Magnetrol PULSAR RADAR R86 Instructions for use

Other Magnetrol Transmitter manuals

Magnetrol

Magnetrol E3A Modulevel User manual

Magnetrol

Magnetrol R82 User manual

Magnetrol

Magnetrol 82 CE Series User manual

Magnetrol

Magnetrol Orion Jupiter Enchanced 2 Series User manual

Magnetrol

Magnetrol Eclipse 706 User manual

Magnetrol

Magnetrol eclipse 705 User manual

Magnetrol

Magnetrol Pulsar R86 Installation and operating instructions

Magnetrol

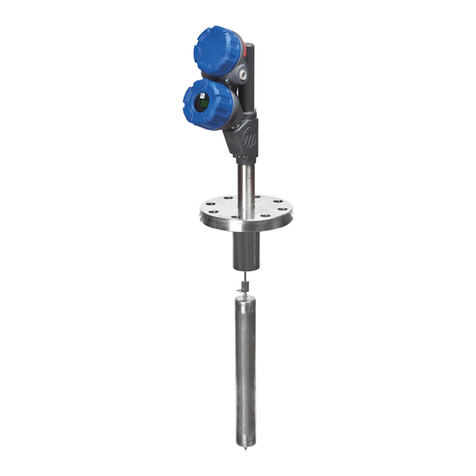

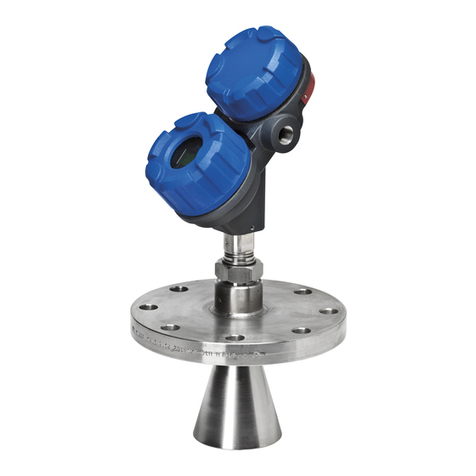

Magnetrol STI KOTRON 805 User manual

Magnetrol

Magnetrol Kotron II Series 801 User manual

Magnetrol

Magnetrol Kotron 805 series User manual

Magnetrol

Magnetrol Echotel 300 User manual

Magnetrol

Magnetrol Echotel 335 Assembly instructions

Magnetrol

Magnetrol E3A Modulevel User manual

Magnetrol

Magnetrol STI Echotel 338 User manual

Magnetrol

Magnetrol Eclipse 706-512 User manual

Magnetrol

Magnetrol Pulsar R96 User manual

Magnetrol

Magnetrol Kotron RF 2-Wire Series User manual

Magnetrol

Magnetrol KOTRON SMART RF 805 User manual

Magnetrol

Magnetrol ES Modulevel User manual

Magnetrol

Magnetrol Eclipse 706GWR User manual

Popular Transmitter manuals by other brands

Dejero

Dejero EnGo 3x manual

Rosemount

Rosemount 4600 Reference manual

Speaka Professional

Speaka Professional 2342740 operating instructions

trubomat

trubomat GAB 1000 instruction manual

Teledyne Analytical Instruments

Teledyne Analytical Instruments LXT-380 instructions

Rondish

Rondish UT-11 quick start guide