8

4Precautions for Usage

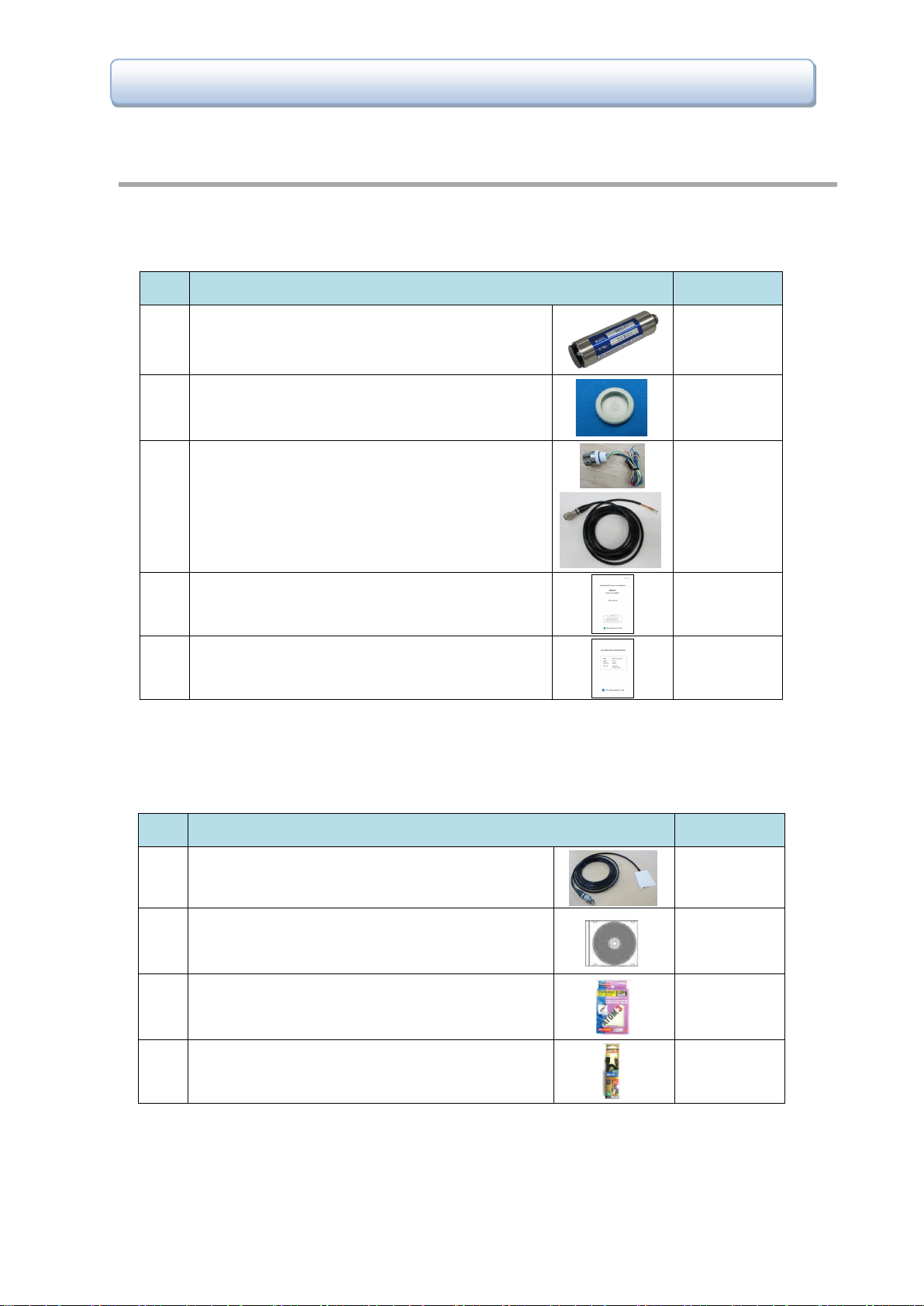

Use of instrument4.1

(1) After every use, clean with fresh water, remove moisture with a soft cloth, and store securely.

(2) The oxygen detection film is highly delicate and requires handling with care. Significant damage causes

inaccurate data and requires a replacement of the oxygen detection film.

(3) When not in use, place the protection cap and turn off the power supply.

(4) Do not drop the instrument or apply impact.

(5) Before touching the instrument, release static electricity by touching a metal.

(6) As storage location, avoid places with temperature above 40 °C, high humidity, or high amount of dust.

(7) If the instrument was not used for a long time, inspect each part before connecting to the power supply.

(8) When using the instrument in water, it is recommended to use it at 30 °C or below. When it is used in

water at 30 °C or above, the tracking for correction of temperature change can slow down, requiring

more time to resume to the normal value.

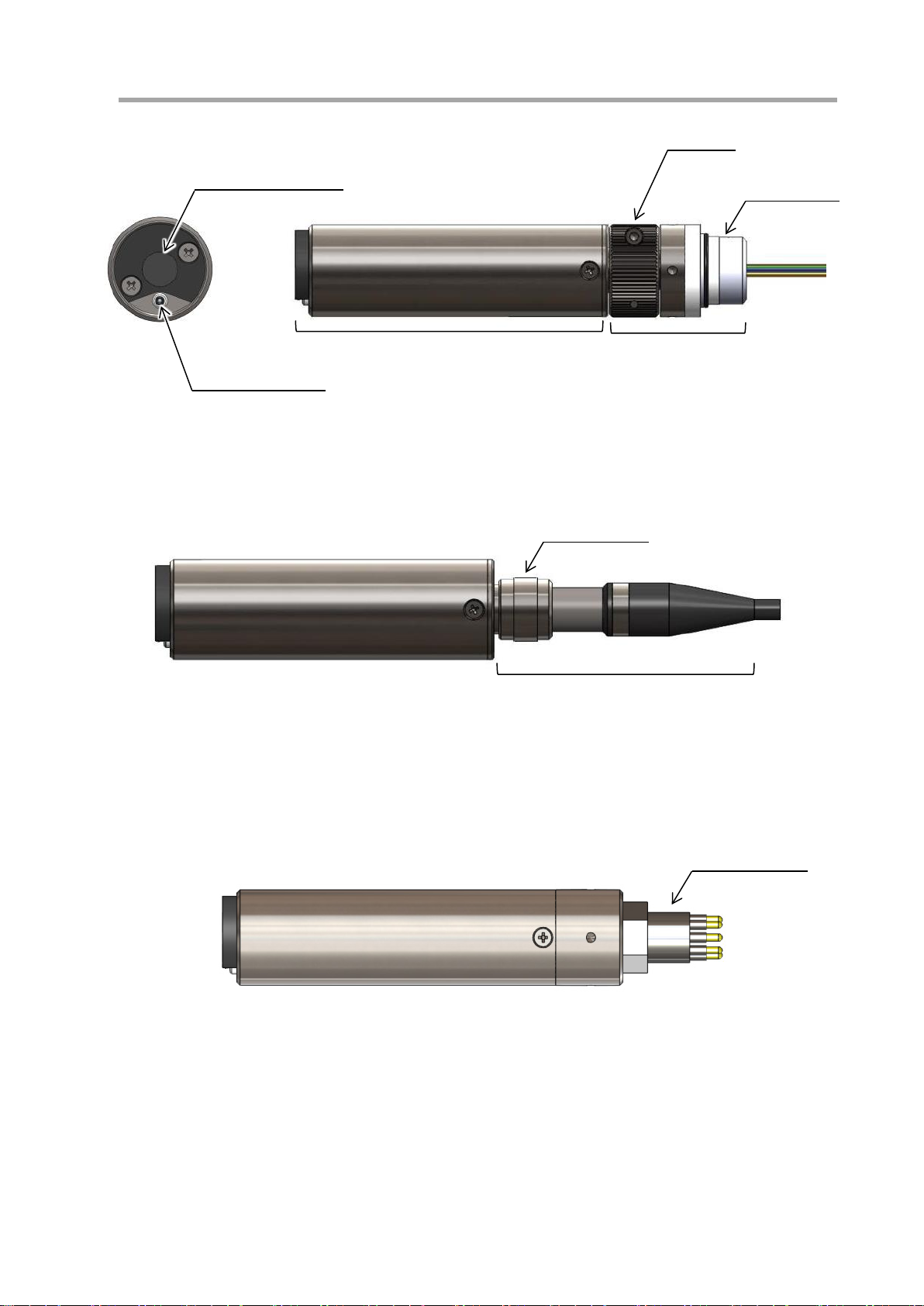

(9) The insulation screw is for preventing electrolytic corrosion due to contacts between different metals.

Software4.2

(1) It is prohibited to copy or reproduce part or whole of the software without JFE Advantech’s written

approval.

(2) The content and specifications may change without notice.

(3) We try our utmost to comprehensive content, but please contact JFE Advantech for any suspicion or

suggestions.

(4) In this user’s manual, Microsoft Windows 7/8/8.1 is used for demonstrations. Computer’s control

display or method may be different depending on the environment used.

Disposal4.3

When disposing of this product, ensure to abide by law and regulations.