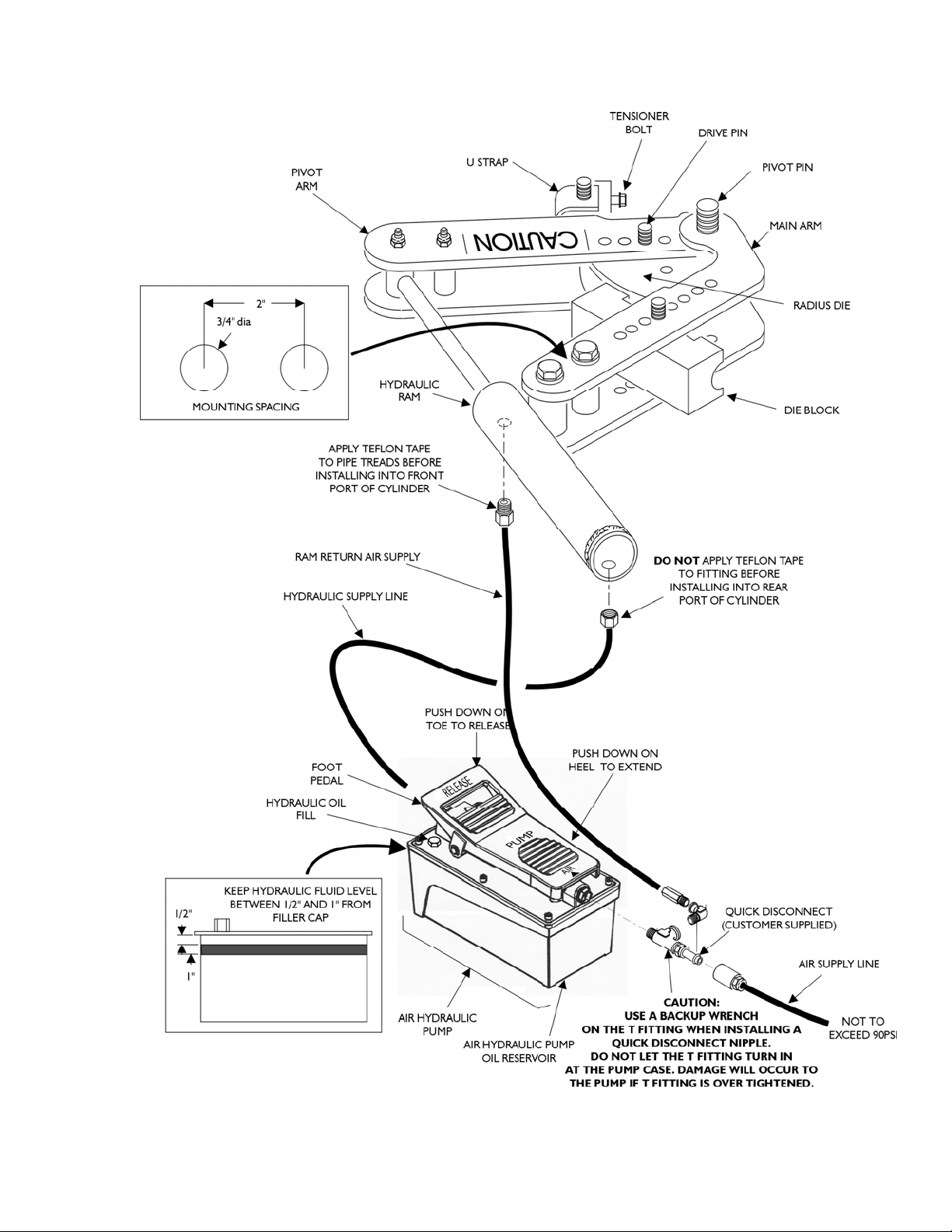

7. Using the foot control valve, extend the ram (down on the heel portion of the

foot valve. See Figure 1.) to the full stroke (or as needed for shorter bends).

WARNING

DO NOT hold the foot valve down any more than a few seconds after the full

stroke is attained. Serious injury and/or equipment damage may occur if foot

valve is held open and excess pressure is allowed to build up in the hydraulic

cylinder.

Burst hazard exists if hose or connection pressure exceeds rated pressure.

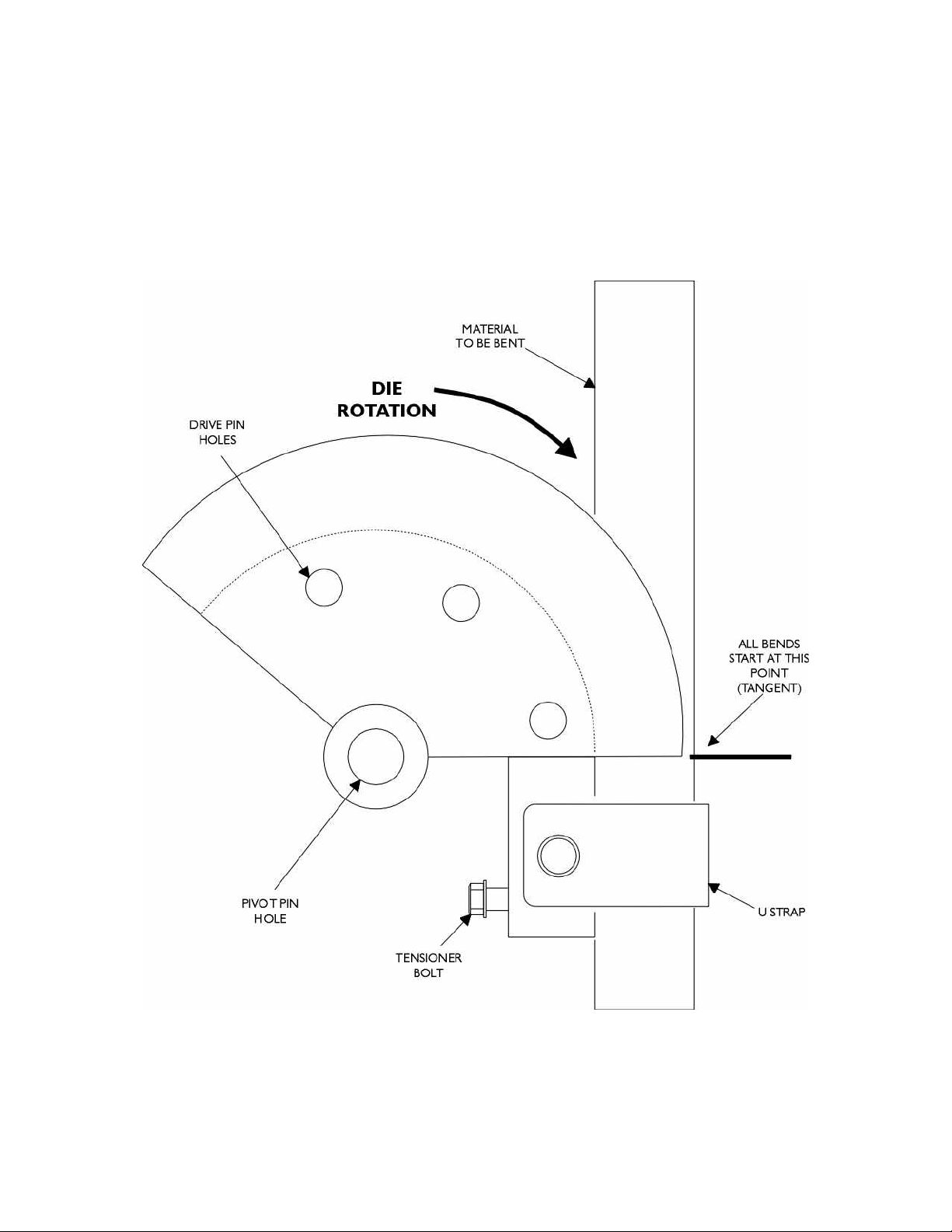

8. There is an approximate maximum 41º bend for each full stroke of the ram.

9. Pulling up on the drive pin, begin to slowly retract the ram (down on the toe

of the foot control valve) removing the pin when tension on the pin is released

and before it starts to rotate the die.

WARNING

In some cases when retracting the ram the tubing being bent could become

stuck in the radius die. Using great caution, pull sharply on the end of the

tubing to

release the tubing from the radius die.

10. Slowly retract the ram (down on the toe of the foot control valve) until the

second die drive hole lines up.

11. Re-install the pin fully and repeat the above bend process to complete the total

bend.

12. To repeat bends, without the degree wheel, measure ram's travel.

13. When the tube is bent the desired amount, slowly retract (down on the toe of

the foot control valve) the ram allowing the drive pin to rotate the die and

releasing the tube. It may be necessary to loosen the U-strap retaining bolt.

WARNING

Because of the precision air return NEVER store or leave the cylinder in the

full extended/open position. If left in the extended position the hydraulic fluid

will drain from the cylinder. When the air supply is reattached the cylinder

could retract uncontrollably and could cause equipment damage and/or sever

personal injuries. Use extreme care when reattaching the air supply to the

bender. Make sure there are no dies, pins, body parts on the bender when

reattaching the air source to the pump.

WARNING

In some cases when retracting the ram the tubing being bent could become

stuck in the radius die. Using great caution, pull sharply on the end of the

tubing to release the tubing from the radius die.

14. Remove the tube.

15. Use the smaller diameter drive pin (included) with any die that uses the first

drive hole (closest to the pivot point).