5

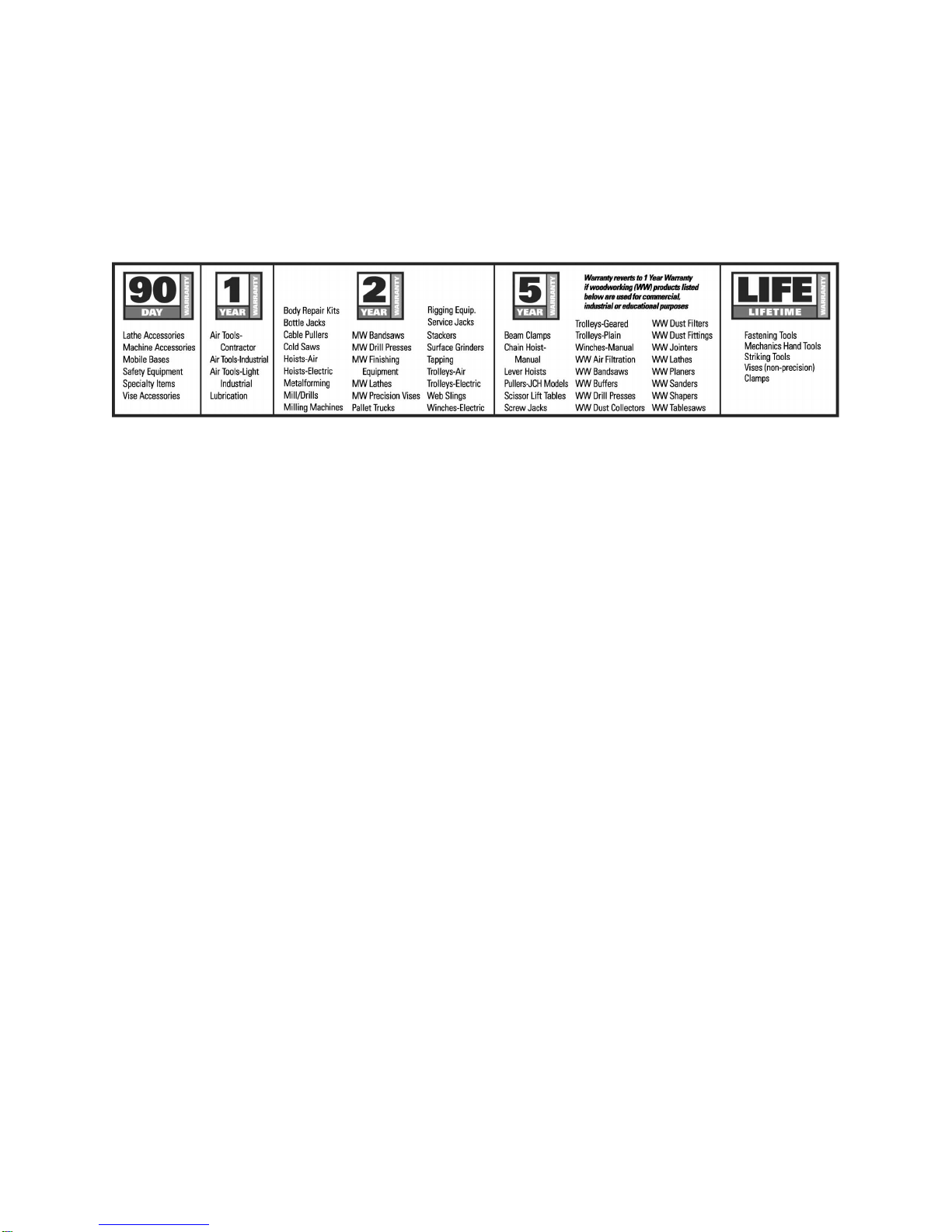

Specifications JTAS-10XL

Stock Number............................................................................................................708661 (3 HP, 1 Ph)

......................................................................................................................708666 (5 HP, 1 Ph

.....................................................................................................................708664 (5 HP, 3 Ph)

Blade Diameter.....................................................................................................................................10”

Arbor Diameter....................................................................................................................................5/8”

Maximum Depth of Cut...........................................................................................................................3”

Maximum Thickness at 45°Cut........................................................................................................2-1/8”

Table in Front of Saw Blade at Maximum Cut.......................................................................................12”

Maximum Width of Dado.................................................................................................................13/16”

Maximum Diameter of Dado...................................................................................................................8”

Dust Port Diameter.................................................................................................................................4”

Table Height.........................................................................................................................................34”

Table Size (with extension)....................................................................................................27”D x 40”W

Table Size (without extension)..............................................................................................27” D x 20”W

Arbor Speed ............................................................................................................................. 4200 RPM

Motor.........................................................................................................................................................

JTAS-10XL-1 ...............................................................................................3HP, 1Ph, 230V only

JTAS-10XL-5/1............................................................................................5 HP, 1Ph, 230V only

JTAS-10XL-3 .....................................................................5HP, 3Ph, 230/460V, prewired 230V*

Net Weight (approx.) .....................................................................................................................374 lbs.

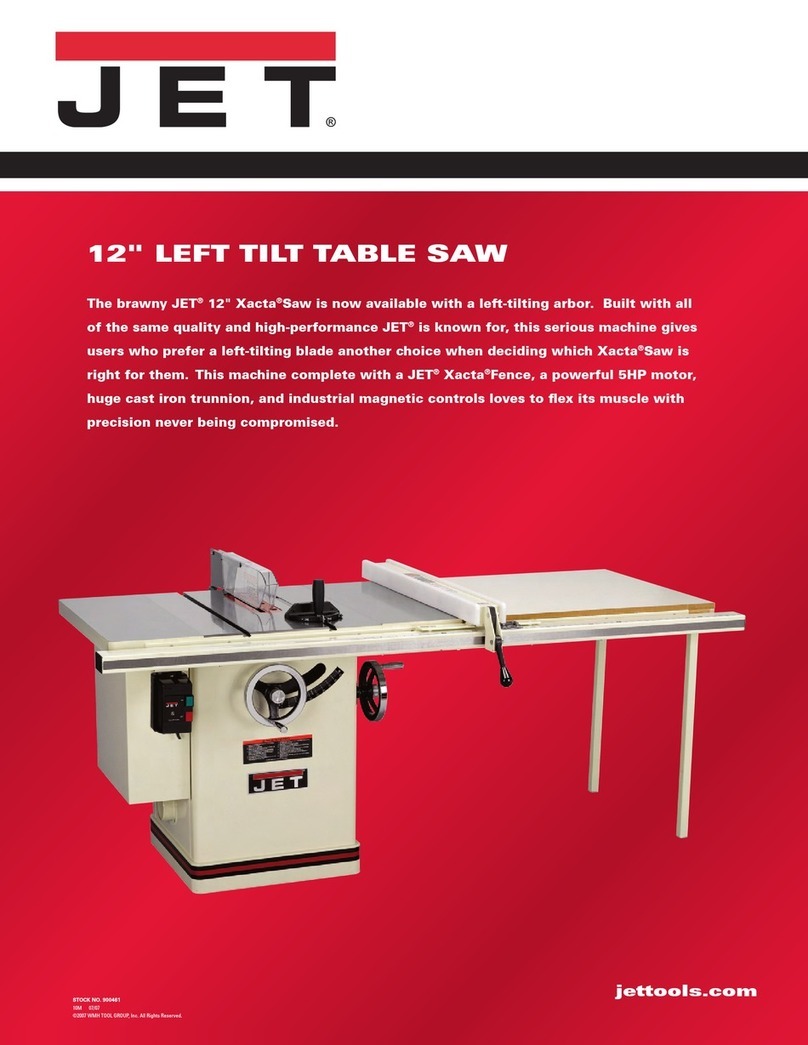

Specifications JTAS-12XL

Stock Number............................................................................................................708537 (5 HP, 1 Ph)

.....................................................................................................................708542 (5 HP, 3 Ph)

Blade Diameter.....................................................................................................................................12”

Arbor Diameter.......................................................................................................................................1”

Maximum Depth of Cut...........................................................................................................................4”

Maximum Thickness at 45°Cut........................................................................................................2-7/8”

Table in Front of Saw Blade at Maximum Cut.......................................................................................12”

Maximum Width of Dado.................................................................................................................13/16”

Maximum Diameter of Dado...................................................................................................................8”

Dust Port Diameter.................................................................................................................................4”

Table Height.........................................................................................................................................34”

Table Size (with extension)....................................................................................................29”D x 44”W

Table Size (without extension)..............................................................................................29” D x 22”W

Arbor Speed ............................................................................................................................. 4200 RPM

Motor.........................................................................................................................................................

JTAS-12XL-5/1.............................................................................................5HP, 1Ph, 230V only

JTAS-12XL-3 ....................................................................5 HP, 3Ph, 230/460V, prewired 230V*

Net Weight (approx.) .....................................................................................................................396 lbs.

*Conversion to 460V requires the purchase and installation of switch #JTAS10-23B.

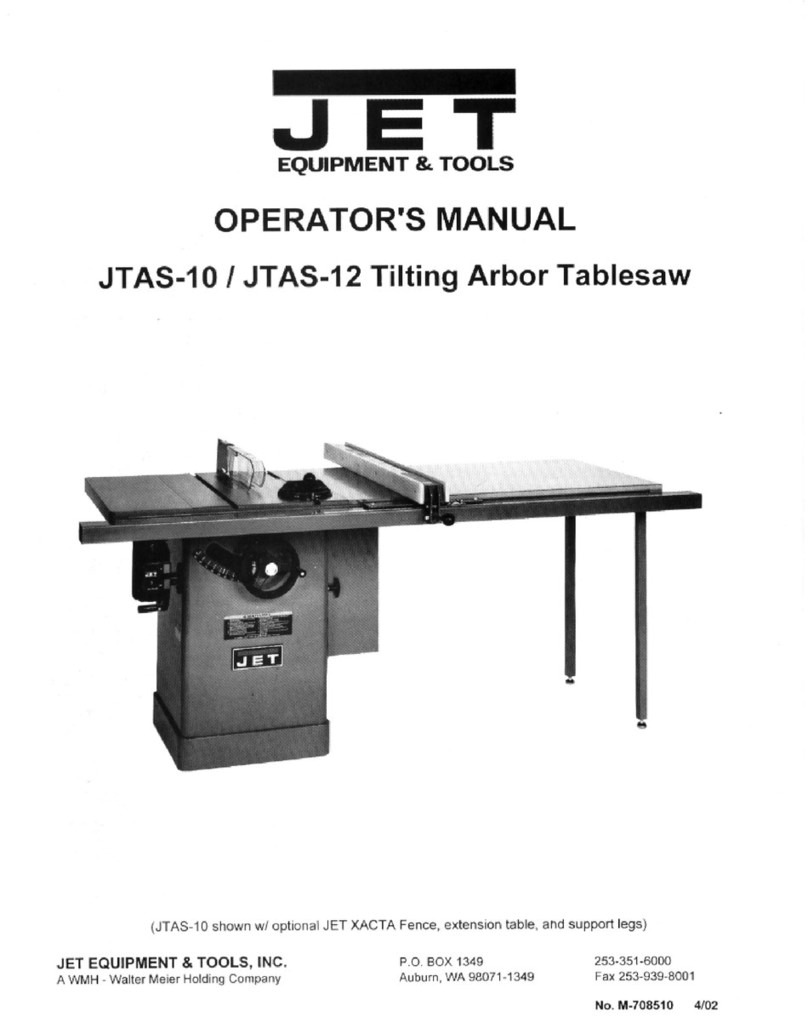

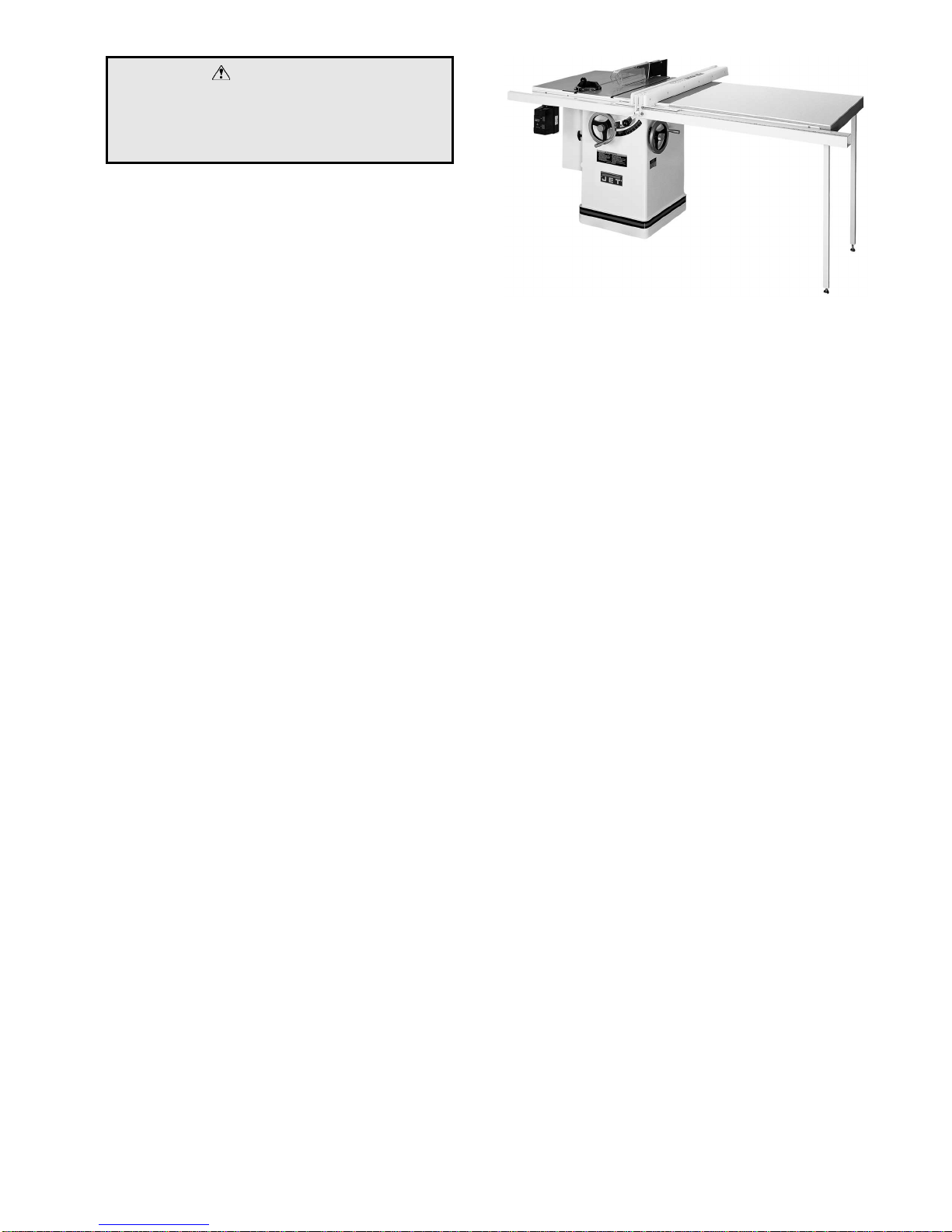

The JTAS-10XL and JTAS-12XL Tilting Arbor Tablesaws are designed to allow the use of several

precision fences by various manufacturers. Please follow the directions for mounting the fence and rails

that come with the fence system you have purchased.

The specifications in this manual are given as general information and are not binding. JET Equipment

and Tools reserves the right to effect, at any time and without prior notice, changes or alterations to

parts, fittings, and accessory equipment deemed necessary for any reason whatsoever.