JessEm Rout-R-Fence II User manual

Rout-R-Fence II

Model #04600

x

TO REDUCE THE RISK OF INJURY, USER MUST READ OPERATORS

MANUAL

THANK YOU FOR CHOOSING

Thank you for choosing this product from JessEm Tool Company. We appreciate

your support and hope that our product serves you well. This product is designed

to provide many years of reliable service provided it is used as intended and taken

care of.

X

This user manual will assist you in assembly and general operaon of this product.

It is not our intent to teach you about woodworking. It is assumed that you are an

experienced woodworker with the basic skills and experience necessary to use this

product safely. If aer reading the following instrucons you are unsure or

uncomfortable about safely using this product, we urge you to seek addional

informaon through widely available woodworking books or classes.

X

As part of our Connuous Product Improvement Policy, JessEm products are always

advancing in design and funcon. Therefore, there may be dierences between

what is shown in our catalogs, website or at retail display and what is sold at me

of purchase. We reserve the right to make posive changes to our products at our

discreon.

If you have any quesons about our products or service, please call

Find us on social media

youtube.com/JessEmToolCompany

facebook.com/JessEmTools

instagram.com/jessemtoolcompany

324 Desbrisay Avenue

Moncton, New Brunswick,

E1E 0G8, Canada

Toll Free: 800-436-6799

Local Phone: 506-777-2582

Fax: 705-327-0295

Website: www. JessEm.com

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

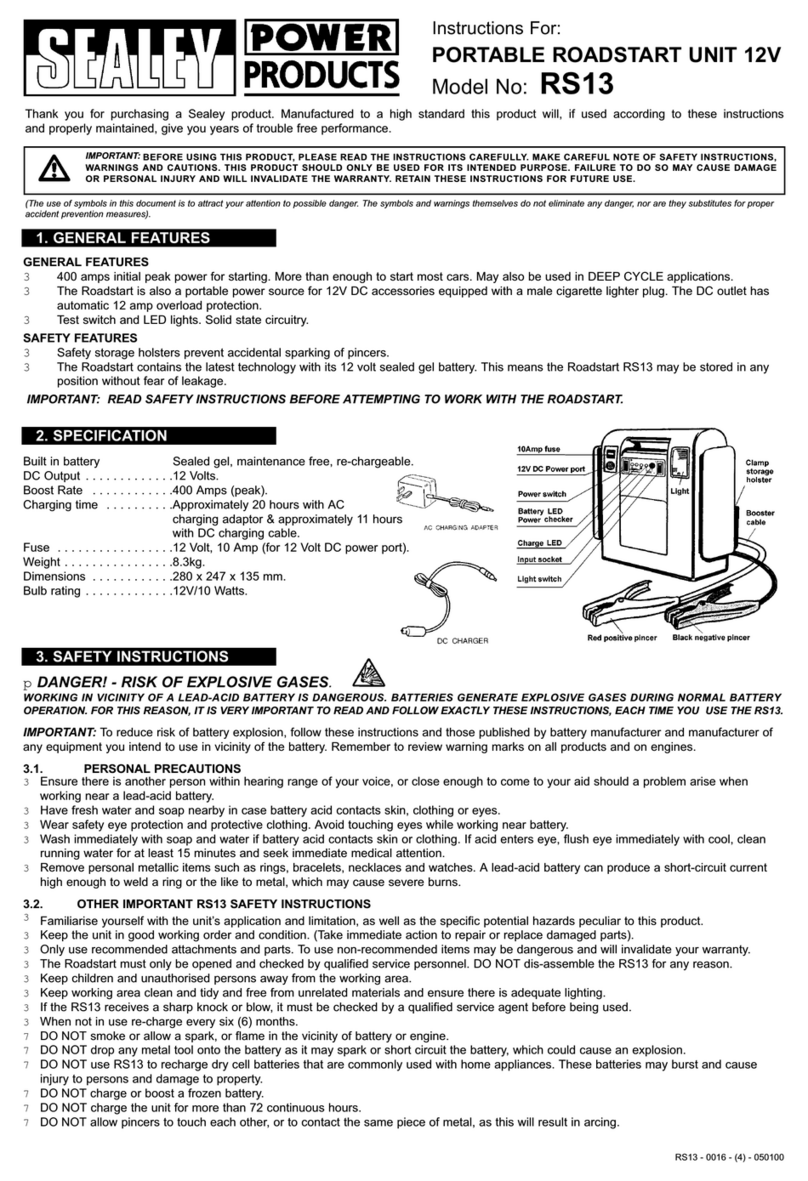

WHATS IN THE BOX

Item #

Product Code

Descripon

QTY.

1

F0573

M6 x 35mm Carriage Bolt

4

2

M0458-1-C

Fence Face

2

3

S0076-9-C

5/16” – 18 x 2” SHCS

2

4

S0053-50-C

Adjustment Nut

2

5

S0092-9-C

Clamp Adjustment Bracket

2

6

S0092-8-C

Fence Clamping Bracket

2

7

F0549

1/4”-20 x 1/2" SHCS

8

8

S0002-8-C

Clamp pad

2

9

S0092-10-C

Cam Lock Handle

2

10

F0347

1/4”-20 x 5/8” SHCS

2

11

S0054-16-C

Fence Cam

2

12

S0076-7-C

Pivot Bolt

2

13

F0348

1/4” Washer

4

14

E0326-1-C

Fence T-Track

1

15

F0531

10-32 x 3/8” Pan Head Screw

10

16

02104

Bit Guard Height Adjustment Knob

2

17

02104

Bit Guard

1

18

1

02104

1/4”-20 Square Nut

2

19

M0452

3 lobe knob

4

20

M0280

Fence Vacuum Port

1

21

F0122

1/4"-20 Lock Nut

2

22

F0581

1/4" Thin Jam Nut

6

23

S0075-8-C

1/4”-20 x 1 1/8” Set Screw

6

24

S0062-42-C

Fence Squaring Nut

6

25

S0092-7-C

Main Fence

1

26

S0092-11-C

Clamp Bracket Alignment Plate

2

27

F0558

10-32 Lock Nut

2

28

S0076-8-C

Vacuum Mounng Screw

2

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

WARRANTY

JESSEM TOOL LIMITED WARRANTY

All JessEm products are warranted to be free

from defects in material and workmanship.

JessEm will repair or replace any product which

upon inspecon proves to be defecve for a

period of (1) year from dated receipt and proof of

purchase. All warranty claims should be made

direct to JessEm Tool Company.

Contact JessEm for a warranty claim return

authorizaon and instrucons to proceed. The

consumer is responsible for shipping costs to

return product to JessEm Tool Company. We will

repair or replace the product at our discreon

and JessEm Tool will return shipment to you at no

charge.

WARRANTY LIMITATIONS

This warranty does not cover:

• Repairs or alteraons made or aempted by

anyone other than JessEm Tool Company or an

authorized JessEm service professional.

-Normal wear and tear

-Abuse, misuse or neglect.

-Improper care or maintenance.

-Connued use aer paral failure.

-Products that have been modied in any

way.

-Products used with improper accessories

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

IMPORTANT SAFETY PRECAUTIONS

•Always make sure the fence on your router table is

locked rmly into posion before each use

•Never overload the router beyond the expectaons of

the tool

•Be sure at least ¾ of the bit shank length is inserted

securely in to the router collet

•Never boom out the bit in the collet. Allow 1/16”

clearance between the shank and boom of the collet.

•Always rout in mulple passes when large amounts of

stock must be removed

•Use reduced rotaonal speeds for large diameter bits.

Below is approximate speeds for dierent bit sizes.

These values can change based on your specic

applicaon.

•Before operang any machinery or power tool, read

and understand all safety instrucons in the owners

manual that came with them

•If you do not have a manual, contact the manufacturer

and obtain one before using any power tool

•Always wear eye protecon compliant with ANSI

safety standards when operang power tools

•Always use proper guards and safety devices when

operang power tools and machinery.

•Carefully check router bits before each use. If

damaged or a defect is suspected do not use

•Do not wear loose clothing or jewelry that may catch

on tools or equipment

Unplug the tool or machinery when mounng or making any

adjustments

A) Personal Safety

i) Stay alert, watch what you are doing and use common sense

when operang a tool. Do not use a power tool while you are

red or under the inuence of drugs, alcohol or medicaon.

Serious personal injury could result if complete aenon is not

given while operang power tools.

ii) Always wear safety glasses. Everyday eyeglasses are not

safety glasses. Safety glasses have specially constructed frames,

lenses and side shields for beer protecon.

iii) Use safety equipment. Use a face or dust mask when the

cung operaon is dusty. Safety equipment such as dust

masks, hard hats, non-skid safety shoes and hearing protecon

reduces personal injuries when used for appropriate condions.

If devices and tools allow for dust extracon and collecon,

ensure these are connected and properly used.

iv) Do not overreach. Keep proper foong and balance at all

mes. This allows for beer control of the power tool in

unexpected situaons.

v) Never stand on the machine. Serious injury could occur if the

tool ps or if the cung tool is unintenonally contacted.

vi) Secure workpieces. Use clamps or vises to hold work when

praccal. This is safer than using your hands and frees both

hands to operate the tools.

vii) Dress appropriately. Do not wear loose clothing or jewelry.

Ensure you keep clothing, hair and gloves away from moving

parts. Loose clothing, jewelry or long hair can be caught in

moving parts. Roll up long sleeves to the elbow. Wear

protecve hair covering to contain long hair.

viii) Avoid accidental starng. Ensure the switch is in the o

posion before you plug it in. Carrying a power tool in you

hands with your nger on the switch or plugging in a power

tool that has the switch on is inving accidents.

ix) Remove any adjusng key or wrench before turning the

power tool on. A wrench or a key le aached to a rotang part

of the power tool could result in personal injury.

B) Work Area Safety

i) Make your workshop child proof. Use padlocks, master

switches, or remove starter keys.

ii) Keep work area clean and well lit. Cluer and/or dark areas

encourage accidents.

ii) Keep children and bystanders away while operang a power

tool. Complete aenon is required when operang a power

tool.

C) Electrical Safety

i) Ground electrical tools. If the tool is equipped with a three-

prong plug, it must only be plugged into a grounded three-hole

electrical outlet. If required, a qualied electrician can install

one. Never remove the third prong or modify the plug that is

provided in any way.

ii) Never expose a power tool to rain or wet condions. You will

increase the risk of electric shock if water enters the power

tool. iii) Using power tools in damp or wet locaons or

condions is extremely dangerous.

iv) Do not operate any power tool in an explosive atmosphere,

in the presence of ammable liquids, gases or dust. Power tools

can create sparks which may ignite the fumes or dust.

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

WARNING: To reduce the risk of injury, always

unplug your tool before performing any

maintenance. Never disassemble the tool or try to

do any rewiring on the tool's electrical system.

WARNING: This product can expose you to

chemicals including lead and/or chromium,

known to the State of California to cause cancer and

birth defects or other reproducve harm.

WARNING: Read and understand all

instrucons before using. Failure to follow all

instrucons listed above or to us the fence in a safe

manor may result in serious personal injury.

WARNING: Drilling, sawing, sanding or

machining wood products can expose you to

wood dust, a substance known to the state of

California to cause cancer. Avoid inhaling wood dust

or use a dust mask or other safeguards for personal

protecon.

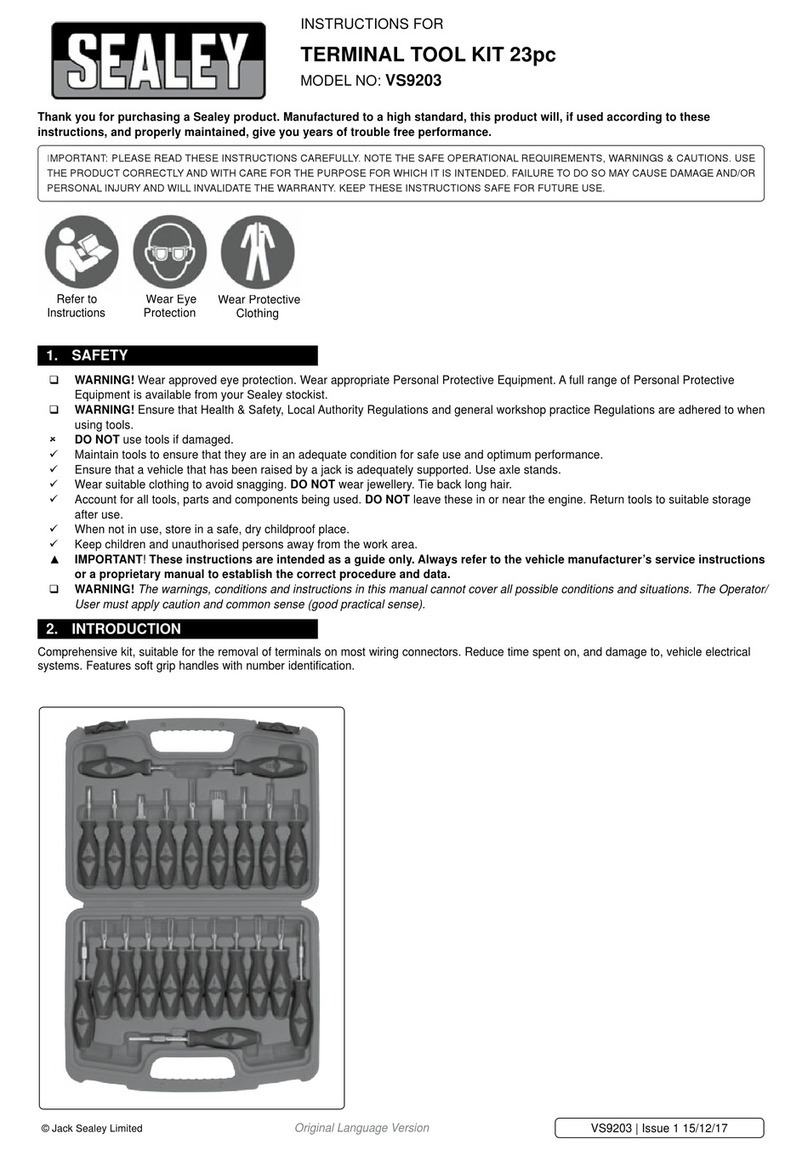

Adjusng for Dierent Table Thickness

JessEm’s Rout-R-Fence II is designed to accommodate

table top thicknesses between 3/4” and 1-1/8”. To set the

top thickness, or to change between them, the following

instrucons will have to be followed:

1- Loosen the two screws holding the clamp

adjustment bracket in place, as seen in gure 1.

Repeat for the other side.

2- With both cam handles in the unlocked posion

(see gure 2), loosen or ghten the screws below

the clamp adjustment brackets unl there is a

very small gap between the clamp adjustment

bracket and the top (just enough to allow you to

move the fence when unlocked).

3- Reghten the screws loosened in step 1.

4- Test the cam locks to ensure they now work on

your top. The cam locks should move smoothly

and hold the fence rmly in place, but should not

be so ght as to be dicult to lock down.

If your fence is sll too loose, repeat the rst

three steps to raise the clamping bracket. If it is

too ght, lower the clamping bracket sightly.

Figure 1 – Screws Menoned in step 1

Figure 2 – Cam handle posion and screw menoned

in step 2

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

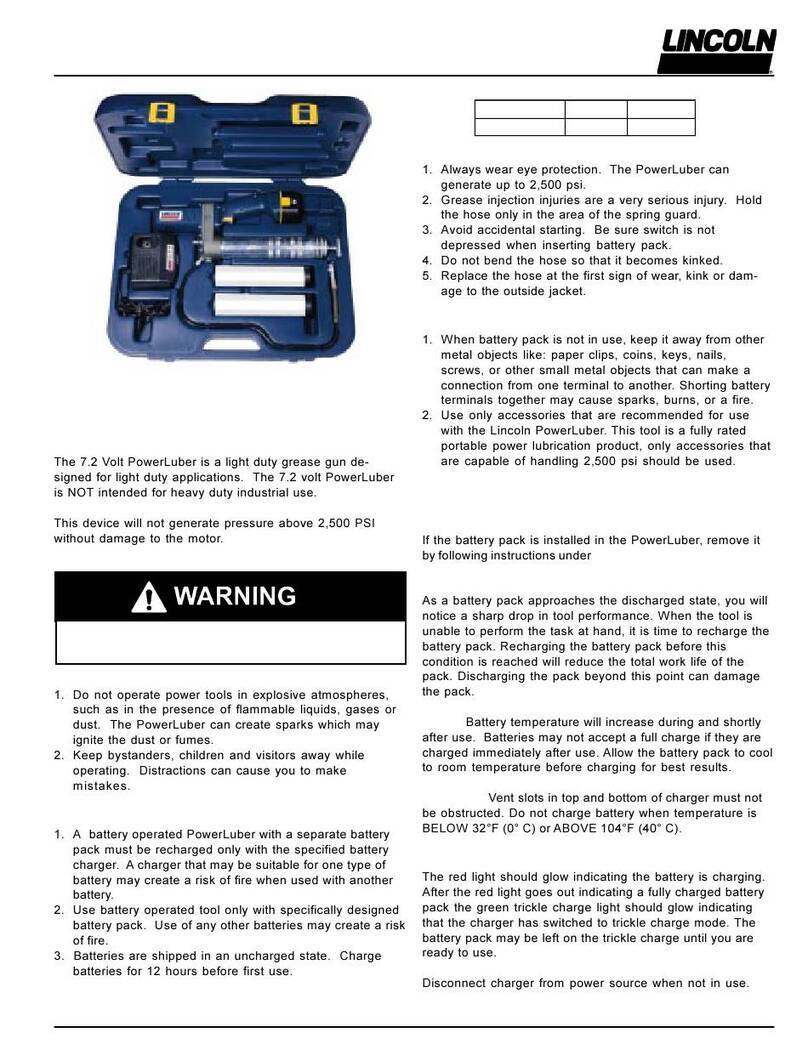

Adjusng the Fence Faces and Bit Guard

To opmize work piece support and to maximize safety,

the fence faces will have to be adjusted before using the

fence.

1. With your fence located where you intend to use

it, loosen the four knobs shown in gure 3.

2. Slide the fence faces unl they create a small gap

around your bit and reghten the four knobs.

3. To ensure safe operaon and to prevent damage

to your fence faces, ensure the fence faces clear

the diameter of the router bit before starng the

motor.

Once the fence faces are set, it is important to set the bit

guard height. This is done by loosening the bit guard

height adjustment knobs and sliding it up or down before

reghtening.

Figure 3 – Knobs to adjust fence faces

Figure 4 – Bit guard adjustment knobs

Squaring Fence Face to Table

This fence will arrive pre-squared from the factory;

however, several factors can cause it to go out of square.

It is relavely easy to adjust the fence back to square if

needed following the steps below:

1. Loosen all six of the ¼”-20 jam nuts

2. Using a square, determine where the fence has to

be adjusted and use the ¼”-20 set screws to

adjust it one way or the other

3. Holding the set screw in place with a hex key,

reghten the jam nut to lock the set screw

posion in place.

4. Repeat along the length of the fence unl all six

set screws are locked in posion and the fence is

square to the table top.

Figure 5 – Set screw locaons for squaring fence

Figure 6 – Checking Fence Faces

JessEm.com FOR TECHNICAL SUPPORT CALL 1-800-436-6799

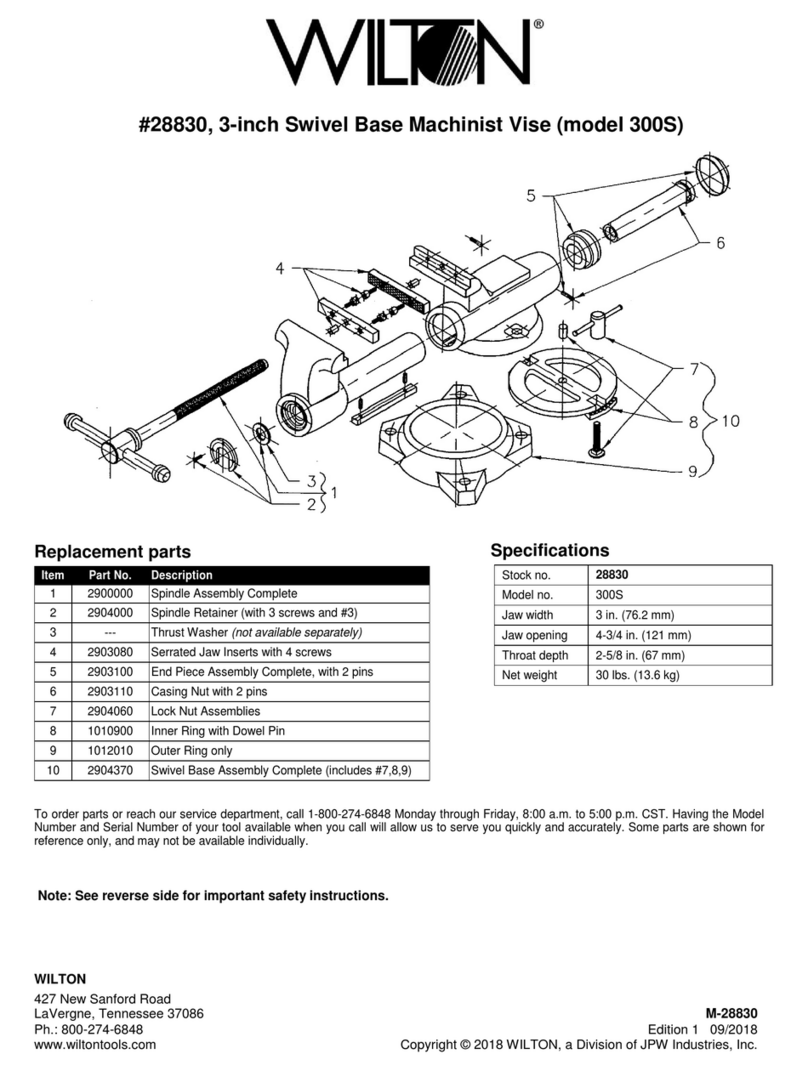

Replacing Fence Faces

Over me, your fence faces may start to show

signs of wear or get damaged. At this me, the

fence faces should be replaced to ensure your

fence keeps performing the same as the day it

came out of the box.

To replace your fence faces, remove the four

knobs on the back of the fence, as shown in

gure 3. Using a hammer, lightly tap the end of

each fastener in the fence faces to remove the

carriage bolts.

Insert the carriage bolts into the new fence faces

and aach them to the fence with the four knobs.

Adjust as explained previously.

Following the drawing below, you can make your

own replacement fence faces. The original faces

that came with the fence were made out of

laminated MDF, however many materials would

work. Ideally the material will be wear resistant

and unlikely to warp over me. Torreed

hardwoods or laminated products would make

excellent choices.

This manual suits for next models

1

Table of contents

Other JessEm Tools manuals