Jetter JCM-501-E00 User manual

User Manual

JCM-501-E00

We automate your success.

Jetter AG

Graeterstrasse 2

71642 Ludwigsburg

Germany

Phone

Switchboard +49 7141 2550-0

Sales +49 7141 2550-531

Technical Hotline +49 7141 2550-444

E-mail

Technical Hotline [email protected]

Sales [email protected]

Translation of the original User Manual

Revision 4.08.1

Date of issue 1/29/2020

This document has been compiled by Jetter AG with due diligence, and based on the known

state of the art. Revisions and further development of our products are not automatically

mentioned in a reviewed document. Jetter AG shall not be liable for errors in form or content,

or for missing updates, as well as for damages or disadvantages resulting from such failure.

Jetter AG Table of contents

JCM-501-E00 User Manual iii

Table of contents

1 Introduction .....................................................................................................................................6

1.1 Information on this document .................................................................................................. 6

1.2 Typographical conventions......................................................................................................6

2 Safety ...............................................................................................................................................7

2.1 General information.................................................................................................................7

2.2 Purpose ...................................................................................................................................7

2.2.1 Intended use................................................................................................................7

2.2.2 Usage other than intended ..........................................................................................7

2.3 Warnings used in this document ............................................................................................. 7

3 Product description ........................................................................................................................8

3.1 Design .....................................................................................................................................8

3.2 Features ..................................................................................................................................8

3.3 Status indication ......................................................................................................................8

3.3.1 Diagnostics capabilities by means of status indication................................................9

3.4 Scope of delivery.....................................................................................................................9

3.5 Nameplate ...............................................................................................................................9

4 Technical specifications...............................................................................................................10

4.1 Dimensions............................................................................................................................10

4.2 Electrical properties............................................................................................................... 10

4.3 Mechanical specifications......................................................................................................11

4.4 Environmental conditions ...................................................................................................... 11

4.5 Acoustic signal generator ...................................................................................................... 11

4.6 Ports and interfaces ..............................................................................................................11

4.6.1 CAN port....................................................................................................................11

4.6.2 USB interface ............................................................................................................12

4.6.3 Ethernet interface ......................................................................................................12

4.6.4 RS-232 interface .......................................................................................................13

4.7 EMI values.............................................................................................................................13

5 Mechanical installation.................................................................................................................14

5.1 Requirements for the installation location ............................................................................. 14

5.2 Installing the control ..............................................................................................................15

6 Electrical connection ....................................................................................................................16

6.1 Pin assignment of Deutsch connector................................................................................... 17

6.2 Pin assignment of M12 connector ......................................................................................... 17

7 Programming.................................................................................................................................18

7.1 Abbreviations, module register properties and formats......................................................... 18

Table of contents Jetter AG

iv JCM-501-E00 User Manual

7.2 CANopen® STX API .............................................................................................................19

7.2.1 STX Functions...........................................................................................................19

7.2.2 Heartbeat monitoring.................................................................................................20

7.2.3 CANopen® Object dictionary ....................................................................................20

7.3 SAE J1939 STX API..............................................................................................................21

7.3.1 STX Functions...........................................................................................................21

7.4 Serial interface RS-232 ......................................................................................................... 22

7.4.1 Operating principle ....................................................................................................22

7.4.2 Registers - Description ..............................................................................................24

7.4.3 Programming.............................................................................................................29

7.4.3.1 Activating the serial interface ....................................................................................29

7.4.3.2 Configuring the serial interface..................................................................................29

7.4.3.3 Sending characters ...................................................................................................29

7.4.3.4 Receiving characters.................................................................................................29

7.4.3.5 Sending Texts ...........................................................................................................30

7.4.3.6 Sending values..........................................................................................................30

7.4.3.7 Receiving values .......................................................................................................30

7.5 Real-time clock...................................................................................................................... 31

7.6 File system ............................................................................................................................ 31

7.6.1 Directories .................................................................................................................31

7.7 FTP server.............................................................................................................................31

7.8 Storage options - Overview ................................................................................................... 32

7.8.1 Types of program and data memory .........................................................................32

7.8.2 Operating system memory ........................................................................................32

7.8.3 File system memory ..................................................................................................33

7.8.4 Application program memory ....................................................................................33

7.8.5 Flash disk ..................................................................................................................33

7.8.6 USB flash drive..........................................................................................................34

7.8.7 Storing registers and variables..................................................................................34

7.8.8 Flag ...........................................................................................................................34

7.9 Monitoring interface activities ................................................................................................ 35

7.10 User-programmable IP interface ........................................................................................... 35

7.11 Automatic copying of controller data ..................................................................................... 36

7.11.1 Loading the Autostart function...................................................................................37

7.11.2 Executing the AutoStart function ...............................................................................37

7.11.3 Terminating the AutoStart mode ...............................................................................37

7.11.4 autostart.bat - Structure.............................................................................................37

7.11.5 Example of a command file .......................................................................................38

7.11.6 Data files ...................................................................................................................38

7.12 Operating system update ...................................................................................................... 39

Jetter AG Table of contents

JCM-501-E00 User Manual v

7.12.1 Updating the operating system via programming tool ...............................................40

7.12.2 Performing the operating system update via FTP .....................................................40

7.12.3 Performing the operating system update via USB ....................................................40

7.12.4 Performing an operating system update via the device website ...............................41

7.12.5 Performing an OS update via JetEasyDownload ......................................................42

7.13 Application program .............................................................................................................. 43

8 Registers - Overview.....................................................................................................................44

8.1 Default address on the CANopen® bus ................................................................................44

8.2 General overview - Registers ................................................................................................ 44

8.3 Flags - General overview ...................................................................................................... 44

8.4 Electronic nameplate.............................................................................................................44

8.5 Electronic name plate (device as a whole)............................................................................ 45

8.6 LEDs......................................................................................................................................45

8.7 Configuration .........................................................................................................................45

8.8 Ethernet.................................................................................................................................46

8.9 CAN.......................................................................................................................................46

8.10 Serial interface RS-232 ......................................................................................................... 46

8.11 Flash memory........................................................................................................................46

8.12 System information................................................................................................................47

8.13 USB flash drive......................................................................................................................47

8.14 General system registers ...................................................................................................... 47

8.15 Application program .............................................................................................................. 48

8.16 Networking via JetIP..............................................................................................................49

8.17 Modbus/TCP server .............................................................................................................. 50

8.18 File system/data file function ................................................................................................. 50

8.19 User-programmable IP interface ........................................................................................... 50

8.20 Application registers .............................................................................................................. 50

8.21 Flag .......................................................................................................................................50

8.22 System Functions..................................................................................................................52

8.23 Real-time clock...................................................................................................................... 53

9 Maintenance and repairs ..............................................................................................................54

9.1 Maintenance, repairs and disposal........................................................................................54

9.2 Storage and shipment ........................................................................................................... 54

10 Service ...........................................................................................................................................55

10.1 Customer service .................................................................................................................. 55

11 Spare parts and accessories .......................................................................................................56

11.1 Accessories ...........................................................................................................................56

Jetter AG Introduction | 1

JCM-501-E00 User Manual 6 / 59

1 Introduction

1.1 Information on this document

This document forms an integral part of the product and must be read and under-

stood prior to using it. It contains important and safety-related information for the

proper use of the product as intended.

Target groups This document is intended for specialists with appropriate qualifications.

Only competent and trained personnel is allowed to put this device into operation.

During the whole product life cycle, safe handling and operation of the device

must be ensured. In the case of missing or inadequate technical knowledge or

knowledge of this document any liability is excluded.

Availability of infor-

mation

Make sure this document is kept at the ready in the vicinity of the product

throughout its service life.

For information on new revisions of this document, visit the download area on our

website. This document is not subject to any updating service.

Start | Jetter - We automate your success.

For further information refer to the following information products:

■Version updates

Information about new versions of software products or of the operating sys-

tem of your controller.

■Online help of the JetSym software

Detailed description of software functions with application examples

■Application-oriented manuals

Information on file systems and communication interfaces

1.2 Typographical conventions

This manual uses different typographical effects to support you in finding and

classifying information. Below, there is an example of a step-by-step instruction:

üThis symbol indicates requirements which have to be met before executing

the following action.

►This sign or a numbering at the beginning of a paragraph marks an action in-

struction that must be executed by the user. Execute the instructions one after

the other.

ðThe target after a list of instructions indicates reactions to, or results of these

actions.

More information on this subject is available on our website.

Start | Jetter - We automate your success.

INFO In the info box you will find helpful information and practical tips about your prod-

uct.

Jetter AG Safety | 2

JCM-501-E00 User Manual 7 / 59

2 Safety

2.1 General information

At the time of placing on the market, this product corresponds to the current state

of the art and meets the recognized safety rules.

Besides this user manual, laws and regulations in the operator's country are rele-

vant to the operation of the product. The operator is responsible for complying

with the directives mentioned below:

■Applicable legislation, rules, and regulations

■Relevant accident prevention regulations

■Accepted safety rules

■EU directives and other country-specific regulations

2.2 Purpose

2.2.1 Intended use

The device is intended for controlling applications in the field of commercial vehi-

cles and mobile machines.

Operate the device only in accordance with the intended conditions of use, and

within the limits set forth in the technical specifications.

Intended use of the product includes its operation in accordance with this man-

ual.

SELV/PELV If this device is not used in a vehicle or mobile machine, a SELV or PELV power

supply unit must be used to supply the device.

2.2.2 Usage other than intended

This device must not be used in technical systems which to a high degree have

to be fail-safe.

Machinery Directive This device is no safety-related part as per Machinery Directive 2006/42/EC, and

must, therefore, not be used for safety-relevant applications. This device is NOT

intended for the purpose of personal safety, and must, therefore, not be used to

protect persons.

2.3 Warnings used in this document

DANGER High risk

Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING Medium risk

Indicates a potential hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION Low risk

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE Material damage

Indicates a situation which, if not avoided, could result in malfunctions or material

damage.

Jetter AG Product description | 3

JCM-501-E00 User Manual 8 / 59

3 Product description

The JCM-501-E00 controller forms the heart of compact, distributed architec-

tures. With its numerous interfaces, as well as the proven, powerful 32-bit CPU, it

can be used in system solutions of simple to medium complexity.

3.1 Design

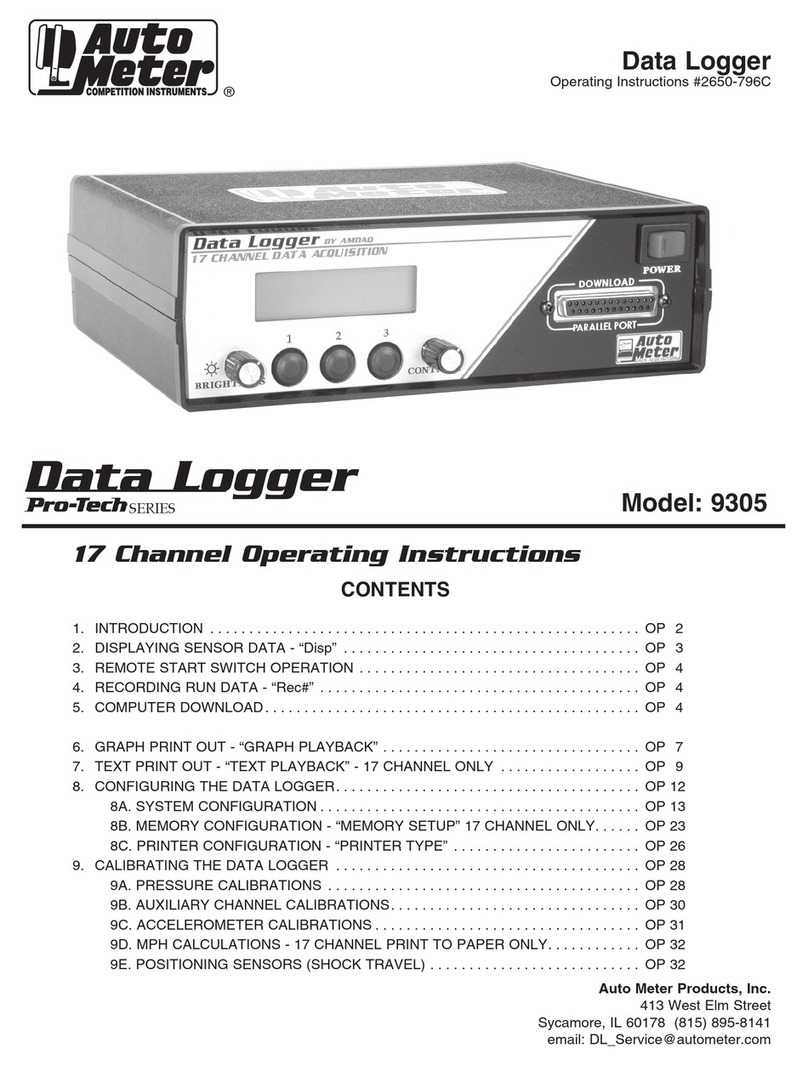

4

2

1

1

3

1

1

Fig.1: Device configuration

1Screw hole 2Deutsch connector

3M12 male connector 4Nameplate

3.2 Features

■Deutsch connector DT06-12S

■Ports and interfaces: 2x CAN, 1x USB, 1x RS-232 (all in Deutsch connector),

as well as Ethernet port in separate M12 connector

■CPU: ARM11, 500 MHz, 128 MB RAM, 512 MB Flash

■Front/rear degree of protection: IP65/IP65:

■Integrated real-time clock

3.3 Status indication

The JCM-501-E00 has 2 LEDs which can be configured by the user.

1 2

Fig.2: Status indication

1"D2" LED 2"D1" LED

Jetter AG Product description | 3

JCM-501-E00 User Manual 9 / 59

3.3.1 Diagnostics capabilities by means of status indication

Colors and flashing patterns of the LEDs are an excellent source of information to

analyze problems.

Diagnostics via the setup window of the JetSym software is another option.

LED Status Color Description

D2 OFF --- This LED is controlled by register 108008. If bit

2 and bit 3 of register 108008 are 0 at the same

time, the LED is off.

ON Red Bit 3 is set in register 108008.

ON Green Bit 2 is set in register 108008.

ON Orange In register 108008, bits 2 and 3 are set simulta-

neously.

D1 OFF --- This LED is controlled by register 108008. If bit

0 and bit 1 of register 108008 are 0 at the same

time, the LED is off.

ON Red Bit 1 is set in register 108008.

ON Green Bit 0 is set in register 108008.

The system is switched on (MR 108008=1).

ON Orange In register 108008, bits 0 and 1 are set simulta-

neously.

3.4 Scope of delivery

Scope of delivery Item number Quantity

JCM-501-E00 10001811 1

Installation manual 60884761 1

3.5 Nameplate

Fig.3: Nameplate

1Logo 2Serial number

3Barcode 4Article number and hardware re-

vision

5Model code number

Jetter AG Technical specifications | 4

JCM-501-E00 User Manual 10 / 59

4 Technical specifications

4.1 Dimensions

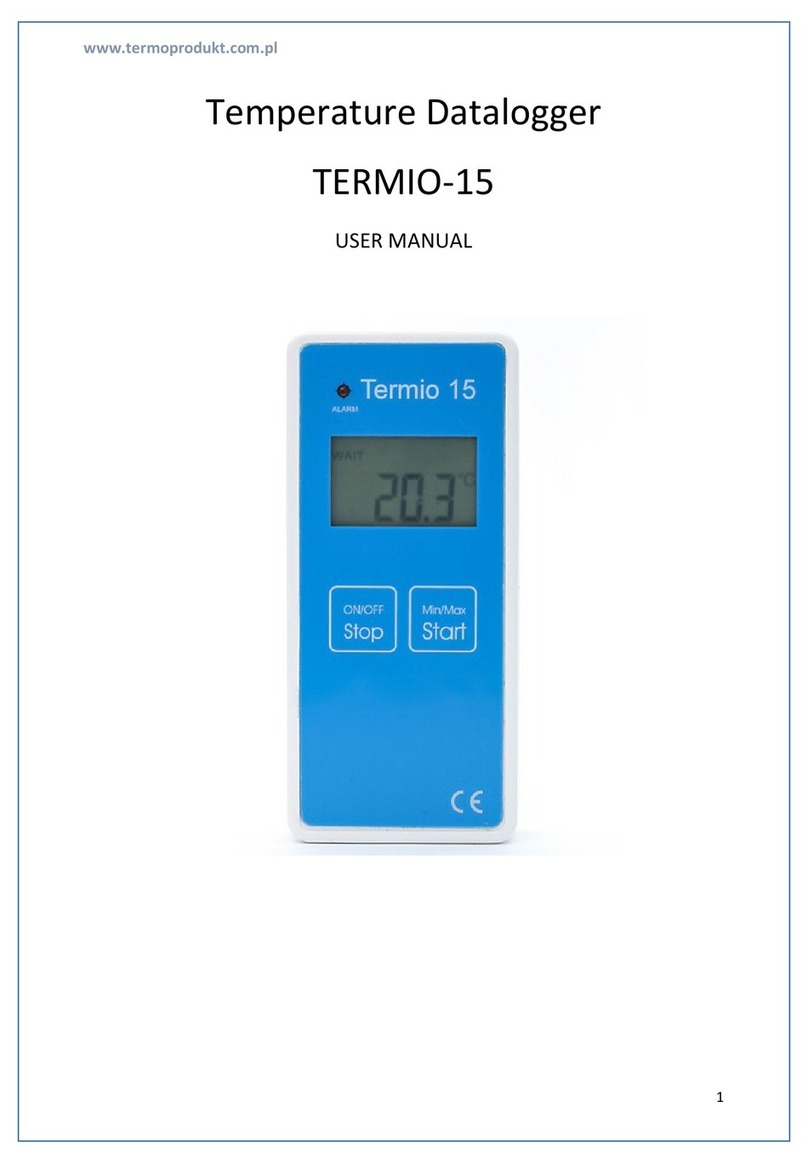

119.8

104.8

R9.9

27.955

83

41.5

63.4

103.5

44.4

R200

8

39.5

25°

.

28

45.6

38.1

22.2

Ø

2.3

2x

Fig.4: Dimensions (in mm)

4.2 Electrical properties

Power supply

VBAT_ECU

Category Description

Rated voltage DC 12 V or 24 V

Permissible voltage range

VBAT_ECU

DC 8 V ... DC 32 V

Maximum current 2 A

Typical current consumption

logic circuit (VBAT_ECU)

170 mA at DC 12 V

90 mA at DC 24 V

Power consumption Approx. 2 W

Integrated protective func-

tions

Reverse polarity protection, overvoltage, voltage

surges

Tab.1: Power supply VBAT_ECU

Jetter AG Technical specifications | 4

JCM-501-E00 User Manual 11 / 59

4.3 Mechanical specifications

Category Description Standards

Vibration

Broadband noise 10 Hz / 0.005 (m/s2)2/Hz DIN EN 60068-2-64

200 Hz / 0.02 (m/s2)2/Hz

300 Hz / 0.01 (m/s2)2/Hz

350 Hz / 0.002 (m/s2)2/Hz

Period 3x 24 h

Shock resistance

Type of shock Half-sine wave DIN EN 60068-2-27

Intensity and duration 30 g (300 m/s2) for 18 ms

Number and direction 18 shocks in all 6 direc-

tions

Degree of protection

Front panel: IP65 DIN EN 60529

Rear panel: IP65

Tab.2: Mechanical specifications

4.4 Environmental conditions

Category Description Standards

Operating temperature -20 … +65 °C ISO 16750-4

Climatic conditions Humid heat

Storage temperature -20 … +70 °C ISO 16750-4

DIN EN 60068-2-1

DIN EN 60068-2-2

Air humidity 10 … 95 % DIN EN 61131-2

Pollution degree 2 DIN EN 61131-2

Tab.3: Environmental conditions

4.5 Acoustic signal generator

Category Description

Type Speakers Adjustable frequency

and volume.

Volume 83 dB 10 cm distance and res-

onance frequency 2.670

Hz

Tab.4: Acoustic signal generator

4.6 Ports and interfaces

4.6.1 CAN port

CAN interfaces Category Description

Quantity 2 CAN_1 and CAN_2

Baud rate 125, 250, 500 kBaud

Protocol CANopen® SAE J1939

Default node ID on

the CANopen® bus

127 (0x7F)

Jetter AG Technical specifications | 4

JCM-501-E00 User Manual 12 / 59

Category Description

Bus terminating resistor CAN 1 Internally not installed.

CAN 2 Internally installed (120

Ω).

External bus termination Required for CAN 1 120 Ω

Cable specification Twisted pair conductors, unshielded

Tab.5: CAN interfaces

Specification - CAN

bus cable

Category Description

Wire cross-section 500 kBaud: 0.34 … 0.50 mm2

250 kBaud: 0.34 … 0.60 mm2

Cable capacitance 60 pF/m max.

Resistivity 500 kBaud: Max. 60 Ω/km.

250 kBaud: Max. 60 Ω/km.

Number of cores 2

Twisting CAN_L and CAN_H cables are twisted pairwise

Tab.6: Specification - CAN bus cable

Line lengths The maximum permitted cable length depends on the baud rate used and the

number of CANopen® devices connected.

Baud rate Max.

line length

Max. stub

line length

Total

line length

500 kBaud 100 m 5 m 30 m

250 kBaud 250 m 10 m 60 m

Tab.7: Line lengths

4.6.2 USB interface

INFO The USB port does not meet the immunity requirement of the E1 directive.

Therefore, use the USB port only for service purposes and not while the unit is in

operation.

Category Description

Supply unit 5 V, 500 mA max.

Data rate USB 2.0

High-speed type 480 MBaud max.

Protocol USB host interface

Line length limitation 30 cm

Tab.8: USB interface

4.6.3 Ethernet interface

Category Description

Socket M12 connector (female), 4-pin, D-coded

Bit rate 10, 100 Mbit/s

Number of ports 1

Auto-crossover Yes

Connection topology Single connector (M12)

Tab.9: Ethernet interface

Jetter AG Technical specifications | 4

JCM-501-E00 User Manual 13 / 59

4.6.4 RS-232 interface

Category Description

Baud rates Up to 115,200 baud 8N1

Connection topology 1x Deutsch connector socket

Tab.10: RS-232 interface

4.7 EMI values

The JCM-501-E00 has E1 approval according to ECE R10 Rev. 5 and CE con-

formity according to ISO 14982.

INFO The USB port does not meet the immunity requirement of the E1 directive.

Therefore, use the USB port only for service purposes and not while the unit is in

operation.

Pulses to ISO

7637-2

Test pulse Values Functional class

1 -450V C

2a +37V A

2b +20V C

3a -150V A

3b +150V A

4 Ua1: -12 V / 50 ms

Ua2: -5 V / 500 ms

A (24 V systems)

Ua1: -6 V / 15 ms

Ua2: -2.5 V / 1000 ms

C (12 V systems)

Tab.11: Pulses to ISO 7637-2

Irradiation to ISO

11452

Parameter Values Functional class

Protection against RF

noise

20 MHz ... 2 GHz 30 V/m A

Tab.12: Irradiation to ISO 11452

ESD EN 61000-4-2 ESD EN 61000-4-2 Values Functional class

Contact discharge ±4 kV (to conductive sur-

faces)

A

Discharge through air ±8 kV (to insulating sur-

faces)

A

Tab.13: ESD EN 61000-4-2

Jetter AG Mechanical installation | 5

JCM-501-E00 User Manual 14 / 59

5 Mechanical installation

NOTICE Damages to material or functional impairment

Welding on the chassis may cause damages to material of the device, or impair

its functions.

►Before you start welding, disconnect all connections between the device and

the electric system of the vehicle.

►Protect the device from flying sparks and welding beads (splatter).

►Do not touch the device with the welding electrode or earth clamp.

5.1 Requirements for the installation location

The installation location must meet the following requirements:

■The installation location must allow air to circulate.

■The installation location must be of sufficient size.

■The device must be easily accessible to allow for service work.

Space required for

installation and ser-

vice

It should be possible to disconnect the connectors at any time.

70

Fig.5: Space requirements for installation work (in mm)

Avoiding unsuit-

able installation lo-

cations

The following installation locations are unsuitable for mounting the device:

Unsuitable installation location Reason

Outdoor installation The device must not be exposed to rain

or a jet of water. Do not use a steam jet

or other such devices to clean the de-

vice.

Installation location close to heat-sensi-

tive materials

The materials could become warped or

misshapen as a result of heat produced

by the device.

Tab.14: Unsuitable installation locations

Jetter AG Mechanical installation | 5

JCM-501-E00 User Manual 15 / 59

5.2 Installing the control

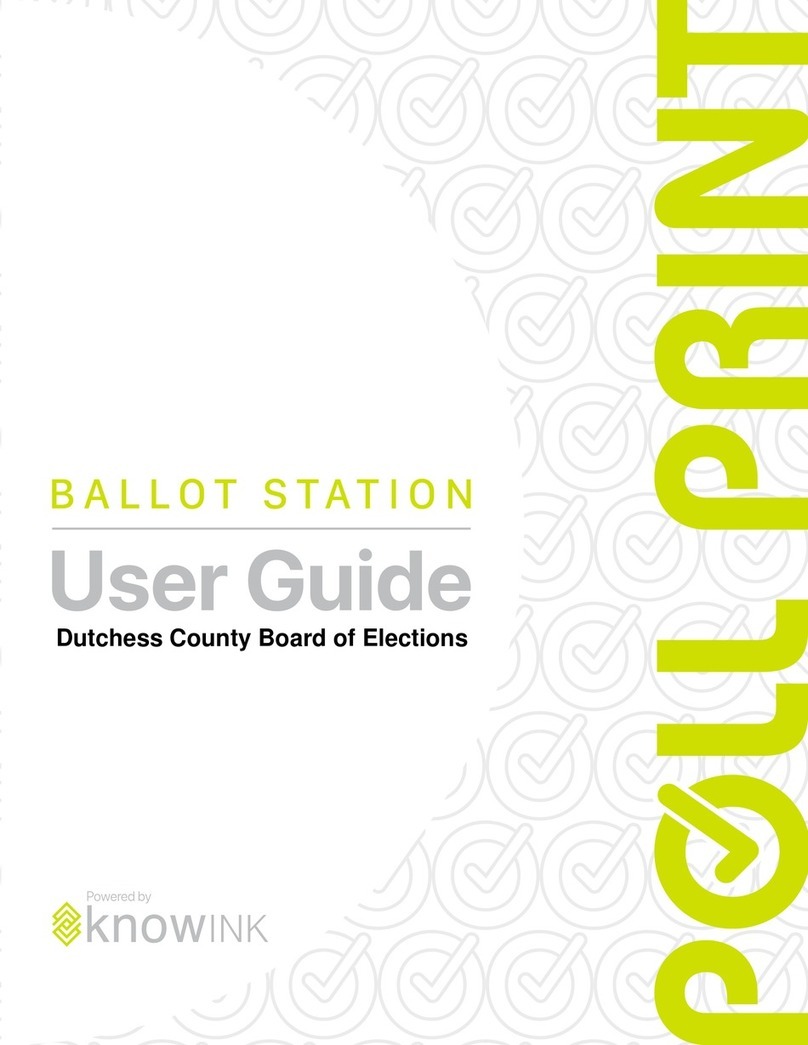

Screw holes

27.955

83

O3.1

4 x

Fig.6: All dimensions of screw holes are in millimeters.

Installing the strain

relief

Install strain reliefs for the connecting cables.

■Ensure that there is sufficient clearance between the strain reliefs and the con-

nectors.

■Connectors must not be obstructed, so that they can be removed in the event

of service.

Fig.7: Installing the strain relief

Jetter AG Electrical connection | 6

JCM-501-E00 User Manual 16 / 59

6 Electrical connection

NOTICE Damages to material or functional impairment

Improper implementation of the wiring harness may cause mechanical stress.

►Protect the cables from bending, twisting or chafing.

►Install strain reliefs for the connecting cables.

NOTICE Surges resulting from missing protection or fusing

Surges may cause malfunctions or damage to the product.

►Protect the voltage inputs from surges according to the requirements.

►Ensure that the device is handled in accordance with ESD regulations.

Jetter AG Electrical connection | 6

JCM-501-E00 User Manual 17 / 59

6.1 Pin assignment of Deutsch connector

Features The Deutsch connector has the following functions:

■Power supply to the JCM-501-E00

■CAN communication

■USB

■RS232

INFO Current consumption

When the JCM-501-E00 is energized, the current consumption is temporarily

higher. To ensure a reliable start-up of the device, provide at least 3 times the

typical current required.

1 6

712

Fig.8: Deutsch connec-

tor, 12 pins

12 CAN_2_H 1GND

11 CAN_2_L 2USB_+5V

10 CAN_1_H 3USB_D+

9CAN_1_L 4USB_D-

8RXD_RS232 5GND

7TXD_RS232 6VBAT_ECU

Mating parts Compatible mating parts for the 12-pin DEUTSCH connector are as follows:

Category Description

Manufacturer Deutsch

Manufacturer item num-

ber - Housing

DT06-12S

Manufacturer item num-

ber - Wedgelock

W12S

Manufacturer item num-

ber - Crimp contact (re-

ceptacle)

0-462-201-16141

Wire size range 1.0 ... 1.5 mm2(AWG 18 ... 16)

6.2 Pin assignment of M12 connector

Features The M12 connector has the following function:

■Ethernet communication

1

2

3

4

Fig.9: M12 connector, 4

pins

1TX+ 2TX-

3RX+ 4RX-

5n.c.

Jetter AG Programming | 7

JCM-501-E00 User Manual 18 / 59

7 Programming

7.1 Abbreviations, module register properties and formats

Abbreviations The abbreviations used in this document are listed in the table below:

Abbreviation Description

R 100 Register 100

MR 150 Module register 150

Tab.15: Abbreviations

Module register

properties

Each module register is characterized by certain properties. For many module

registers most properties are identical. For example, their value after reset is 0. In

the following description, module register properties are mentioned only if a prop-

erty deviates from the default properties listed below.

Property Standard design

Type of access Read/write

Value after reset 0 or undefined (e.g. revision/version number)

Takes effect Immediately

Write access Always

Data type Integer

Tab.16: Module register properties

Numerical formats The numerical formats used in this document are listed in the table below:

Notation Format of numerical val-

ues

100 Decimal

0x100 Hexadecimal

0b100 Binary

Tab.17: Numerical formats

JetSym sample pro-

grams

The notation for sample programs used in this document is listed in the table be-

low:

Notation Format of numerical val-

ues

Var, When, Task Keyword

BitClear(); Commands

100 0x100 0b100 Constant numerical values

// This is a com-

ment

Comment

// ... Further program processing

Tab.18: JetSym sample programs

Jetter AG Programming | 7

JCM-501-E00 User Manual 19 / 59

7.2 CANopen® STX API

CANopen® is an open standard for networking and communication, e.g. in the au-

tomotive sector. The CANopen® protocol has been further developed by the CiA

e.V. (CAN in Automation) and works on the physical layer with CAN Highspeed in

accordance with ISO 11898.

Specifications The CANopen® specifications can be obtained from the CiA e.V. homepage at

http://www.can-cia.org.

The key specification documents are:

■CiA DS 301 - This document is also known as the communication profile and

describes the fundamental services and protocols used under CANopen®.

■CiA DS 302 - Framework for programmable devices (CANopen® Manager,

SDO Manager)

■CiA DR 303 - Information on cables and connectors

■CiA DS 4xx - These documents describe the behavior of a number of device

classes in, what are known as, device profiles.

7.2.1 STX Functions

Application STX functions are used in the communication between the JCM-501-E00 and

other CANopen® nodes.

The JCM-501-E00 supports the following STX functions:

Features Description

CanOpenInit() The function CanOpenInit() lets you initialize

one of the CAN busses.

CanOpenSetCommand() The function CanOpenSetCommand() lets you

change the heartbeat status of the device itself and

of all other devices (NMT slaves) on the CAN bus.

CanOpenUploadSDO() The function CanOpenUploadSDO() lets you ac-

cess a particular object in the Object Directory of

the message recipient and read the value of the

object. Data is exchanged in accordance with the

SDO upload protocol.

CanOpenDownloadSDO() The function CanOpenDownloadSDO() lets you

access a particular object in the Object Directory of

the message recipient and specify the value of the

object. Data is exchanged in accordance with the

SDO download protocol.

CanOpenAddPDORx() By calling up the CanOpenAddPDORx() function,

process data, sent by other CANopen® devices,

can be entered for reception.

CanOpenAddPDOTx() By calling up the CanOpenAddPDOTx() function,

process data can be placed on the bus.

INFO Further information about STX functions can be found in the application-oriented

manual "CANopen® STX-API" on our homepage and in the JetSym online help.

Jetter AG Programming | 7

JCM-501-E00 User Manual 20 / 59

7.2.2 Heartbeat monitoring

The heartbeat protocol is for monitoring the activity of communication partners. If

the inactivity exceeds the set interval (Heartbeat consumer time), the status is set

to "offline".

The application program lets you define heartbeat functions, such as

■Displaying information to the user

■Rebooting the device

■Ignoring process data

INFO Further information about this subject can be found in the topic "Heartbeat moni-

toring" in the application-oriented manual "CANopen®-STX-API" on our home-

page.

7.2.3 CANopen® Object dictionary

The operating system of the JCM-501-E00 supports the following objects:

Index

(hex)

Object

(code) Object name Data type Type of

access

1000 VAR Device type Unsigned32 RO (read

only)

1001 VAR Error Register Unsigned8 RO

1002 VAR Manufacturer status Unsigned32 RO

1003 ARRAY Pre-defined error field Unsigned32 RO

1008 VAR Manufacturer

Device Name

String const 1008

1009 VAR Manufacturer

Hardware Version

String const 1009

100A VAR Manufacturer

Software Version

String const 100A

100B VAR Node ID Unsigned32 RO

1017 VAR Producer

Heartbeat Time

Unsigned16 R/W

(read &

write)

1018 RECORD Identity Identity RO

1200 RECORD Server 1 -

SDO parameter

SDO

parameter

RO

1201 RECORD Server 2 -

SDO parameter

SDO

parameter

R/W

1203 RECORD Server 3 -

SDO parameter

SDO

parameter

R/W

1203 RECORD Server 4 -

SDO parameter

SDO

parameter

R/W

INFO Further information about this subject can be found in the topic "CANopen® Ob-

ject Directory" in the application-oriented manual "CANopen® STX-API" on our

homepage.

Table of contents

Other Jetter Data Logger manuals