Tilga Insert 14 Tilga Insert 3

Installation

WARNING

!

Installation THE INSTALLATION OF THIS APPLIANCE MUST BE CARRIED OUT AS PER THIS

MANUAL AND THE FLUE MANUFACTURER’S SPECIFICATIONS.

WE RECOMMEND THAT YOU USE A QUALIFIED INSTALLER TO CARRY OUT

THE INSTALLATION.

If you have any other enquiries, please contact the dealer from whom you

purchased your heater.

THIS APPLIANCE WEIGHS IN EXCESS OF 200 KILOGRAMS. EXTREME CARE

SHOULD BE TAKEN WHEN HANDLING THE APPLIANCE.

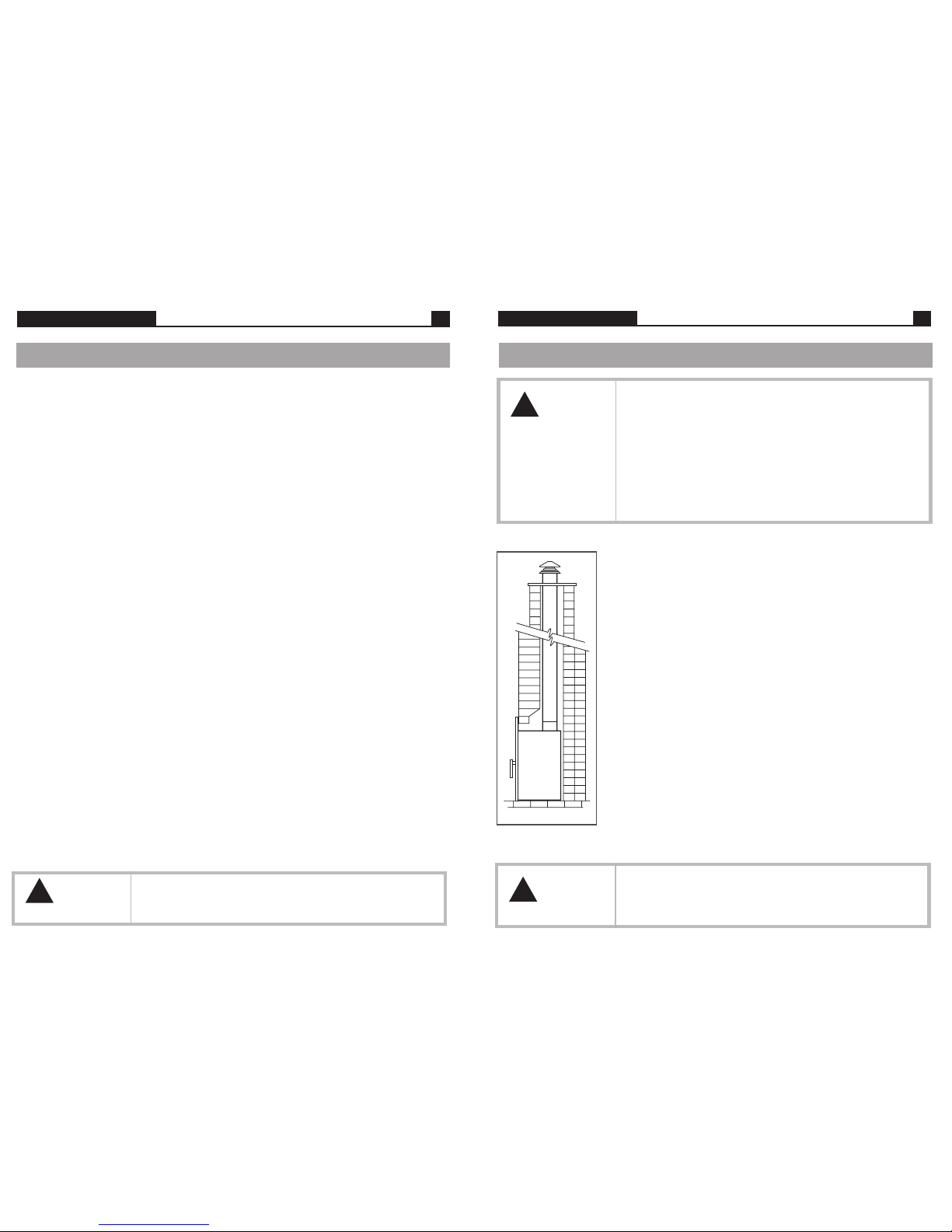

This heater is to be installed into a masonry replace or a Jindara Zero

Clearance Cabinet.

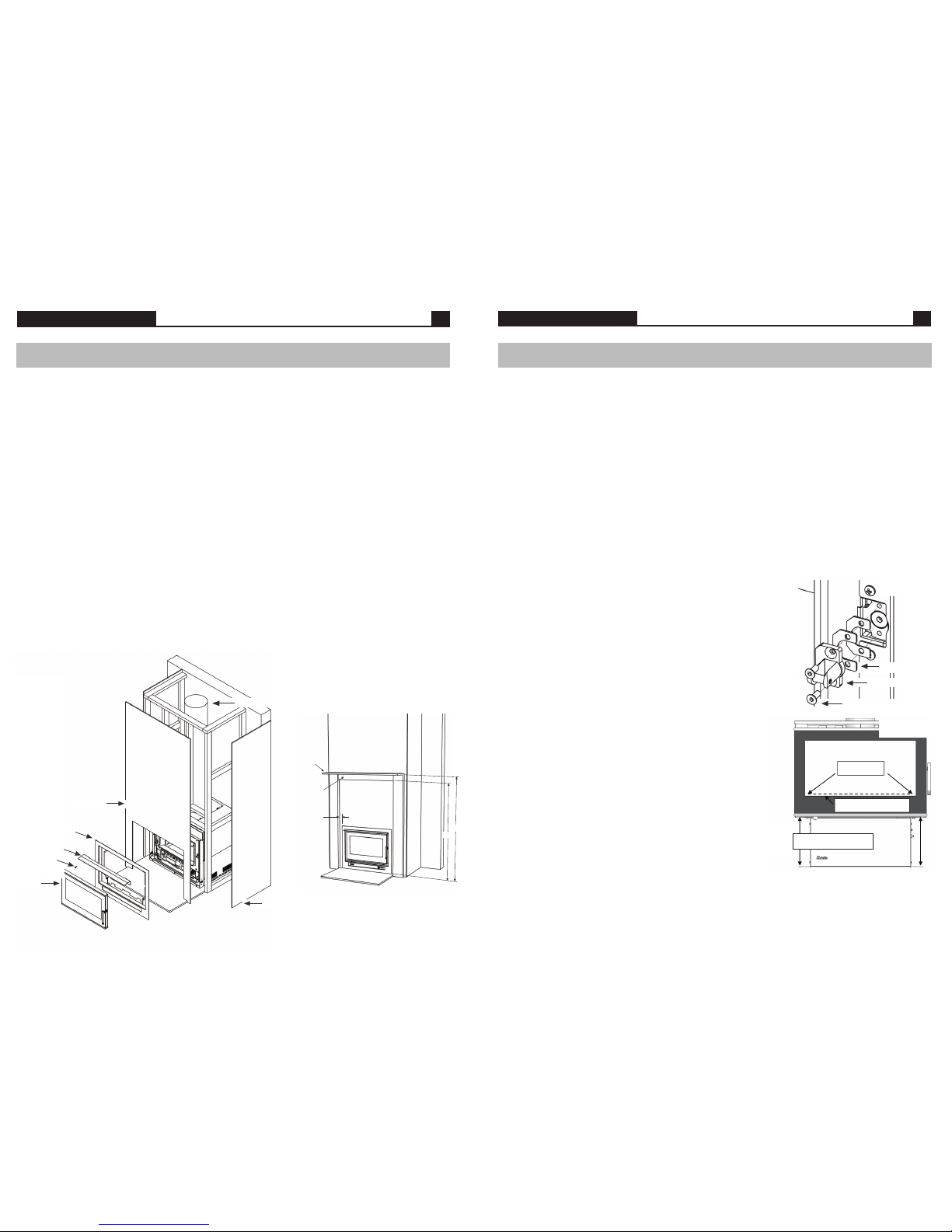

Section showing Installation

Figure 1. Masonry Installation

WARNING

!

Brick Removal

IF BRICKS REQUIRE REMOVAL WHEN PREPARING THE FIREPLACE, ENSURE

THAT YOU DO NOT EXPOSE COMBUSTIBLE MATERIALS BEHIND THE

BRICKWORK OR WEAKEN THE INTEGRAL STRUCTURE OF THE CHIMNEY.

AF Gason Pty. Ltd. accepts no liability whatsoever for any interpretation of AS/NZS 2918:2001.

It is important you understand these installation instructions and minimum clearances to

combustible materials before selecting a position for your Jindara Tilga, to ensure safe and

correct installation is achieved.

Installation permit

Depending on your local authority requirements, a permit may be required for the installation

of your heater. It is your responsibility to arrange the same.

Installation into existing or masonry replace

The Jindara Tilga Insert can be installed into a masonry replace with a ue system that is in

accordance with the relevant sections of AS/NZS 2198:2001. No combustible or heat sensitive

material maybe placed closer then 1410mm from the top of the hearth/base of the appliance

and 55mm either side of the appliance’s fascia.

In a masonry replace installation, the minimum hearth depth of 550mm from the front of

the fascia panel must be achieved. In the instance the replace is raised above a combustible

oor, and it is desirable to reduce the hearth depth, please refer to the elevated installation

instructions on page 5 for hearth reduction information.

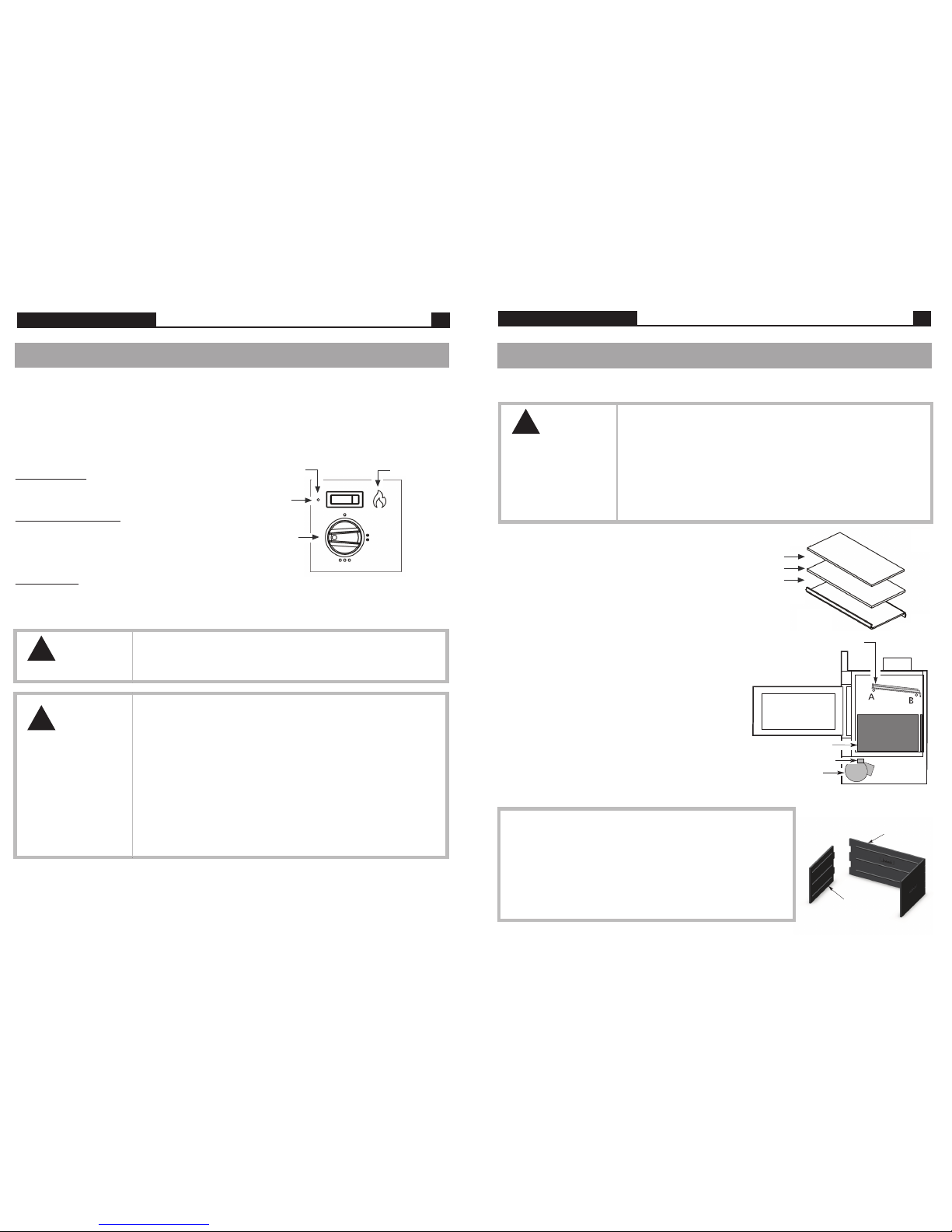

For detailed mantle clearance dimensions, refer Figure 5 on page 6.

If installing the Jindara Tilga under a combustible mantle, a hot air deector must be attached

onto the front of the fascia.

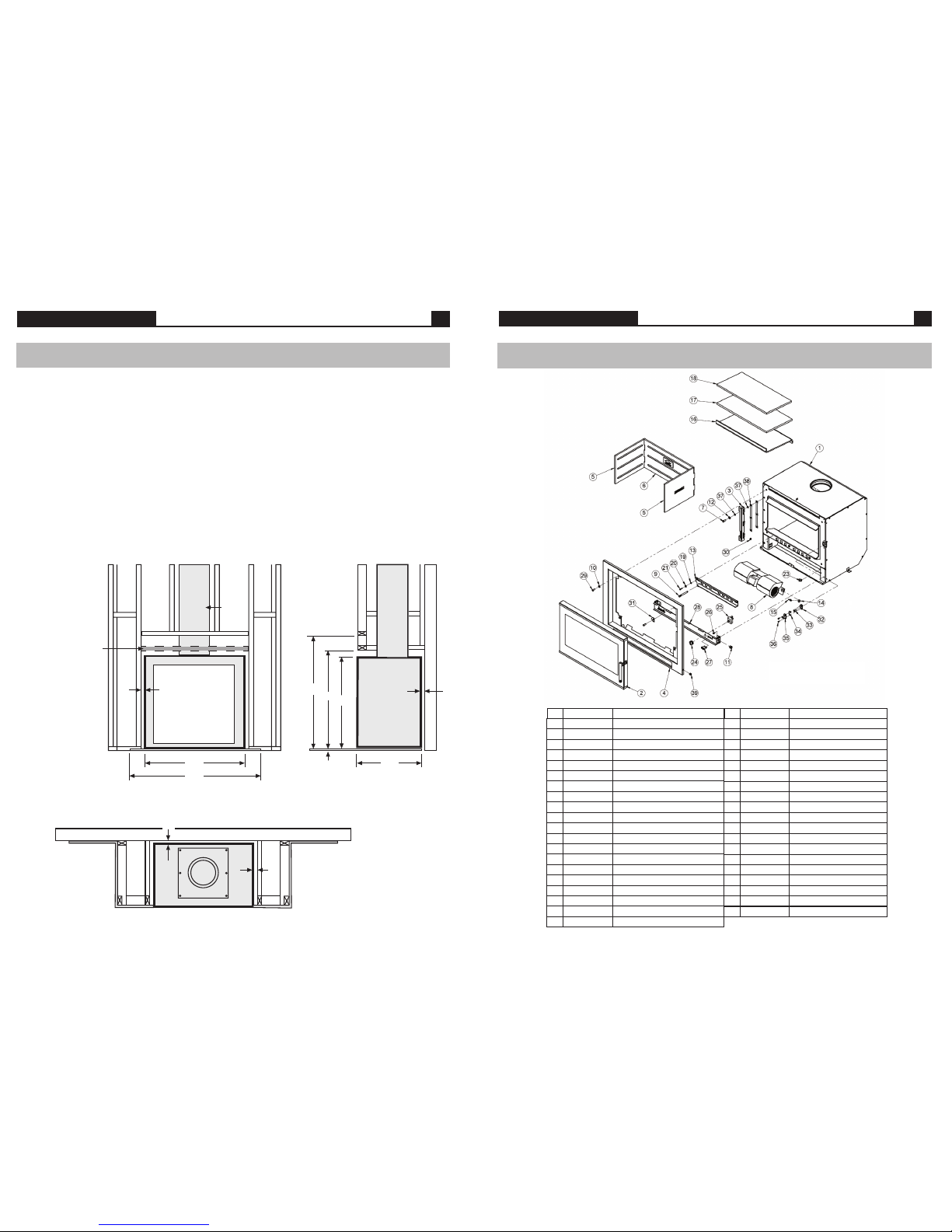

Installation into Zero Clearance Cabinet - ZCC

The Jindara Tilga Insert can be installed in conjunction with a Jindara ZCC into a wall enclosure

directly onto a oor or elevated above a oor.

The Jindara Tilga Insert conforms to AS/NZS 2918:2001 Appendix B, when the appilance is

placed in relation to combustible surfaces as per these installation instructions.

For additional clearance details, or access to the Jindara Tilga Insert Conformance Certicate,

please contact your local Jindara Dealer from whom you purchased your heater.

Installation

Operating your Eureka

Troubleshooting

• Noisy Fan

Turn the power o and remove the three pin plug from the power point. Remove door and carefully place to one side.

Remove the four M8 Cap Screws that hold the fascia onto the rebox. Remove the fascia. Remove switch mount panel.

Disconnect the wiring loom via the plastic joiner. Unscrew the wing nuts which hold the fan in position and remove

the fan. Clean any dust with a dry paint brush and vacuum the fan blades. Clean around the motor.After completion

place two or three drops of sewing machine oil on the shafts at the bearings. Replace the fan in reverse to the removal.

•Fan not working

are rmly connected. If the fan still fails to function, remove the fan and switches by rstly removing knob o the rotary

switch by pulling it away from the heater. Undo the holding nut and pull the switch out.

Squeeze locator tabs together on the rear of the thermostat switch and push through outside of pedestal.

Disconnect the wiring from the power lead and remove the fan. Convey the same to the authorised Jindara Dealer from

whom you purchased your unit for service.

Replace in the reverse order.

• Air control jamming

Access to the air slide is available when the door is opened.

There are three screws holding the air slide in place. Undo them and remove the air slide.Wipe any ash or dust that may

have accumulated on the back of the air slide or on the face of the heater. If any burrs have developed on the back of the

air slide or on the face of the heater, rub them o with ne wet and dry sand paper till you have a smooth surface and

edges. Replace the air slide and make sure the washers and spacers are on the bolts when you screw the bolts back into

the face of the heater. Do not apply any type of lubricant to the air slide whatsoever as this will attract dust and make the

slide stick.

• No overnight burn

Remove the air slide as per air control jamming and check that the air slide is hard against the face of the heater. If it is

loose, tighten up the bolts holding the air slide to the face of the heater. Do not overtighten.

Check that the door rope has an even indentation from its contact with the face of the rebox. If it is uneven

and it appears as though air could leak through the seal,the door hinge and latch can be adjusted or the door rope may

need to be replaced. Refer door adjustments and rope replacement instructions.

WARNING

!

Overring

NEVER OPERATE THE HEATER WITH THE DOOR LOOSE, OR SUCH THAT THE FIREBOX

IS NOT AIR TIGHT. OVERFIRING COULD RESULT IN DETRIMENTAL WEAR AND TEAR

ON THE FIREBOX AND FLUE SYSTEM.

Check the power connection with another appliance. If the power point is ok, shift focus to the fan or the switches.

Move thermostat switch into the ‘Override’ position, and select one of the three fan speeds. If the fan fails to function,

isolate power as above, remove fascia to gain access to loom. Check that the terminals on the loom and both switches

• Excessive ash build up

Some woods will give large amounts of ash despite how you run the heater. Others will give you very little. Use the wood

which is most convenient for you as long as it is dry. After a period of time you will get to know when to empty your unit.

Bark will give you excessive ash. Try not to burn it. If you are burning wood that gives you charcoal, you may nd that after

running the heater say for 8 hours at maximum burn rate, the charcoal builds up excessively. An overnight burn will reduce

this charcoal back to a ne ash. If you are not ready to shut down for an overnight burn when you next fuel the stove, load the

stove with only one piece of wood and lay it across the rebox on top of the charcoal. Open the air control wide open and

you will nd the charcoal will burn down with the one piece of wood. Repeat the process until the ash level is signicantly

reduced.

• Excessive smoking - smoke entering the room maybe caused by:

• Insucient length of ue (Flue to be 4500mm minimum underneath the base of heater to underside of cowl)

Increase height of ue

• Flue downdraught - Consult dealer or increase height of ue.

• Creosote build up in ue - Remove cowl and clean ue as per cleaning instructions. Check moisture content of

wood.