小牛电动

Niu Electric

Maintenance Information

The maintenance and reparation information contained in this manual is for technical specialists only.

Maintenance or reparation performed by those who are not trained properly and provided with

appropriate tools and equipment may cause injuries to themselves or others and also lead to damages

or unsafe conditions of the scooter.

The proper maintenance and reparation procedures, some of which require special tools and equipment,

are described in this manual. The risks in terms of personal safety and scooter operation safety, which

may be resulted from the use of components, maintenance procedures or tools not recommended by

Niu, must be verified.

Please make replacement with original electric components made by Niu or equivalents that have

corresponding part numbers. We strongly recommend you not to use inferior components.

Customer Safety Notice

The proper maintenance is crucial for customer safety and scooter reliability. Any errors or omissions in

scooter maintenance may result in operating malfunctions, scooter damages or injuries.

Improper maintenance or reparation may lead to unsafe conditions under which serious injuries or even

death of your customers or other people may be incurred.

Please carefully follow the procedures and cautions in this manual and other maintenance materials.

Personal Safety Notice

This manual is used only by professional maintenance technicians, and the warning information about

multiple basic workshop safety operation procedures (such as the procedure that requires gloves when

working on hot components) is not set forth herein. We recommend you not to carry out procedures

specified in this manual without readiness if you have not received the workshop safety training or

grasped the knowledge about maintenance safety specifications.

The following are listed as several most importance general notes to maintenance safety. However, we

are unable to set forth the warning for each of risks that may arise from maintenance and reparation

procedures. You have to determine at your discretion whether a detail task should be implemented.

Failure to properly follow relevant instructions and notes may result in serious injuries or even death.

Please carefully follow procedures and notes in this manual.

Importance Safety Notes

Make sure that you have completely understood basic workshop operation safety procedures and taken

on proper protective clothes and are provided with safety equipment. Extra attention should be paid to

the following in the implementation of a maintenance task:

Read all the relevant instructions before operation, and make sure that you have necessary tools, spare

parts, components and skills to implement a maintenance task safely and completely.

There are high-voltage circuits in the scooter system, which can cause electric shock. It must be verified

that your maintenance site, tools, protective equipment and operation procedures are in compliance with

the insulation requirement.

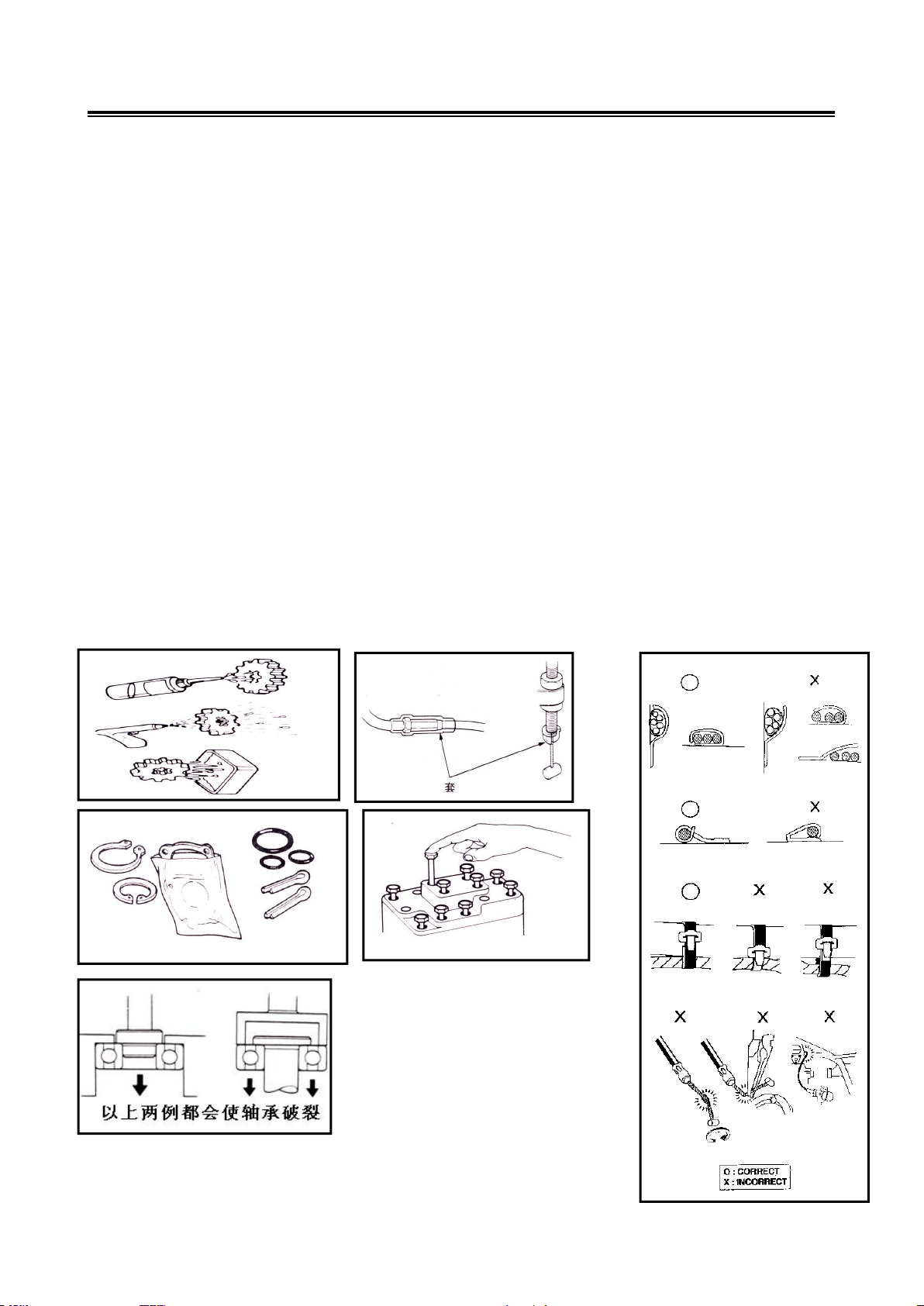

Eyes should be protected with proper safety glasses, goggles or masks in operations such as

hammering, drilling, polishing or prying or working around high-pressure air or liquid tanks, springs or

other energy storage components. Eye protection devices should be worn as long as there are

suspicious conditions.