Townsend Freestanding Townsend Freestanding

Jindara Townsend Installation

!WARNING

THE INSTALLATION OF THIS APPLIANCE MUST BE CARRIED OUT AS PER THIS

MANUAL AND THE FLUE MANUFACTURER’S SPECIFICATIONS.

WE RECOMMEND THAT YOU USE A QUALIFIED INSTALLER TO CARRY OUT

THE INSTALLATION OF THIS APPLIANCE.

EXTREME CARE SHOULD BE TAKEN WHEN HANDLING THE APPLIANCE.

If you have any other enquiries regarding installation of the appliance, please

contact the dealer from whom you purchased the heater.

Installation

Scope Of Installation Specifications

The Jindara Townsend is tested in accordance with the requirements of AS/NZS 2918:2018 for the congurations

and ue types specied in this manual. Any installation that falls outside of the specications in this manual other than

the addition of bends or extensions to the ue, is considered to be an untested installation as per AS/NZS 2918:2018.

AF Gason Pty. Ltd. accepts no liability whatsoever for the safety of installations under such circumstances.

AF Gason Pty. Ltd. accepts no liability whatsoever for any interpretation of AS/NZS 2918:2018.

It is important that you understand these installation instructions and minimum clearances to combustible

materials before selecting a position for your wood heater, to ensure a safe and correct installation is achieved.

Installation Permit

Depending on your local authority requirements, a permit may be required for the installation of your heater. It is your

responsibility to arrange the same.

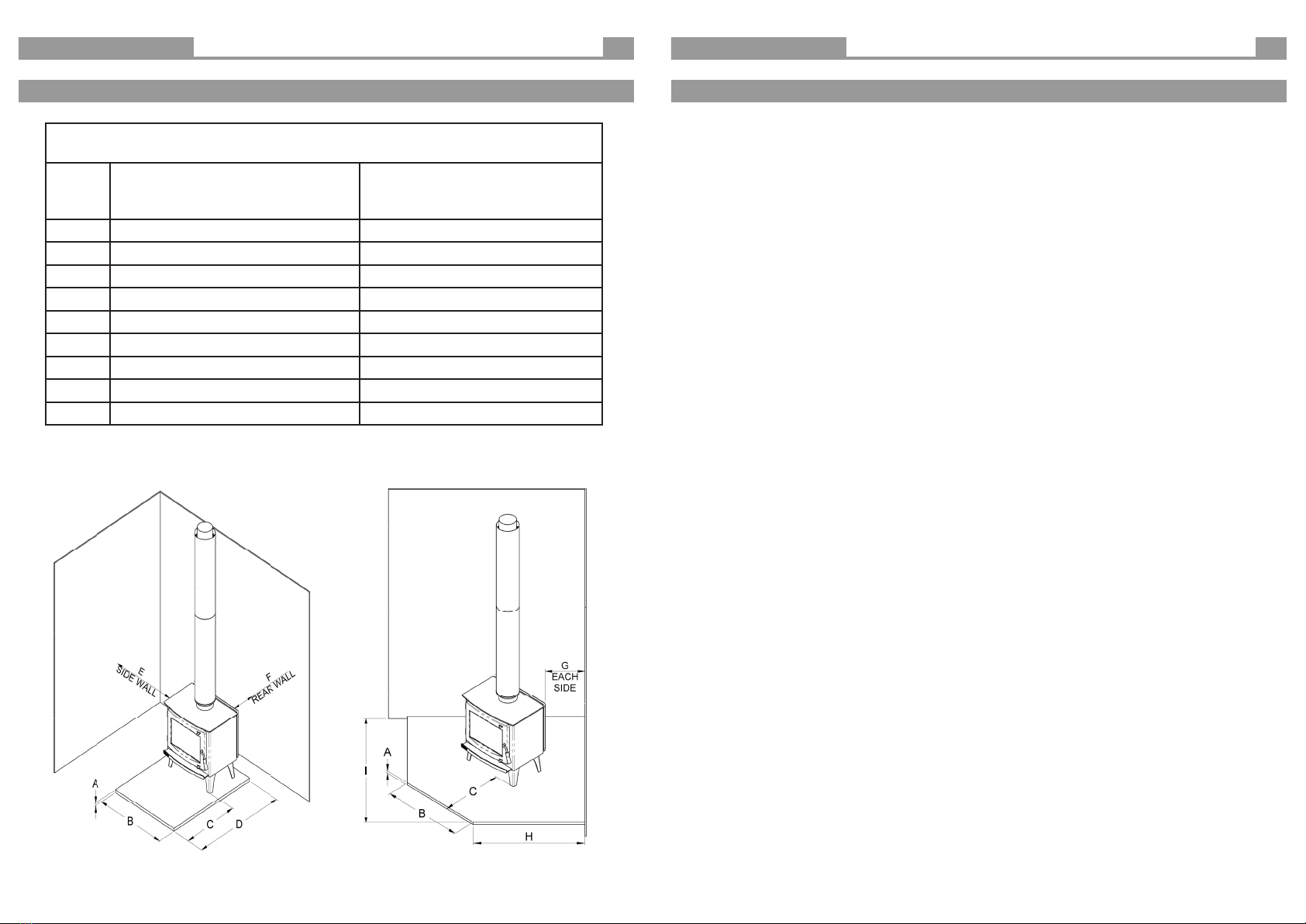

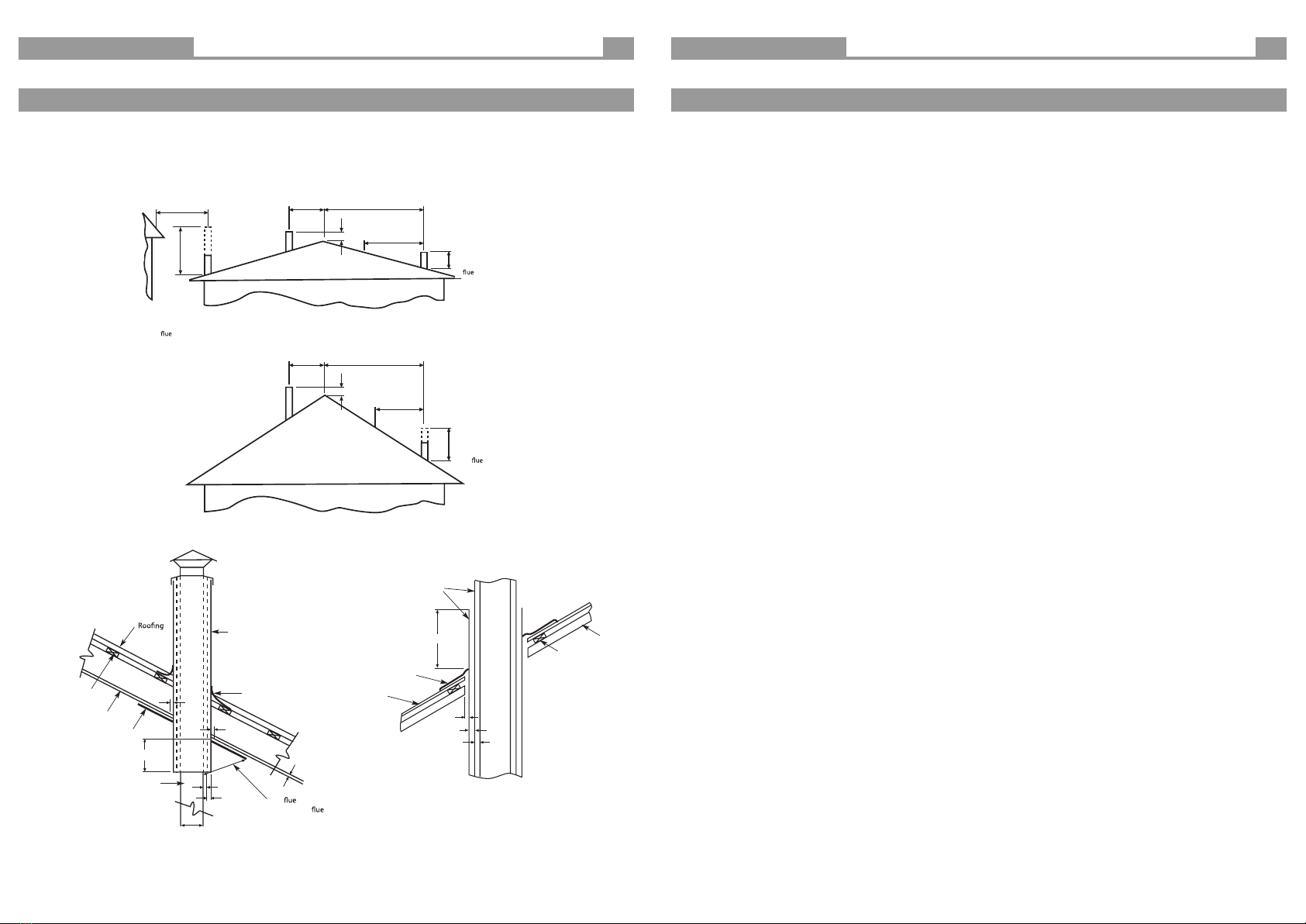

Flue Requirements

As per the dimensions in Table A (referencing gures 1 and 2), the Jindara Townsend must be installed with either of the

following ue types:

• Standard 6” Decromesh Default Flue Kit incorporating an additional 900mm high x 180 degree stainless steel rear

ue shield tted between the Decromesh and the active ue, or

• 6” Half shield Default Kit (Double Sleeve Flue Kit).

NOTE THAT INSTALLATION CLEARANCES ARE DIFFERENT FOR EACH FLUE TYPE.

The ue system installed with the Jindara Townsend must comply with Australian and New Zealand installation stan-

dards AS/NZS 2918:2018, and be installed to the ue manufacturer’s instructions.

The performance of your heater is highly dependant on an eective ue system. In many cases, poor start-up, dirty

glass, down draft causing smoke spillage when the door is open, and reduced heat output, can all be caused by the ue

system being too short or incorrectly installed. Excessive ue length is also undesirable, as it can cause excessive ue

draft, resulting in short burn times and over-ring of the heater.

Clearance To Combustibles

The Jindara Townsend conforms to AS/NZS 2918:2018 when positioned in relation to combustible surfaces as specied

in Table A (referencing gures 1 and 2), and as per these instructions. The gures shown state the minimum distance the

heater can be placed in relation to any combustible materials - plaster, wallpaper, timber, MDF, etc.

In the instance that your Jindara heater is surrounded by non-combustible materials - brick, stone, concrete, cement

sheet or similar, wall clearances can be reduced to 50mm. A 50mm clearance is required to ensure room air can circulate

around the wood heater during operation.

For further information regarding installation of your heater, please contact the Jindara dealer from whom you

purchased the heater.

Hearth & Floor Requirements

If the Jindara Townsend is to be installed onto a combustible oor, a cement sheet or similar non-combustible hearth

or oor (as per specications on page 3) protector must be placed in between the appliance and the combustible oor.

Minimum hearth requirements are specied in Table A (referencing gures 1and 2).

If the heater is to be installed onto a non-combustible surface that meets the minimum oor protector requirements

specied, an additional oor protector may not be required.

13 2

Troubleshooting + tips

• Air Controls Jamming

• Check that there are no visible physical obstructions to the air slides, such as charcoal or wood.

• Try freeing the air slide using WD-40, or a similar lubricant. It may be necessary to remove the air plates and gain

access to the air slides, in order to clean out any debris or contamination contributing to the jamming.

• Heater Emitting Smoke

• It is normal for your wood burning heater to emit a certain amount of smoke when the door is opened during

operation. Smoke will move in the path of least resistance as it rises from the re, and when your heater door is

opened, the opening becomes that path of least resistance.

• It is important that you adhere to the instructions in this manual, and that the heater is operated with the door

closed at all times, except for when you are lighting the re, or refuelling.

• A sluggish or lazy re will generate more smoke than an active hot re. If you have shut your re down for a long

burn, more smoke will be generated when you open the door.

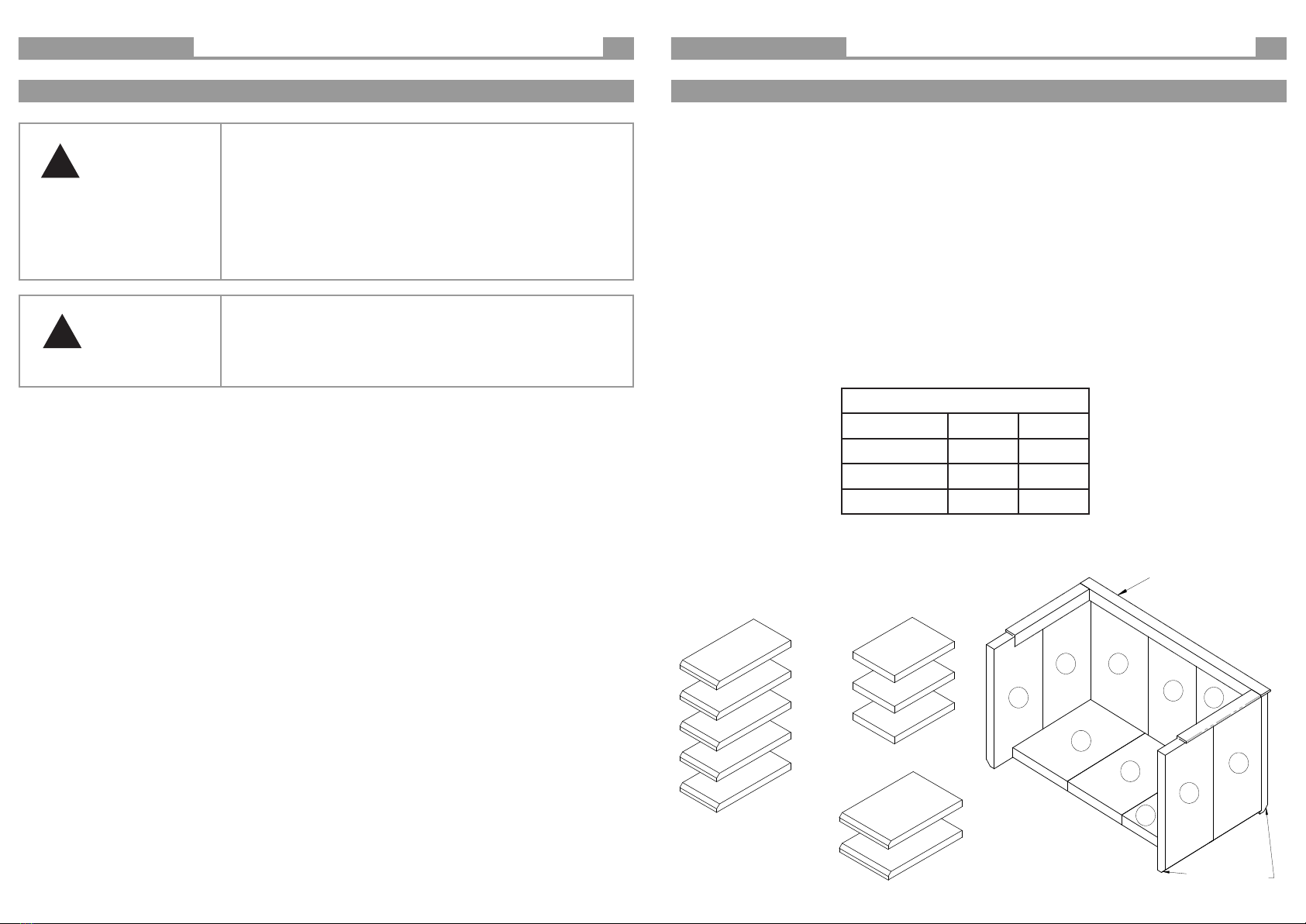

• If you nd that your re is emitting noticable amounts of smoke into the room during normal operation, or

excessive amounts of smoke when the door is opened, check that the baes are correctly tted and in good

condition, and that there are no other visible defects with the heater. If there is no problem found with the heater

itself, there is more than likely a problem with your ue system and you should have it inspected by a plumber

for blockages or downdraft.

• No Overnight Burn

• Check that the air slides are not stuck open, and that the upper and lower air plates are xed securely to the door.

• Ensure that the baes are correctly installed and are free from any damage.

• Ensure that the door rope is sealing against the door opening, all the way around the door opening. This can be

checked by placing a strip of paper between the door and the rebox and closing the door, then checking to see

if the paper is clamped in place or free to move. If the paper is free to move, you will need to inspect your door

seal and either replace the rope or adjust your door catch.

• Ensure that you have a reasonable ash bed in the base of your rebox. The ash bed acts as a heat store, and helps

to maintain hot coals once the re has burnt low.

• Ensure that you are loading your re with good quality hardwood, and in sucient quantities for an overnight

burn. You should try to ll the rebox as much as possible when loading for an overnight burn, with large logs at

least 15cm in diameter.

• Round logs with smooth outer surfaces tend to take longer to burn when compared to logs that have been split

from larger pieces and have exposed rough surfaces.

• Excessive Ash Build Up

• Dierent types of wood will generate dierent amounts of coals and ash, depending on its composition and on

how you use the heater. Given the variety of wood available in Australia, you will need to determine which wood

is available to you that best suits the heater.

• All testing and certication for wood heaters sold in Australia is carried out using seasoned River Red Gum,

which is an energy dense hardwood. Red Gum burns hot with large coals that reduce to very little ash, and is the

recommended wood in ideal circumstances.

• Depending on what wood is available to you, you may nd that your rebox builds up with ash more quickly than

desired. This is unfortunately a function of the wood being burnt, not the heater itself.

• Ensure your wood is well seasoned and not overly sappy. Good hardwood with moisture content below 16% is

ideal.

• Burning bark will generate excessive ash, try to avoid burning it.

• Consistently running your re with the air slides shut down will generate excessive coals and ash, as well as

creosote build up. Burning a hot re will help to reduce these back down after a couple of cycles.