Jetion solar JTxxxSFb series User manual

Installation Manual

Visionary green energy

Installation Manual

Please read this manual carefully before installation,and keep it for future reference.

Introduction

• JetionSolarPhotovoltaicmodulesconsistofcrystalline

siliconsolarcells,hightransmissionandlowirontoughened

glass,anti-agingEVAandhighameresistantbacksheet,and

anodizedaluminumalloyframe.

• JetionmodulesarequaliedfornationalstandardIEC

61215.2andIEC61730,whichhavepassedexamination

oftheauthorisedtytestcenter.Jetionmodulescanbeused

inroofsolarsystems,PVstations,communicationstations,

petrol,ocean,meteorological,trafcandPVbuildingsetc.

• Wearecommittedtoprovidingtechnicalandinstallation

supportforourcustomersworldwide.

• ThisInstallationManualisapplicabletotheinstallation

ofthefollowingJetionmodules:

JT***SFa/bJT***SAa/bJT***SBa/b

JT***SFcJT***SEcJT***SDcJT***SCcJT***SAc

JT***PFeJT***PEeJT***PDeJT***PCeJT***PAe

JT***SAa/b(Black)JT***SDc(Black)JT***SCc(Black)

Notes: 1.JT***SFa/bisusedhereasanexample.

2.“***”istheratedpoweroftherelatedJetionmodule.

• Thismanualcontainsimportantinformationregardingthein

stallation,safehandlingandmaintenanceofPVmodules

madebyJetion.

• Allinstructionsshouldbereadandunderstoodpriorto

installingthemodules.Theinstallershouldconformto

allrequirementsinthismanual.Theappropriatelocalstan-

dardsandregulations,constructionrulesandsafetyinst-

ructionsshouldalsobefollowedduringinstallation.Allwork

onaPVsystemmustbecarriedoutbyappropriatelyqualed

engineers,whomustbefamiliarwiththemechanicaland

electricalrequirementsforsuchaPVsystem.

Disclaimer of liability

• Theinstallation,handlinganduseofJetionmodulesarebey-

ondcompanycontrol.Therefore,Jetionassumesnores-

ponsibilityforloss,damage,injuryorexpenseresultingfrom

improperinstallation,handling,useormaintenance.

• Jetionreservestherighttoupdatetheproduct,specications

orthisInstallationManualwithoutpriornotice.

1) Certificates requests

1.1) IEC 61730

JetionmodulesaredesignedtofulllthecriteriaofApplica-

tionclassArequirementsaccordingtoIEC61730-1.

ModulesratedforuseinapplicationclassAmaybeusedin

systemsoperatingatgreaterthan50VDCor240W,where

generalcontactaccessisanticipated.Modulesqualiedfor

safetythroughIEC61730-1andIEC61730-2withinapplica-

tionclassAareconsideredtomeettherequirementsfor

safetyclass.

1.2) UL

• Theelectricalcharacteristicsarewithin+/-10%oftherated

valuesofIsc,VocandPmpundertestconditions(irradiance

of100mW/cm2,AM1.5spectrum,andcelltemperatureof

25°C).

• Thestand-offheightshouldbeatleast100mm(3.94in),and

therecommendedstand-offheightis115mm(4.53in).If

othermountingmeansareemployed,thismayaffectthe

ListingForFireClassRatings.

• ThemoduleshavebeenevaluatedbyULforamaximum

positiveornegativedesignloadingof30lb/ft²(146.5kg/m²).

• WiringmethodsshouldbeinaccordancewiththeNEC.

• ForinstallationinCanada,theinstallationshallalsobein

accordancewithCSAC22.1,safetyStandardsforElectrical

Installations,CanadianElectricalCode,Part1.

2) Installation requirements

2.1) Installation environment requirements

•Avoidshading:

Evenifthesmallestlocalshelter/shadow(suchasdustdepo-

sition)willalsodecreasetheoutputpower.

•Adequateventilation:

Hightemperatureofthemodulemayreducetheperfor-

manceandoutputpowerofthemodule.Goodventilation

caneffectivelyavoidtheoverheatingofPVmodules.

• Others:

- Donotinstallthemodulenearinammablegas(suchas

gasstation,gastanketc.)

- Donotinstallthemodulenearnakedameorammable

materials.

- Donotinstallthemoduleinalocationwithpotentialforextre-

mesandanddustdamage.

- Donotinstallthemoduleinalocationwithextremeair

pollution,suchaschemicalvapors,acidrain,and/orsoot.

- Donotexposethemoduletoalasersource.

- Donotinstallthemoduleinalocationwithextremehailand/

orsnow.

- Donotinstallthemoduleinalocationwhereitcouldbe

immersedinwaterorcontinuallyexposedtowaterfroma

sprinklerorfountain.

- Donotinstallthemoduleinamarineenvironmentand/or

areawheresaltywindhitdirectly.Itisrecommendedthatthe

modulebeinstalledatleast500mfromthesea.

- Environmenttemperature-20°Cto40°C.

- Operatingtemperature-40°Cto85°C.

2.2) Orientation and tilt for modules installation

• Solarmodulesproducethemaxpowerwhentheyare

pointeddirectlyatthesun.Inordertoachievemaximum

annualyield,optimumorientationandtiltofPVmodulesis

necessary.Themodules,whichconnectedinasystem,must

beinsameorientationandtilt,otherwise,itwilllosethepow-

erbecauseofthedifferencesofsunshineradiation.

• Themodulesmustbefacingthenorthinthesouthhemis-

phere,andfacingsouthinnorthhemisphere.

• Foroff-gridinstallationswheretheJetionmodulesareat-

tachedtoapermanentlystructure,theJetionmodules

shouldbetitledforoptimumwinterperformance.Asarule,

ifthesystempowerproductionisadequateinwinter,itwillbe

satisfactoryduringtherestoftheyear.Themoduletiteangle

ismeasuredbetweenthesolarmodulesandtheground.

Fig.1: ModuleTiltAngle

RECOMMENDEDTILTANGLESFORAFIXEDSYSTEM

SITELATITUDEINDEGREES FIXEDTILTANGLE

0°to15° 15°

15°to25° SAMEASLATITUDE

25°to30° LATITUDE+5°

30°to35° LATITUDE+10°

35°to40° LATITUDE+15°

40°+ LATITUDE+20°

Table1: ModuleTiltAngle

2.3) Materials requirements

• Supportstructure

Thesupportstructureofthemoduleismadeofabrason

proof,corrosionresistantandUVresistantmaterialswhich

correspondstotheappropriatestructuralrequirements.The

mountingstructureandthemoduleattachmentsmustbe

designedinaccordancewiththelocalwindandsnowloads.

• Bypassdiode

Partialshadingofanindividualmodulecancauseareverse

voltageacrosstheshadedmodule.Currentisthenforced

gothroughtheshadedareabytheothermodules.Whena

bypassdiodeiswiredinparallelwiththeseriesstring,the

forcedcurrentwillowthroughthediodeandbypassthe

shadedmodule,therebyminimizingmoduleheatingandarray

current losses.

• Supportstructure

Inasystemthatusesabattery,blockingdiodesaretypically

placedbetweenthebatteryandthemoduleoutputtoprevent

batterydischargeatnightandrainyweather.Diodesthatare

usedasblockingdiodesmusthavea:

a)RatedAverageForwardCurrent[[IF(AV)][abovethemaximum

systemcurrentathehighestmoduleoperatingtemperature.

b)RatedRepetitivePeakReverseVoltage[(VRRM)[abovethe

maximumsystemvoltage[(Vmax)[atthelowestmodule

operatingtemperature[(IEC:[Vmax=1000V;[UL:[Vmax=600V).

• Battery

Whensolarmodulesareusedtochargebatteries,thebattery

mustbeinstalledinamannerwhichwillprotecttheperfor-

manceofthesystemandthesafetyofitsusers.Thebattery

shouldbeawayfromthemainowofpeopleandanimal

trafc.Selectabatterysitethatisprotectedfromsunlight,

rain,snow,debris,andiswellventilated.Mostbatteries

generatehydrogengaswhencharging,whichisexplosive.

Donotlightmatchesorcreatesparksnearthebatterybank.

Whenabatteryisinstalledoutdoors,itshouldbeplacedin

aninsulatedandventilatedbatterycasespecicallydesigned

forthepurpose.

• Cableandothercomponents

a)Ensurethatallcomponentsmeettherequirementsofthe

system´smaximumvoltage,current,moistureandtempera-

turewhentheyareexposedtosunlight.Werecommended

thatallwiringandelectricalconnectionscomplywiththe

appropriatenationalelectricalcode.

b)Undernormalcondition,aphotovoltaicmoduleislikelyto

experienceconditionsthatproducemorecurrentand/or

voltagethanreportedatstandardtestconditions.

Accordingly,thevaluesofIscandVocmarkedonthismodule

shouldbemultipliedbyafactorof1.25whendetermining

componentvoltageratings,conductorcurrentratings,fuse

sizesandsizeofcontrolsconnectedtothePVoutput.Refer

tosection690-8oftheU.S.NationalElectricCodeforan

additionalmultiplyingof1.25whichmaybeapplicable.

c)Onlycableswithoneconductoraretobeused.

Module

Sunlight

Tilt Angle

Horizontal

d)Theareaofthecablematedwiththeconnectorisre-

commendedtobe4~6mm²,length:1000mm,tempera-

turerange:-40[to90.Themaximumseriesfuse[IMax.Series

fuse[(Mono-125:[IMax.Seriesfuse=10A[Mono-156&Poly-156

IMax.Seriesfuse=15A)[.

2.4) The requirements for different types of mount

•Groundmount

Selecttheheightofthemountingsystemtopreventthe

lowestedgeofthemodulefrombeingcoveredbysnowfora

longtimeinwinterinareasthatexperienceheavysnowfalls.

Inaddition,assurethelowestportionofthemoduleisplaced

highenoughsothatitisnotshadedbysandandstone

drivenbywind.

•Roofmount

a)Wheninstallingamoduleonarooforbuilding,ensurethatit

issecurelyfastenedandcannotfallasaresultofwindor

snowload.

b)Themodulesaresupportedparalleltosurfaceofthebuilding

wallorroof.Clearancebetweenthemoduleframesand

surfaceofthewallorroofisrequiredtopreventwiringdama-

geandtoallowairtocirculatebehindthemodule.

Thestandoffheightshouldbeatleast100mm[(3.94in).The

recommendedstand-offheightis115mm[(4.53in).[

c)Theroofinstallationofmodulesmayaffectthereproofper-

formanceofbuildingstructure.

d)ThemodulesmustbeinstalledontoaClassiedRoong

system.ThemodulesareClassC.Youcanmountthemover

aClassC,BorAroof.Theamountofareathemodules

covermaydegradetheroof‘soriginalreratinginsomeloca-

tions.Donotinstallmodulesonarooforbuildingduring

strongwindsincaseofaccident.

•Polemount

Wheninstallingamoduleonapool,chooseapoleand

modulemountingstructurethatshouldwillwithstandantici-

patedwindsforthearea.

3) Mounting Methods

Topreventbending,vibration,mechanicalstressor

warpage,mountthemoduleontoaatcontactsurface.The

minimaldistancebetweenmountedmodulesshouldbeno

lessthan20mm.Useallthemountingpointsprovidedand

avoiddirectcontactbetweenglassandmetal[(e.g.mounting

rails).,

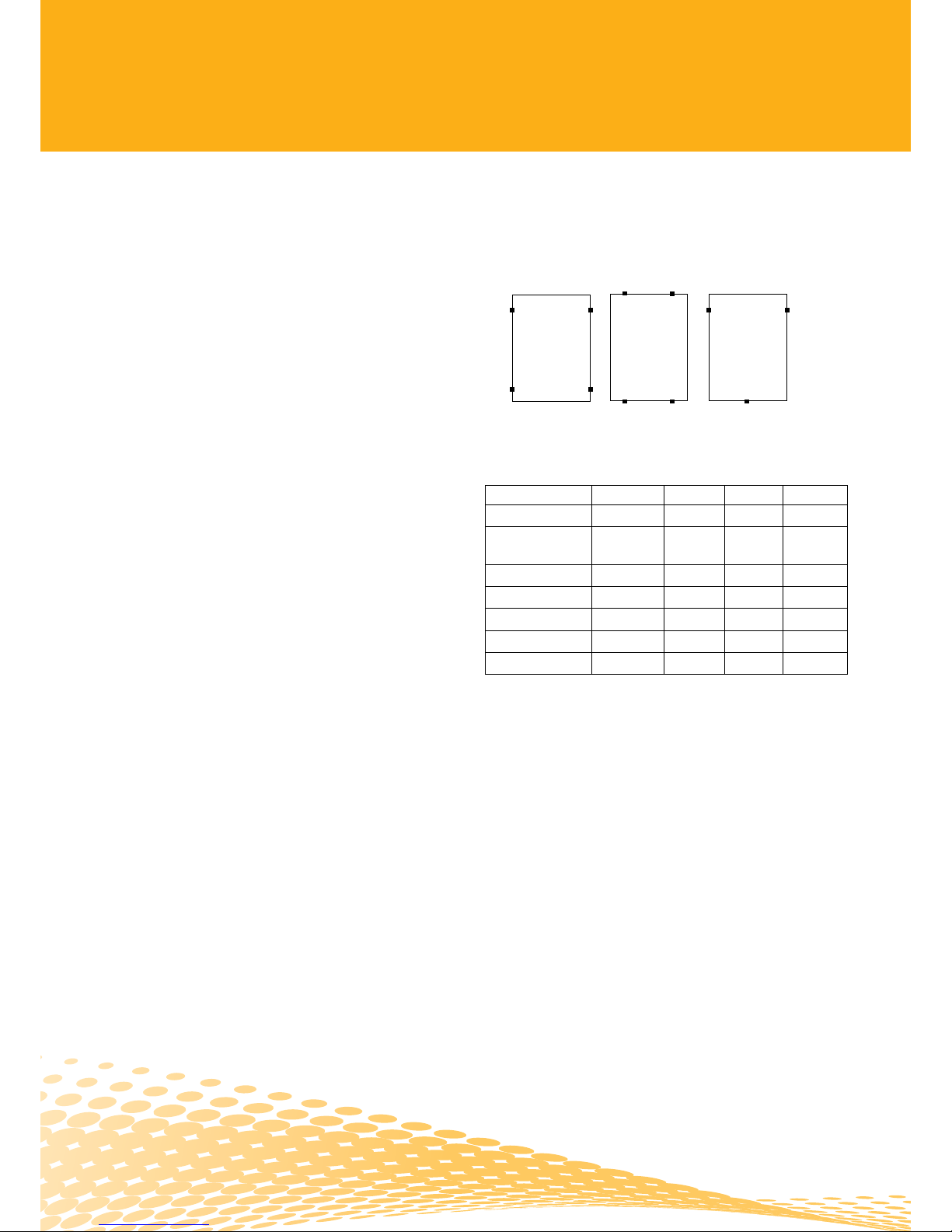

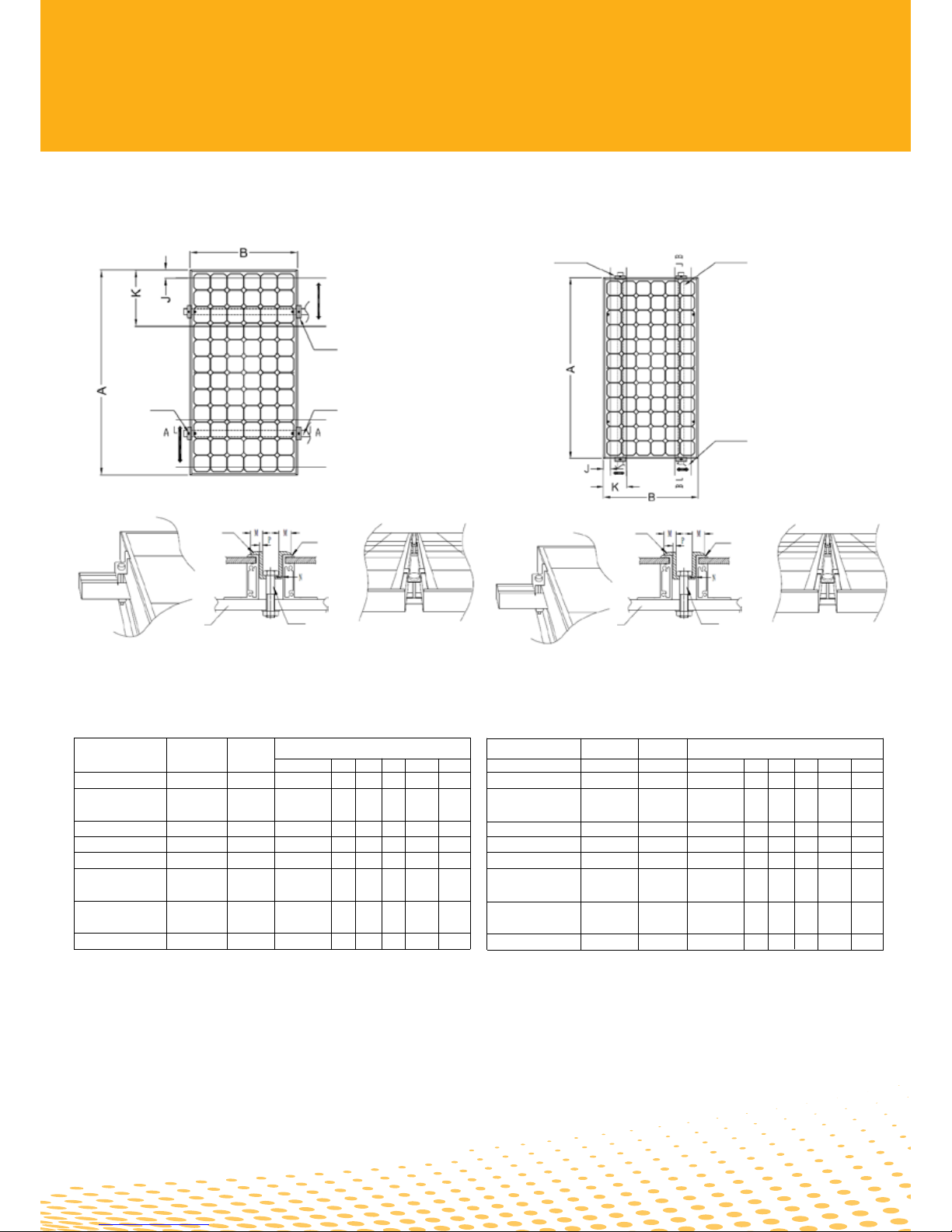

•Option1:ClampingMounting

Theclampsmustnotoverlaptheglassorshadethemodule

surface,ordistorttheframe.Recommendedtorqueis5Nm.

Fig.2

ModuleType Frame Type1 Type2 Type3

JT***SFa/b 30mm

JT***SAa/b

JT***SAa/b(Black) 40mm

JT***SC-Fc 40mm

JT***SC-Dc(Black) 40mm

JT***PC-Fe 40mm

JT***PAe/JT***SAc 45mm

JT***SBa/b 45mm

Table2

Notes:

1)JT***SFa/bisusedasanexample.

2)Where“***”istheratedpoweroftheJetionmodule.

3)““indicates5400paavailable;““indicates2400pais

available;““indicatesnoallowed.

4)Differentframeheightshouldchooseappropriateclampand

bolt.

5)MechanicalloadtestperformedaccordingtoIEC

standard,notapplicableforULproducts.

Type 1 Type 2 Type 3

Standard Mounting Short Side Mounting Triangle Mounting

FringeModules

Installation

MountingRail

Clamp

JT***SFa/b

JT***SAa/b

JT***SAa/b(Black)

JT***SBa/b

JT***PFe/JT***SFc

JT***PEe/JT***SEc

JT***PDe/JT***SDc/

JT***SDc(Black)

JT***PCe/JT***SCc/

JT***SCc(Black)

JT***PAe/JT***SAc

Mono

Mono

Mono

Poly/Mono

Poly/Mono

Poly/Mono

Mono

Poly/Mono

Mono

Poly/Mono

4x9

6x12

8x12

4x9

6x8

6x9

6x10

6x12

•Type1:StandardMounting

Fig.3

ModuleTypeCellTypeCellDimensions(mm)

Quantity AxBJKMNP

Table3(Foryourinformation)

Notes:

1)JT***SFa/bisusedasanexample.

2)Where“***”istheratedpoweroftheJetionmodule.

3)Dimension„N“representsthedistancebetweenclampandframe.

4)Dimension„P“representsthethicknessofclamp.

Themovementofthe

mountingrailandthe

clampscenter-lineare

recommendedtobe

withintheblackarrow

area.Pleasendspecic

datafromTable3.

MountingRail

M8Screw

MiddleModules

Installation

Frame(longside)

200

200

200

200

200

200

200

200

1195×541

1580×808

1580×1069

1482×676

1324×992

1482×992

1655×992

1956×992

50

50

50

50

50

50

50

50

12

12

12

12

12

12

12

12

0.5~2

0.5~2

0.5~2

0.5~2

0.5~2

0.5~2

0.5~2

0.5~2

2.5~3

2.5~3

2.5~3

2.5~3

2.5~3

2.5~3

2.5~3

2.5~3

M8Screw

MiddleModules

Installation

Frame(longside)

MountingrailClamp

Themovementofthe

mountingrailandthe

clampscenter-lineare

recommendedtobe

withintheblackarrow

area.Pleasendspecic

datafromTable4.

FringModules

Installation

•Type2:ShortSideMounting

Fig.4

ModuleTypeCellTypeCellDimensions(mm)

Quantity AxBJKMNP

Table4(Foryourinformation)

Notes:

1)JT***SFa/bisusedasanexample.

2)Where“***”istheratedpoweroftheJetionmodule.

3)Dimension„N“representsthedistancebetweenclampandframe.

4)Dimension„P“representsthethicknessofclamp.

200

200

200

200

200

200

200

200

1195×541

1580×808

1580×1069

1482×676

1324×992

1482×992

1655×992

1956×992

50

50

50

50

50

50

50

50

12

12

12

12

12

12

12

12

0.5~2

0.5~2

0.5~2

0.5~2

0.5~2

0.5~2

0.5~2

0.5~2

2.5~3

2.5~3

2.5~3

2.5~3

2.5~3

2.5~3

2.5~3

2.5~3

JT***SFa/b

JT***SAa/b

JT***SAa/b(Black)

JT***SBa/b

JT***PFe/JT***SFc

JT***PEe/JT***SEc

JT***PDe/JT***SDc/

JT***SDc(Black)

JT***PCe/JT***SCc/

JT***SCc(Black)

JT***PAe/JT***SAc

Mono

Mono

Mono

Poly/Mono

Poly/Mono

Poly/Mono

Mono

Poly/Mono

Mono

Poly/Mono

4x9

6x12

8x12

4x9

6x8

6x9

6x10

6x12

•Option2:BoltingMounting

Eachmoduleshouldsecuretheframesofmoduletosup-

portingstructurethroughatleast4mountingholes(corres-

pondingtothemountingrail2and3).Forhighwindand

snowloads,8holes(correspondingtothemountingrail1to

4)shouldbesecured.Themoduleframemustbeattached

tothemountingrailsusingM8corrosion-proofscrews

togetherwithspringwashersandatwashers.Recommen-

dedtorqueis5Nm.Usetheexitinginstallationholesinstead

ofdrillingadditionalholesforinstallation(Drillingholesis

againstthereliabilityandwarrantyofJetionmodules).Please

usecorrosion-resistantinstallationandattachmentmaterials.

Fig.5

Mountingrail1

Mountingrail2

Mountingrail4

Mountingrail3

8-[ 9×14

Nut

Mountingrail

M8srew

960

1300

1300

1100

1044

1100

1225

1676

1195×541x30

1580×808x40

1580×1069x45

1482×676x40

1324×992x40

1482×992x40

1655×992x40

1956×992x45

660x508

800x758

800x1019

700x626

544x942

700x942

725x942

1176x942

JT***SFa/b

JT***SAa/b

JT***SAa/b(Black)

JT***SBa/b

JT***PFe/JT***SFc

JT***PEe/JT***SEc

JT***PDe/JT***SDc/

JT***SDc(Black)

JT***PCe/JT***SCc/

JT***SCc(Black)

JT***PAe/JT***SAc

Mono

Mono

Mono

Poly/Mono

Poly/Mono

Poly/Mono

Mono

Poly/Mono

Mono

Poly/Mono

4x9

6x12

8x12

4x9

6x8

6x9

6x10

6x12

ModuleTypeCellTypeCellDimensionsMountingHoleMountingHole

Quantity AxBxC(mm) E (mm) GxF(mm)

Table5

Notes:

1)JT***SFa/bisusedasanexample.

2)Where“***”istheratedpoweroftheJetionmodule.

4) Grounding

• Toavoidtheriskofelectricalshockorre,themoduleframe

shouldbegroundedbeforetheelectricalconnectionofthe

modulesisoperated.

• TheframeshallbegroundedinaccordancewithNECArticle

250[USA[orCECinCanada.

• Foranadequateground,thegroundinghardwareshould

penetratetheanodizationlayer.

• OnlyULlistedcomponentsshouldbeusedforgrounding.

• Jetionrecommendsusingthefollowingcomponentsorequi-

valents.

1 StainlesssteelboltM4x30

2 StainlesssteelnutM4

3 StainlesssteelspringwasherM4

4&6StainlesssteelatwasherM4

5 Stainlesssteellock-toothedwasherM4

7 StainlesssteelcupwasherM4

8 Groundingwire

Fig.6

Washer

ModuleTypeCellTypeCellDimensionsMountingHoleMountingHole

Quantity AxBxC(mm) E (mm) GxF(mm)

• Attachaseparateconductorasgroundingwiretothe4mm

diametergroundingholeswithasetofM4bolt,cup

washer,atwasher,lock-toothedwasher,springwasherand

nut.

• Exposedcopperofthegroundingwireshallnotcontactsthe

moduleframeincaseofcorrodingtheframe.

5) Wiring

For the wiring, pay attention to:

• Tominimizetheriskofindirectlightingstrike,avoidforming

closedloopswhendesigningthesystem.Checkthatwiring

iscorrectbeforestartingthegenerator.Ifthemeasuredopen

circuitvoltage(Uoc)[andshort-circuitcurrent[(Isc)different

fromthespecications,theremaybeawiringfault.

• JetionmodulesusetheJ-Box,onthebacksideofthemodule,

isweatherproofandisdesignedtobeusedwithstandard

wiringorconduitconnections.Wiringmethodsshouldbein

accordancetotheNEC(NationalElectricalCode).Bypass

diodesandcableclampsareincludedwitheachmodulewhen

shippedfromthefactory.

• Usemodulesofthesamecongurationsinthesamesystem.

Whenconnectedinseries,allmodulesmusthavethesame

current.Whenconnectedinparallel,themodulesmustallhave

thesamevoltage.Thequantityofmodulesconnectedshould

matchthevoltagespecicationsofthedevicesusedinthe

system.Themodulesmustnotbeconnectedtogetherto

createavoltagewhichishigherthanthepermittedsystem

voltage.WhendesigningtheJetionsystem,pleasealways

takeintoconsiderationthevariationofthevoltageunder

differenttemperatures(pleasechecktherespectivetempera-

turecoefcientsofthemodules,theVocofthemoduleswillbe

risewhenthetemperaturedrops).

• Thenumberofmodulesinseriesandinparallelinasystem.

• Whileconnectingthemodulesinseries,thetotalvoltage

shouldbelessthanthemaximumsystemvoltageUmax[(IEC:[

Umax=1000V;[UL:[Umax=600V).

• Whileconnectingthemodulesinparallel,thetotalcurrent

shouldbelessthanthemaximumsystemcurrent.

6) Maintenance and Cleaning

• DonotchangethePVcomponentsoptionally(diode,junction

box,plugconnectors).

• Givenasufcienttilt(atleast15°C),itisnotgenerallyneces-

sarytocleanthemodules(rainfallwillhaveaself-cleaning

effect).Incaseofheavysoiling(whichwillresultinoutput

reductions),werecommendcleaningthemodulesusing

plentyofwater(fromahose)withmilddetergentandusing

agentlecleaningimplement(asponge).CAUTION[DON’T

USEDETERGENTSCONSISTINGOFABRASIVE,ACETONE

OROTHERCORROSIVEELEMENTS.Donotcleanthe

moduleswithcoldwaterduringthewarmerhoursoftheday

inordertoavoidcreatinganythermalshockthatmaybe

damagethemodule.

Dirtmustneverbescrapedorrubbedawaywhen

dry,asthiswillcausemicro-scratches.Werecommendthat

thesystemisbeinginspectedatregularintervals.

7) Checklists

• Allfasteningsaretightandsecureandfreeofcorrosion.

• Allcableconnectionsaresecure,tight,cleanandfreeof

corrosion.

• Cablesarenotdamagedinanyway.

• Checkingtheearthingresistivelyofmetals.

8) Warning

• Themaximumloadonthemodulemustnotexceed30lb/ft²

(146.5kg/m²).Toavoidexceedingthemaximumload,site-

specicliveloadssuchaswindandsnowshouldtakeinto

account.

• Werecommendthatthemaximumnumberofmodulesin

parallelshouldbenomorethan2.Whenmorethantwo

modulesorstringsareplannedtobeputinparallel,usestring

fuses.Thenumberofmodulesinserieshastobemade

accordingtothemaxsystemvoltageoftheinverterwhichis

beingused.HowevertheVocVoltageofallmodulesinseries

shouldneverexceedmorethan1000V.

• Theplugconnectorhasitsownpolarity.Makesurethatthe

connectionissafeandtight.Ensurethattheyareingood

electricalandmechanicalcondition.

• Theplugconnectorshouldnotreceiveexternalstress.

• Donotattempttodrillholesintheglasssurfaceofthe

modules.

• Donotdrilladditionalmountingholesintheframeofthe

modules.

• DonothoistthemodulethroughtheJ-Boxorcable.

• Neveruseamodulewithbrokenglassortornsubstrate.

Brokenmodulescannotberepairedandcontactwithany

modulesurfaceorframecanleadtoelectricalshock.

• Donotinstallorhandlemoduleswhentheyarewetorduring

theperiodofhighwind.

• Keepchildrenwellawayfromthesystemwhiletransporting

andinstallingmechanicalandelectricalcomponents.

• Donotstrikeorphysicallydamagethemodule.

• Avoidcuttinganddamagingtheframeandthefrontsideor

backsidesurfaceofthemoduleduringhandlingandinstallati-

on.

• Donotstandorsteponthemodule.

• Donotputextraobjectsonthemoduleincaseofglass

broken.

• TheJ-Boxmustbeonthehighersideofthemodulewhenitis

mounted.

• Donotdismantleordropthemoduleanddonotremoveany

attachednameplateorcomponentsfromthemodule.

• Donotbendortwistthemodule.

• Donotapplypaintoradhesivetomoduletopsurface.

• Donotusepointedorsharpobjectswiththemodule.

• Articiallyconcentratedsunlightshallnotbedirectedonthe

module.

• Precipitationcanrunoffthroughsmallopeningsonthe

backsideofthemodule.Makesurethattheopeningsare

notmaskedaftermounting.

• Donotwearingrings,watches,ormetaljewelryduringinstal-

lations.

9) Hazard Warnings

Danger of death from electric shock!

PVmodulesgenerateelectricityassoonastheyareexposedto

sunlight.Onemodulegeneratesasafe,extralowvoltagelevel,

butmultiplemodulesconnectedinseries(summingthevoltage)

orinparallel(summingthecurrent)representadanger.Thefol-

lowingpointsmustbenotedwhenhandlingthesolarmodules

toavoidtheriskofre,sparkingandfatalelectricshock.

•Donotinsertelectricallyconductingpartsintotheplugsor

sockets!

• Donottsolarmodulesandwiringwithwetplugsand

sockets!

• Exerciseutmostcautionwhencarryingoutworkonwiring

andsafetyequipment(useinsulatedtools,insulatedgloves,

etc.)!

• Donotusedamagedmodules!Donotdismantlemodules!

Donotmarkontherearofthemoduleusingsharpobjects!

• Exerciseutmostcautionwhenworkingonwiringandthe

inverter.Besurecarefullytofollowmanufacture’sinstallation

instructions!

Danger of death from arcing!

Modulesgeneratedirectcurrentwhenlightshinesonthem.An

electricarcmaybegeneratedwhenconnectorsareusedto

turnthecircuitonoroff.Wethereforerecommendedcovering

moduleswithalightproofclothduringinstallation.Whenbrea-

kingaconnectedstringofmodules(e.g.whendisconnecting

theDClinefromtheinverterunderload),alethallystrongarc

canoccur.

•Neverdisconnectthesolargeneratorfromtheinverterwhile

theinverterisconnectedtothemainsgrid—removethefuse

fromtheACsideontheinverterrst!

• Ensuretheconnectorsarecleanandhavenotbeenconta-

minatedandthattheelectricalconnectionandmechanical

jointaregood!

JTInstallationsguideen©JetionSolar|11/2011

Printedonenvironmentallyfriendlypaper.

JETION SOLAR EUROPE

JetionSolar(Europe)Ltd.

Industriering10

9491Ruggell

Liechtenstein

Phone: +4232653830

Fax: +4232653839

E-Mail:info@jetion.biz

www.jetion.biz

JETION SOLAR CHINA

JetionSolar(China)Co.,Ltd.

No.1011,ZhenchengRoad

Shengang,JiangyinMunicipality

JiangsuProvince214443

PeoplesRepublicofChina

Phone:+8651086687300

Fax: +8651086687315

E-Mail:marketing@jetion.com.cn

www.jetionsolar.com

JETION SOLAR USA

10900-ASouthCommerceBlvd

Charlotte,NC28273

Phone: +17049441069

Tollfree: 8006068569

Fax: +17049441080

E-Mail:[email protected]

www.JetionSolarUS.com

This manual suits for next models

19

Table of contents