The load bearing capacity of the roof / roof construction (rafters, purlins, trapezoidal metal, number of

adhesive points, folded seams, etc.) must be checked by the user or a check be commissioned.

Physical building aspects concerning insulation penetrations (e.g. condensation) must be taken into

account by the user.

Notes on mounting

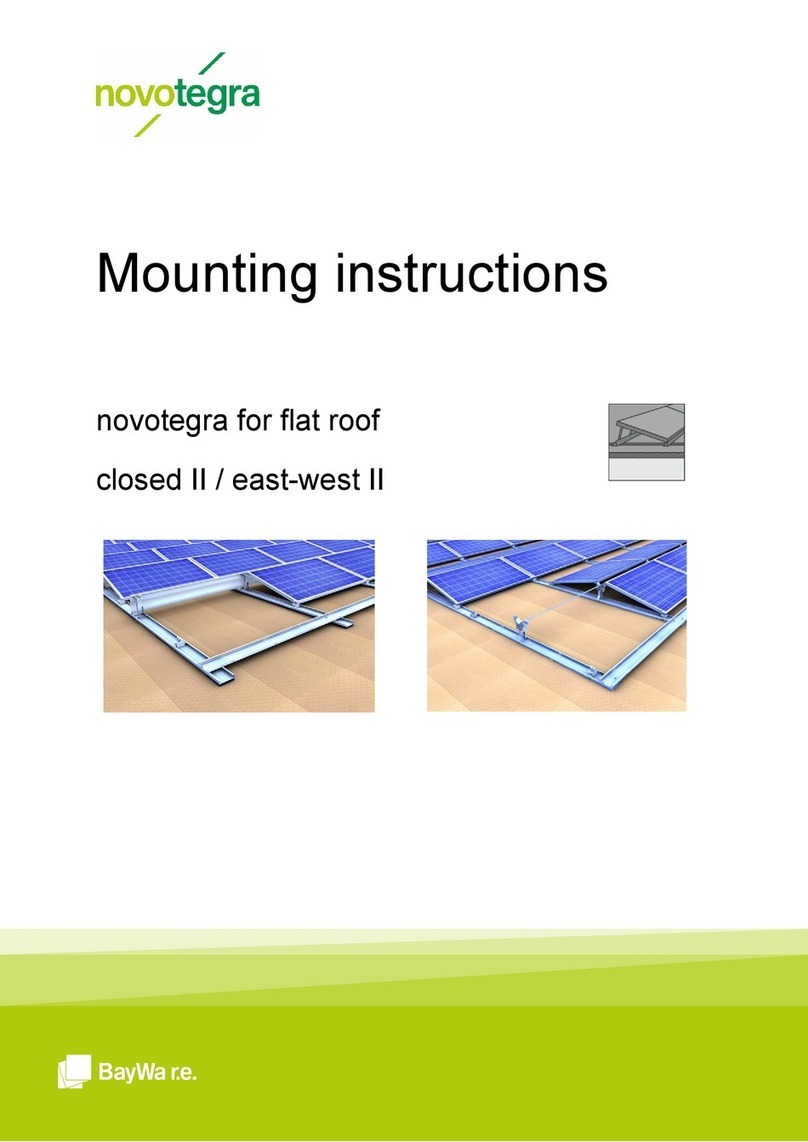

The components of the novotegra mounting system are intended exclusively for the attachment of PV

modules. Dependent on the roof type of the building the designated mounting system components must be

used.

A condition for the intended use of the novotegra mounting system is the mandatory compliance with the

specifications in these instructions regarding safety information and mounting.

In case of unintended use and non-compliance with the safety information and mounting instructions and

non-utilisation of the corresponding mounting components or use of third party components not belonging

to the mounting system any warranty and liability claims against the manufacturer are voided. The user is

liable for damage and resulting consequential damage to other components, such as PV modules, or the

building as well as personal injury.

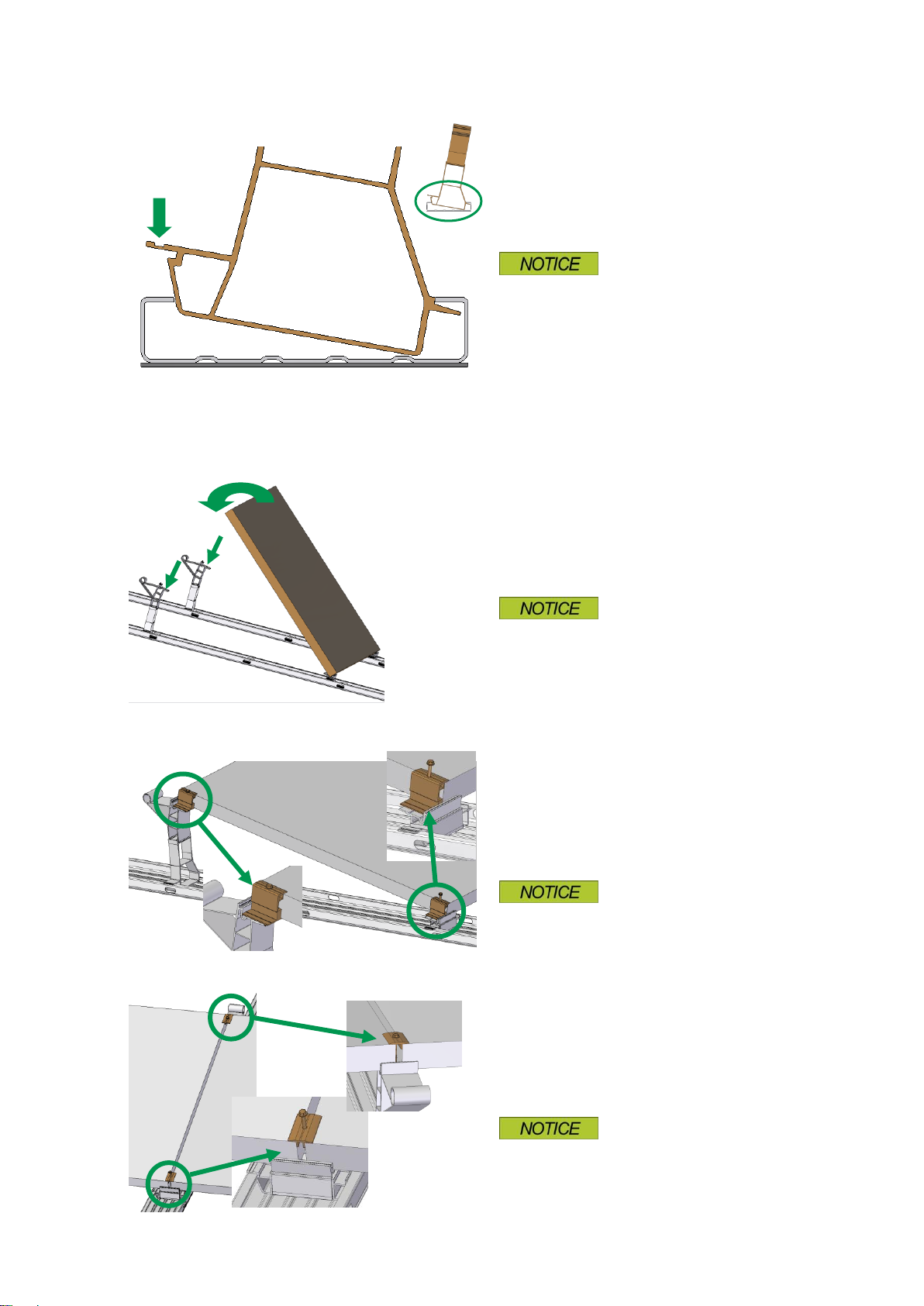

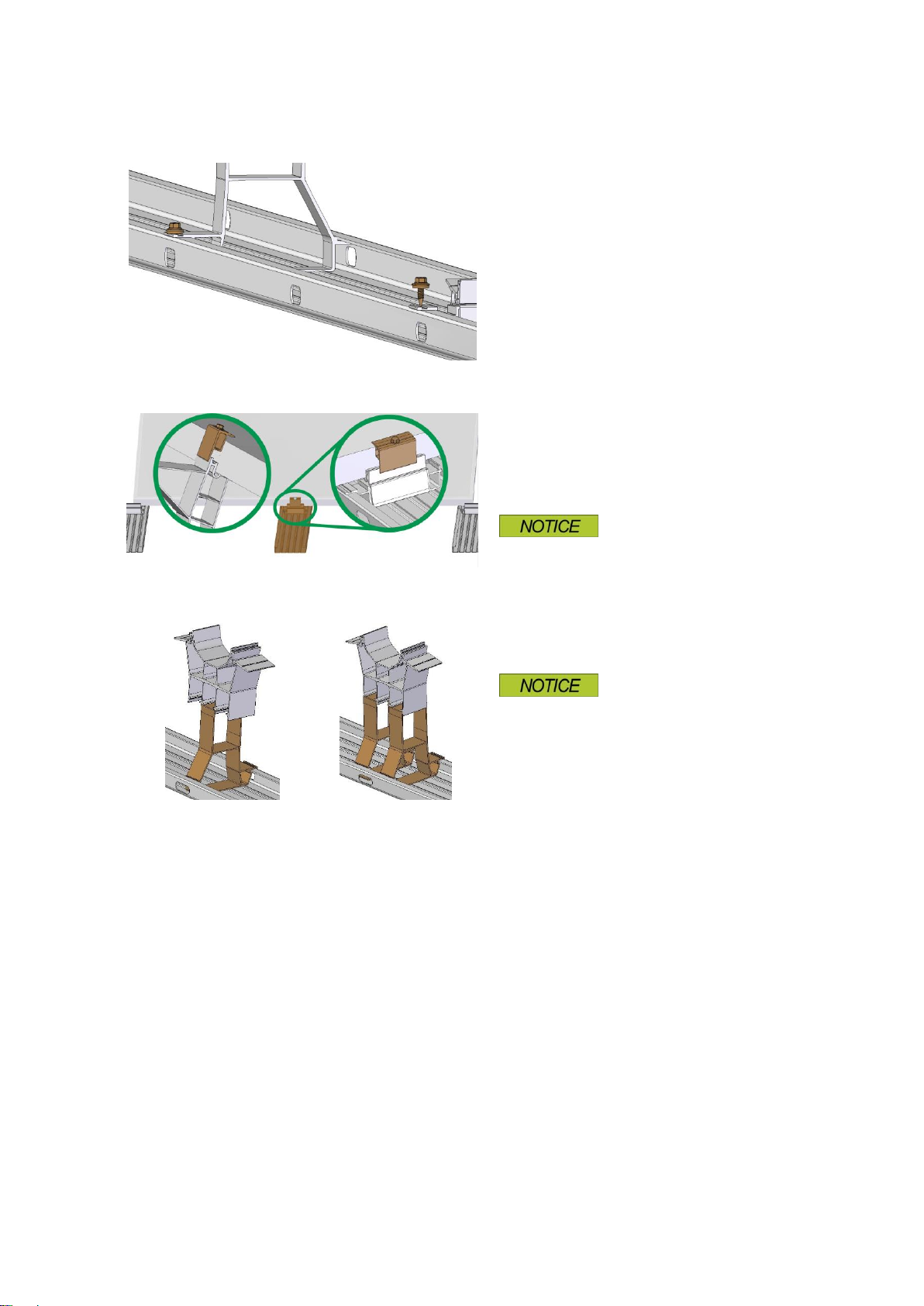

The user must read the mounting instructions prior to mounting. Unresolved issues must be clarified with

the manufacturer prior to mounting. The mounting sequence in these instructions must be adhered to.

It must be ensured that a copy of the mounting instructions is accessible in the immediate vicinity of the

work on site.

The mounting specifications (module load, attachment, clamping areas etc.) of the module manufacturer

must be observed and complied with.

Prior to mounting the mounting system must be statically calculated with the loads to be assumed for the

building project in accordance with the national standards. Information relevant to mounting (e.g. roof hook

distance, lengths of bolts, overhang and protrusions) must be determined by the static calculation using the

design software Solar-Planit.de.

The permissible roof inclination for the use of the mounting system in accordance with these mounting

instructions is 0 to 60 degrees.

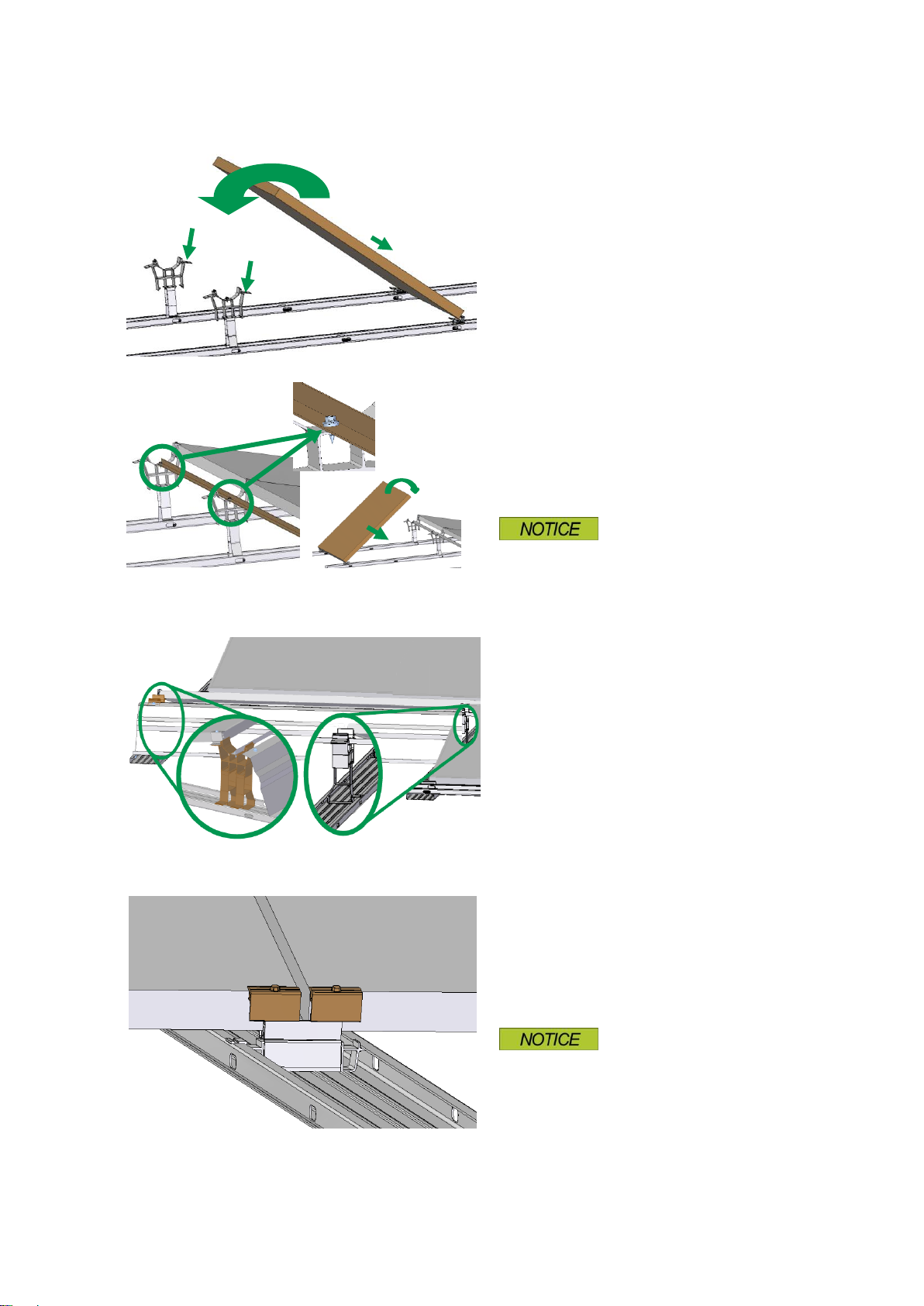

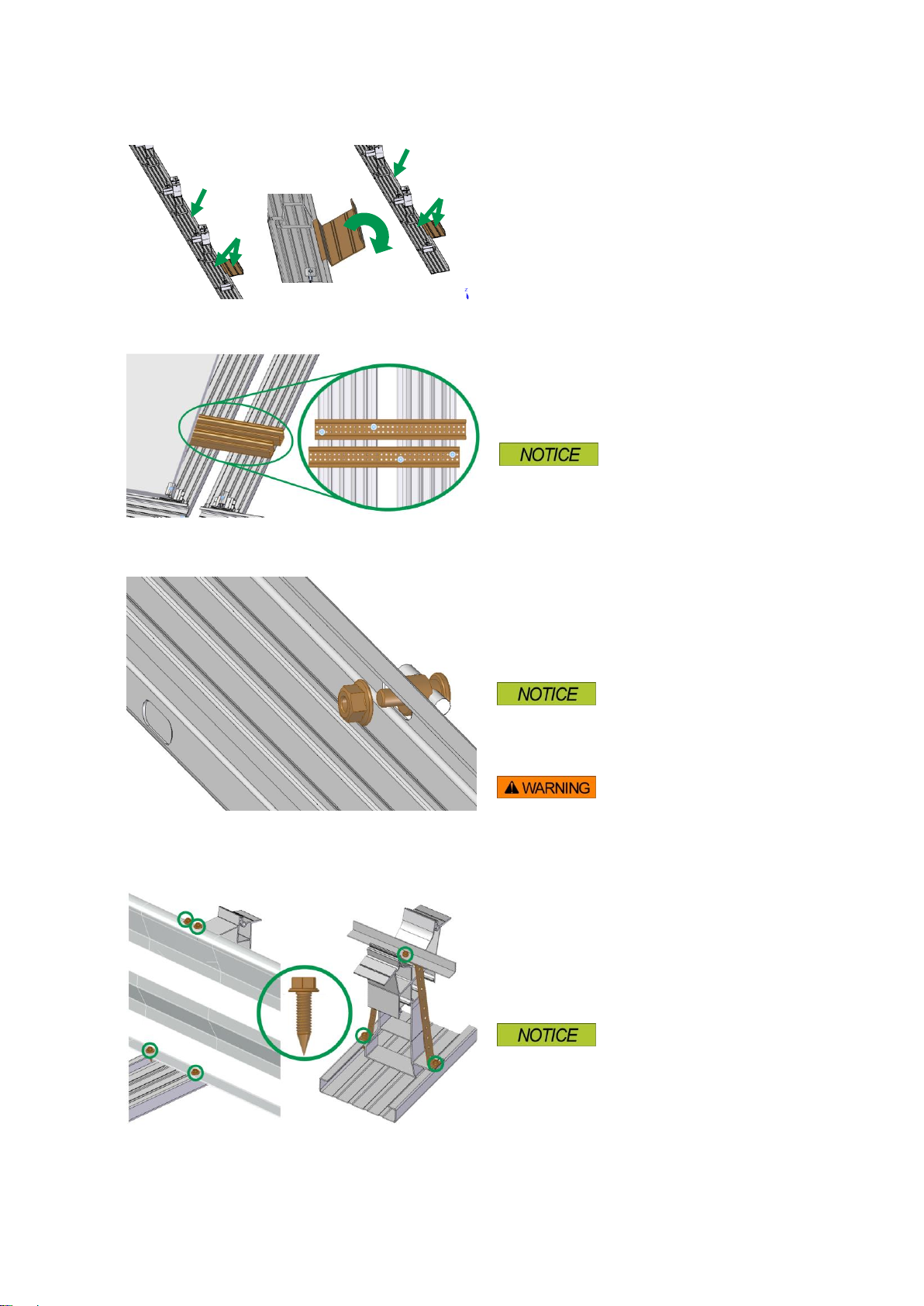

For each module two module support rails must be fitted symmetrically under the modules for the even

load introduction to the substructure.

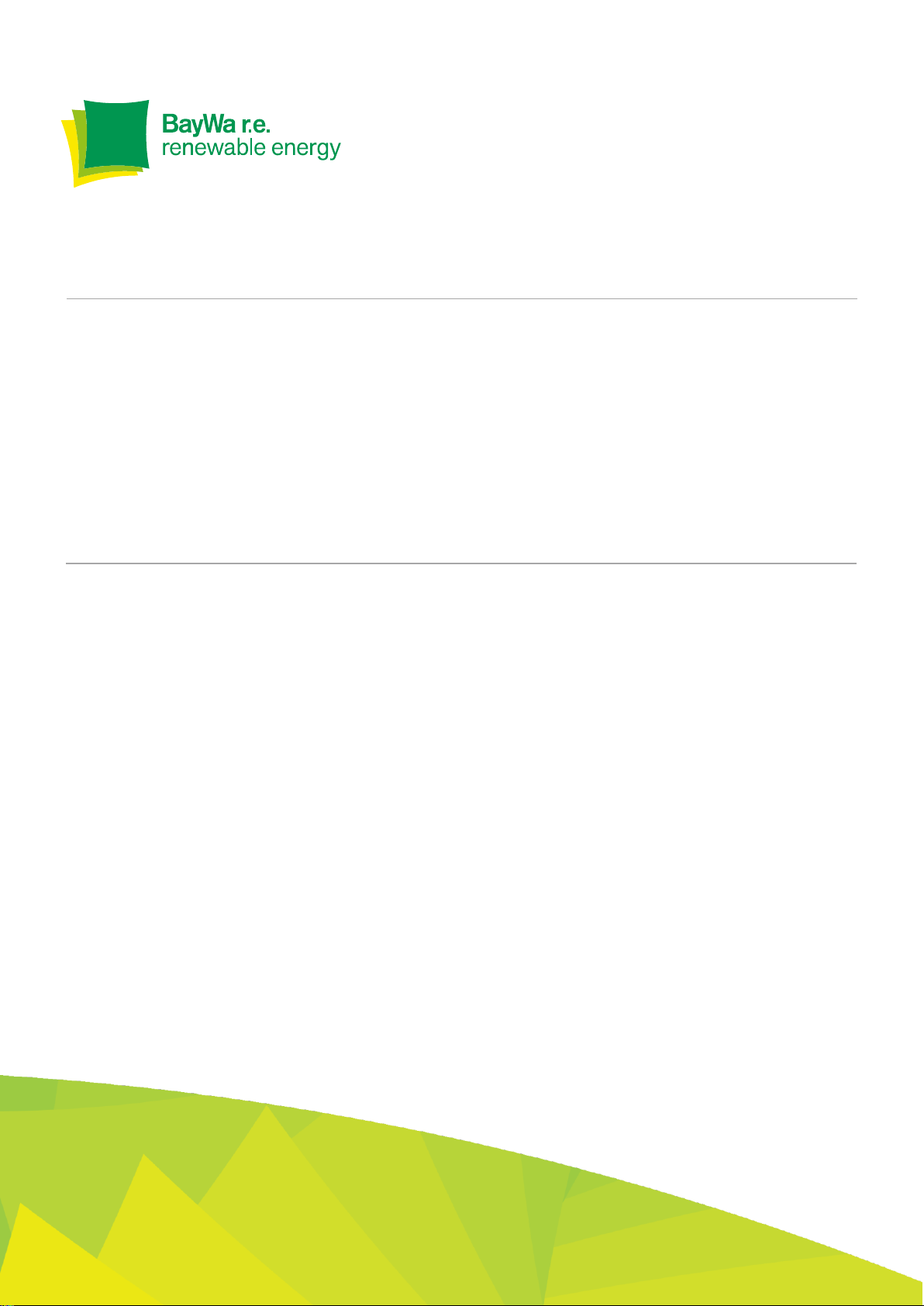

The specified tightening torques must be adhered to and checked randomly on site.

Notes on static calculations

The mounting system must generally be statically calculated for each individual project using the design

software Solar-planit.de.

The static calculation only determines the load bearing capacity of the novotegra mounting system and also

takes account of the attachment to the building (rafters, purlins, trapezoidal metal etc.). The load transfer

within the building is not considered (customer static calculations).

The load bearing capacity of the mounting system components is determined on the basis of the planned

module layout and the underlying roof information (project data recording). Deviations from the planning on

site may lead to different results.

The load assumptions (load and roof division) are country-specific in accordance with the specifications of

the Eurocode load standards. The determination of the loads to be assumed for Switzerland is in

accordance with SIA 261.

The modules may not be fitted above the gable end, ridge and eaves (increased wind load). At the ridge

the modules may be fitted up to max. a theoretical horizontal line with the ridge tile and perfectly flush with

the gable end. In the eaves area the modules may reach to max. the end of the roof cover due to loads.

In case of an exposed building position (with wind load e.g. at the edge of a slope) or snow accumulation

(e.g. dormer or catchment grill) the specifications of the Eurocode load standards or SIA 261 (Switzerland)

must be taken into account by the user within his own responsibility. The design software does not consider

these cases.