EN

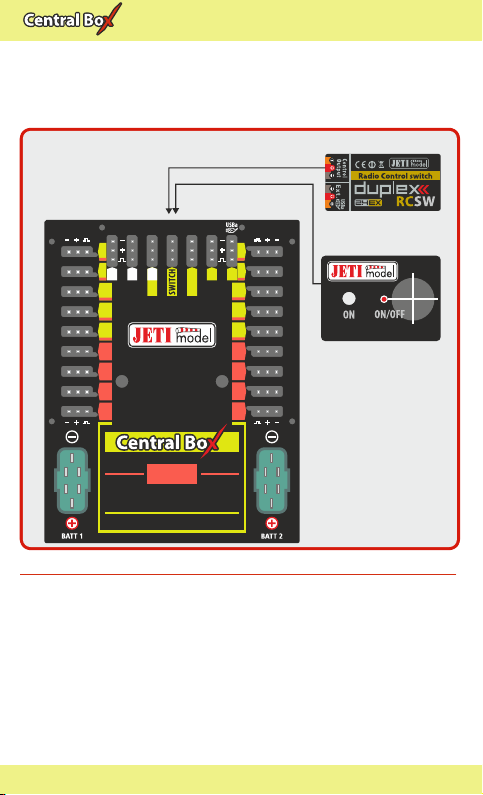

3.1 Power supply of Central Box 310/320

The Central Box 310/320 can only be powered from batteries

connected to BATT1 or BATT2. When selecting the power supply it

is necessary to follow the power requirements and the number of

the servos you use. Batteries for power supply must be sufficiently

large to prevent a decrease of the output voltage for servos when

loaded (voltage depression) and to allow the overload protection

function properly (Central Box 320).

Together, both power supply methods must be able to supply a 20A

continuous and 120A peak current. To take full advantage of

internal BEC we recommend to power the Central Box from three

Lixx cells.

The power batteries are connected to the Central Box using MPX

connectors. The Central Box allows up to two batteries to be

connected. If the voltage of the batteries is the same, the power can

be used from both batteries at the same time. This rule applies to

the standard power supply. This means that the power battery

voltage should be greater than the required BEC voltage setting.

When the voltage of the batteries is different, the power is not

shared and each pack is isolated from the other. This allows you to

9 EN

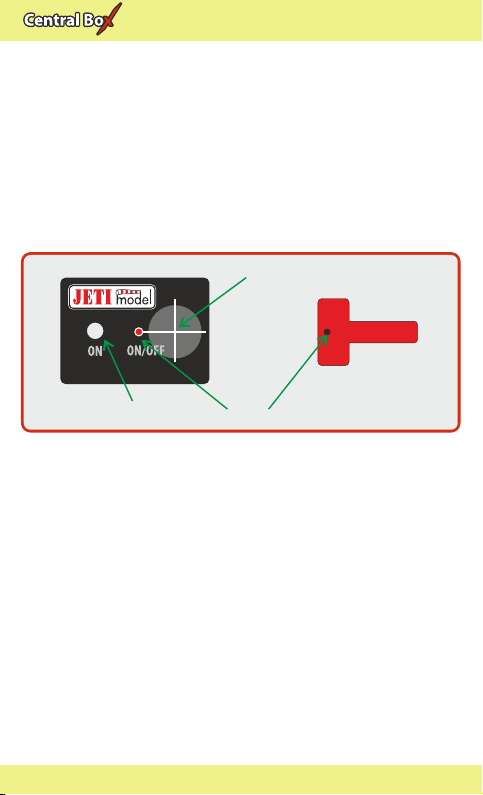

reasons, always switch the system off via magnetic switch before

disconnecting the power batteries.

When turning “ON”, connect the batteries first and then turn the

system on via magnetic switch. Keep the same rule when switching

off. First switch the system “OFF” via magnetic switch and then

disconnect the batteries.

3 Connection

The Central Box is connected to the power supply, receiver, servos,

controller/controllers and eventually sensors. Please follow the

subsequent general guidelines about proper connection of the

Central Box and these other components.