Siskiyou MC1100e User manual

User's Manual For

MC1100e

Motion Controller

Siskiyou Corporation MC1100e User's Manual

Siskiyou Corporation Phone (toll free): 1-877-313-6418

www.siskiyou.com Phone: 1-541-479-8697

Page 2

Service Information

Please call, email, or fax in your questions to Siskiyou Corporation at:

Telephone (toll free): 1-877-313-6418

Facsimile: 1-541-479-3314

For a mailing address, refer to page 9.

Product Warranty

Siskiyou Corporation products carry the following warranty, effective for a period of one year

from the original invoice date unless otherwise stated in the product literature:

Siskiyou Corporation products will be free of defects in material and workmanship.

Siskiyou Corporation products will meet the specifications stated in this catalog.

If you find any defects in material or workmanship, or a failure to meet specifications within the

warranty period, return the product to us clearly marked with a Return Authorization (RA)

number and we will either repair or replace it at our discretion. Call our toll free telephone

number and ask for the service department to request RA numbers.

Our warranty excludes products that have been improperly installed or maintained, modified or

misused. Notification of claim must occur within the warranty period. Siskiyou Corporation’s

liabilities are limited as set forth in our STANDARD TERMS AND CONDITIONS, copies of which

are available upon request.

Siskiyou Corporation products unused and undamaged may be returned to Siskiyou

Corporation within 30 days of the initial invoice date (60 days outside of the US), but are

subject to a 25% restocking fee.

Warranty Repairs

Before shipping a part to Siskiyou Corporation, a Return Authorization (RA) number must be

obtained by calling our service department at our toll free telephone number. The product

must be shipped prepaid in the original or equivalent packing with the RA number clearly

marked on the outside of the box. Pack carefully to prevent damage. Place actuators, stages,

manipulators, and controllers in a clean plastic bag to prevent contamination from packing

materials. Siskiyou Corporation cannot be responsible for any damage occurring in transit to us.

Products are not accepted without a Return Authorization number on the outside of the

shipping carton.

Siskiyou Corporation MC1100e User's Manual

Siskiyou Corporation Phone (toll free): 1-877-313-6418

www.siskiyou.com Phone: 1-541-479-8697

Page 3

Table of Contents

Introduction: ................................................................................................................................... 3

Inspection / Items Included: ........................................................................................................... 3

Description:..................................................................................................................................... 4

Installation: ..................................................................................................................................... 5

Interface:......................................................................................................................................... 5

Junction Box ................................................................................................................................ 5

Controller .................................................................................................................................... 6

Operation:....................................................................................................................................... 7

Troubleshooting:............................................................................................................................. 8

Maintenance and Service: .............................................................................................................. 8

Related Products:............................................................................................................................ 9

Switching Box .............................................................................................................................. 9

Digital Readout............................................................................................................................ 9

EU Declaration of Conformity....................................................................................................... 10

Contact Information...................................................................................................................... 11

Introduction:

This manual describes the operation of Siskiyou’s Model MC1100e micromanipulator motion

controller.

Specifications:

Input Power Requirements: 90-264VAC, 47-63Hz

via included power supply adapter

Output: 18VDC / 2.5A

Inspection / Items Included:

Siskiyou products are shipped in sturdy, cushioned boxes. Please inspect the instrument

immediately and notify the carrier if damage is obvious. Remove all items from packing

materials and confirm that all items listed in the table below are available.

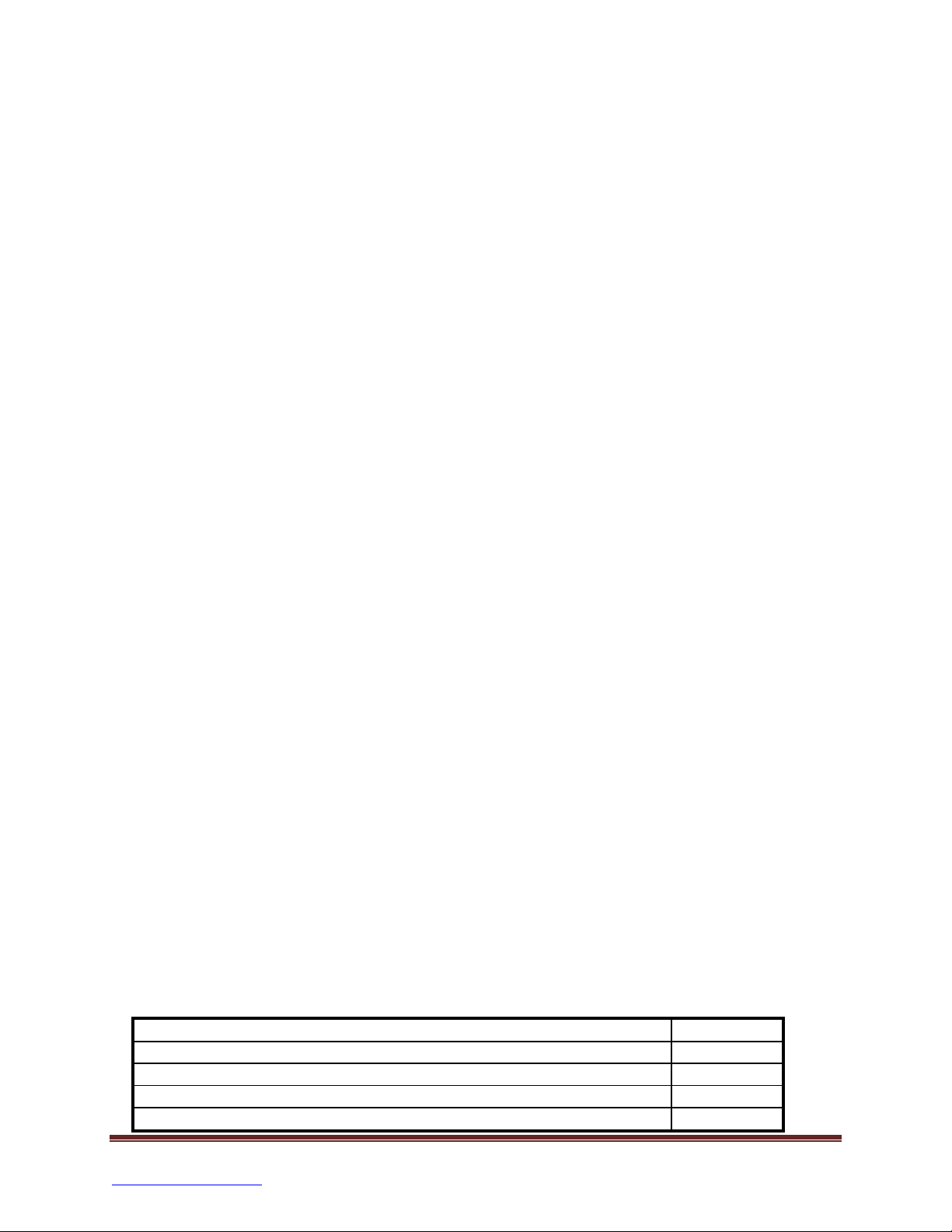

DESCRIPTION

QUANTITY

MC1100e 4 AXIS PUSH BUTTON TARGETING CONTROLLER

1

MC1100e 4 AXIS JUNCTION BOX with mounting hardware

1

POWER SUPPLY ADAPTER

1

POWER CABLE

1

Siskiyou Corporation MC1100e User's Manual

Siskiyou Corporation Phone (toll free): 1-877-313-6418

www.siskiyou.com Phone: 1-541-479-8697

Page 4

Description:

The MC1100e is a simple push-button controller with submicron positioning capability and a

user selected target feature. The MC1100e uses the same control features as our popular

MC1000e controller with a Target/Retract feature on one axis. The Target/Retract allows the

user to set a target location at a desired point. When it becomes necessary to back away from

the experiment area, the user simply depresses the “Retract” button on the controller. The

stage/actuator plugged into that axis then automatically retracts to its full negative limit. The

user can then return to the previously set position by simply depressing the “Target” button.

The MC1100e 4-axis controller has two preset speed settings: rapid (1.7 mm/second) and

medium (300 μm/second). The third speed selector (slow) has a variable 330° potentiometer

that enables settings from high speed (50μm/second) to low speed (2μm/second). With the

speed selector set at the slowest settings, consistent 0.2 μm moves are easily made by the

simple bump of an axis button. The controller uses encoder feedback from the motor to drive

the device. This encoder coupling enables the use of the DR1000 digital readout for repeated

positioning requirements.

The MC1100e uses a universal switching power supply adapter as its source for clean DC power.

All cables are shielded and a central ground lug is located on the junction box to ensure noise-

free operation during sensitive electrophysiology experiments.

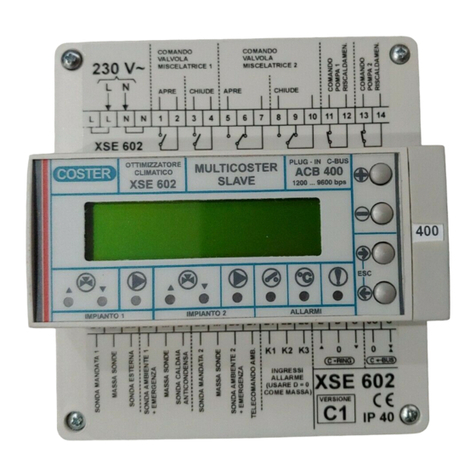

Figure 1: Interface

Siskiyou Corporation MC1100e User's Manual

Siskiyou Corporation Phone (toll free): 1-877-313-6418

www.siskiyou.com Phone: 1-541-479-8697

Page 5

Installation:

CAUTION: MAKE SURE ALL CONNECTORS ARE SECURELY PLUGGED IN BEFORE POWER IS

TURNED ON. DO NOT REMOVE CONNECTORS WHILE POWER IS ON. FAILURE TO DO SO

CAN RESULT IN A SHORT CIRCUIT AND PERMANENT DAMAGE TO THE SYSTEM.

To install the MC1100e, please refer to Figure 1: Interface or the supplied set up

instructions. Supplied with the MC1100e are two ¼-20 screws that can be used to

secure the junction box to the work station. It is also possible to use cable ties (not

included) to mount the junction box.

It is advised to place the controller away from the experiment area. Any liquid that may

come in contact with the controller can cause permanent damage to the system. It is

also advised to add a ground wire onto the junction box and attach the free end of the

wire to a metal surface outside of the system. The lug to use is labeled by the electrical

symbol for “ground”:

Interface:

Junction Box

Power In: Using the supplied power adapter, the user can connect the power adapter to

the junction box and supply power to the system.

Power Switch: The power switch turns on the junction box and the controller. This is

required to be on in order to use the MC1100e. Turning off the power switch will cease

all operations with manipulators remaining in place. The same applies to loss of power.

Ground: By attaching a wire from the ground lug to a metal surface (that is not part of

the experimental system), the users helps prevent damage from static shock and to

ensure noise-free operation while in use. The lug is represented by the electrical symbol

for “ground”:

Controller: The 25 pin, male connector, is used for connecting the controller to the

junction box.

1, 2, 3, and 4 Ports: The 25 pin, female connectors, are used for connecting the motor

drive cables to the junction box. A motor drive must be plugged into port 1 for the

MC1100e to work.

Siskiyou Corporation MC1100e User's Manual

Siskiyou Corporation Phone (toll free): 1-877-313-6418

www.siskiyou.com Phone: 1-541-479-8697

Page 6

Controller

Drive No. 1, 2, 3, and 4: The eight buttons located by the respective labels of 1, 2, 3, and

4 are used to control the motor drives in both the positive and negative direction of the

respective axes plugged into the junction box. Multiple buttons on different axes may be

pressed at the same time, but two buttons on the same axis will not have any effect.

Slow/Med/Rapid: This knob is used to change the speed of the motor drives. It has

three different speeds: slow, medium, and rapid. This feature sets the speed for all

axes. Individual axis speed settings are not available.

The MC1100e 4-axis controller has two preset speed settings: rapid (1.7 mm/sec) and

medium (300 µm/sec).

Slow Range: The slow range knob is used during the slow speed of the Slow/Med/Rapid

knob. The Slow Range knob has a variable 330° potentiometer that enables settings

from high speed (50 µm/sec) to low speed (2 µm/sec). With the speed selector set at

the slowest settings, consistent 0.2 µm moves are made by a bump of the axis button.

This feature works for all axes.

Target Set: This is the small red button that is located in the upper-middle of the

controller. This button only affects Drive No. 1.

When the user has found a reference position that they would like to automatically

return to, the user can push this button and the location will be saved. Pressing Drive

No. 2, 3, or 4 will change the target location. A green LED will become illuminated when

this button is pressed.

Siskiyou Corporation MC1100e User's Manual

Siskiyou Corporation Phone (toll free): 1-877-313-6418

www.siskiyou.com Phone: 1-541-479-8697

Page 7

Retract: This is a black button that is located in the middle-right of the controller. This

button only affects Drive No. 1.

After the user has pressed the red “Target Set” button that creates the desired HOME

position to have the axis 1 return to, the user can press the “Retract” button and the

axis 1 motor drive will move to the rear of travel. Axes 2, 3, and 4 will still be able to

move in this retracted mode. The user will need to be cautious not to press any of the

buttons for Drive No. 2, 3, or 4 as doing so will result in a change in the

micromanipulator stage position. A red LED will illuminate when the motor drive is in

this position.

Target: This is a black button located in the middle-left of the controller. This button

only affects Drive No. 1.

When a target is set, and the user has pressed the “Retract” button, the user can press

the “Target” button, and the motor drive will return to the targeted position. This

feature only works in the retracted position. A green LED will become illuminated when

the motor drive has reached the targeted position.

Operation:

When the MC1100e has been correctly installed, the user can begin use of the system. The

operation may be bench tested prior to installing the unit to an experiment.

When the user presses a button for the Drive No. 1, 2, 3, or 4, the motor drive that is plugged

into the respective port will also move. For example, if the X axis motor drive is plugged into

port 1 on the junction box, when Drive No. 1 is pressed, the X axis will move. The speed will

based on the setting selected from the 3 position speed selection knob.

The targeting axis is set to Drive No.1. To set a point of reference when axis 1 is in a desired

position, push the “Target Set” button. To retract the motorized axis 1, push the “Retract”

button. Once the axis has reached its reverse limit switch, the red LED will light up. To bring the

axis back to the target position, push the “Target” button. When the green LED lights up, the

motorized axis is in the target position.

For best results and to avoid backlash, the direction of travel when the target set position is

pushed should be a forward move. This is the same travel direction as the movement from the

limit switch to the target.

Siskiyou Corporation MC1100e User's Manual

Siskiyou Corporation Phone (toll free): 1-877-313-6418

www.siskiyou.com Phone: 1-541-479-8697

Page 8

Troubleshooting:

Axis 1 is retracted and I accidently hit the “Target Set” button and now nothing will work.

Typically, with our lab testing, if axis 1 is retracted, and the “Target Set” button is pressed

(which creates a new target position at the retracted position, where both LEDs lights up), all of

the axes should still be able to move. However, if multiple “random” button pressing occurs

during this scenario, it will cause a full system lockup. In order to recover from this lockup (or

similar lockups), the system will need to be powered off by pressing the power button on the

junction box. Once off, the user can then turn the system back on. The user can then press the

Drive No. 1 button to move axis out of the retracted position (red LED turns off). Once out of

the retracted position, the user can specify a new target position. Be careful not to press the

“Target”, “Retract”, or “Target Set” buttons before the drive axis is out of the retracted mode

as doing so can cause an additional system lockup.

I accidently hit the retract button. Is there any way to stop it?

While in automatic motion, either in retract or target mode, none of the drive axis controllers

will work. If the retract button is accidently pressed, the user can turn off the system by

pressing the power button on the junction box. This will stop all motion. The user can then

manually place the drive motor back into position by using Drive No. 1. However, it may be best

to let the system finish the retract function. Once retracted, the user can press the “Target”

button to return to the previous target.

The system was turned off. Will I still have my previous target?

Yes. The system has an onboard memory that stores the location of the last target used on axis

1. By placing the drive axis in the retracted mode, the user can press the “Target” button to

return to the previous target. It is recommended to not move axes 2, 3, or 4 as doing so can

change the target location of axis 1.

Note: Due to the programming capabilities of the unit, this feature will not work initially on

power up if axis 1 is in the retracted mode (red LED is on). By moving the axis out of the

retracted mode (red LED is off), the user can then hit the “Retract” button and then the

“Target” button to return to the previous target.

Maintenance and Service:

There are no user serviceable parts inside the controller or junction box. In the event of the

need for service, call Siskiyou Corporation and ask to speak with technical support.

If the problem cannot be solved through telephone or email communication, an RA number will

be provided to return the unit to Siskiyou Corporation.

Siskiyou Corporation MC1100e User's Manual

Siskiyou Corporation Phone (toll free): 1-877-313-6418

www.siskiyou.com Phone: 1-541-479-8697

Page 9

Related Products:

Switching Box

ABCD switching box allows control of one to four 4-axis micromanipulators by one controller.

The basis of the design is simple and requires only an extra controller junction box for each

added micromanipulator or motor drive group (up to four per group). Junction boxes must be

purchased separately.

Digital Readout

The DR1000 Digital Readout provides an accurate, highly visible display for axis position. The

digital readout may be installed on any of our e series controllers and is connected in series via

a double-sided connector between the controller junction box and the device D connector.

Siskiyou Corporation MC1100e User's Manual

Siskiyou Corporation Phone (toll free): 1-877-313-6418

www.siskiyou.com Phone: 1-541-479-8697

Page 10

EU Declaration of Conformity

In accordance with EN 45014: 1998

Manufacturer: Siskiyou Corporation

Address: 110 SW Booth Street

Grants Pass, OR 97526-2410

USA

Declare that:

Equipment Motion Controller

Model Name/Number MC1000e Series

Serial Number N/A

In accordance with the following directives:

2014/35/EU The Low Voltage Directive and its amending directives

2014/30/EU The Electromagnetic Compatibility Directive and its amending

directives

2006/42/EC The Machinery Directive and its amending directives

2011/65/EU Restriction of use of certain hazardous substances (RoHS)

I hereby declare that the equipment above has been designed and found to comply with

the relevant sections of the above referenced specifications. The unit complies with all

essential requirements of the Directives.

Signed by:

Name: John Wingerd

Position: Engineering

Place: USA

Date: August, 1, 2018

06

Siskiyou Corporation MC1100e User's Manual

Siskiyou Corporation Phone (toll free): 1-877-313-6418

www.siskiyou.com Phone: 1-541-479-8697

Page 11

Contact Information

Mailing Address

Siskiyou Corporation

110 S.W. Booth Street

Grants Pass, OR 97526-2410

Sales and Service

phone (toll free): 1-877-313-6418

Technical Assistance

phone: 1-541-479-8697

facsimile: 1-541-479-3314

Website

www.siskiyou.com

International

please call or visit our website for

international contacts

Table of contents

Other Siskiyou Controllers manuals

Popular Controllers manuals by other brands

Morningstar

Morningstar SUNSAVER MPPT SS-MPPT-15L Installation and operation manual

ready robotics

ready robotics Forgelos5 Startup guide

Saftronics

Saftronics CV10 quick start guide

BRONKHORST

BRONKHORST FLOW-SMS Series instruction manual

PCB Piezotronics

PCB Piezotronics 683A111002 Installation and operating manual

Coster

Coster B 268 manual

Bernard Controls

Bernard Controls AQ Logic Series Startup guide

Samson

Samson 42-37 Mounting and operating instructions

Toho Electronics

Toho Electronics TTM-339 Operation manual

S&S Northern

S&S Northern Merlin 1000VW+ Installation & operation manual

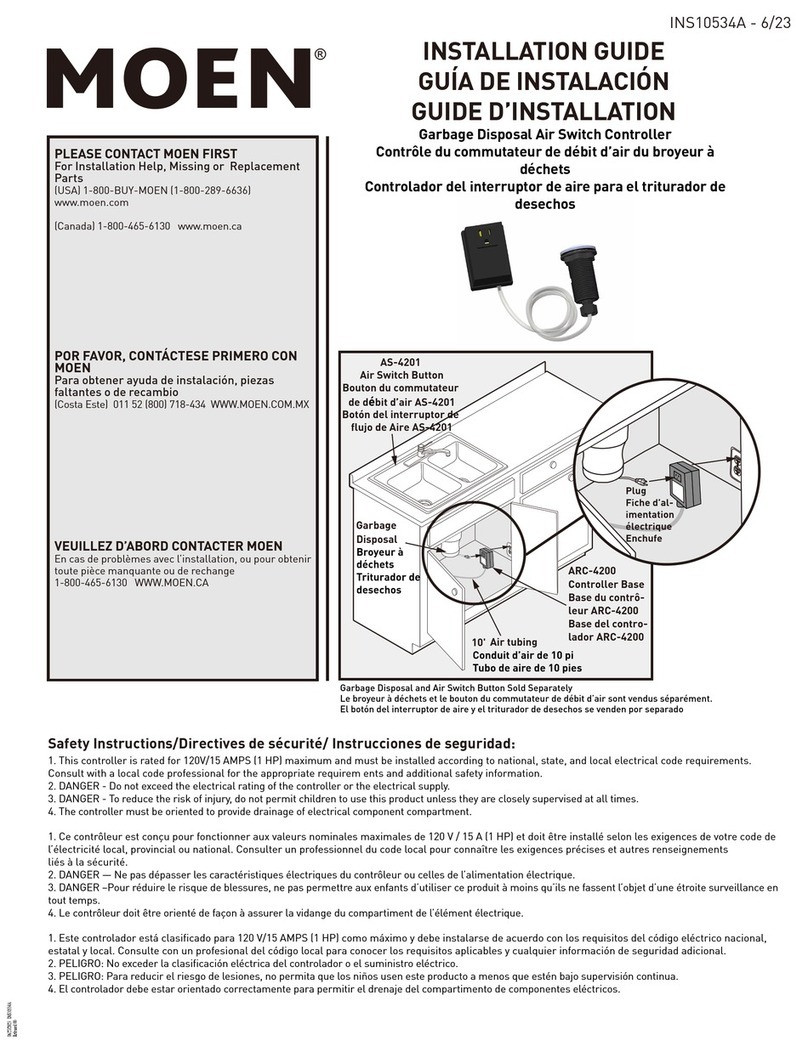

Moen

Moen AS-4200 installation guide

Vega

Vega VEGAMET 342 operating instructions