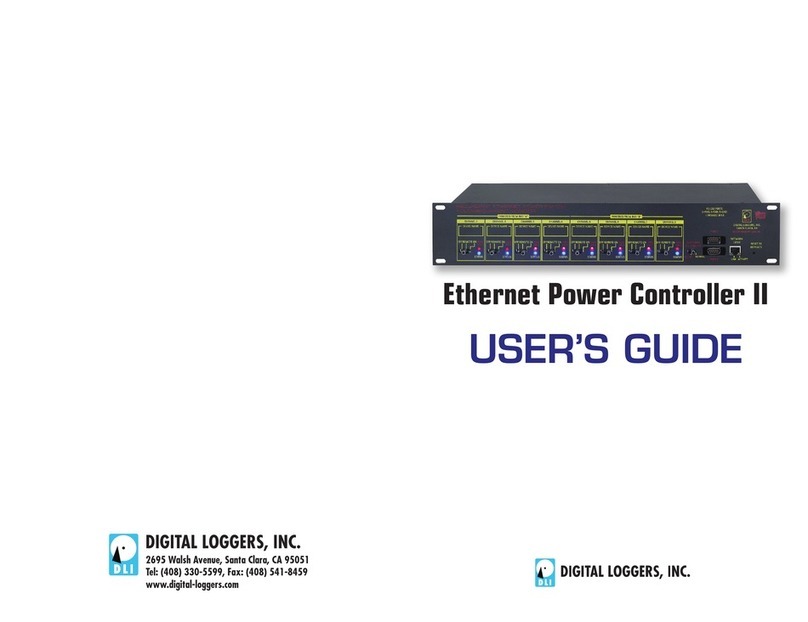

Digital Loggers Web Power Switch 7 User manual

USER’S GUIDE

Ethernet Power Controller 7

Ethernet Power Controller 7 digital-loggers.com

2

Features

Congratulations on selecting the DLI Ethernet Power Controller 7,

a smart rack-mount AC power switch. Features include:

Simple Web Interface

The internal web server is accessible from any browser; simply

enter an IP. Conguration and control are web-based.

AutoPing™ Reboot

AutoPing continuously monitors an IP address. If a server, router,

or other peripheral goes down, AutoPing can power cycle to

automatically reboot it without user intervention. Several devices

can be monitored simultaneously.

8 Switched Duplex Circuits + 2 Unswitched Outlets

Eight individual switch control circuits are provided with duplex

outlets. Outlets are spaced for plugs and adapters. Un-switched

outlets are provided for “always on” devices. Switched outlets are

metered in two banks. Unswitched outlets are unmetered.

Programmable LCD Display and Keypad

A 2x16 LCD displays status for each outlet. Custom messages

can be displayed via Lua scripts. A front-panel keypad provides

local control and can be disabled.

Multi-User Password Security

Multi-user authentication limits access to the power controller. The

administrator selects which outlets each user controls.

Sequenced “On Timer”

A programmable delay timer allows outlets to be switched on

in sequence, rather than simultaneously. Many devices draw

a surge of power when initially switched on. Using this timer,

more equipment can share a single circuit without overloads.

Programmable scripts can be used to create customized power-up

and shut-down sequences with variable timing.

Ethernet Power Controller 7 3

MOV Surge Suppression

Dual 3600W metal oxide varistors clamp power surges and

spikes, protecting attached devices.

Scripting Language, Syslog, and Utilities

Lua scripting can be used to create custom control and reboot

sequences, schedule periodic reboots, etc. Internal and external

event logs are provided.

UPDATED Features

New hardware features include powerline surge dection, a high

current driver for external relays, and larger internal power relays.

Recently added features include context sensitive help, REST-ful

API, MQTT support, Amazon Alexa compatibility, environmental

sensor port, option expansion port, E-mail, SNMP and Jabber

notication, improved power metering, a light sensor, internal

temperature sensor, RS-232 for future expansion, extended

battery life, HTTPS, WiFi support, web power meters/charts and

Lua scripting. Future rmware upgrades may be necessary to

access newer hardware features. Firmware is constantly being

improved and is eld upgradeable via Ethernet.

Package Contents

• Ethernet Power Controller 7 with NEMA 5-15 plugs and outlets.

• Reversable rack ears attached to front of unit.

• RP-SMA WiFi Antenna.

• Internal web server backup battery.

(Battery is disconnected before shipment, located behind right

front panel hatch)

Please contact the freight carrier immediately if your package

appears opened or damaged in transit. Call DLI at (408) 330-5599

for tech support, service, and hardware upgrades.

Ethernet Power Controller 7 digital-loggers.com

4

Important Factory Defaults

IP: 192.168.0.100

User name: admin

(lower case)

Password: 1234

To reset to factory defaults,

gently press the reset-to-

defaults button below the LCD

to enter the reset menu, then select a reset option.

Quick Setup

Experienced? Use these shortcuts.

We recommend that rst-time installers skim the entire manual.

• Unpack. Save the carton. Attach line cords to 15A circuits.

• Attach an Ethernet cable from the controller to your LAN. Switch

power on. If you are attached through a switch, you may need to

cycle switch power to establish a connection.

• Ping the default address 192.168.0.100 to conrm that a

network connection is established. If you don’t receive a response,

proceed to the IP Setup section below.

• Log in to the power controller using the default user name

admin and the password 1234 Note: “admin” must be entered in

lower case.

• Click the Settings link to reach the conguration page. Select

the safest power-loss conguration for your installation: (all OFF,

all sequential ON, or pre-powerloss sequential ON). Note that

pre-powerloss means the last previously congured state, and it

does not take cycling into account. “Power loss” is dened as loss

of AC power on both inputs and battery depletion or disconnection.

• Congure the power switch as described below. After each

change, click Submit and wait for the page to refresh before

continuing.

Tip: A three-bulb electrical safety-tester is handy for checking

conguration before attaching live loads.

Ethernet Power Controller 7 5

IP Setup

If your network settings won’t access the default IP, use a direct

cable connection (temporarily bypass any switch or router)

and follow these steps to add a compatible static IP, such as

192.168.0.50 Before adding an IP, close all programs and

browsers. After the link is established, you can enable DHCP.

Windows Step 1

In Windows, the rst step is locating the network adapter TCP/IP

properties. The procedure diers for each Windows version:

Windows XP, 2000, 2003: Open Start / Control Panel / Network

Connections. In “classic view”, select Start / Settings / Control

Panel /Network Connections. Right-click on Local Area

Network Connection and select Properties. Proceed to step 2.

Windows Vista: Open Start, right click on Network, then on

Properties. Double click Network and Sharing Center, click

Manage Newtork Connections. A Network Connections window

appears. Right click on the network connection to the switch, ie.

Local Area Network. Proceed to step 2.

Windows 7: Open the Start orb, click on Control Panel. Click

View Network Status and Tasks, then Change Adapter

Settings. Proceed to step 2

Windows 8-10: Mouse or swipe to the bottom right corner and

select Settings. Select Control Panel. Select Network and

Sharing Center or Network->Network Settings. Click change

Adapter Settings or Adapter Options. Right click on your

connected network and select Properties. Proceed to step 2

Windows Step 2

The second step is adding an IP such as 192.168.0.50

Temporarily disable DHCP while conguring the switch.

Ethernet Power Conroller 7 digital-loggers.com

6

Select Internet Protocall TCP/IP V4 Properties and click

Properties. Enter a compatible static IP such as: Click Apply and

close windows. Ping the power switch to conrm the connection.

Point your

browser to

192.168.0.100

Log in. Detailed

instructions are at

digital-loggers.

com/ip_setup

Max OS X

Turn AirPort o temporarily. Click the Apple logo, then System

Preferences, then Network. Select Built-In Ethernet and then

Congure. Under the TCP/IP tab, select Manually and enter an IP

address such as 192.168.0.0 as shown:

Make the changes shown. Point a browser to 192.168.0.100 Log

in. Find Mac setup details at digital-loggers.com/mac_ip_setup

Ethernet Power Controller 7 7

Network Conguration

HTTPS is disabled by default. WiFi is enabled with a random

key. Start by establishing a hard-wired network connection to

192.168.0.100, or use the LCD and keypad to display the default

WiFi SSID and password. The Settings page controls network

conguration:

The IP address of the controller usually must match the “class C”

of your system. In other words, the rst three bytes (192.168.0)

must match the IP on your computer to access the controller.

Using a Ping utility is a good way to conrm a valid network

conguration. An “unreachable” report from Ping indicates a

miscongured network.

Once you have a connection, the controller may be operated via a

web browser. To access the controller, enter the IP address in the

URL eld of your web browser. The default is http://192.168.0.100

SSH is disabled by default.

After setup, the HTTP and SSH ports (if enabled) may be moved

to improve security. For example, changing the HTTP port to 2015

requires a browser URL of 192.168.0.100:2015 to reach the power

Ethernet Power Controller 7 digital-loggers.com

8

controller. Note that some browsers will deny connections to

ports under 1024.

Home (Outlet Control) Page

To access the home page, rst enter the controller’s IP address in

the browser URL eld, then log in. User admin has access to all

features. Other users have limited access to outlets as assigned

by the administrator.

Outlet Control

Clicking “Outlet Control” links to the home page used for

manually switching outlets on and o. Access to specic outlets is

determined by username. Admin controls all circuits.

Setup

The setup page lets you set outlet names, create web links, adjust

startup delays, and set a power loss recovery mode. You can also

add user accounts and change login credentials on this page.

Scripting

An updated scripting language based on Lua lets you customize

Ethernet Power Controller 7 9

the power controller. Scripts may be started manually,

automatically on power-up, by external http commands, or by

AutoPing events. Find a list of commands and examples at:

digital-loggers.com/scripts.html

AutoPing

The AutoPing page lets you set parameters to automatically

reboot attached equipment. First, specify an IP address to ping.

Next, adjust the timing settings and use the checkboxes to link the

IP to power circuits. For example, if a router is unreachable, you

may choose to automatically reboot both a router and a switch

attached to two dierent circuits. See page 12.

System Log

The power controller keeps an internal event log including logins,

outlet switching, power interruptions, and AutoPing events. Recent

events are stored in the log and accessible from the System Log

page. SYSLOG export is supported. For more information: digital-

loggers.com/syslog.html

Logout

Browser logout is automatic when a session is closed or after a

time-out period. Use this link to logout in advance.

Programmable Web Links

User-dened web links are provided. Set names and destination

URLs for these links on the Settings page.

Switching Outlets

The outlet control page lets you control any duplex outlet (except

the always-on pair). A master control allows those users with

access to switch all outlets on or o.

To switch an outlet, simply click to the right of the outlet name or

number. On->O switching is immediate O->On switching is

subject to the congurable On Sequence Delay..

Ethernet Power Controller 7 digital-loggers.com

10

Use the front panel keypad for local control: Select an outlet

using the arrow keys, then press on, o, or cycle. Press ON or

OFF for 5 seconds to lock or unlock an outlet. Locking prevents

web access. To change the display mode, press the up and

down arrows simultaneously. The keypad may be disabled on

the Setup page.

You may want to Cycle a device which is connected to the

controller. This feature is useful for rebooting Ethernet devices

which may interrupt the web link to the controller. Clicking Cycle

switches power o, waits for the Cycle time, and then switches

power back on while conforming to the ON Sequence Delay.

This reboots the attached device.

You can also cycle all outlets using the Master Control on the

bottom of the page. An adjustable ON sequence

delay takes eect when outlets are turned on

one after another, either when using the All

Outlets On button, on power-up, or when

switching manually using the front panel. This

prevents power surges. A separate Cycle delay

setting is provided on the setup page.

Depending on your web browser settings, you may need to click

the Refresh button or F5 key to update the on-screen status

display after changing settings. Screen refresh rate is adjusted

in two places: on the Setup page and in your browser settings.

Setup Page

The Setup page allows the admin to congure:

Controller and Outlet Names

Use the controller name eld to assign a Controller Name to

the power controller itself. An example is Server Rack 4 PDU.

The Controller Name will appear on top of all pages. Assign a

separate name to each outlet, such as DSL Router 1 or Email

Server to aid identication. Check the Conrm button to the

right of the outlet name if you would like a pop-up window to

Ethernet Power Controller 7 11

appear before switching critical outlets.

Power-On Sequence Delay

When a time value is entered in the All ON Sequence Delay eld,

the power controller will pause for a period of time before switching

each outlet on in sequence. This delay helps prevent power

surges and blown circuit breakers which can occur when multiple

devices are switched on simultaneously. A delay of 60 seconds is

suggested for server applications.

You may also enter a screen refresh delay in this section. If Enable

screen refresh is checked, and a delay value is entered, your

browser should periodically update the status screen.

Wrong Password Lockout

After three failed login attempts, the switch can disable access for

a selected period of time (0-60 minutes).

Power Loss Recovery Modes

The power loss recovery mode setting has a very important setting

that determines operation after a power failure:

1. Turn all outlets o (all systems will be switched o until

manually turned on later, possibly by a script).

2. You can automatically turn all outlets on using the

sequence delay timer described above.

3. You can return to the same outlet settings that were

used prior to the power loss. ie. 1 On, 2 O, etc. The ON

Sequency delay timer is used here as well.

Note: If you have written a power-on script, the recovery mode

takes eect before script execution begins. Scripts start after self-

test, approximately 30 seconds after power-up.

Ethernet Power Controller 7 digital-loggers.com

12

User Dened Links

Add hyperlinks to other power controllers, your own web pages,

or remote web sites by entering URLs in the Setup page. For

example, enter “Site Two Power Controller” in the description eld

and a URL of “192.168.0.250” These links appear on the left side

of the web pages.

Access Control

The administrator can grant users access to only certain

outlets. To set permissions, login as admin rst, then create

a permissions matrix by entering user names on the left and

checking allowed outlets on the right.

Network Settings

A valid xed IP address, network mask, and gateway must be

entered in this section.

When changing IPs, you may need to restart your network switch

to validate the new IP on an “auto-conguring” switch port. Be

sure to record the new IP address.

Use the Protect button to lock the network settings. Once

protected, the network settings cannot be changed except by

pressing the physical reset button below the LCD.

AutoPingTM

AutoPing Operation and Settings

AutoPing is an automatic system for rebooting IP equipment

without human intervention. AutoPing will monitor a device. If

it stops responding, AutoPing can cycle power to reboot it. For

example, you might use AutoPing to monitor an external multi-

cast IP to automatically reboot a DSL router or WiFi AP.

To use AutoPing, rst add an IP address. Next, link that IP

address to one or more outlets. Timing settings must be

considered.

Ethernet Power Controller 7 13

Add IP Address to AutoPing

Use this option to specify the address of an IP device you

wish to monitor. After entering the IP address, the settings

page will refresh and you can select the outlets associated

with this address. Use the checkboxes in the AutoPing

section to correlate the IP address to one or more outlets. If

communications to the target IP is lost, these outlets will be

rebooted. Four main parameters control AutoPing:

Time between pings

This is the time between each “ping” check of the IP address. 60

seconds should be useful for most applications.

Ping failures before reboot

This sets the number of failed communications attempts that

must be sequentially detected before a power cycle. For

example, when set to 5, the target system must fail to respond

5 times in a row before it is rebooted. Since occasional network

timeouts and packet loss can occur during normal Ethernet

operation, between 5 and 10 pings is suggested.

Times to Attempt Reboot

If you have an unreliable target device, limit the number of times

it will be rebooted by entering that value here. For example,

entering 5 will reboot your server up to 5 times before giving up.

Device Reboot Delay

After power cycling to reboot a device, a waiting period will occur

before the IP address is re-checked by AutoPing. This delay

allows the device time to reboot. Most devices take some time

to reboot. Windows and Linux servers can force automatic le

system checks which may take several minutes to complete.

To allow for startup delays, enter a time delay in the Device

Reboot Delay period. For example, a reasonable value for a

typical server might be 10 minutes (600 seconds). Entering 600

would cause the power controller to start checking the server for

normal IP operation 10 minutes after reboot.

Find more details at: digital-loggers.com/AutoPing2.html

Ethernet Power Controller 7 digital-loggers.com

14

AutoPing Example

In this example, we use AutoPing to automatically reboot a DSL

router. Since the switch is connected inside the router, we select a

target IP of 8.8.8.8 This is a multi-cast address which connects to

a multitude of Google name servers. We can safely assume that if

none of them respond, we have lost network connectivity.

We connect the router to outlet 1, enter the external IP on the left,

and leave all timing values at defaults.

Internet Access

Like to access your power controller over the Internet? Learn

how to congure your router at port-forward.com A rewall is

recommended.

Mobile Device Access

Non-admin accounts have simplied UIs suitable for smaller

LCDs. Third-party apps are available to control various DLI

products from Android and IOS. These apps are sold and

supported by independent developers, not by DLI. Learn more:

digital-loggers.com/mobile.html

Ethernet Power Controller 7 15

Real-Time Clock

An internal Real-Time-Clock (RTC) is provided. Set it manually

using the Date/Time link. The time zone is selectable based on

GMT. Clock batteries have an estimated 15-year lifetime.

Web Server Backup Power

A separate rechargable battery pack maintains web server

operation for a few minutes during power failures. Batteries

are located on right side of teh faceplate. To open the battery

compartment door, press the latch to the left of the door.to

access the battery and connect the cable. Allow 48 hours for full

recharge. Web server batteries should be replaced after 5 years

of use.

Lua Scripting

The controller can be customized using the Lua language. A

full description is beyond the scope of this manual. Please visit

digital-loggers.com/Lua.html

RESTful API

To easily develop your own control app, please read

digital-loggers.com/restapi.pdf

Power Metering and Time Integration

Four web meters provide voltage and current readings on the

A&B bus. Cumulative killowatt hours are displayed. For non-

PFC loads, a power factor correction value may be manually

enetered on the setup page. Current metering includes only

the switched outlets. Co-location users may elect to use the

unswitched outlets for “house power”. To avoid tripped breakers,

take the current drain of the unmetered outlets into account

when operating near the 15A per circuit maximum rating.

Ethernet Power Controller 7 digital-loggers.com

Meters & Charts

Histograms can be created with user-selectable time scales and

metering sources: AC input currents, AC input voltages, battery

voltage, and CPU / Relay voltages are metered. A thermistor

monitors CPU and control board temperature, which should never

exceed 185F. An external sensor port is provided for Dallas 1-wire

and similar sensors. The 5V meter monitors the control board

VCC, and the 12V meter indicates control relay power. Batteries

are fully charged at 5.60V and 90% discharged at 4.60V.

Safety Shutdown“E Breaker”

Supplementary over-current, over-voltage, and low-voltage

shutdown are provided on the safety shudown page. Take care

when conguring the E-Breaker so as not to create an oscillation.

Open Source Code

In compliance with the spirit of the GNU public license, most

source code is provided for reference. Purchasing a TLA and

signing an NDA from Atheros are highly recommended before

attempting any custom development. DLI cannot provide warranty

or tech support for modied units.

Tech Support

Please register. Painless online registration gets you free tech

support, rmware updates, and information. Check the FAQs link

below. Also note that internal help links are now context sensitive.

Suggestions

Looking for a new feature? Let us know:

FAQs

Please check the FAQs at:

digital-loggers.com/epcr7faqs.html

16

Ethernet Power Controller 7 17

Specications

Alert Beeper 73dBa at 12” Programmable

Applications Test equipment, industrial, datacenter

power control and reboot. Indoor use only.

Circuit Breakers Manual reset, 15A Thermal, UL Supplemental

Clock / RTC 15 year Li battery

Controls / Display Reset -to-factory-default switch, 2x16 Backlit LCD

w/ PowerSave, 5 button keypad, E-Stop

Enclosure Steel, double grounded. Vented 4 sides Fanless

Environmental Port RJ-12. Suitable for DHT/SHT series sensors

Ethernet Interface 10/100 autosensing, Static IP, TCP port selectable,

8 pin RJ-45 w/ internal FCC ltering

FCC Testing Part 15 FCC ID 2ACIUEPCR5

Humidity 8-80% RH Operating

Input Power Cord Fixed 14AWG with 5-15 plug standard 120VC only

Inlet and Outlet Rating UL, CSA 15A, 120VAC only

Input Frequency Power supply - DC-400Hz

Metering Accuracy +/- 2V, +/- .5A when calibrated at 50-60Hz only

Operating Temperature -30º to 170ºF, -34º to 77ºC

Options - Factory Input cord length and 120V plug style

Power Supply Rating 90-240V, AC/DC Autosensing

Password Transmission Encrypted, base 64 or HTTPS

Power Dissipation 5.3W Typ Max (all on, battery charging) <3 W idle

Power Fail Hold-Over 350ms minimum (all relays on)

Power-Up Modes Last used settings, all power on or o, sequential

on or run user-script ~30s after power-up

Relay Contact Spec 15-25A AC/DC, 1/2HP

Surge Protection Dual 3600WMetal Oxide Varistors

Size 3.5x5.5x19” 8.9x14x48cm 2-U

Weight (packed) Single unit 10.3lbs 4.7kg

WiFi Atheros 9331 2.4G 802.11n RP-SMA - FCC Note:

The EPCR5 may only be used with (1) the manu-

facturer supplied antenna (Gain: 2.0dBi), or (2) a

50 Ohm antenna of equal or lesser gain

Ethernet Power Controller 7 digital-loggers.com

18

Limited Five Year Warranty

The terms of this warranty may be legally binding. If you do not agree to the terms

listed below, return the product immediately in original unopened condition for a full

refund. The purchaser assumes the entire risk as to the results and performance of

the unit. DLI warrants this power controller to be free from major defects. No agency,

country, or local certications are included with this unit. It is the responsibility of

the user to obtain such certications if necessary for the customer’s application.

Buyer acknowledges and agrees that he is solely responsible for proper use,

certication and safety testing of components supplied by DLI. DLI’s entire liability

and exclusive remedy as to defective hardware shall be, at DLI’s option, either (a)

return of the purchase price or (b) replacement or repair of the hardware that does

not meet DLI’s quality control standards and has been returned through proper

RMA procedures. DLI’s liability for repair or replacement is to DLI’s customer ONLY.

NO SUPPORT IS PROVIDED FOR MODIFIED FIRMWARE. MODIFICATION

OF FIRMWARE VOIDS ALL WARRANTY. Warranty service requires an original

invoice from DLI and an RMA number provided by technical support. RMA material

must be shipped prepaid to DLI. RMA numbers are valid for 15 days from date of

issue. This warranty does not cover products which are modied (including rmware

modications), subjected to rough handling, or used in applications for which they

were not originally intended. Batteries are not covered under warranty. Physical

damage caused by customer or in transit to DLI is not covered under warranty.

Please insure your shipments. No oral advice or verbal warranties made by DLI’s

employees, dealers, or distributors shall in any way increase the scope of this

warranty. DLI makes no warranty as to merchantability or tness for any particular

purpose. DLI assumes no liability for incidental or consequential damages arising

from the use or inability to use this product. This warranty gives you specic legal

rights. You may also have other rights that vary from state to state. Since some

states do not allow the exclusion of liability for consequential damages, some of

the above limitations may not apply to you. Auto-PingTM is a registered trademark

of Computer Performance, Inc. Since this is a FLASH based product, rmware

should not be updated over the Internet or a busy LAN. Packet loss could result

in FLASH corruption, requiring mail-in service. This product is designed for indoor

use only. It is not intended for and should not be used in outdoor, mobile, airborne,

or FDA Class III applications.

DIGITAL LOGGERS, INC.

2695 Walsh Avenue

Santa Clara, CA 95051

Digital-Loggers.com

© 2022 DLI This product is protected by pending US patents and foreign patents

Released 8/01/2022

Other manuals for Web Power Switch 7

1

Table of contents

Other Digital Loggers Controllers manuals

Popular Controllers manuals by other brands

Honeywell

Honeywell UDC3200 series product manual

ABB

ABB Relion 670 series Commissioning manual

Savant

Savant LCB-DMX1 Deployment guide

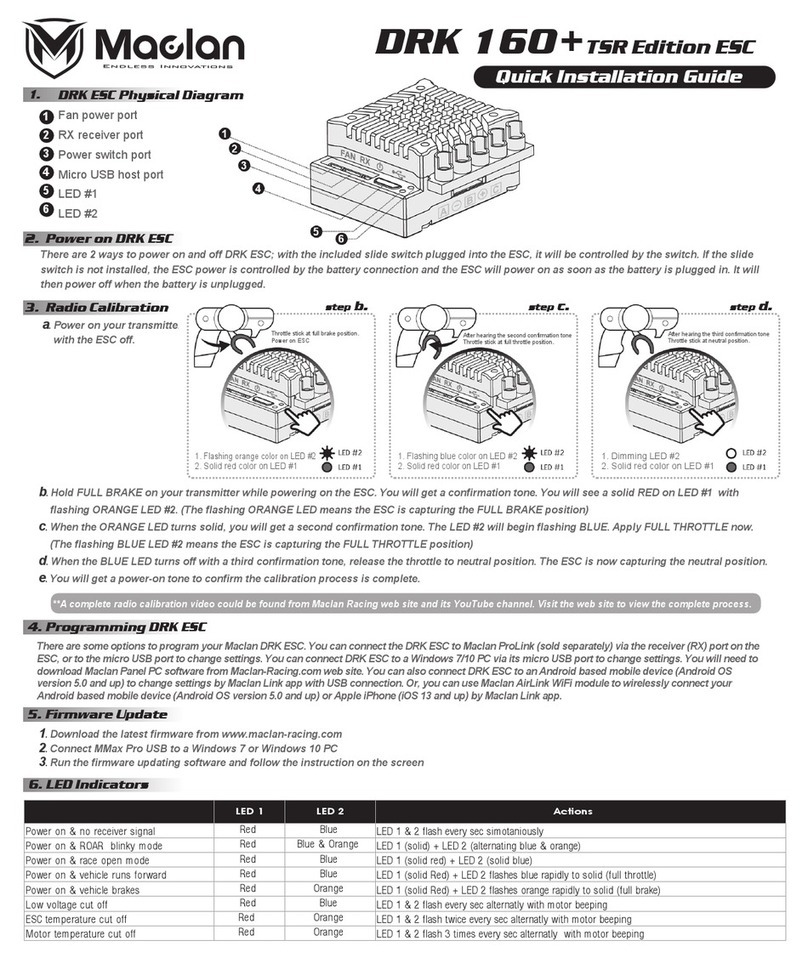

Maclan

Maclan DRK 160+TSR Edition ESC Quick installation guide

Dwyer Instruments

Dwyer Instruments DCT1010DC Installation and operating instructions

LSIS

LSIS XBC-DN32U user manual