&, WARNING

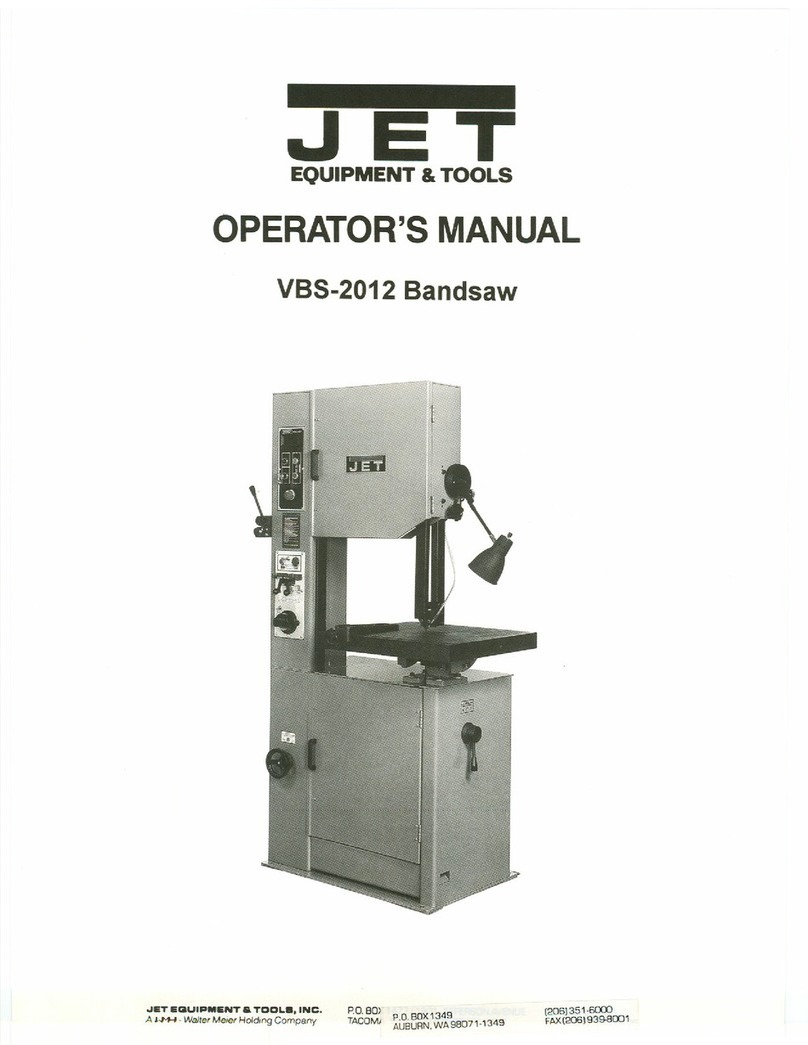

.Read and understand the entire .Replacewarning labels if they become

instruction manual before operating obscuredor removed.

machine. .Make certain the motor switch is in the OFF

.This manual is intended to familiarize positionbeforeconnectingthe machineto

you with the technical aspects of this the power supply.

bandsaw. It is not, norwas it intended

to be, a training manual. .Giveyourworkundividedaftention.

Lookingaround,carryingona

.This machine is designed and intended conversation,and"horse-play" are careless

for use by properly trained and acts that can result in serious injury.

experienced personnel only. If you are

not familiar with the proper safe use of a.Keepvisitors a safe distance from the work

bandsaw, do not use this machine until area.

proper training and knowledge has been

obtained. .Use recommendedaccessories; improper

accessories may be hazardous.

.Always wear approved safety glasses/face

shields while using this machine. .Makea habitof checking to see that keys

andadjustingwrenchesareremoved

.Make certain the machine is properly beforeturningon the machine.

grounded. .Never attemptany operation or adjustment

.Before operating the machine,removetie, if the procedure is not understood.

rings,watches, otherjewelry, and roll up

sleeves above the elbows. Removeall .Keepfingers away from the bladewhile in

loose clothing and confine long hair. Do operation.

not wear gloves. .Keep beltguard in place and in working

.Keepthe floor around the machineclean order.

and free of scrap material, oil and grease. .Never force the cutting action.

.Keep machineguards in place at all times

whenthemachineisinuse. Ifremovedfor .Do notattempt to adjust or remove tools

maintenance purposes, use extreme during operation.

caution and replacethe guards

immediately. .Always keep the blade sharp.

.Do not over reach. Maintaina balanced .Always use identicalreplacement parts

stance at all times so thatyou do not fall or when servicing.

lean against bladesor other moving parts. .Readand understandall warnings posted

.Make all machine adjustmentsor on the machine.

maintenancewith the machine unplugged

from the power source. .Failureto complywith all of these warnings

may cause serious injury.

.Use the right tool. Don't force a tool or

attachment to do ajob which it was not

designed for.