and body, please go to

step 35.

15. Loosen Bolt (key 16), remove Washer (key 17), remove the actuator Lower Casing (key 54) from top of Bonnet (key 12)

carefully. Check the O-ring (key 15), replace it with new spare part if needed. If no further maintenance of internal parts

needed, please go to step 34.

Replacing Trim Parts

Perform this procedure when inspecting, cleaning or replacing individual internal trim parts.

16. Carefully remove the flange Nut (key 13) and Washer (key 8), Slowly remove the Bonnet (key 12), checking the O-ring

(key 11) on the corner of the bonnet and body contact area and the O-ring (key 10) in the upper groove of the Sleeve

Guide (key 6). Replace it with new spare part if needed. If no further maintenance needed, please go to step 27.

17. Taken out the Main Vale Spring (key 5), slowly slide the Sleeve (key 4)/Stem (key 14) assembly out of the Sleeve Guide

(key 6), remove the Sleeve Guide (key 6) and Cage (key 18), check the O-ring (key 7) and Sliding (key 9) in the inner

groove of the Sleeve Guide (key 6), replace it with new spare part if needed. If no further maintenance of the Seat (key 3),

please go to step 24.

18. Loosen the Seat (key 3) with suiTable tools and remove it out slowly. Check the O-ring (key 2) in the contact area of Seat

(key 3) and body (key 1). Replace it with new spare part if needed.

19. In the assemble of Sleeve/Stem, loosen the Nut (key 29), take out Washer (key 24) and check the corresponding parts,

replace it with new one if needed.

20. Take out the Stem Bushing (key 20) from the Bonnet (key 12), check the O-ring (key 22, key 23) and Bushing (key 21),

replace it with new spare part if needed.

Reassembling the Backpressure Regulator

Make sure all the parts which needed to be maintenance are properly handled or replaced, then perform the following procedure:

21. Assemble the Stem (key 14) and Sleeve (key 4) together. Assemble the Washer (key 24), tighten the Nut (key 29) using

the torque value listed in Table 11.

22. Lubricate the O-ring (key 23) and Bushing (key 21) slightly and assemble them onto the inner groove of the Stem Bushing

(key 20). Lubricate O-ring (key 22) and assemble it into the outer groove of the Stem Bushing (key 20). Press the Stem

Bushing assemble into the stage hole on the top of Bonnet (key 12) slowly until it reaches the stopping position.

23. Clean and purge the inner surface of the body, lubricate O-ring (key 2) and put it onto the corner of the mating face

of body and seat. Put the Seat (key 3) onto the inner stage of the Body (key 1), make sure the O-ring (key 2) are

not damaged.

24. Put the Cage (key 18) onto the groove of Seat (key 3).

25. Lubricate the O-ring (key 7) and Sliding (key 9), put them onto the inner groove of the Sleeve Guide (key 6) carefully. Put

the Stem/Sleeve assemble in step 21 into the Sleeve Guide (key 6).

26. Put the Stem/Sleeve/Sleeve Guide assemble onto the stage of Cage. And put the Main Vale Spring (key 5) onto the stage

of Sleeve (key 4).

DG Series Regulators

20

!

WARNING

!

WARNING

!

WARNING

27. Lubricate the O-ring (key 10) and assemble it onto the outer groove of the Sleeve Guide (key 6); Lubricate O-ring (key 11)

and assemble it onto the stage corner of the body (key 1). Assemble the Bonnet (key 12) onto the body (key 1), Avoid

scratch or damage the Stem during the assemble process and make sure all the bolting holes are aligned. Lubricate the

screw of Bolt (key 13), Connect the Body and Bonnet together using the Bolt (key 13) and Washer (key 8), tighten the Bolt

in an alternating pattern using the torque value listed in Table 11.

For assemble procedure of Low-Pressure Actuator, please go to step 28.

For assemble procedure of High-Pressure Actuator, please go to step 34.

28. Lubricate O-ring (key 15), then assemble it onto the end groove of the Bonnet (key 12); Put the actuator Lower Casing

(key 33) onto the Bonnet (key 12), Make sure the bolting material is aligned and check the direction of the signal

connection port. Put the Lower Casing Plate (key 35) into the Lower Casing (key 33), make sure the bolting holes are

aligned. Lubricate the screw of Bolt (key 16), Fix the Lower Casing (key 33) and Lower Casing Plate (key 35) onto the

Bonnet (key 12) using Bolt (key 16) and Washer (key 17). Tight it with the torque value listed in Table 11.

29. Lubricate the O-ring (key 68), assemble it onto the inner groove of the Diaphragm Head (key 36); let Stem (key 18) go

through the Diaphragm Head (key 36), press the Diaphragm Head (key 36) until it reaches the Plate (key 35).

30. Lubricate the flange face of Lower Casing (key 33) and the groove sealing face of Diaphragm Head (key 36), Assemble the

Diaphragm (key 39) onto the lower plate, make sure the pin holes on diaphragm and lower plate are aligned and make

sure the diaphragm bolts holes are aligned with the bolts holes on flange. Assemble the Pin (key 66) into the Pin hole

carefully. Lubricate the groove sealing side of the diaphragm upper plate (key 38), let it go through the Stem (key 18),

assemble it onto the upper side of the Diaphragm (key 39) with the pin hole side aligned to the Pin (key 66). Assemble the

Lower Spring Seat (key 37) onto the upper plate (key 38). Lubricate the top screw of the Stem (key 18), tight it using Thin

Nut (key 34) and Nut (key 60) using the torque values listed in Table 11.

31. Lubricate the O-ring (key 46), put it onto the groove of Base (key 47), lubricate the screw of Bolt (key 45), fix the Base

(key 47) onto the Upper Casing (key 43) using Bolt (key 45).

32. Lubricate the flange face of Upper Casing (key 43), Assemble the Upper Casing/Base Assemble on to the diaphragm

(key 39) carefully, make sure the bolts holes are aligned. Lubricate the screw of Bolt (key 42), connecting the Upper and

Lower Casing using the Bolt (key 42), Nut (key 40) and Washer (key 41). Tight the bolts in an alternating pattern using the

torque value listed in Table 11.

Note: Exercise care to ensure that the diaphragm (key 39) is not pinched, twisted or wrinkled while compressing between the

upper and lower diaphragm casings (keys 42 and 33).

33. Lubricate the screw on the end of Spring Case (key 49) which side has no bleed hole. And Screw it into the Base (key 47).

Then go to step 39.

34. Lubricate O-ring (key 15) and assemble it onto groove at the end of the Bonnet (key 12); put the actuator Lower Casing

(key 54) onto the Bonnet (key 12), make sure all the bolting holes are aligned and check the direction of the signal

connection port; lubricate the screw of the Bolt (key 16), fix the Lower Casing (key 54) onto the Bonnet (key 1) using Bolt

(key 16) and Washer (key 17). Tight it with the torque value listed in Table 11.

35. Lubricate O-ring (key 68) and assemble it onto the inner groove of Diaphragm Head (key 36); Let the Stem (key 18) go

through the Diaphragm Head (key 36) and press the Diaphragm Head (key 36) until it reaches the Lower Casing (key 54).

36. Lubricate the flange face of Lower Casing (key 54) and the sealing groove face of Diaphragm Head (key 36), assemble

the Diaphragm (key 56) onto the lower plate carefully. Make sure the pin holes on lower plate and diaphragm are aligned

and make sure the bolts holes on diaphragm and bolts holes on flange faces are aligned. Assemble the Pin (key 66) into

the Pin hole carefully. Lubricate the groove sealing side of the Diaphragm Upper Plate (key 55), Let it go through Stem

(key 18), align the pin hole to the Pin (key 66) and assemble it onto the upper side of the Diaphragm (key 56). Assemble

the Lower Spring Seat (key 37) onto the upper side of the upper plate (key 55). Lubricate the screw on the top of the Stem

(key 18), tight it using the Thin Nut (key 34) and Nut (key 60) with the torque value listed in Table 11.

Personal injury, equipment damage or leakage due to escaping fluid may result if regulator bolts are not tightened to

proper load. Always tighten bolts in an alternating pattern.

Personal injury, equipment damage or leakage due to escaping fluid may result if regulator bolts are not tightened to

proper load. Always tighten bolts in an alternating pattern.

Personal injury, equipment damage or leakage due to escaping fluid may result if regulator bolts are not tightened to

proper load. Always tighten bolts in an alternating pattern.

Table of contents

Popular Controllers manuals by other brands

Carrier

Carrier Toshiba BMS-CT5120UL owner's manual

Digital Loggers

Digital Loggers Web Power Switch 7 user guide

Federal Signal Corporation

Federal Signal Corporation SignalMaster 330104 SMC1 instructions

Xilinx

Xilinx Zynq-7000 Design guide

Siskiyou

Siskiyou MC1100e user manual

Emerson

Emerson Bettis Nuclear Series Operation and maintenance manual