2

EN

These instructions...

i

...give you a brief description of the installation of the RolloTube Automation

Set.

These instructions do not replace the enclosed manual for the

tubular motor.

Before you begin, please read these instructions through completely and

follow all the safety instructions.

Damage resulting from non-compliance with these instructions and the safety

instructions will void the warranty.We assume no liability for any consequential

damage.

There is a risk of fatal injury from electric shock when working on all

electrical systems.

◆The electrical connection for the tubular motor and all work on the electrical

systems may only be undertaken by an authorised electrician in accordance

with the connection diagramsin the original manual forthe enclosed tubular

motor.

◆Carry out all installation and connection work only when the product is

disconnected from the mains power.

There is a risk of fatal injury in the event of failure to observe these

instructions!

Observe the regulations for installing products in damp rooms.

◆Observe DIN VDE 0100, parts 701 and 702 in particular when installing the

product in damp rooms. These regulations contain mandatory protective

measures.

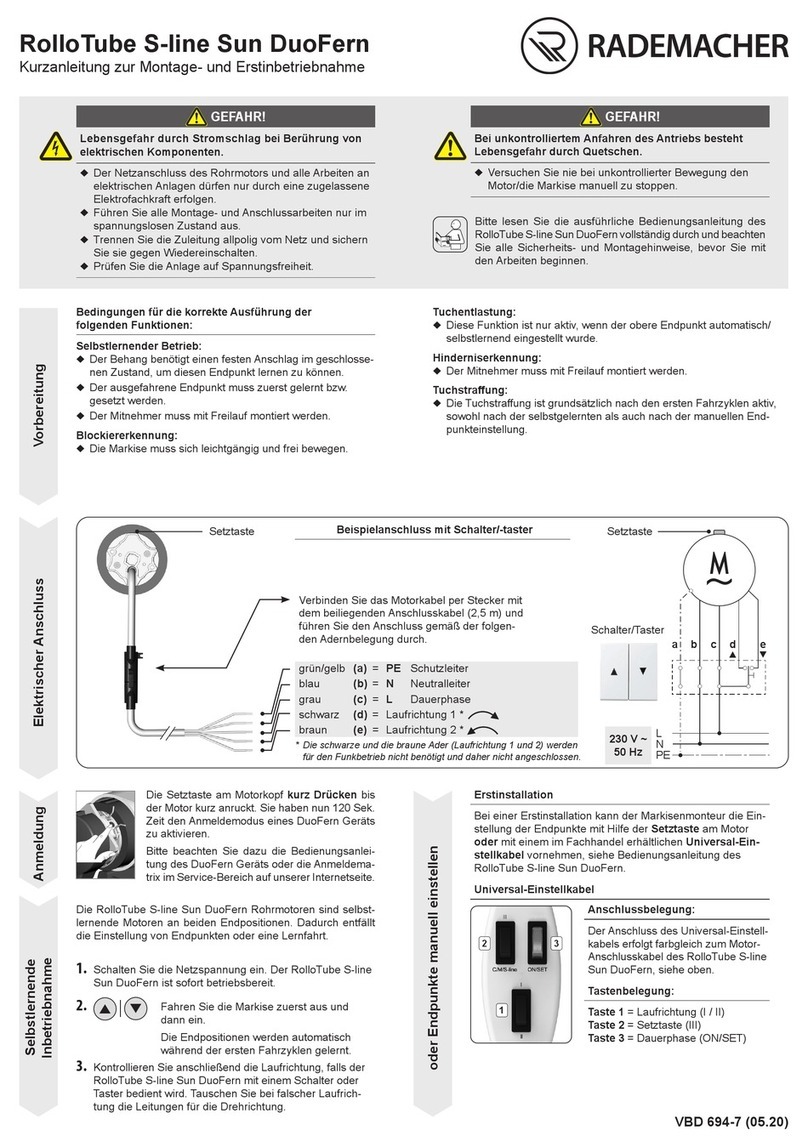

Installation

ATTENTION!

Never knock the motor (8) into the

winding shaft (5.2) with force.

Doing so will cause serious damage.

ATTENTION!

Never drill in the area of the drive or

insert screws in order to secure the

roller shutter.

Removing the old roller shutter mechanism

◆Open the roller shutter box.

◆Close the roller shutter completely and release the roller shutter casing

from the winding shaft.

◆Then remove the existing belt winder and winding belt and close the belt

inlet opening in the roller shutter box.

CAUTION!

There is a risk of injury from the pre-tensioned spring in the old belt

winder.

Hold the spring unit firmly when loosening the belt and allow it to recoil

slowly until the spring unit has completely unwound.

1.

◆Remove the winding shaft and all bearings.

(14)

1

(1) (2) (4) (6)

(5.2) (7) (8) (9) (11) (12)(3) (10)

(5.1)

(1) Counter bearing

(2) Ball bearing

(3) Axle pin on the roller capsule

(4) Roller capsule

(5.1) Telescopic shaft

(5.2) Winding shaft

(6) Ties or rigid shaft connectors

(7) Catch

(8) Tubular motor

(9) Adapter

(10) Set button or 2 adjustment

screws

(11) Drive head

(12) Click drive bearing

(13) * Motor cable with/without

connector, see page 1

(14) Roller shutter casing

(13) *

iMark the position of the centre of the old

bearings so that you can install the new bearings

and the winding shaft horizontally in the same

position.