3

GB‐ENGLISH

OperatingInstructions

DearCustomer,

ManythanksfortheconfidenceyouhaveshowninuswiththepurchaseofyournewJET‐machine.Thismanualhasbeen

preparedfortheownerandoperatorsofaJET JWDS‐2244OSC‐M oscillating drum sander to promote safety during

installation, operation and maintenance procedures. Please read and understand the information contained in these

operatinginstructionsandtheaccompanyingdocuments.Toobtainmaximumlifeandefficiencyfromyourmachine,and

tousethemachinesafely,readthismanualthoroughlyandfollowinstructionscarefully.

TableofContents

Section Page

1.Declarationofconformity.............................................................................................................................................4

2.Warranty.......................................................................................................................................................................4

3.Safety...........................................................................................................................................................................4

3.1Authorizeduse..........................................................................................................................................................4

3.2Generalsafetynotes.................................................................................................................................................4

3.3Remaininghazards....................................................................................................................................................5

3.4Labelsandpositions..................................................................................................................................................5

4.0Specifications.............................................................................................................................................................6

5.0FeaturesandTerminology.........................................................................................................................................7

6.0Setupandassembly...................................................................................................................................................8

6.1Shippingcontents.....................................................................................................................................................8

6.2Toolsrequiredforassembly.....................................................................................................................................8

6.3Assemblingstand......................................................................................................................................................9

6.4Mountingsandertostand........................................................................................................................................9

6.5Handleandhosehanger...........................................................................................................................................9

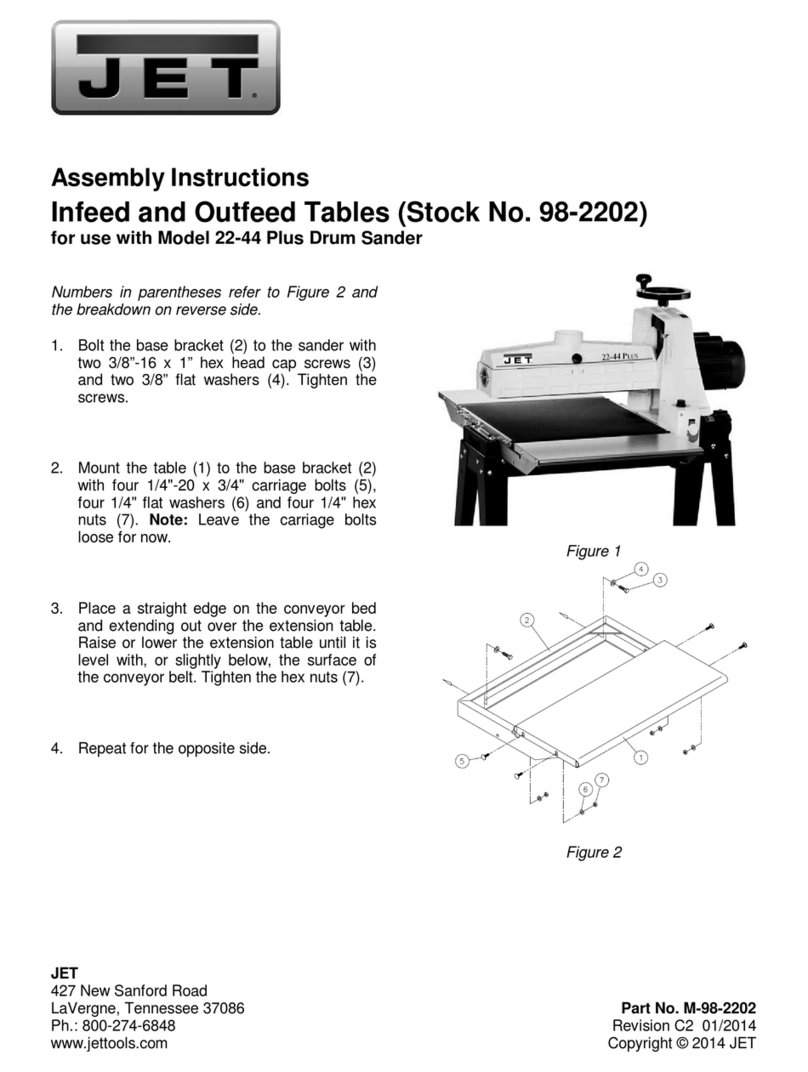

6.6Infeedandoutfeedtables(optionalaccessory).......................................................................................................9

6.7Dustcollection........................................................................................................................................................10

6.8Installingabrasives..................................................................................................................................................10

7.0Electricalconnections..............................................................................................................................................11

8.0Adjustments.............................................................................................................................................................11

8.1DrumHeightControl...............................................................................................................................................11

8.2Depthscale.............................................................................................................................................................11

8.3Infeed/Outfeedtableadjustment(Optional).........................................................................................................11

8.4Conveyorbelttension/tracking..............................................................................................................................11

8.5Inspectingdrumalignment.....................................................................................................................................12

8.6Tensionrolleradjustment.......................................................................................................................................13

9.0Operations...............................................................................................................................................................13

9.1Drumandconveyormotoroperation.....................................................................................................................14

9.2Oscillatingmode.....................................................................................................................................................14

9.3BasicOperatingProcedure.....................................................................................................................................14

9.4Settingdepthofcut................................................................................................................................................14

9.5Establishingdrumheight........................................................................................................................................14

9.6SelectingSandSmart™feedrates...........................................................................................................................14

9.7Maximumperformancetips...................................................................................................................................15

10.0User‐maintenance.................................................................................................................................................16

10.1Cleaningandlubrication.......................................................................................................................................16

10.2Drummaintenance...............................................................................................................................................17

10.3Conveyorbeltreplacement..................................................................................................................................17

10.4Commutatorbrushinspection..............................................................................................................................17

10.5Additionalservicing..............................................................................................................................................18

11.0Trackerkit..............................................................................................................................................................18

12.0Abrasives................................................................................................................................................................19

12.1Selectingdrumabrasives......................................................................................................................................19

12.2Cleaningabrasivestrips........................................................................................................................................19

12.3Increasingabrasivelife.........................................................................................................................................19

12.4Abrasiveselectionguide.......................................................................................................................................19

13.0Troubleshooting.....................................................................................................................................................20

14.0Optionalaccessories..............................................................................................................................................21