JessEm Mite-R-Excel II User manual

Owners Manual

61 Forest Plain Road

Oro-Medonte, Ontario,

Canada, L3V0R4

Toll Free: 1-800-436-6799

Local: 705-726-8233

Email: [email protected]

Web: www.jessem.com

Model #07150

MITE R EXCEL II™

All JessEm products are warranted to be free from

defects in material and workmanship. JessEm will

repair or replace any product which upon inspec-

tion, proves to be defective for a period of (1) year

from dated receipt and proof of purchase from an

authorized JessEm Distributor. All warranty claims

should be made direct to JessEm Tool Company.

Contact JessEm for a warranty claim return

authorization and instructions to proceed. The

consumer is responsible for shipping costs to

return product to JessEm Tool Company. We

will repair or replace the product at our

discretion and JessEm Tool will return shipment to

you at no charge.

JessEm Tool Company - Limited Warranty - Warranty Limitations

This warranty does not cover:

•Repairs or alterations made or attempted by anyone

other than JessEm Tool Company or an authorized

JessEm service professional.

•Normal wear and tear.

•Abuse, misuse or neglect.

•Improper care or maintenance.

•Continued use after partial failure.

•Products that have been modified in any way.

•Products used with improper accessories

Thank you for choosing the Mite-R-Excel II™ from JessEm Tool Company. We appreciate your support

and hope that our product serves you well. This product is designed to provide many years of reliable

service, provided it is used as intended and taken care of.

Message to our Customer

IMPORTANT

Read and understand the contents of

this manual before assembly or

operation of this product

This user manual will assist you in assembly and general operation of this product. It is not our intent to

teach you about woodworking. It is assumed that you are an experienced woodworker with the basic

skills and experience necessary to use this product safely. If after reading the following instructions, you

are unsure or uncomfortable about safely using this product, we urge you to seek additional information

through widely available woodworking books or classes.

Continuous Product Improvement Policy

As part of our Continuous Product Improvement Policy, JessEm products are always advancing in

design, quality and function. Therefore, there may be differences between what is shown in our

catalogs, on our website, on retail displays and what is sold at time of purchase. We reserve the right to

make positive changes to our products at our discretion to ensure you, the customer, have the very best

product.

2

SAFETY PRECAUTIONS

If you do not have a manual, contact the

manufacturer and obtain one before using any

power tool.

Always use proper guards and safety devices

when operating power tools and machinery.

Carefully check table saw blades before each

use.

Do not use if damage or defect is suspected.

Do not wear loose clothing or jewelry that may

catch on tools or equipment.

Unplug the tool or machine when mounting or

making any adjustments to mechanical

performance.

Important Safety Precautions

A)Personal Safety

i) Stay alert, watch what you are doing and use common

sense when operating a tool. Do not use a power tool while

you are tired or under the influence of drugs, alcohol or

medication. Serious personal injury could result if complete

attention is not given while operating power tools.

ii) Always wear safety glasses. Everyday eyeglasses are

not safety glasses. Safety glasses have specially constructed

frames, lenses and side shields for better protection.

iii)Use safety equipment. Use a face or dust mask when

the cutting operation is dusty. Safety equipment such as dust

masks, hard hats, non-skid safety shoes and hearing

protection reduces personal injuries when used for

appropriate conditions. If devices and tools allow for dust

extraction and collection, ensure these are connected and

properly used.

iv) Do not overreach. Keep proper footing and balance at

all times. This allows for better control of the power tool in

unexpected situations.

v) Never stand on the machine. Serious injury could occur if

the tool tips or if the cutting tool is unintentionally contacted.

vi) Secure workpieces. Use clamps or vises to hold work

when practical. This is safer than using your hands and frees

both hands to operate the tools

vii) Dress appropriately. Do not wear loose clothing or

jewelry. Ensure you keep clothing, hair and gloves away from

moving parts. Loose clothing, jewelry or long hair can be

caught in moving parts. Roll up long sleeves to the elbow.

Wear protective hair covering to contain long hair.

viii) Avoid accidental starting. Ensure the switch is in the

off position before you plug it in. Carrying a power tool in

your hands with your finger on the switch or plugging in a

power tool that has the switch on is inviting accidents.

ix) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool could result in personal injury.

B) Work Area Safety

i)

switches, or remove starter keys. ii) Keep work area clean

and well lit. Clutter and/or dark areas encourage accidents

ii)Keep children and bystanders away while operating a

power tool. Complete attention is required when operating a

power tool.

C) Electrical Safety

i) Ground electrical tools. If the tool is equipped with a

three-prong plug, it must only be plugged into a grounded

three-hole electrical outlet. If required, a qualified elctrician

can install one. Never remove the third prong or modify the

plug that is provided in any way.

ii) Never expose a power tool to rain or wet conditions.

You will increase the risk of electric shock if water enters the

powertool.

iii) Using power tools in damp or wet locations or conditions

is extremely dangerous.

iv) Do not operate any power tool in an explosive

atmosphere, in the presence of flammable liquids, gases or

dust. Power tools can create sparks which may ignite the

fumes or dust.

When using the JessEm Mite-R-Excel II™ in

conjunction with any other tool, first read and

follow all instructions and safety information in

that tool's owner's manual.

When using the Mite-R-Excel II™, always keep

your hands clear of the cutter and the line of cut.

Always turn off the power and make sure that the

cutter comes to a complete stop before changing

the setting of any part of the Mite-R-Excel II™

Always securely tighten the large clamping knob

before starting any cut.

Always wear safety glasses, hearing protection,

and follow all normal shop safety practices.

After making any adjustments to the miter angle

of your Mite-R-Excel II™, always verify safe

clearance between the cutter and all parts of the

JessEm Mite-R-Excel II™

Always wear eye protection in compliance with

ANSI safety standards when operating any

power tool.

Make your workshop child proof. Use padlocks, master

3

Before operating any machinery or

power tool, read and understand all

safety instructions in the owner’s

manual that came with that tool's

owner's manual.

QUANTITY AND CONTENTS OF PACKAGING TOOLS REQUIRED FOR ASSEMBLY

Important Safety Precautions

IMPORTANT!

Make sure that no part of the

Mite-R-Excel II™ or fence can make

contact with the blade or cutter and all

knobs are securely tightened before

each use.

(1) - Mite-R-Excel II Gauge and Bar Assembly

(1) - Mite-R-Excel II Fence

(1) - Fence Stop and Mounting Hardware

(1) - 3/8" ID x 1" OD Washer

(1) - Handle

(1) - Fence Stop T-Bolt (Short)

(2) - Fence Clamping T-Bolt (Long)

(3) - 1/4" ID x 5/8" OD Washer

(1) - ¼-20 x 1/2" Button Head Cap Screw

(1) - ¼-20 x 3/4" Button Head Cap Screw

(2) - ¼-20 Square Nut

(2) - ¼-20 x 1-1/4" Phillips Flat Head Screw

(1) - 5/32" Hex Key

(1) - 1/8" Hex Key

(1) - 3/32" Hex Key

(1) - 5/64" Hex Key

(1) - 3/32" Hex Key Extension

(1) - 5/32" Hex Key (included)

(1) - 1/8" Hex Key (included)

(1) - 3/32" Hex Key (included)

(1) - 5/64" Hex Key (included)

(1) - 3/32" Hex Key Extension (included)

Contents of Packaging

WARNING: This product can expose you

to chemicals, including chromium which is known to

the State of California to cause cancer and birth

defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov

WARNING: Drilling, sawing, sanding or

machining wood products can expose you to wood

dust, a sub-stance known to the State of California

to cause cancer. Avoid inhaling wood dust or use a

dust mask or other safeguards for personal

protection. www.P65Warnings.ca.gov/wood

4

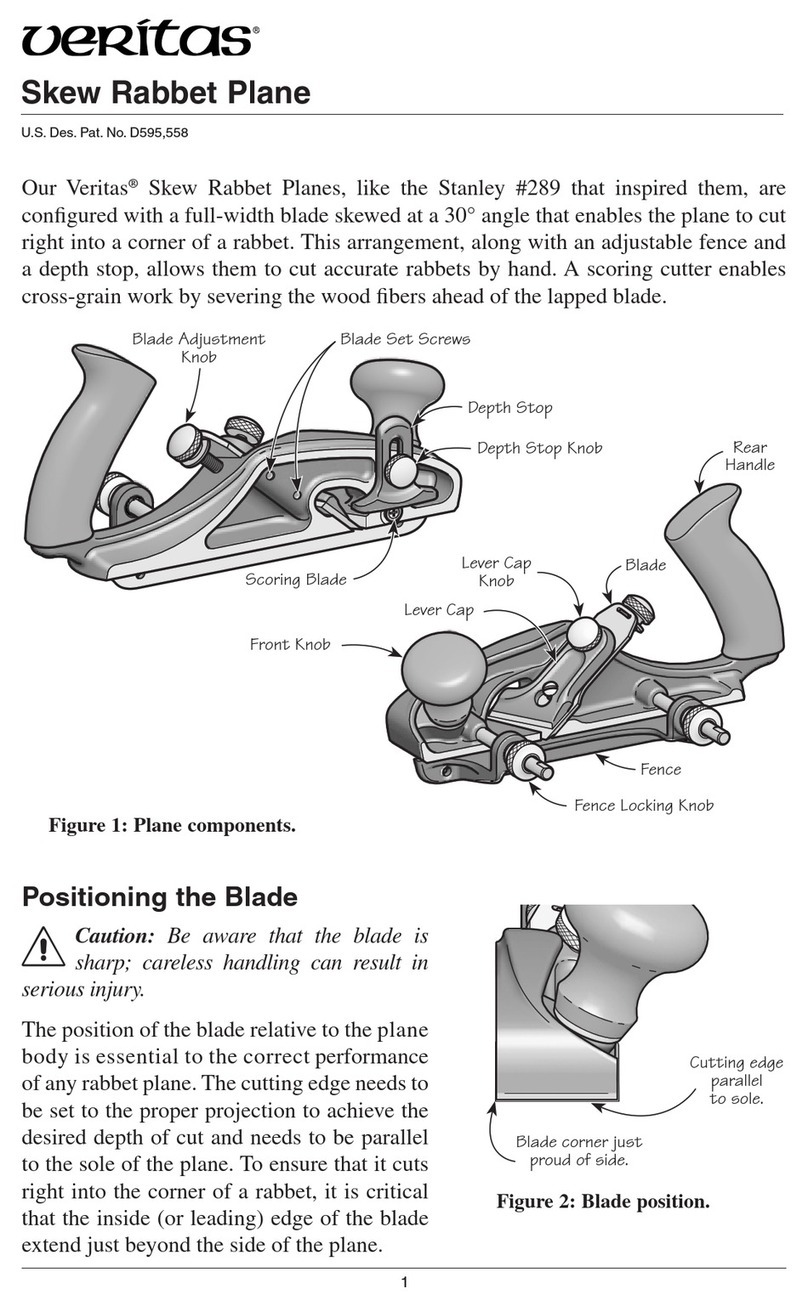

Assembly Instructions

Step 1: Assembly of the Flip Stop

a. Using the 5/32" hex key, attach the flip stop upper

(Part #20) and the flip stop lower (Part #13) using

(1) ¼-20 x ½" button head cap screw (Part #17)

and (1) ¼-20 x ¾" button head cap screw (Part

#18) along with (2) ¼” x 5/8" washers (Part #19).

See Figure 1

b. Attach the clamping handle (Part #11) along with

(1) 1/4" x 5/8" washer (Part #19) to the flip stop

assembly using the Flip Stop T-Bolt - Short (Part

#35) as shown in Figure 1.

a. Loosen the clamping handle (Part #11) and slide the Flip Stop T-Bolt - Short (Part #35) into

the T-slot on the Fence Extrusion (Part #33). See Figure 2

Figure 1

Figure 2

Step 2: Attaching the Flip Stop to the Mite-R-Excel II™ Fence

35

17 18

19

20

13

11

11 35 33

5

The following instructions are for assembling the Mite-R-Excel II™. Please note that the Mite-R-Excel II™

is factory set and only assembly is required.

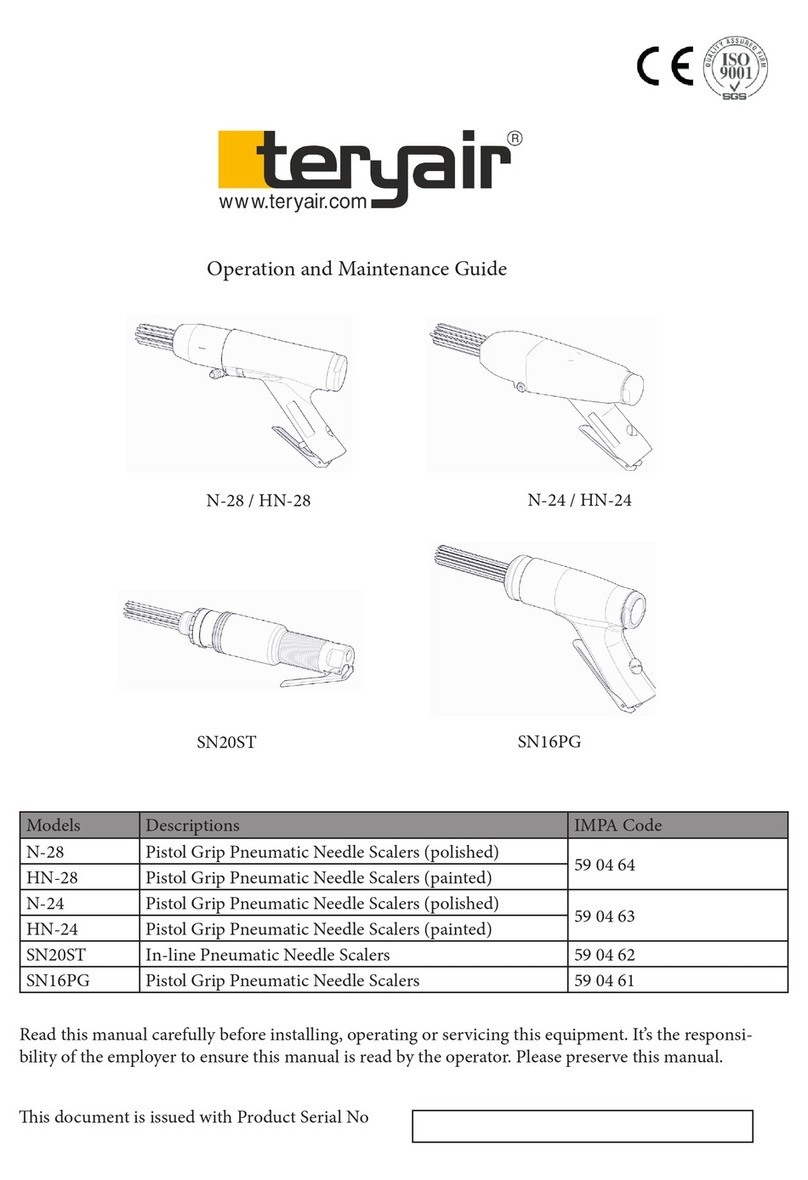

Slide (2) Flence Clamping T-Bolts - Long (Part #64) into the Fence Mount (Part #44) and secure

them in place with the Fence Knobs (Part #45) as shown in Figure 3.

Figure 3

b.

Step 3: Assembling the Mite-R-Excel II™

a. Slide the 3/8" x 1" Stainless Steel Washer (Part #41) onto the Handle (Part #10) and thread the

handle into the guide bar (Part #56) as shown in Figure 3.

Step 4: Setting/Tightening the Guide Bar in the Miter Slot

** NOTE ** Since all miter slots are machined differently, it is important to set the

guide bar so that it moves smoothly during operation. If after following our directions

below, you notice a tight spot on the miter slot, you can either file or stone off the

high spot on the Miter Slot in your table saw or reset the Mite-R-Excel II™ in that area.

6

44

10

45

41

56

64 64

45

6

b.

c.

Place a single sheet of paper in between one of the snuggers (See Part E in Figure 4) on the

guide bar and the side of the miter slot. See Figure 4. With the 3/32" hex key tighten the snugger

mounting screw (Part #3) Repeat this step at each of the three snugger locations.

Test to make sure the Mite-R-Excel II™ moves smoothly. Refer to the note above in order to fix

any possible tight spots on the miter slot.

Figure 4

Place paper in front of snugger, then slide gauge over paper

a. With the 3/32" hex key, loosen the (3) three snugger screws (Part #3), and slide the gauge into the

miter slot on your table saw.

2

23

3

23

E

7

Figure 5

Step 5: Attaching the Fence Extrusion to the Mite-R-Excel II™ Assembly

**NOTE ** The Fence Locating Pin Knob was designed to always allow for the user to

keep their fence properly referenced from the blade when the gauge is set to 0 degrees.

Not all table saw are the same. The instructions below will allow you to properly

reference the fence to suit your needs.

a. Pull the Fence Locating Pin Knob (Part # 40) back and loosen

both Fence Knobs (Part #45). Slide the fence extrusion through

both of the Fence Clamping T-Bolts - Long (Part #64). See

Figure 5.

Once the extrusion is through both T-Bolts,

line up the Fence Locating Pin Knob (Part

#40) with the 6 inch mark on the ruler

(See Figure 6). Push the knob forward to

engage it as you slowly slide the fence

towards the blade. At roughly the 6-1/8"

mark on the ruler, (See Part 32 in Figure 6)

the locating pin will engage with the preset

Fence Locating Nut in the fence extrusion.

When the locating pin is engaged, tighten

both fence knobs.

40

32 33

Figure 6

64

45 33

40

b.

8

a.Using the directions above, use the fence locating pin knob to find the preset locating nut inside the

fence.

Once the fence locating pin knob (Part #40) is engaged into the Fence Locating Nut (Part #36) See

Figure 7, tighten the 2 Fence Knobs (Part #45).

b.

c.

** You may remove the handle (Part #10) to

complete the following steps if you choose too.

Slide the flip stop over to the 3" mark on the ruler

(See Figure 8) and lock it into place.

Figure 7

3"

Align Here

Figure 8

Ensure your table saw is OFF and UNPLUGGED before resetting the fence locating nut.

6 3

45 4 4 4 0 3 7 3 6 6 1

How To Set or Reset the Fence Locating Nut Inside the Fence

9

Figure 9

Using the 3/32" Hex Key provided, attach the hex key extension (Part #63) to the Hex Key Figure

9A and insert the hex key into each of the two holes next to the Fence Locating Pin Knob and

loosen the #10-32 x 3/16" Flat Point Set Screws (Part #37). See Figure 9

Add a 3" block of wood in between the blade and flip stop (See Figure 8). **Note: You can use any

size of wood you may have lying around your shop for this step, just be sure to set your flip stop to

the appropriate length **

Slide the fence extrusion either closer or further away from the blade until the block of wood

touches the blade. The distance from the Fence to blade should be roughly 1/16" once the fence

is adjusted.

Once the fence is set, using the 3/32" Hex Key and the hex key extension provided, tighten both

of the #10-32 x 3/16" Flat Point Set Screw (Part #37)

d.

e.

f.

g.

44 6 3

63

61

37

6 1

36

37

4 0

Figure 9A

10

Make sure the gauge is set in the 0 degree position. See Figure 10

a.

Squaring the Fence to the Table

Figure 10

Push the Fence Mount (Part #44) against the Gauge Body (Part #6) and retighten the (4) four

#10-32 x 7/8" Socket Head Screw (Part #9.3 & 9.4), you loosened in step "c" as shown in Figure

13.

d.

Make sure the (2) ¼-28 x 5/16” Flat Point Set

Screw (Part # 39) are loose before moving on to

step (d). Set screws should not contact gauge

(Part #6) Shown in Figure 12

c.

39 Figure 12

Figure 11

9.3

9.4

9.3

9.4

b. Loosen off (4) Four #10-32 x 7/8” Socket

Head Screw on both sides of the gauge (Part

#9.3 & 9.4) as shown in Figure 11.

11

44

9.3

6

9.4

39 Figure 13

6

Using a combination or machine square, position it up against the front face of the Fence

Extrusion. To square the fence to the table, make sure the square is flush with the table and flush

against the extrusion and the gauge is sitting flat on your table. Rotate the fence until you see no

light between the square and the fence, re-tighten screws 9.1 & 9.2 on the left and right side of

the gauge. (See Figure 14)

c.

Slide your Fence Extrusion (Part #33) back onto the Mite-R-Excel II™ (See Figure 14) and

tighten it in position using the Fence Knobs (Part # 45)

a.

Loosen off screws 9.1 & 9.2 on both sides of the fence using the 5/32” Hex Key (Part # 59)

provided.

b.

Figure 14

Vertically Squaring the Mite-R-Excel II™

12

Remove the Fence Extrusion (Part #33) from the Mite-R-Excel II™ and remove the Mite-R-Excel

II™ from the table saw.

b.

Loosen the Fence Knobs (Part #45) and disengage the Fence Locating Pin Knob (Part #40).

a.

Squaring the Mite-R-Excel II™

C45

9.1

33

9.2

Look at both the left and right side of the gauge. If there is any gap or light between the

combination square blade and the Fence Mount on either the left or right side,(Part #44)

follow steps i) thru iii) below.

d.

NOTE: Once the set screw engages with the gauge body, only turn the screw in small

increments while checking to see if the gap has closed after each turn. You will not need

to turn the set screw too many times before the gap is gone.

Re-attach the Fence Extrusion.

Figure 15

Using a machine/combination square, align the base against the guide bar (Part #56) and

the ruler/straight edge against the Fence Mount (Part # 44) See Figure 15.

c.

NOTE: Steps (b) thru (e) do not have to be done on the saw.

Loosen the 10-32 x 7/8" Socket Head Cap Screws (Part 9.3 and 9.4) on the side with gap.

i)

ii)With 1/8” hex key provided, tighten the 1/4-28 x 5/16” Flat Point Set Screw (Part # 39) until

the set screw presses against the gauge body between the blade and fence mount (Part #44)

See NOTE below.

iii)Once the gauge is flush and no light is seen on both sides of the fence mount, retighten the

10-32 x 7/8" Socket Head Cap Screws (Part 9.3 and 9.4)

13

e.

39

44

9.4

9.3

56

C

Left Gap

Right Gap

Engage the Fence Locating Pin Knob (Part #40) and tighten the fence knobs (Part #45).

f.

After making any adjustments to the Mite-R-Excel II™, ensure the fence is clear of the

table saw blade and the clamping handle is tight before making any cuts.

Using the Mite-R-Excel II ™

50

51

5

51

5

50

47

DISENGAGED INDEXING PIN KNOB

Disengaged indexing pin knob. (Pulled out and

turned). Use in this position for adjusting

increments and all non predetermined detent

positions on the gauge.

ENGAGED INDEXING PIN KNOB

Use in this position when using predetermined

detents of 0°, 15°, 22.5°, 30° and 45°

Engaging and Disengaging the Indexing Pin Knob

Figure 16

Figure 17

14

10

33

5

41

45

Pull indexing pin knob

out and turn

Figure 19

b.

c.Turn your gauge until the 45° lines up with the 0° and then rotate the indexing pin knob (Part #5),

releasing the indexing pin knob back into the engaged position. Refer to Figure 16 and Figure

17 for engaged and disengaged positions. Once the indexing pin knob has locked into the 45

degree detent hole on the gauge, lock the Handle (Part #10). You will now be able to perform

your 45 degree cuts.

Repeat the steps above to set the gauge into any of the pre-determined degrees on the gauge.

Loosen the Handle (Part #10).

a.

15

Pull the Indexing Pin Knob (Part #5) out and away from the gauge and turn it to disengage. This

will now allow the gauge to rotate freely.

The example used below is setting the gauge to 45°. See Figure 19

Figure 18

How to Adjust the Mite-R-Excel II™

The Mite-R-Excel II™ is machined with pre-determined detents in the gauge for 0°,15°, 22.5°, 30°, and

45°. The pre-determined detents are laser marked with a diamond on the gauge.

How to Adjust the Mite-R-Excel II™ to Non Predetermined Detents

b. Pull the Indexing Pin Knob (Part #5) out and away from the gauge and turn it to disengage. This

will now allow the gauge to rotate freely. See Figure 19

c.Turn your gauge to the desired setting.

Repeat the steps above to set the gauge into any of the pre-determined degrees on the gauge.

Loosen the Handle (Part #10). See Figure 19

a.

The Mite-R-Excel II™ can be set to non-predetermined detents on both the left and right sides of 0°.

When setting at non-predetermined settings only lock the Handle (Part #10), leaving the Indexing

Pin Knob disengaged.

Lock the Handle (Part #10) and leave the Indexing Pin Knob disengaged. See Figure 19

d.

16

How to set the Mite-R-Excel II™ Extension Stop

Loosen clamping handle (part #11)

a.

Slide fence extension (Part #26) out until the desired read on the fence extension scale bar (Part

#27) is aligned with the end of the fence extrusion (Part #33) See Figure 20.

b.

c.

2733

261 1

Figure 20

Tighten clamping handle (Part #11) to lock the extension in place.

17

How to Set the Vernier Scale

The Mite-R-Excel II™ can be used not only with whole numbers, but is also designed to move 1/10th

degrees on the lower Vernier Scale.

Loosen the Handle (Part #10)

Pull out and lock the Indexing Pin Knob (Part #5) and rotate the gauge to the nearest whole

number.

Using the lower Vernier scale, set your gauge to the 1/10th degree desired.

Once you have your setting, lock only the Handle only (part #10), leaving the Indexing Pin Knob

(Part #5) in the disengaged positon. See Example 1

a.

b.

c.

d.

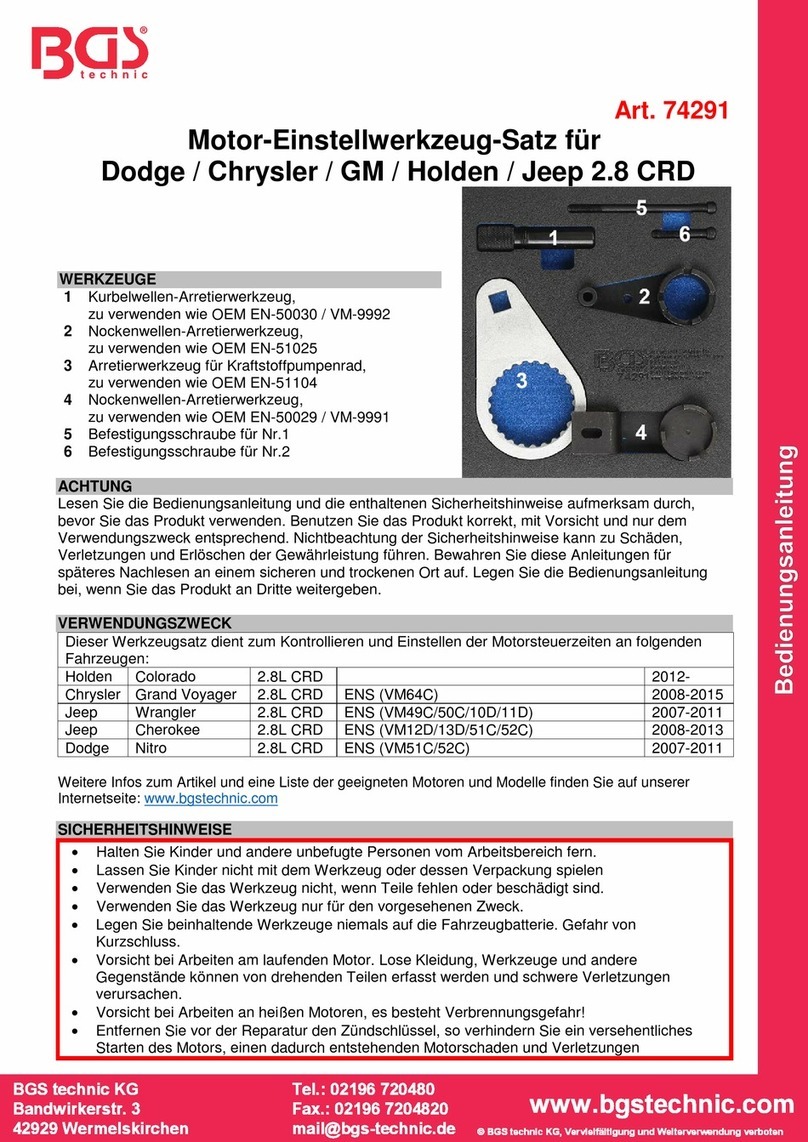

Following are two examples of using the Vernier Scale on the Mite-R-Excel II™

Example 1: Setting Mite-R-Excel II™ at 35.4°

Example 2: Setting Mite-R-Excel II™ at 35.7°

To use this Vernier Scale on the Mite-R-Excel II™ follow these directions.

10

6

50

5

Example #1

INDEXING PIN KNOB

DISENGAGED

Loosen the Handle (Part #10)

Pull out and turn to disengage the Indexing Pin Knob (Part #5). See Figure 16 and 17 to

distinguish locked and unlocked positions of the Indexing Pin Knob

Rotate the gauge to 35° degrees

Using the lower Vernier Scale on the

Indexing Block (Part #50), rotate the

gauge counter clockwise until the desired

1/10th degree aligns with the nearest

whole degree.

In this example the .4 mark on the lower Vernier

Scale will line up with the “39” on the upper scale.

Tighten the Handle (Part #10) and now the gauge

is set to 35.4° degrees.

Example 1:

Setting your gauge to 35.4° degrees (Vernier scale 1)

a.

b.

c.

d.

In this example the .7 mark on the lower Vernier

Scale will line up with the “42” on the upper scale.

Tighten the Handle (Part #10) and now the gauge

is set to 35.7° degrees. Remember to keep the

Indexing Pin Knob in the disengaged position.

Example 2:

Setting your gauge to 35.7° degrees (Vernier Scale 2)

10

50

5

Loosen the Handle (Part #10)

Pull out and lock the Indexing Pin Knob (Part #5). See Figure 16 and 17 for locked and

unlocked position of the Indexing Pin Knob.

Rotate the gauge to 35° degrees

Using the lower Vernier Scale on the

Indexing Block (Part #50), rotate the

gauge counter clockwise until the desired

1/10th degree aligns with the nearest

whole degree.

a.

b.

c.

d.

Example #2

INDEXING PIN KNOB

DISENGAGED

18

6

You will need a ¾" thick piece of stock, cut down to 2-1/2" high and anywhere from 22 - 25"

wide. (See Figure 21)

Mounting A Sacrificial Fence

a.

Measure and mark the first hole 4” from the right side of the board and 1-1/4" from the bottom as

shown in Figure 21.

b.

4"

20"

2-1/2"

4"

1-1/4"

JessEm provides the hardware to mount a sacrificial fence.

Making a Sacrificial Fence

Figure 21

c. Measure from the right side of the stock 20 inches to the opposite side. Mark the 20" spot with a

faint line.

d. Repeat step b. off the 20" mark.

e. Using a 5/16 drill bit, drill the center mark of both locations and use a countersink to allow the (2)

¼-20 x 1-1/8" Phillips Flat Head Screw (Part #58) to sit flush or below with the fence face.

f. Using the (2) ¼-20 square nuts (Part # 57) provided, attach the sacrificial fence (Part D) into the

front T-Slot on the fence extrusion. See Figure 22

** The Flip Stop on the Mite-R-Excel II™ was designed to adjust up to ¾". Be sure to

adjust the Flip Stop so that you can still use the stop with the sacrificial fence.

Figure 21

19

D 5 8

35

1817 19 201615

14

13

21 122 23 24 25

26

28

31

37 36

30

12

11

10

64

33

44

45

40

9

8

7

4

41

42

43

551 50 49

48

47

6

3

2

156 54 53

52

46

38

55

19

19

34

39

27

29

32

58

57

59

60

61

62

63

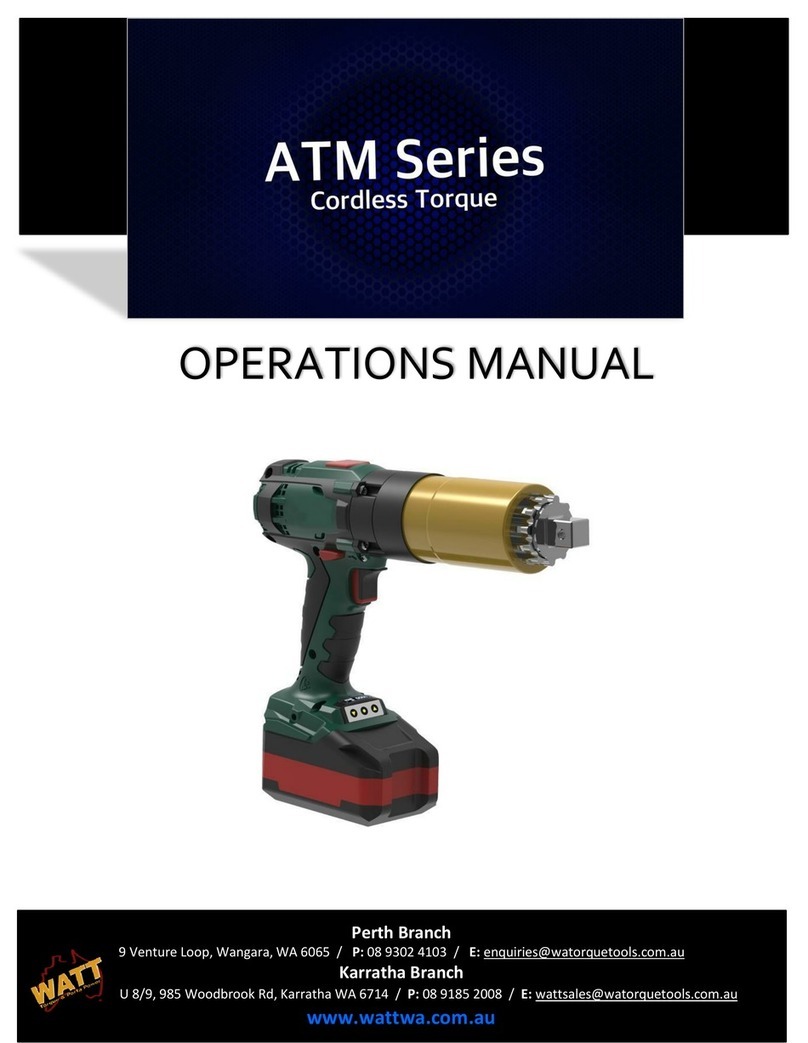

MITE-R-EXCEL II™ PARTS EXPLODED VIEW

This manual suits for next models

1

Table of contents

Other JessEm Tools manuals