15. USE RECOMMENDED ACCESSORIES. Consult the instruction manual for recommended accessories. The use

of improper accessories may cause risk of injury.

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. On machines with magnetic contact starting switches

there is a risk of starting if the machine is bumped or jarred. Always disconnect from power source before adjusting or

servicing. Make sure switch is in OFF position before reconnecting.

17. MANY WOODWORKING TOOLS CAN "KICKBACK" THE WORKPIECE toward the operator if not handled

properly. Know what conditions can create "kickback" and know how to avoid them. Read the manual accompanying

the machine thoroughly.

18. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged should be properly repaired or replaced.

19. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. DO NOT leave tool until it comes to a

complete stop.

20. NEVER OPERATE A MACHINE WHEN TIRED, OR UNDER THE INFLUENCE OF DRUGS OR ALCOHOL. Full

mental alertness is required at all times when running a machine.

21. NEVER ALLOW UNSUPERVISED OR UNTRAINED PERSONNEL TO OPERATE THE MACHINE. Make sure

any instructions you give in regards to the operation of the machine are approved, correct, safe, and clearly

understood.

Additional Safety Instructions for Panel Saws

1. SAFETY ACCESSORIES. Always use the blade guard and riving knife on all ''through-sawing'' operations.

Through-sawing operations are those when the blade cuts completely through the work- piece.

2. KICKBACK. Be familiar with kickback. Kickback happens when the work-piece is thrown towards the operator at a

high rate of speed. Until you have a clear understanding of kickback and how it occurs, DO NOT operate this table

saw!

3. WORKPIECE CONTROL. Make sure the work-piece is placed in a stable position on the table and is either

supported by the rip fence or the crosscut table during cutting operations.

4. PUSH STICK. Always use a push stick when ripping narrow stock.

5. OPERATOR POSITION. Never stand or have any part of your body directly in-line with the cutting path of the saw

blade.

6. REACHING OVER SAW BLADE. Never reach behind or over the blade with either hand while the saw is running. If

kickback occurs while reaching over the blade, hands or arms could be pulled into the spinning saw blade.

7. USING THE RIP FENCE AND THE CROSSCUT FENCE TOGETHER DURING A CUTTING OPERATION. When

using the crosscut fence, the work-piece should never be contacting the rip fence while the saw blade is cutting.

8. STALLED BLADE. Turn the saw off before attempting to "free" a stalled saw blade.

9. COMFORTABLE CUTTING OPERATIONS. Avoid awkward operations and hand positions where a sudden slip

could cause your hand to move into the spinning saw blade.

10. EXPERIENCING DIFFICULTIES. If at any time you are experiencing difficulties performing the intended operation,

stop using the machine! Contact your agent.

11. BLADE HEIGHT. Always adjust the blade to the proper height above the work-piece.

12. DAMAGED SAW BLADES. Never use blades that have been dropped or otherwise damaged.

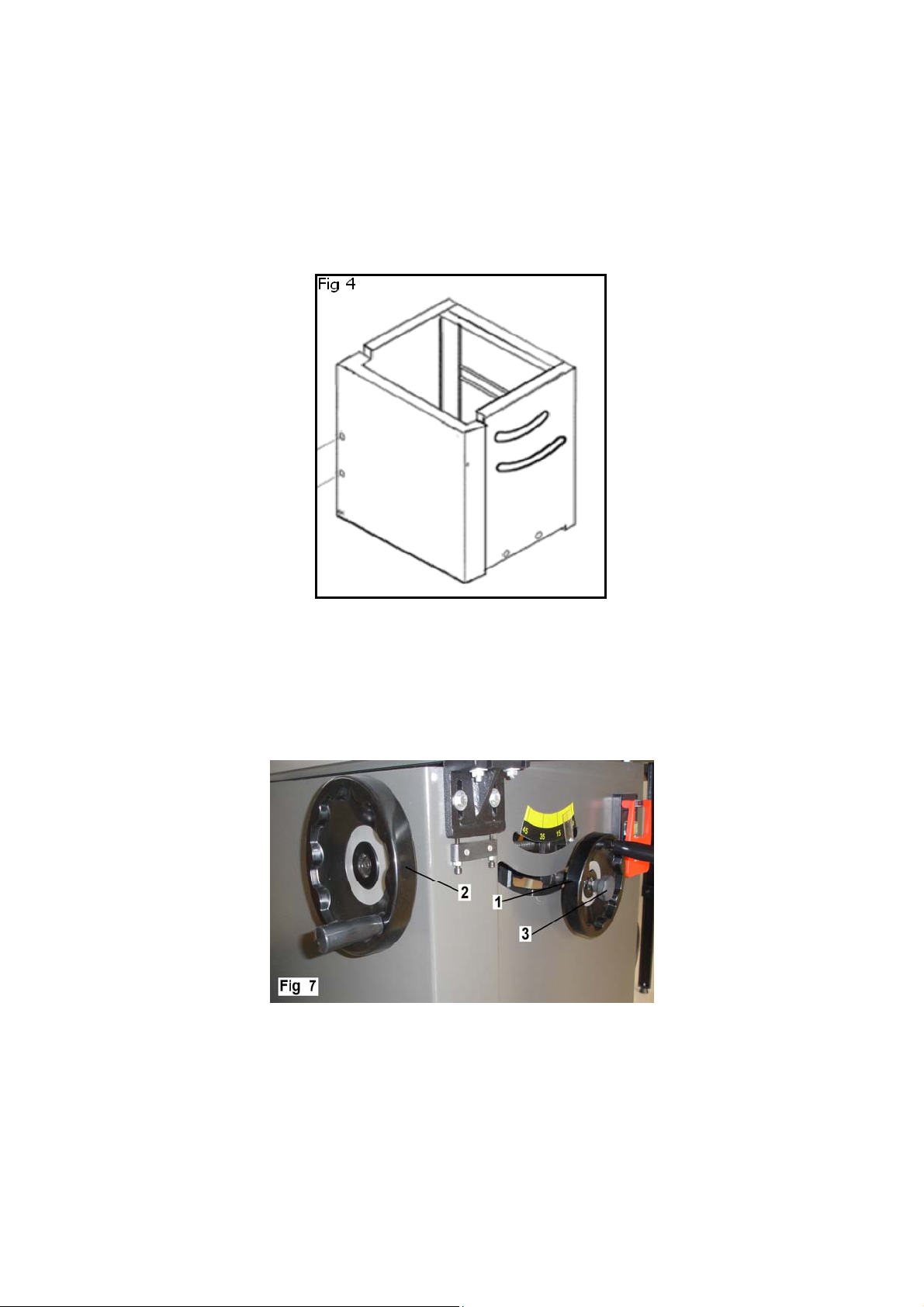

13. RIVING KNIFE ALIGNMENT. Only operate the saw if the riving knife is aligned with the main blade.

Like all machines there is danger associated with this Sliding Panel Saw. Accidents are

frequently caused by lack of familiarity or failure to pay attention. Use this machine with respect

and caution to lessen the possibility of operator injury. If normal safety precautions are

overlooked or ignored, serious personal injury may occur.